Method for preparing high-performance sintered neodymium-iron-boron magnet based on grain boundary addition

A NdFeB high-performance technology, applied in the direction of magnetic objects, inductors/transformers/magnets manufacturing, magnetic materials, etc., can solve the problems that it is difficult to achieve the coercive force and magnetic energy product of NdFeB magnets, and achieve the preparation The method is simple and controllable, the efficiency is high, and the effect of magnetic performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

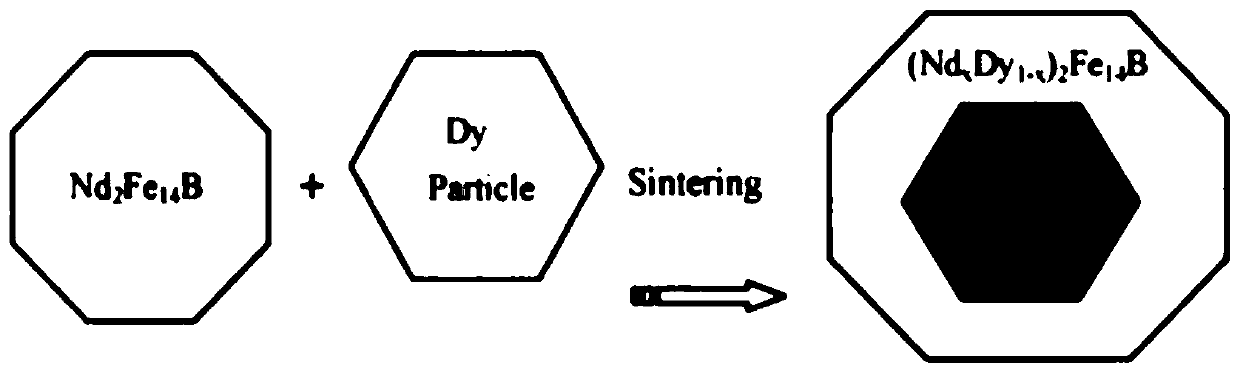

Problems solved by technology

Method used

Image

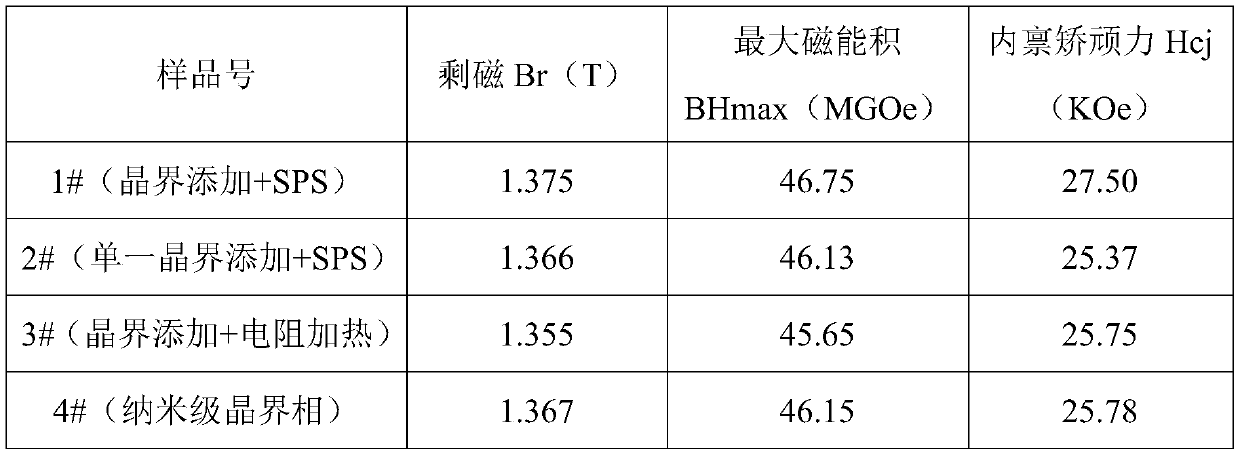

Examples

Embodiment 1

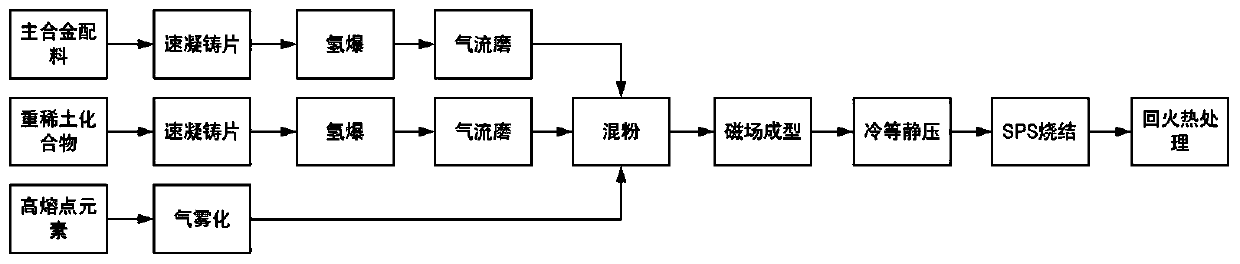

[0054] A method for preparing a high-performance sintered NdFeB magnet based on grain boundary addition, the process is as follows:

[0055] A. Prepare the main alloy: select raw materials with a purity of 99.5% or more, and remove the oxide skin on the surface of the raw materials, according to the alloy composition (PrNd) 30.5 [Fe 0.9 (CuAlZn) 0.1 ] 68.5 B 1 (wt.%), raw materials were weighed with an electronic balance.

[0056] B. Preparation of the main alloy powder: the prepared main alloy is casted quickly to obtain flakes, the melting temperature is 1450°C, and the line speed of the water-cooled copper roll is 2.0m / s; then hydrogen explosion is obtained to obtain coarse powder, and the hydrogen absorption pressure is 0.1 MPa, the dehydrogenation temperature is 590°C, and the dehydrogenation time is 2h; finally, the magnetic powder with an average particle size of 3.2um is obtained by jet milling, and the speed of the classification wheel is 4000r / s.

[0057] C. Pre...

Embodiment 2

[0071] A method for preparing a high-performance sintered NdFeB magnet based on grain boundary addition, the process is as follows:

[0072] A. Prepare the main alloy: select raw materials with a purity of 99.5% or more, and remove the oxide skin on the surface of the raw materials, according to the alloy composition (PrNd) 30.5 [Fe 0.92 (CuGaZn) 0.08 ] 68.2 B 1.03 (wt.%), raw materials were weighed with an electronic balance.

[0073] B. Preparation of the main alloy powder: the prepared main alloy is obtained by quick-setting casting, the melting temperature is 1440°C, and the line speed of the water-cooled copper roll is 2.5m / s; followed by hydrogen explosion to obtain coarse powder, and the hydrogen absorption pressure is 0.1 MPa, the dehydrogenation temperature is 580°C, and the dehydrogenation time is 2.5h; finally, the jet mill obtains magnetic powder with an average particle size of 3.5um, and the speed of the classification wheel is 3500r / s.

[0074] C. Preparati...

Embodiment 3

[0086] A method for preparing a high-performance sintered NdFeB magnet based on grain boundary addition, the process is as follows:

[0087] A. Prepare the main alloy: select raw materials with a purity of 99.5% or more, and remove the oxide skin on the surface of the raw materials, according to the alloy composition (PrNd) 30 [Fe 0.92 (AlGaSn) 0.08 ] 69 B 1 (wt.%), raw materials were weighed with an electronic balance.

[0088] B. Preparation of the main alloy powder: the prepared main alloy is obtained by quick-setting casting, the melting temperature is 1440°C, and the line speed of the water-cooled copper roll is 2.5m / s; followed by hydrogen explosion to obtain coarse powder, and the hydrogen absorption pressure is 0.1 MPa, the dehydrogenation temperature is 570°C, and the dehydrogenation time is 4h; finally, the magnetic powder with an average particle size of 4um is obtained by jet milling, and the speed of the classification wheel is 3200r / s.

[0089] C. Preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com