System and process for realizing zero discharge of gas and steam in iron and steel plants by adopting seawater desalination

A zero-emission technology for iron and steel plants, applied in the field of comprehensive utilization of secondary energy in iron and steel plants, can solve problems such as low-quality steam emissions, difficult storage of gas, and difficult storage of steam, and achieve the effect of improving regulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

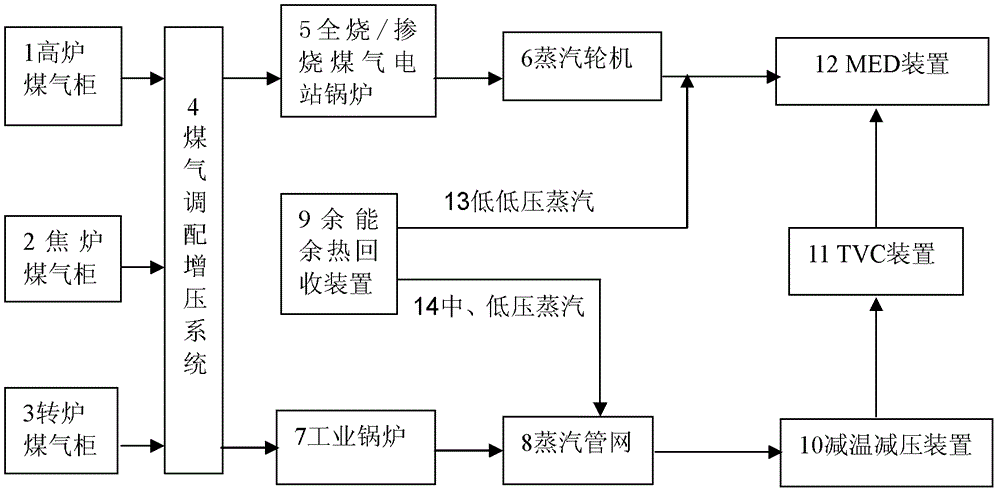

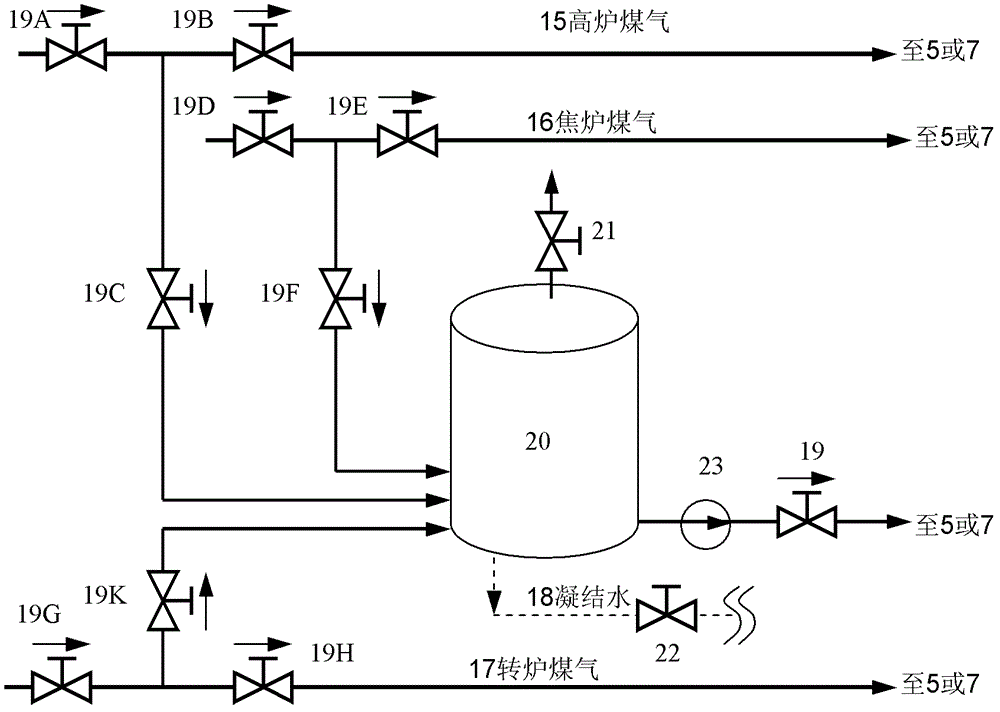

[0024] See attached figure 1 , a steel company collected about 3145kJ / Nm of heat from the blast furnace gas holder 1 with a storage pressure of 10kPa 3 Blast furnace gas 15, the heat value collected by the coke oven gas holder 2 with a storage pressure of 7kPa is about 17900kJ / Nm 3 Coke oven gas 16, the calorific value collected by the converter gas cabinet 3 with a storage pressure of 2.6-3.2kPa is about 7536kJ / Nm 3 The converter gas 17 is directly sent to the full-fired / mixed-fired gas power plant boiler 5 and the 2×35t / h industrial boiler 7 for combustion, of which the full-fired / mixed-fired gas power plant boiler 5 is two 300MW supercritical power plant boilers with rated steam The pressure is 10MPa, equipped with extraction condensing steam turbine 6; or through the gas deployment booster system 4, two sets of independent gas homogeneous booster systems are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com