Treatment method of gasification wastewater of coal chemical industry

A treatment method and technology of coal chemical industry, applied in degassed water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of difficulty in reclaimed water reuse and large fluctuations in sewage treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] This example is to illustrate the treatment of coal chemical gasification wastewater by using the method of the present invention.

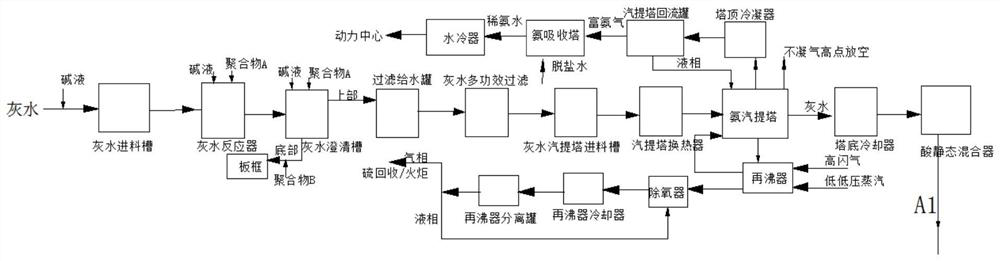

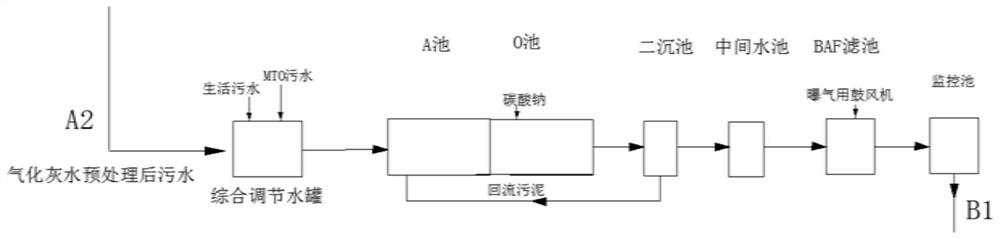

[0092] The first part of the process:

[0093] (1-1) Coal chemical gasification wastewater from the pump outlet of the slag water section (wherein, the components of the coal chemical gasification wastewater include a pH value of 8.5, COD Cr is 1200mg / L, oil content is 1mg / L, ammonia nitrogen is 500mg / L, total phosphorus is 3mg / L in terms of P, dissolved solids are 4000mg / L, and suspended solids are 200mg / L), after adding lye and mixing into the gray water feed tank;

[0094] Boost the pressure to 0.3MPaG by a pump and send it into the gray water reactor, add alkali liquor and polymer A as a flocculant in the gray water reactor (polymer A is a coagulant containing iron salt and / or aluminum salt) In order to promote the settlement of suspended solids in the gray water, the pH in the reactor is controlled to be 11, and the fully stirred gr...

Embodiment 2

[0128] The coal chemical gasification wastewater was treated in the same manner as in Example 1, except that the conditions adopted were different, specifically, as shown in Table 1.

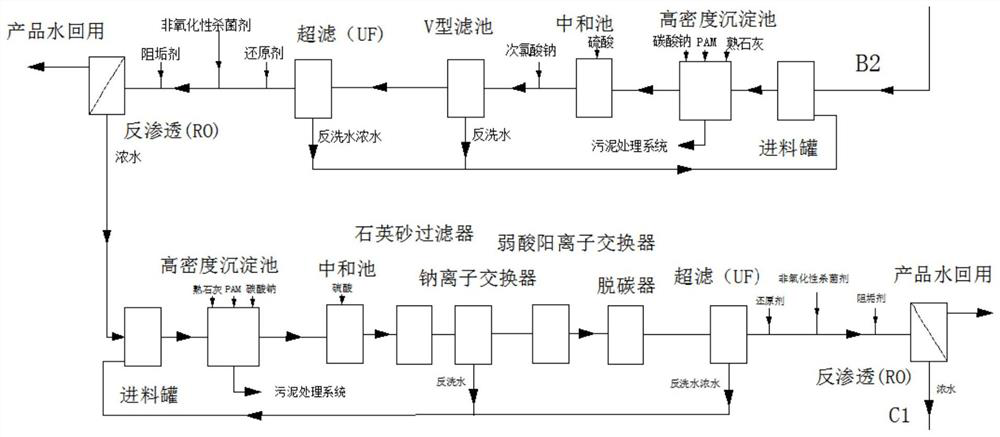

[0129] Results The method can ensure the stable treatment effect of treated sewage; COD Mn ≤2mg / L, pH value is 7.5, oil content is 0.01mg / L, ammonia nitrogen is 0.5mg / L, total phosphorus is 0.2mg / L in terms of P, dissolved solids are 200mg / L, and suspended solids are 0.1mg / L; it can be reused as reclaimed water for further advanced treatment; the accompanying crystalline salt (sodium chloride) can be used as a qualified product.

Embodiment 3

[0131] The coal chemical gasification wastewater was treated in the same manner as in Example 1, except that the conditions adopted were different, specifically, as shown in Table 1.

[0132] Results The method can ensure the stable treatment effect of treated sewage; COD Mn ≤2mg / L, pH value is 7.5, oil content is 0.01mg / L, ammonia nitrogen is 0.1mg / L, total phosphorus is 0.2mg / L in terms of P, dissolved solids are 200mg / L, and suspended solids are 0.1mg / L; it can be reused as reclaimed water for further advanced treatment; the accompanying crystalline salt (sodium chloride) can be used as a qualified product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com