Method for catalytically degrading organic pollutants by zero-valent iron

A catalytic degradation, zero-valent iron technology, applied in water pollutants, chemical instruments and methods, oxidized water/sewage treatment, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

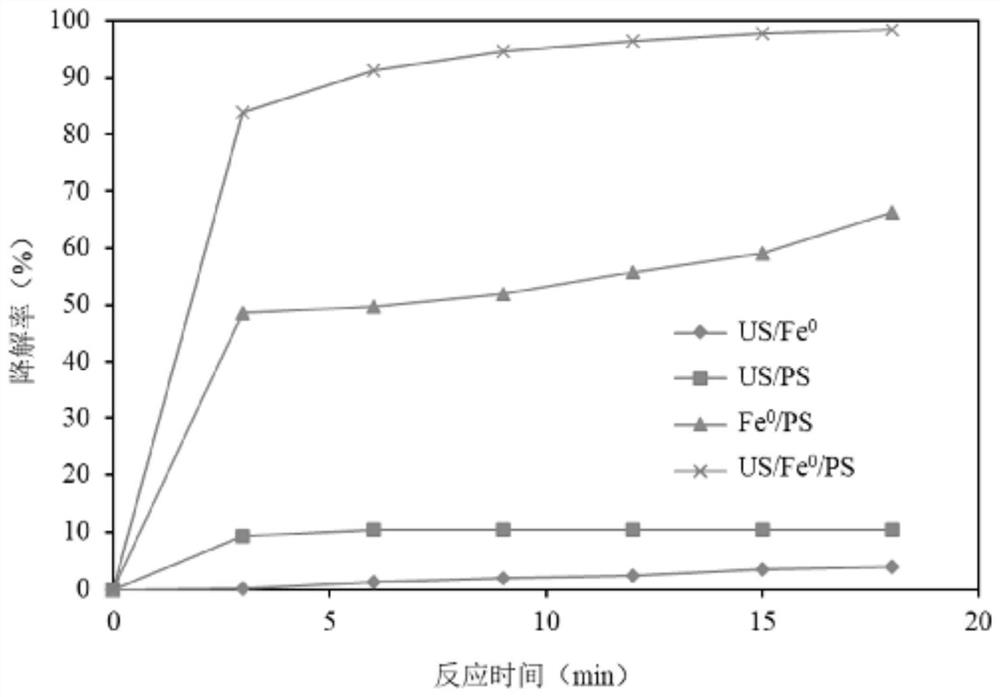

[0040] A method for catalytically degrading organic wastewater using zero-valent iron, comprising:

[0041] 1) Add iron powder and persulfate to organic wastewater for ultrasonic treatment;

[0042] 2) After the reaction is complete, the treated organic wastewater is obtained.

[0043] In some examples, the added amount of the iron powder is not less than 0.1 mg / L.

[0044] In some examples, the iron powder is added in an amount of 0.1-0.5 mg / L. When the amount of iron powder added exceeds a certain limit, it will not bring more positive effects to the progress of the reaction. The amount of iron powder added also has a certain relationship with the particle size of iron powder. The particle size of iron powder is small, and the amount of iron powder added can be relatively reduced; on the contrary, the amount of iron powder added should be increased accordingly.

[0045] In some examples, the particle size of the iron powder is not greater than 1 mm. The finer the particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com