Method for extracting lithium from fly ash

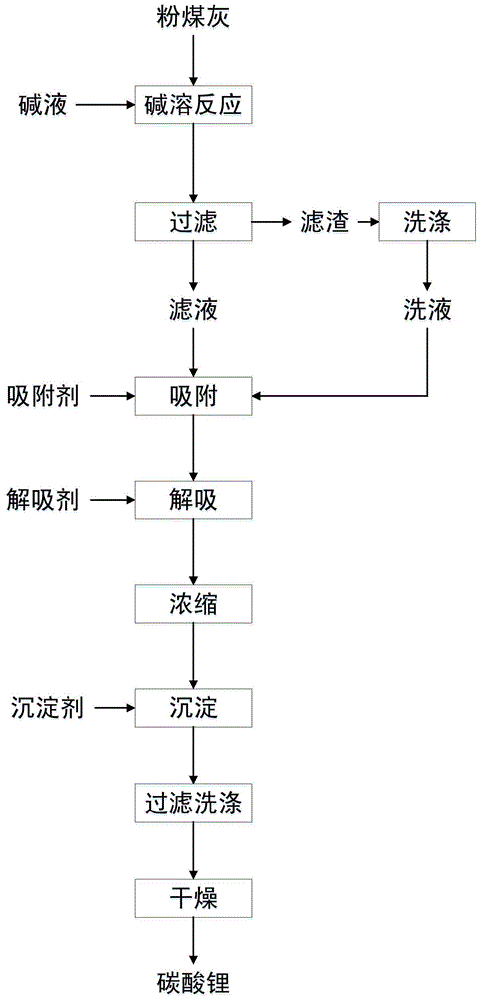

A fly ash, lithium ion technology, applied in lithium carbonate;/acid carbonate and other directions, can solve the problems of long processing process, failure to fully utilize lithium resources, high energy consumption, and achieve low equipment requirements, Low price and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

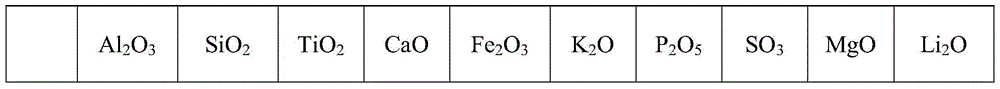

[0050] (1) alkali dissolution reaction: the fly ash described in table 1 is mixed with the sodium hydroxide solution of 15% in mass fraction, carries out alkali dissolution reaction in reactor, and the liquid-solid ratio of lye and fly ash is 3 : 1, the temperature of alkali-dissolution reaction is 90 ℃, with stirring in the alkali-dissolution reaction process, stirring speed is 300r / min, the time of alkali-dissolution reaction is 120min, obtains containing silicon-lithium eluate (lithium ion concentration 110ppm) and desorbed Mixed slurry of silica fume and coal ash;

[0051] (2) Filtration and washing: the mixed slurry is filtered and separated to obtain filter residue and filtrate, and the filter residue is washed. The liquid-solid volume ratio in the process of washing the filter residue is 1:1. The liquid is mixed to obtain a mixed liquid;

[0052] (3) Adsorption: The mixed solution passes through the adsorption column loaded with lithium ion exchange resin at a flow rat...

Embodiment 2

[0059] (1) alkali dissolution reaction: the fly ash described in table 1 is mixed with the sodium hydroxide solution of 20% by mass fraction, carry out alkali dissolution reaction in the reactor, the liquid-solid ratio of lye and fly ash is 2 : 1, the temperature of alkali-dissolution reaction is 95 ℃, with stirring in the alkali-dissolution reaction process, stirring speed is 400r / min, the time of alkali-dissolution reaction is 80min, obtains containing silicon lithium eluate (lithium ion concentration 160ppm) and desorbed Mixed slurry of silica fume and coal ash;

[0060] (2) Filtration and washing: the mixed slurry is filtered and separated to obtain filter residue and filtrate, and the filter residue is washed. The liquid-solid volume ratio in the process of washing the filter residue is 1:1. The liquid is mixed to obtain a mixed liquid;

[0061] (3) Adsorption: The mixed solution passes through the adsorption column loaded with manganese ion sieve at a flow rate of 40L / m...

Embodiment 3

[0068] (1) alkali dissolution reaction: the fly ash described in table 1 is mixed with the sodium hydroxide solution of 10% by mass fraction, carries out alkali dissolution reaction in reactor, and the liquid-solid ratio of lye and fly ash is 4 : 1, the temperature of alkali-dissolution reaction is 100 ℃, with stirring in the alkali-dissolution reaction process, stirring speed is 400r / min, the time of alkali-dissolution reaction is 120min, obtains containing silicon-lithium eluent (95ppm of lithium ion concentration) and desorbed Mixed slurry of silica fume and coal ash.

[0069] (2) Filtration and washing: the mixed slurry is filtered and separated to obtain filter residue and filtrate, and the filter residue is washed. The liquid-solid volume ratio in the process of washing the filter residue is 1:1. The liquid is mixed to obtain a mixed liquid;

[0070] (3) Adsorption: The mixed solution passes through the adsorption column loaded with manganese ion sieve at a flow rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com