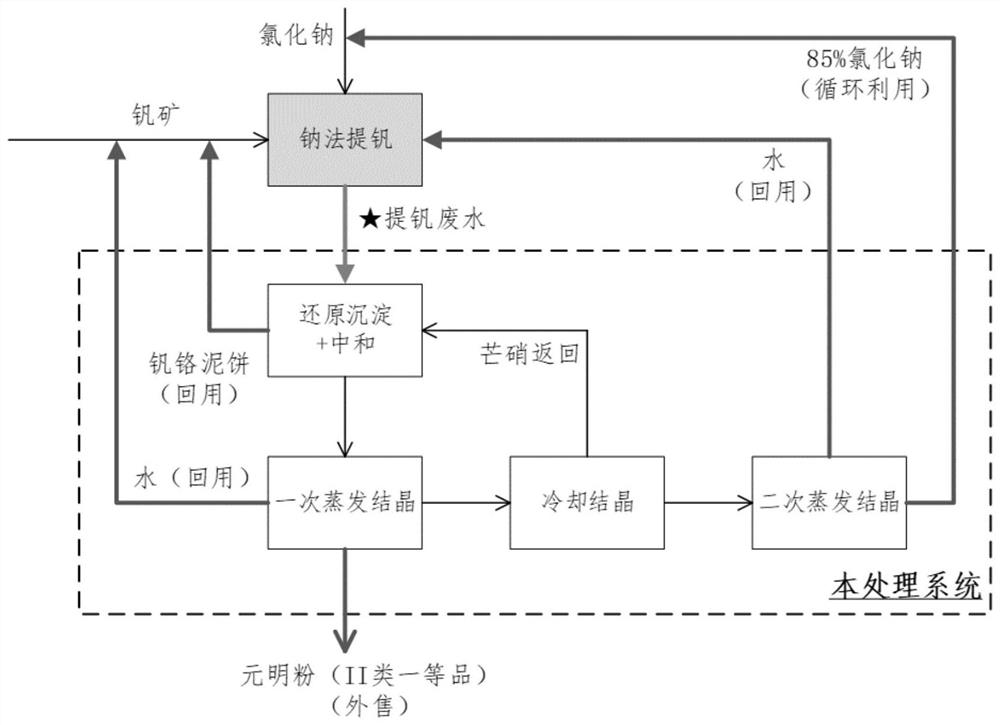

Zero discharge and resource utilization method for vanadium-containing high-salinity wastewater

A technology of high-salt wastewater and treatment method, applied in chemical instruments and methods, metallurgical wastewater treatment, inorganic chemistry, etc., can solve the problems of efflux of miscellaneous salts, difficult treatment, pollution, etc., to ensure zero discharge and realize resource utilization , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The vanadium-containing wastewater (mass flow rate is 500kg / h, wherein sodium sulfate mass fraction is 6.22 wt %, sodium chloride mass fraction is 0.78 wt %, total vanadium content 10mg / L, hexavalent chromium content 0.02 mg / L), add ferrous sulfate (mass flow rate 70 mg / L), and fully react for 20 min. Slowly add sodium hydroxide to the above solution, adjust the pH of the system to about 10, precipitate vanadium and chromium, fully react for 20min, filter and send the precipitate to the sodium extraction process for vanadium for reuse. An appropriate amount of sulfuric acid was added to the precipitated solution to adjust the pH of the solution to 7.1.

[0038] The above-obtained solution was directly sent to an evaporating device at 70° C. for one evaporative crystallization, and the pressure was appropriately reduced to keep the solution in a boiling state. 384.3kg / h steam was evaporated from the evaporative crystallizer, the mother liquor was partially refluxed, and...

Embodiment 2

[0043] Vanadium-containing wastewater (mass flow rate is 500kg / h, wherein sodium sulfate mass fraction is 8.44 wt %, sodium chloride mass fraction is 0.56 wt %, total vanadium content 21mg / L, hexavalent chromium content 0.03 mg / L), add ferrous sulfate (mass flow rate 72 mg / L), and fully react for 20 min. Slowly add sodium hydroxide to the above solution, adjust the pH of the system to about 12, precipitate vanadium and chromium, fully react for 20min, filter and send the precipitate to the sodium extraction process for vanadium for reuse. An appropriate amount of hydrochloric acid was added to the precipitated solution to adjust the pH of the solution to 6.9.

[0044] The above-obtained solution was directly sent to an evaporation device, and evaporative crystallization was carried out at 90° C., and the pressure was appropriately reduced to keep the solution in a boiling state. 408.0kg / h of water vapor was evaporated from the evaporative crystallizer, evaporated in two stage...

Embodiment 3

[0049] Vanadium-containing wastewater (mass flow is 500kg / h, wherein sodium sulfate mass fraction is 8.57 wt %, sodium chloride mass fraction is 0.43 wt %, total vanadium content 15mg / L, hexavalent chromium content 0.02 mg / L) was added with ferrous sulfate (mass flow rate 99 mg / L) to fully react for 20 min. Slowly add sodium hydroxide to the above solution, adjust the pH of the system to about 9, precipitate vanadium and chromium, fully react for 20min, filter and send the precipitate to the sodium extraction process for vanadium for reuse. An appropriate amount of hydrochloric acid was added to the precipitated solution to adjust the pH of the solution to 7.0.

[0050] The above-obtained solution was directly sent to an evaporating device for primary evaporative crystallization, the heating temperature of the heat source was 90° C., and the pressure was appropriately reduced to keep the solution in a boiling state. 413.0kg / h water vapor was evaporated from the evaporative cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com