Water treatment process system for wet desulfurization, and method thereof

A wet desulfurization and process system technology, applied in the field of environmental protection of thermal coal-fired units, can solve problems such as scaling, electric field short circuit, affecting dust emission, etc., and achieve the effects of avoiding scaling problems, high reliability and high economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

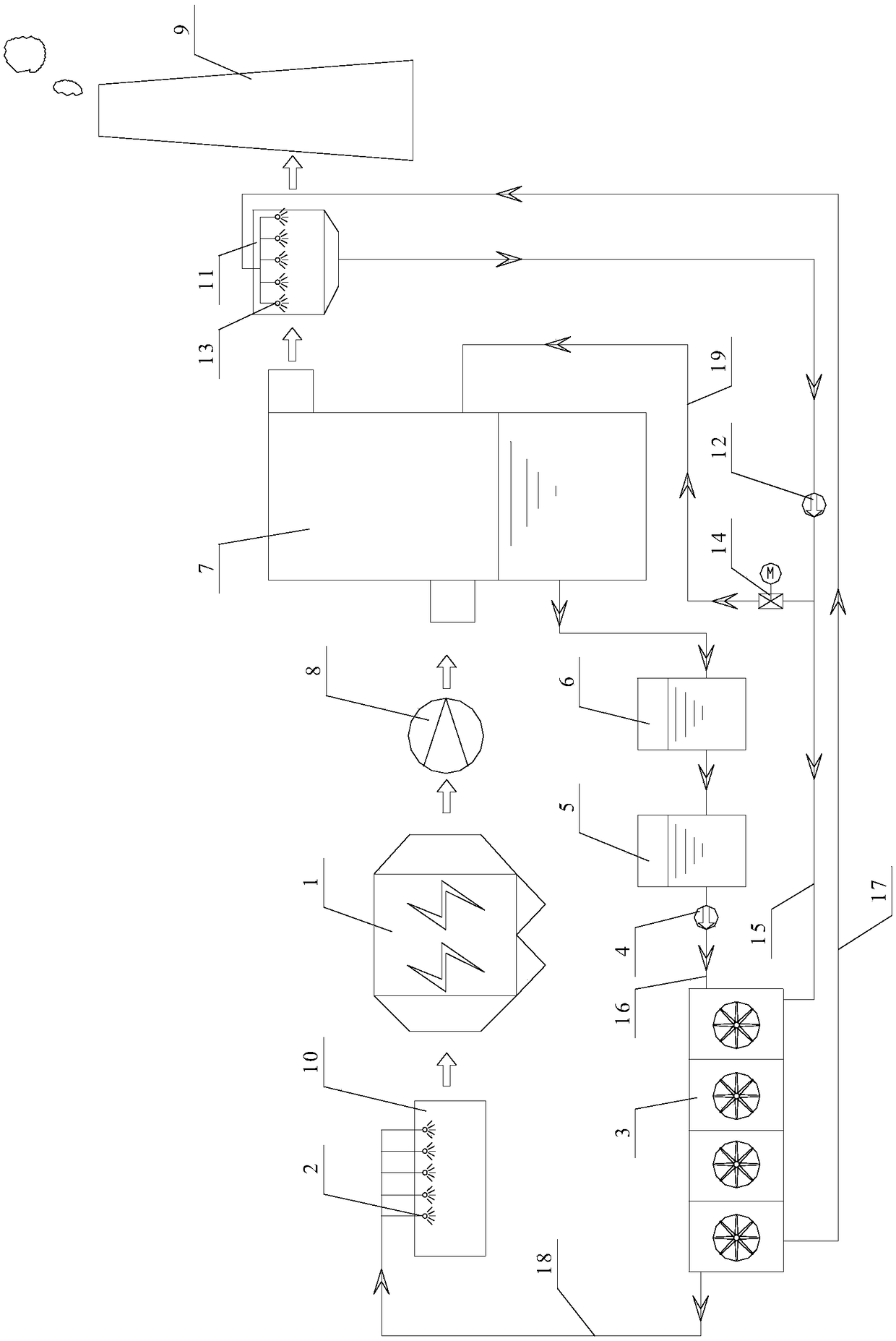

[0048] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] Without loss of generality, this embodiment uses figure 1 The flue gas wet desulfurization system shown in is used as the main body of description, and the wet desulfurization water treatment process system proposed in this application is described in detail. During the working process, the flue gas enters the electrostatic divider 1 through the air preheater flue 10, and enters the wet desulfurization absorption tower 7 through the induced draft fan 8, and finally passes through the desulfurization flue 11 and is discharged into the atmosphere through the chimney 9.

[0050] Such as figure 1As shown, in the water treatment process system for wet desulfurization, a multi-layer spray water collector 13 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com