Technique for manganese recycling and comprehensive treatment of waste water and waste gas in electrolytic manganese industrial wastewater

A technology for production wastewater and wastewater treatment, applied in neutralized water/sewage treatment, reduced water/sewage treatment, water/sewage multi-stage treatment, etc. High-level problems, to achieve the effect of reducing heavy metal content, low pollution, and eliminating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

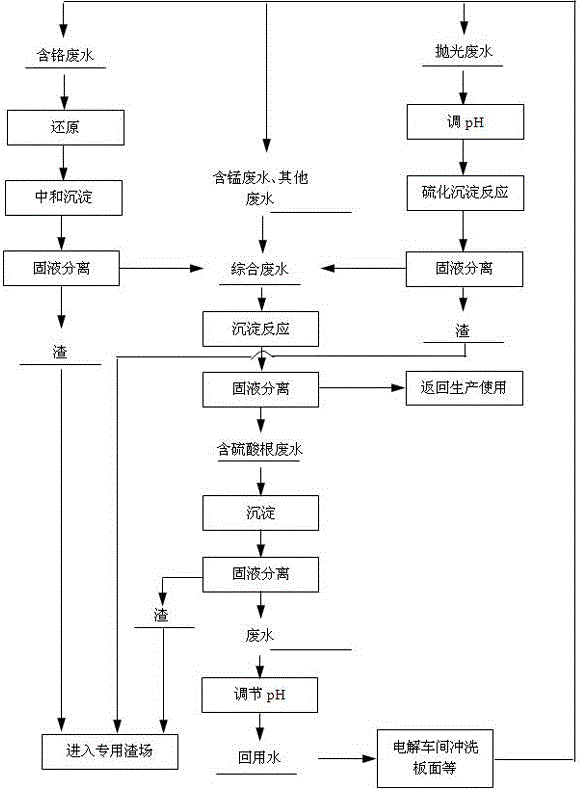

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: chromium-containing waste water 30m 3 , where Cr 6+ The content is 36mg / L, add reducing agent ferrous sulfate 52kg to it, stir and react for 30min, then detect Cr 6+ 0.13mg / L, adding sodium hydroxide to adjust the pH value to 10, stirring for 30 minutes, and then carrying out precipitation and separation, the chromium slag enters the special slag field, and the remaining liquid is mixed into the manganese-containing wastewater;

[0021] Polishing wastewater 5m 3 , where: Cr 3+ 48.63mg / L, Ni 2+ 28.68mg / L, Fe 2+ 136.25mg / L, Cu 2+ 18.45mg / L, adjust the pH to neutral with sodium hydroxide, add 2.5kg of vulcanizing agent SDD, stir and react for 1 hour, carry out precipitation and separation, the slag enters the special slag yard, and the remaining liquid is mixed into manganese-containing wastewater;

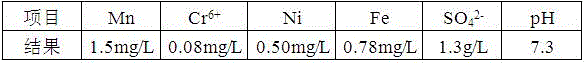

[0022] Comprehensive waste water 100m 3 , where the manganese content is 1800mg / L, add 700kg of precipitating agent ammonium bicarbonate, stir and rea...

Embodiment 2

[0025] Embodiment 2: chromium-containing waste water 30m 3 , where Cr 6+ The content is 55mg / L, add reducing agent ferrous sulfate 80kg to it, stir and react for 30min, then detect Cr 6+ to 0.09mg / L, add sodium hydroxide to adjust the pH value to 10, stir for 30 minutes, and then carry out precipitation and separation. The chromium slag enters the special slag field, and the remaining liquid is mixed into manganese-containing wastewater;

[0026] Polishing wastewater 5m 3 , where: Cr 3+ 69.23mg / L, Ni 2+ 36.68mg / L, Fe 2+ 200.25mg / L, Cu 2+ 10.45mg / L, adjust the pH to neutral with sodium hydroxide, add 2.5kg of vulcanizing agent SDD, stir and react for 1 hour, carry out precipitation and separation, the slag enters the special slag yard, and the remaining liquid is mixed into manganese-containing wastewater;

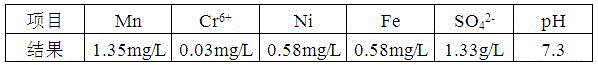

[0027] Comprehensive waste water 100m 3 , where manganese content is 2150mg / L, add precipitant ammonium bicarbonate 840kg, stir and react for 2.8h, the measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com