Magnesium-containing lithium-rich manganese-based positive electrode and preparation method thereof

A magnesium-rich lithium-manganese-based and lithium-rich manganese-based technology is applied to the field of magnesium-containing lithium-rich manganese-based positive electrodes and their preparation, which can solve the problems of poor capacity retention performance and instability of lithium-rich materials, and avoid irreversible damage. The effect of increasing conductivity and tightness, avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Magnesium-containing lithium-rich manganese-based positive electrode using magnesium sulfate as the source of magnesium, magnesium accounts for 2% of the mass of the lithium-rich material

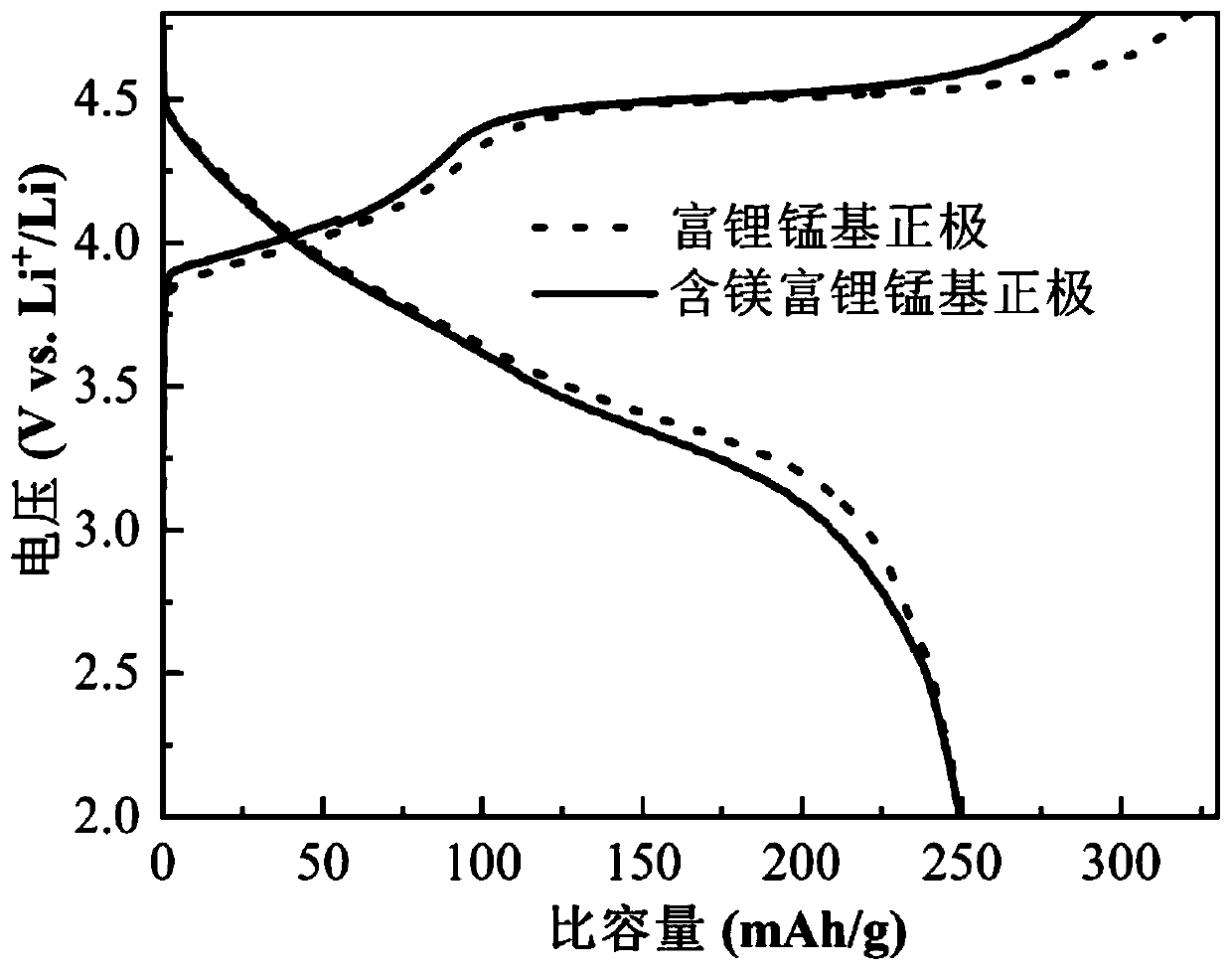

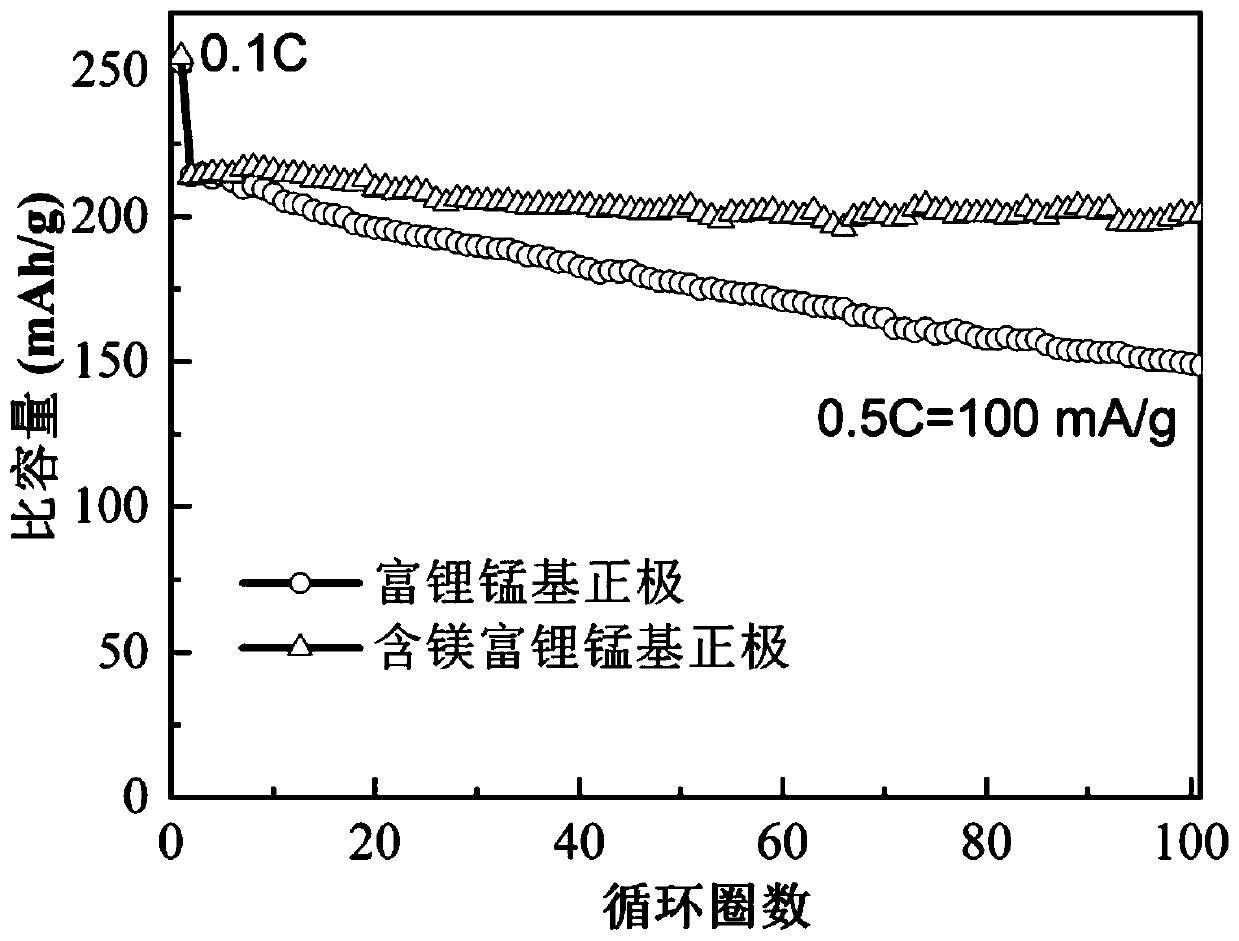

[0035] This example involves the preparation of a magnesium-containing lithium-rich manganese-based positive electrode using magnesium sulfate as a magnesium source, wherein the magnesium element accounts for 2% of the mass of the lithium-rich material, and is cycled with a lithium-rich positive electrode that uses the same preparation method but does not add magnesium sulfate Performance comparison.

[0036] details as follows:

[0037] (1) Take a ball mill jar and several zirconium beads of different sizes. Add 50 mg of lithium-rich material into the tank, magnesium sulfate is added according to 2% of the mass of the lithium-rich material, conductive carbon black is added according to 12% of the mass of the lithium-rich material, and LA binder is added according to 12% ...

Embodiment 2

[0044] Example 2: Magnesium-containing lithium-rich manganese-based positive electrode using magnesium oxide as the source of magnesium, magnesium accounts for 2% of the mass of the lithium-rich material

[0045] This embodiment relates to the cycle performance test of a magnesium-containing lithium-rich manganese-based positive electrode using magnesium oxide as a magnesium source, wherein the magnesium element accounts for 2% of the mass of the lithium-rich material.

[0046] The difference between this example and Example 1 is that the magnesium source used in the magnesium-containing lithium-rich positive electrode is magnesium oxide.

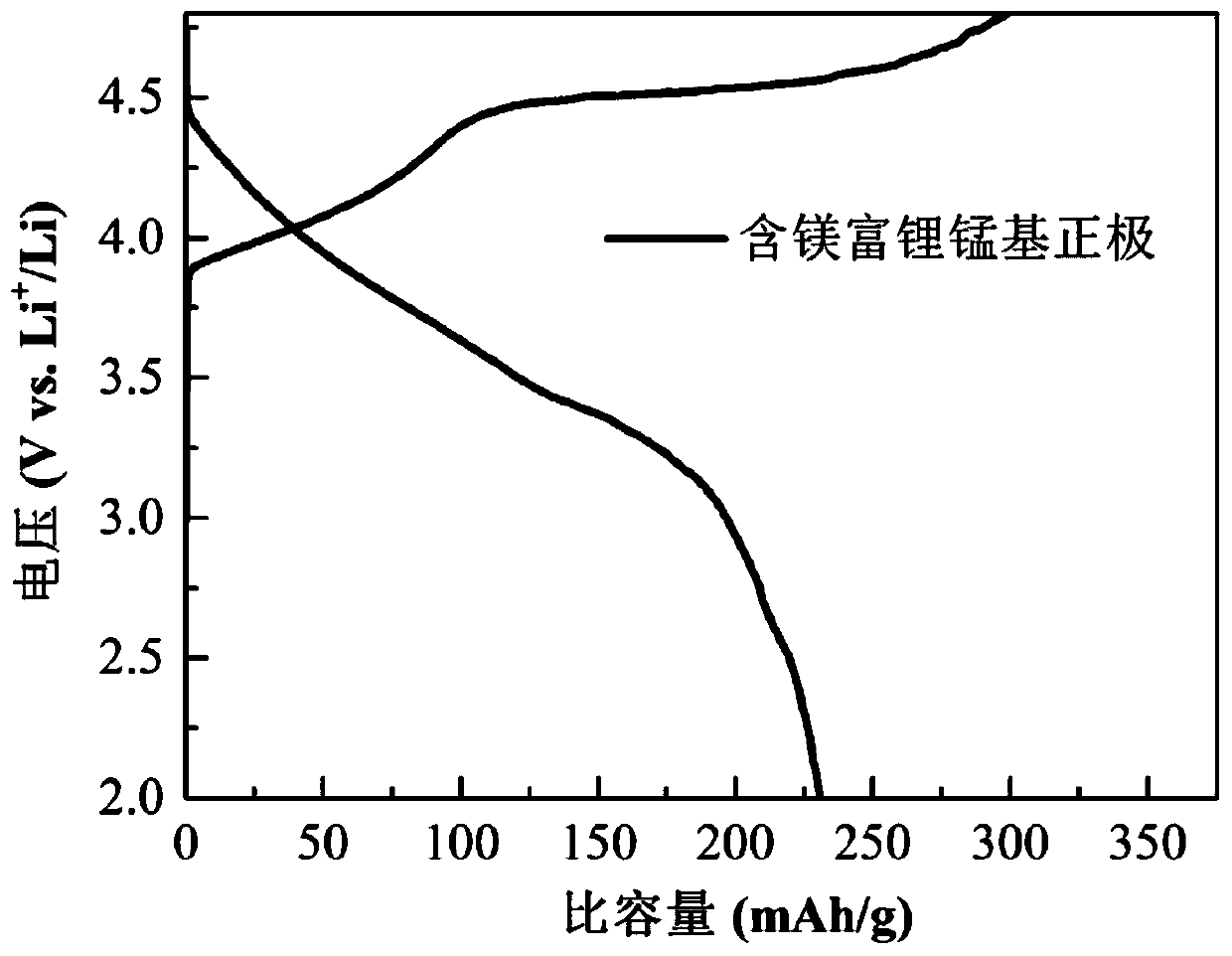

[0047] image 3 It is the first-cycle charge-discharge curve of the magnesium-containing lithium-rich manganese-based positive electrode (the magnesium source is magnesium oxide, and the mass ratio of magnesium to the lithium-rich material is 2%) at a current density of 20mA / g. The first-cycle charge specific capacity is 298.9mAh / g, and th...

Embodiment 3

[0049] Example 3: Magnesium-containing lithium-rich manganese-based positive electrode using magnesium sulfate as the source of magnesium, magnesium accounts for 7% of the mass of the lithium-rich material

[0050] This example relates to the cycle performance test of a magnesium-containing lithium-rich manganese-based positive electrode using magnesium sulfate as a magnesium source, wherein the magnesium element accounts for 7% of the mass of the lithium-rich material.

[0051] The difference between this example and Example 1 is that the magnesium element used in the magnesium-containing lithium-rich positive electrode accounts for 7% of the mass of the lithium-rich material.

[0052] Figure 5 It is the first-cycle charge-discharge curve of the magnesium-containing lithium-rich manganese-based positive electrode (the magnesium source is magnesium sulfate, and the mass ratio of magnesium to the lithium-rich material is 7%) at a current density of 20mA / g. The first charge sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com