Solid waste incineration system and process thereof

A solid waste and waste technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of inability to remove 100% nitrogen and phosphorus, difficult processing, shutdown processing, etc. The effect of improving disposal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

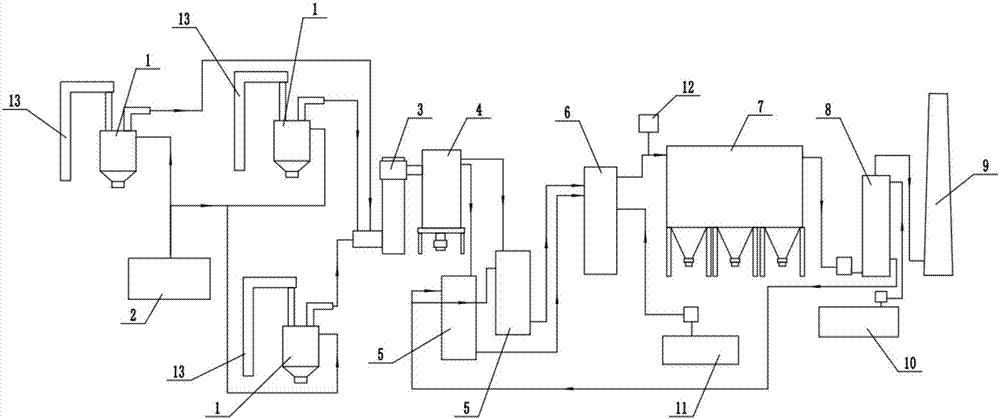

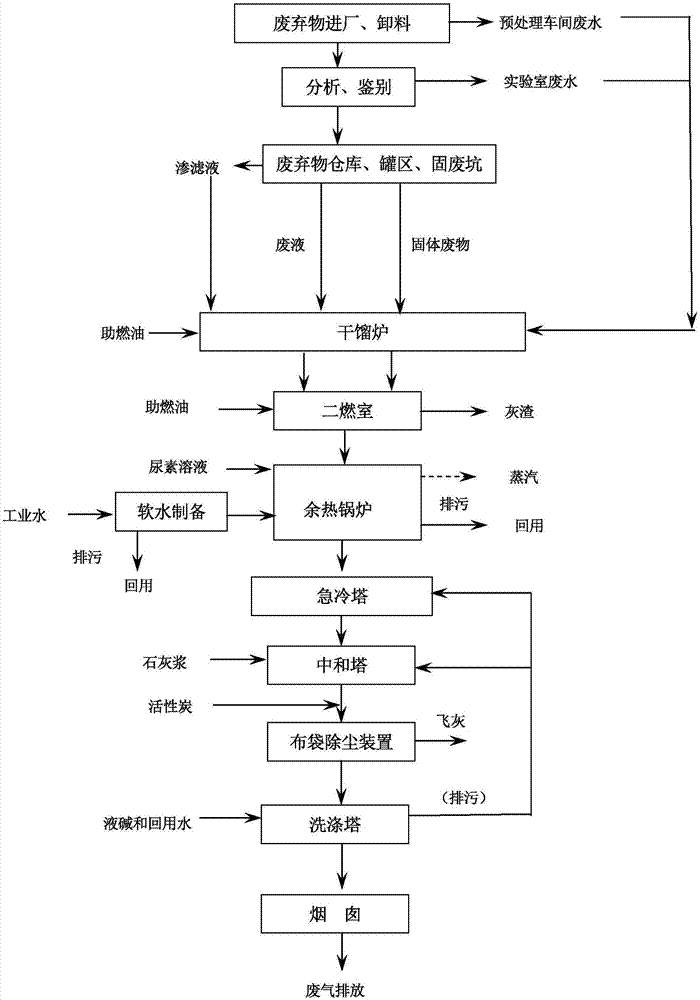

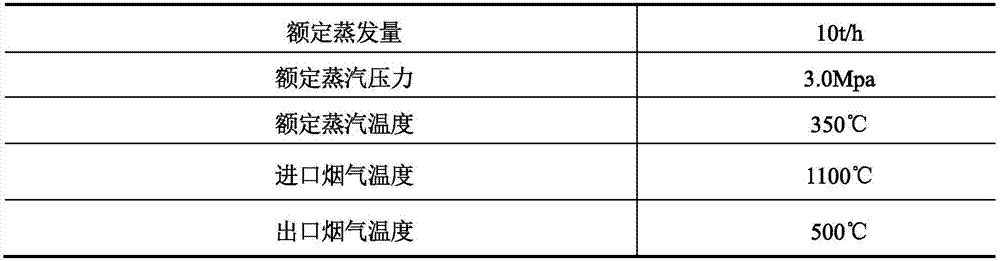

[0023] Embodiment 1: as figure 1 As shown, the solid waste incineration system of this embodiment includes waste feeding device 13, dry distillation furnace 1, secondary combustion chamber 3, waste heat boiler 4, quenching tower 5, neutralization tower 6, bag dust removal device connected in sequence 7. The washing tower 8 and the chimney 9, the retort furnace 1, and the waste heat boiler 4 are all connected to the softening water device 2, the washing tower 8 is connected to the lye pool 10, and the neutralization tower 6 is connected to the lime slurry pool 11. The present invention also provides a treatment process for a solid waste flue gas treatment system, including a semi-dry deacidification process and a wet deacidification process. The semi-dry deacidification process includes introducing the lime slurry in the lime slurry tank 11 into the neutralization tower 6 The reaction process of neutralizing and acid gas in flue gas, wet deacidification includes and passing the...

Embodiment 2

[0024] Embodiment 2: This embodiment has been improved on the basis of Embodiment 1, and the washing tower 8 is connected with the quenching tower 5 through pipelines, and the residual lye, salt, etc. of the washing tower 8 are transported to the quenching tower 5 by delivery equipment . The treatment process of this embodiment also includes a semi-dry deacidification process and a wet deacidification process. The semi-dry deacidification process includes introducing the lime slurry in the lime slurry pool 11 into the neutralization tower 6 to mix with the acid gas in the flue gas. The reaction process of wet deacidification includes and the reaction process of passing the lye in the lye pool 10 into the scrubber and the acid gas in the flue gas; The lye and the salt produced are introduced into the quench tower 5. Since the residual lye is introduced into the quenching tower 5, on the one hand, it is used to enhance the quenching effect of the quenching tower 5, and on the o...

Embodiment 3

[0025] Embodiment 3: This embodiment is further improved on the basis of Embodiment 2. Two sets of quenching towers 5 are arranged. The work can be switched among the towers 5 to realize one for use and one for standby. Since the residual lye and salt in the washing tower 8 are introduced into the quenching tower 5, the salt content in the quenching tower 5 increases. In order not to affect the work effect, the quenching tower 5 needs to be desalted regularly, and the desalination needs to be shut down. Therefore, two sets of quenching towers 5 are used for switching to realize continuous operation. The treatment process of this embodiment includes a semi-dry deacidification process and a wet deacidification process. The semi-dry deacidification process includes introducing the lime slurry in the lime slurry pool 11 into the neutralization tower 6 and the acid gas in the flue gas. The reaction process, wet deacidification includes and the reaction process of passing the lye i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com