Full-intelligent water draining facility

An intelligent and facility technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as oil adhesion, leakage, and inaccurate distinction of floating balls, and achieve the effect of ensuring dehydration safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

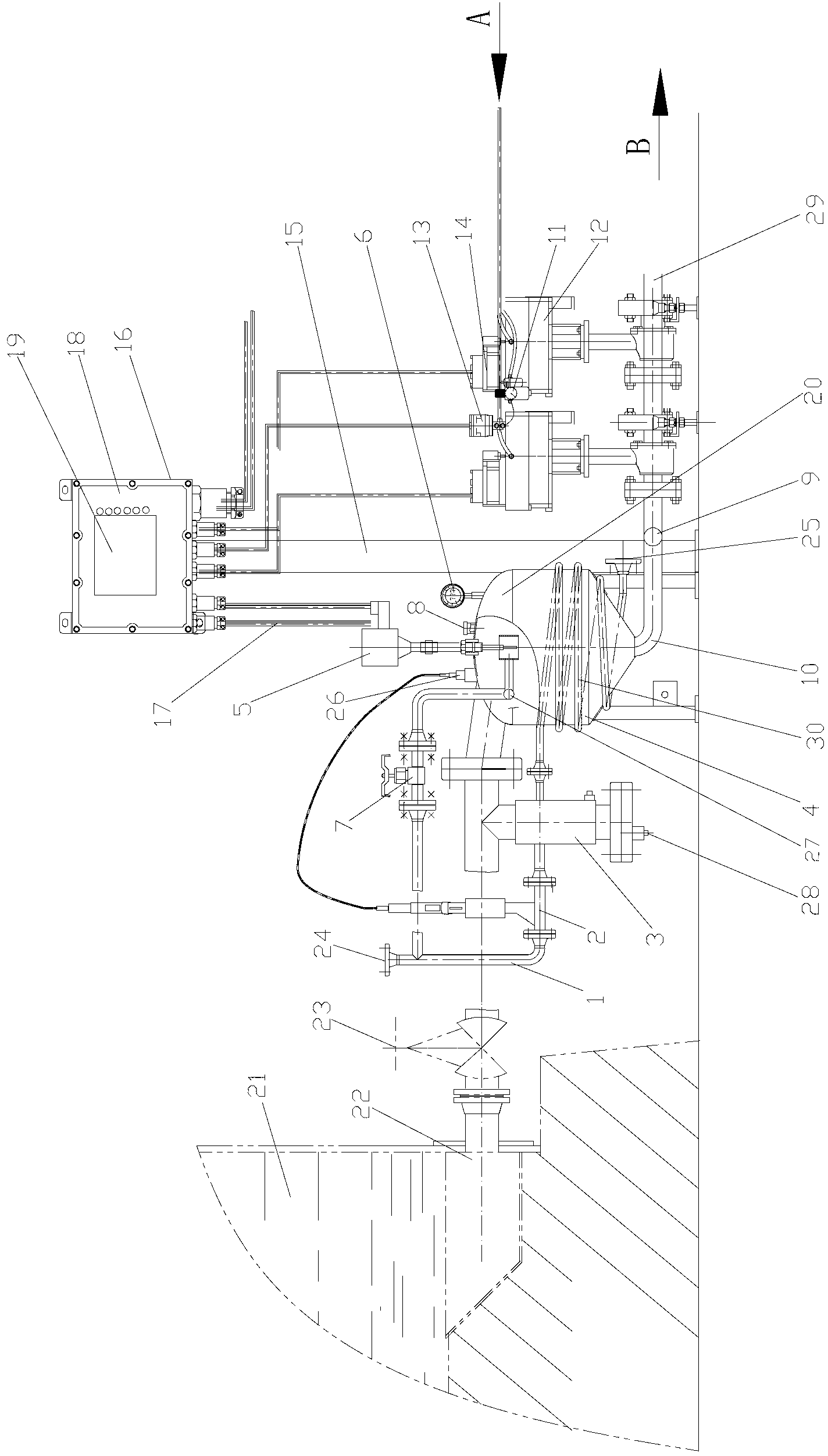

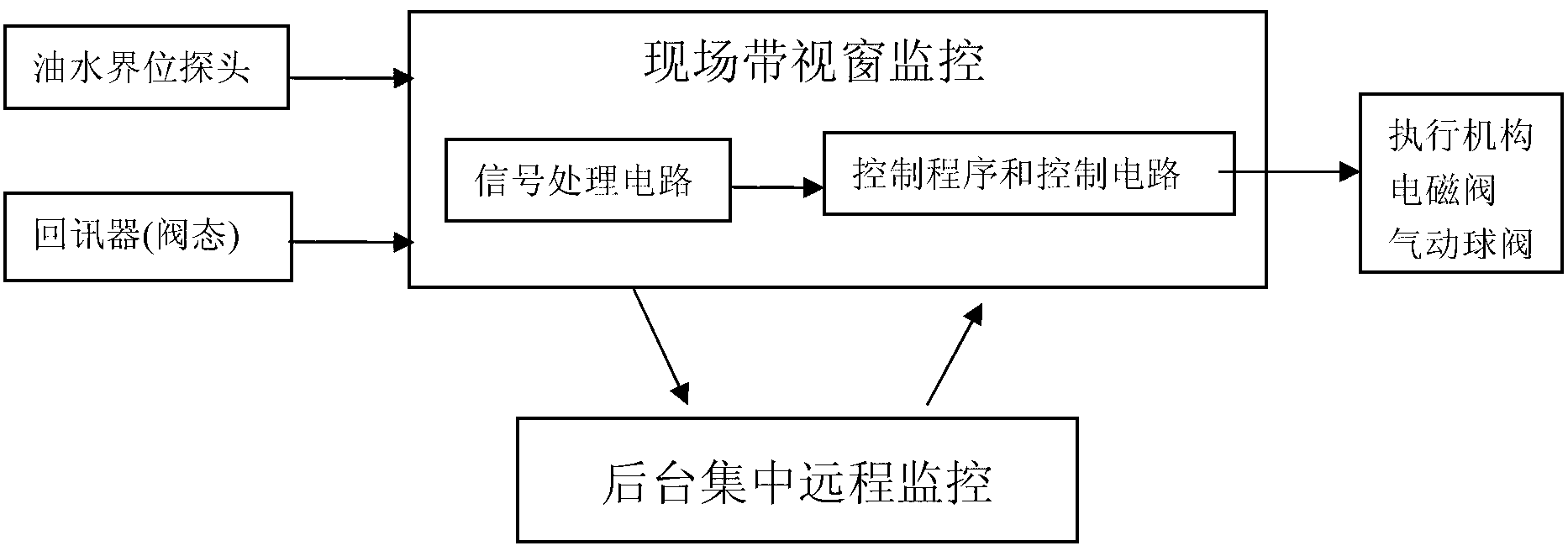

[0022] Such as figure 1 , figure 2 As shown, the fully intelligent water cutting facility is composed of on-site mechanical water cutting device, on-site monitor with window and background centralized monitoring system, among which:

[0023] On-site mechanical water cutting device includes steam pipeline 1, self-operated temperature control valve 2, "T" type filter 3, buffer tank 4, oil-water interface probe 5, thermometer 6, stop valve 7, vent 8, drain pipe 10 , Air source processing part 11, pneumatic ball valve 12, solenoid valve 13 and feedback device 14. The upper part of the buffer tank 4 is provided with a liquid inlet pipe connected to the "T" type filter 3, a thermometer hole (for installing the thermometer 6), an oil-water interface probe hole (for installing the oil-water interface probe 5) and a vent port 8. The vent port 8 is connected to the vent cap. The lower end of buffer tank body 4 is provided with drainpipe 10 and links to each other with pneumatic ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com