Dielectric field screening concentrating machine and metallurgical slag recovering method

A recycling method and dielectric field technology, applied in electrostatic effect separation, chemical instruments and methods, solid separation, etc., can solve problems such as inability to break through the recovery of mineral embedded cloth, and achieve the effect of efficient and environmentally friendly utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

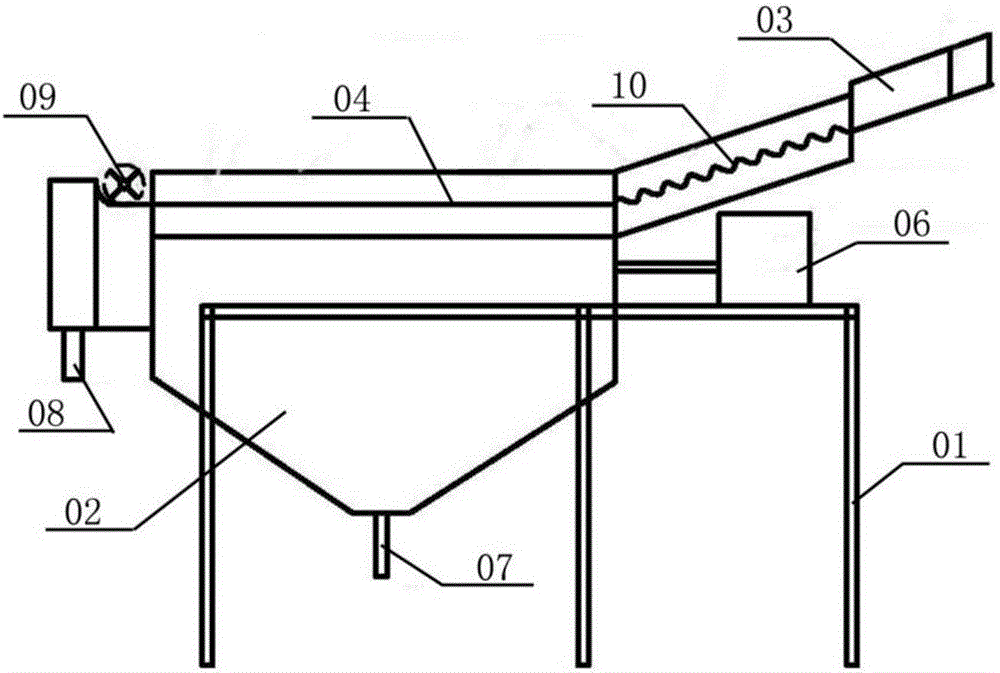

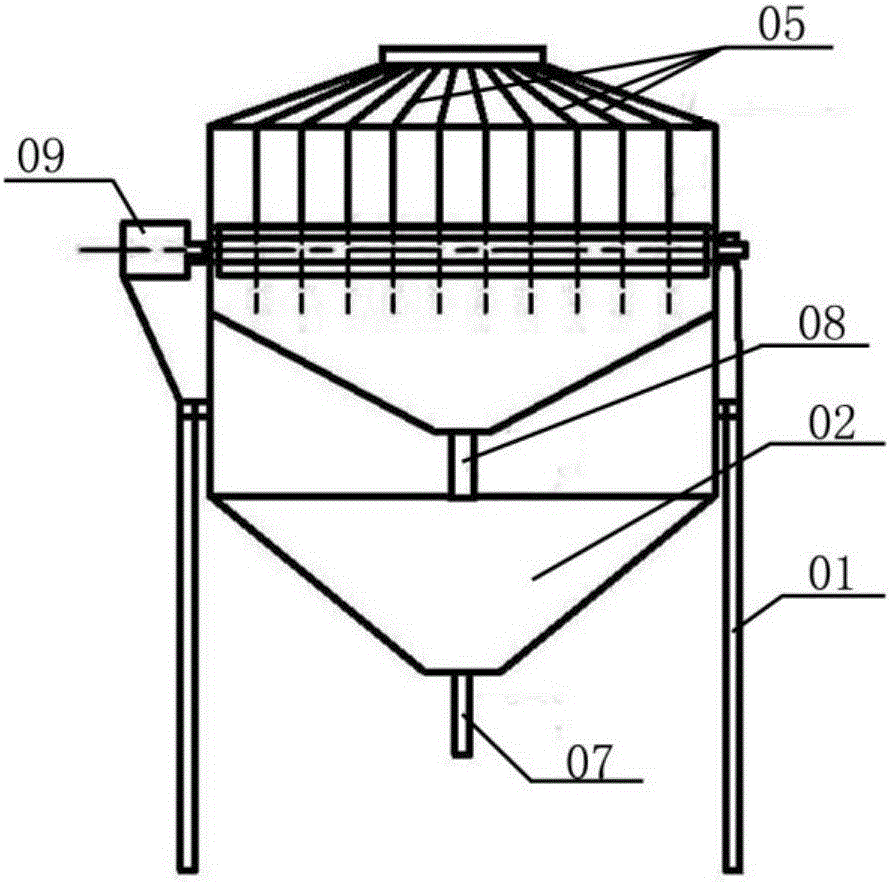

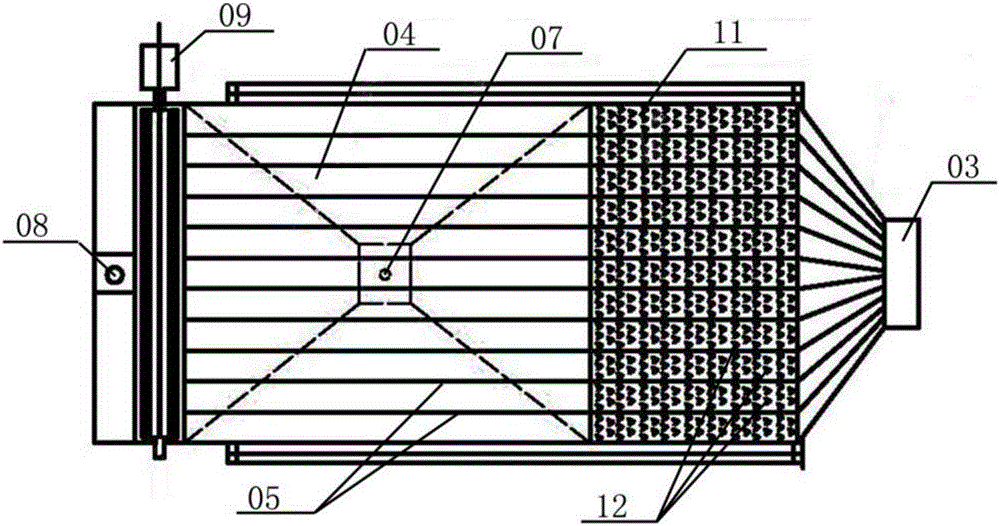

[0024] refer to Figure 1 to Figure 3 , A dielectric field screening concentrator disclosed in this embodiment includes: a support frame 01, a sorting box 02, an ore feeding part 03, a dielectric sieve screen 04, a plurality of electrode plates 05, a quick return mechanism 06, The tailings outlet 07 and the concentrate outlet 08, the sorting box 02 and the quick return mechanism 06 are installed on the support frame 01, the dielectric screen 04 is located in the upper part of the sorting box 02 and installed on the quick return mechanism 06, and the ore feeding part 03 Installed obliquely to the front end of the dielectric screen 04, the ore feeding part 03 is provided with a wave-shaped ore feeding bottom 10 to form a turbulent chain forming area 11, and the turbulent chain forming area 11 is connected to the front end of the dielectric screen 04. A number of obstacles 12 are distributed on the wavy bottom surface 10 of the turbulent chain forming area 11. The tail of the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com