Patents

Literature

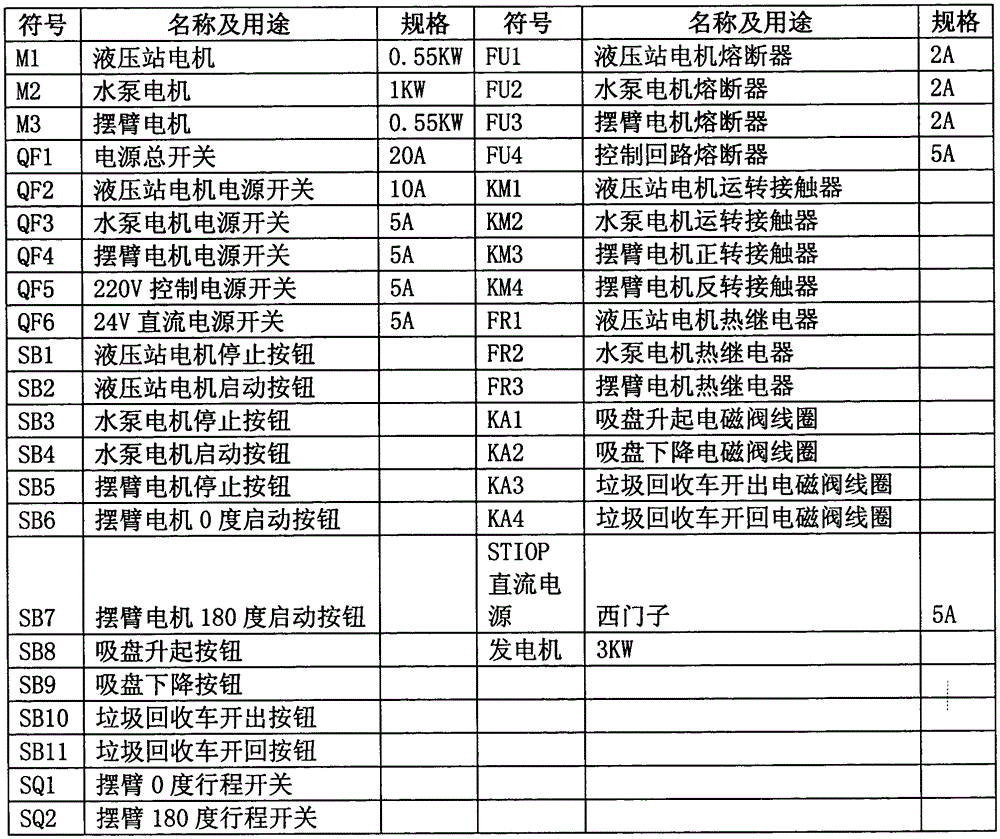

50results about How to "Meet clean up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

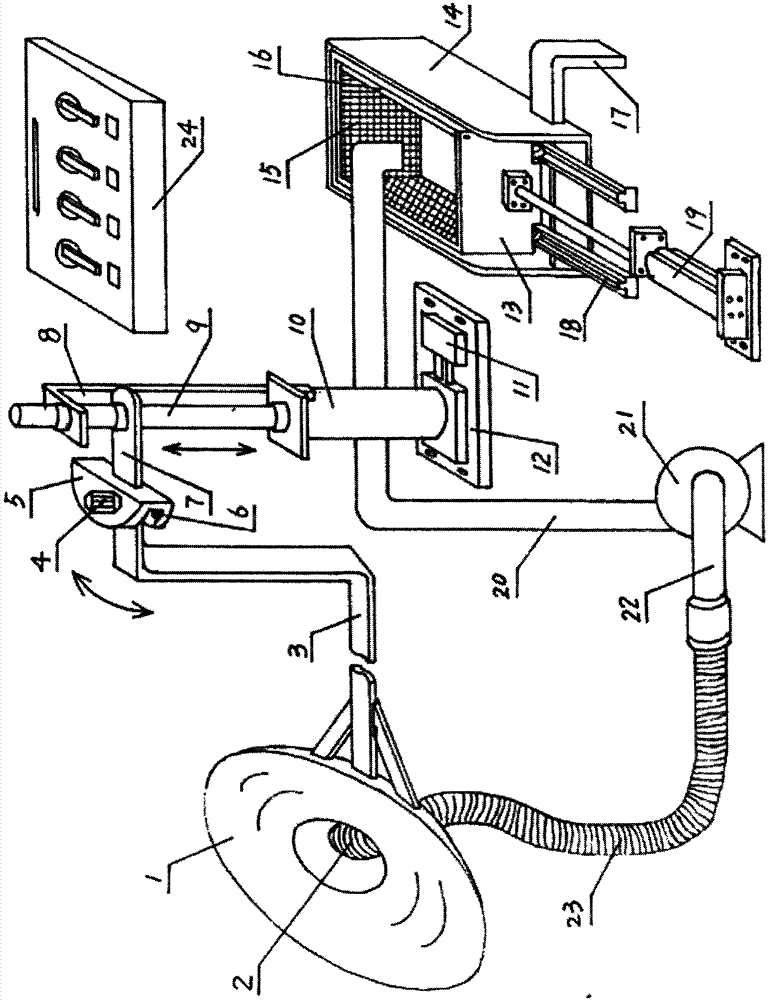

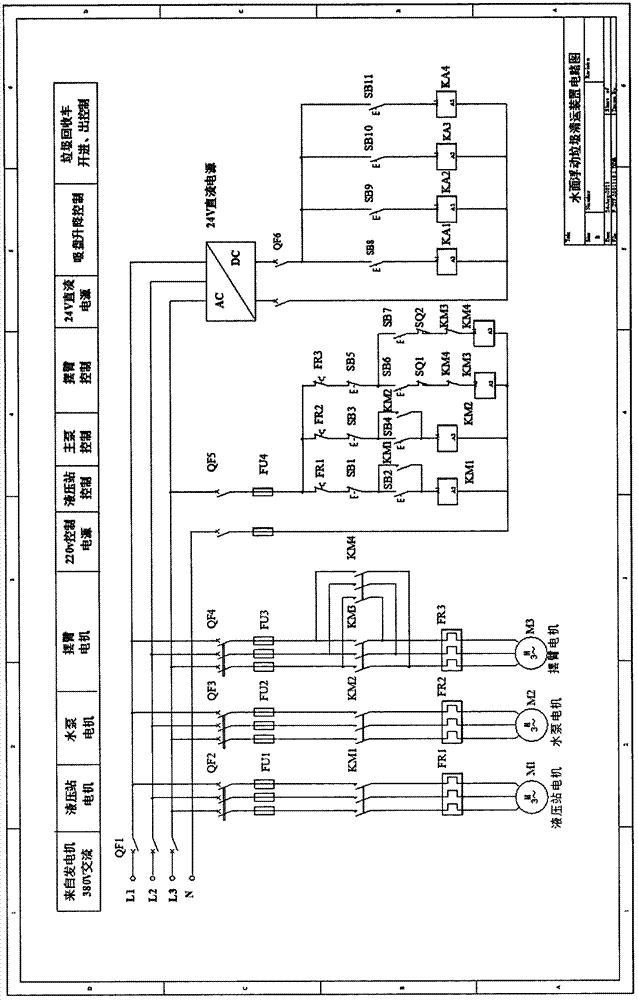

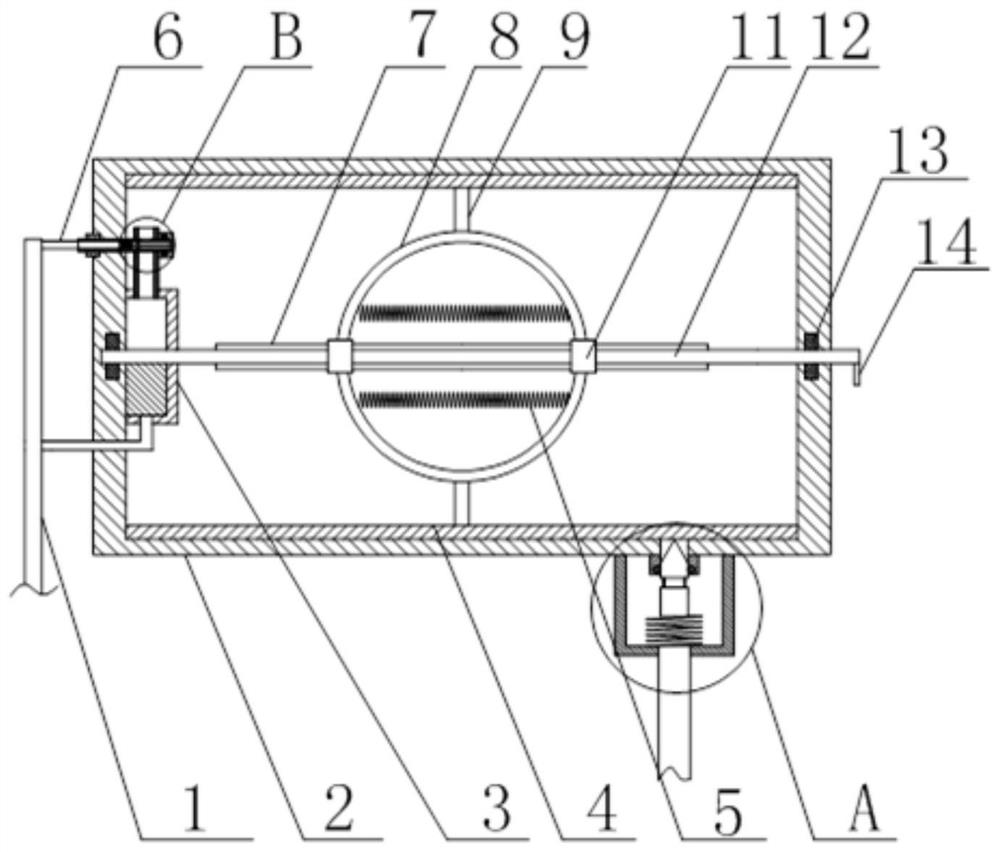

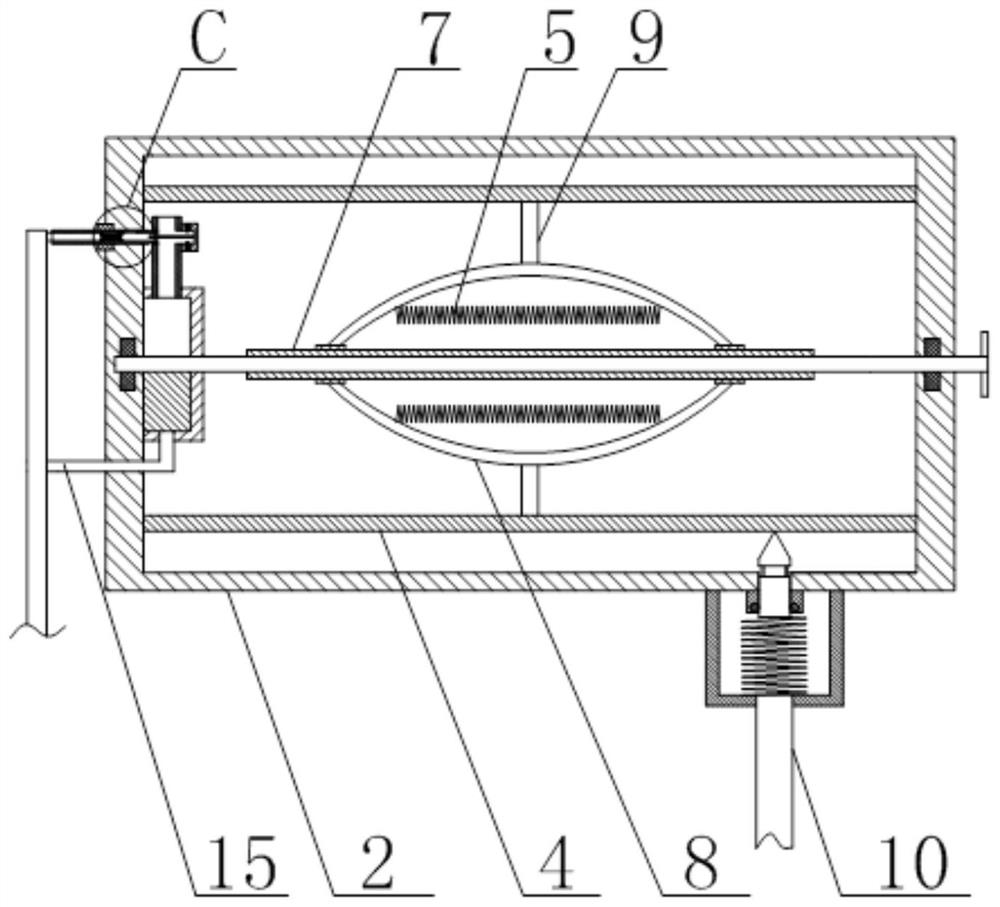

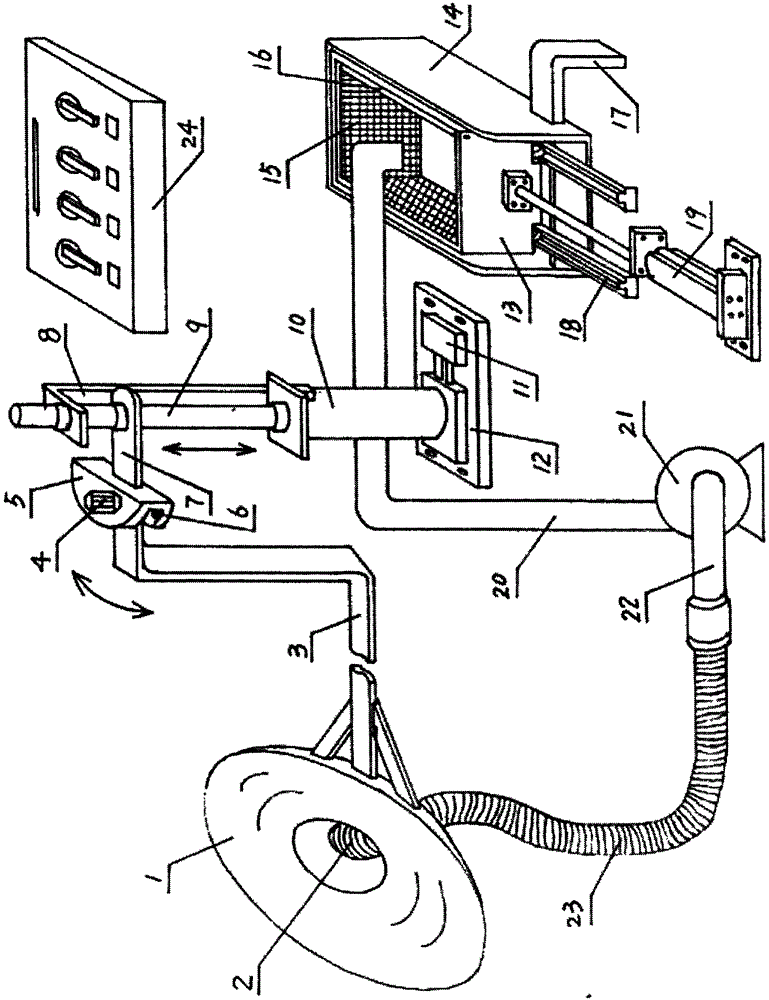

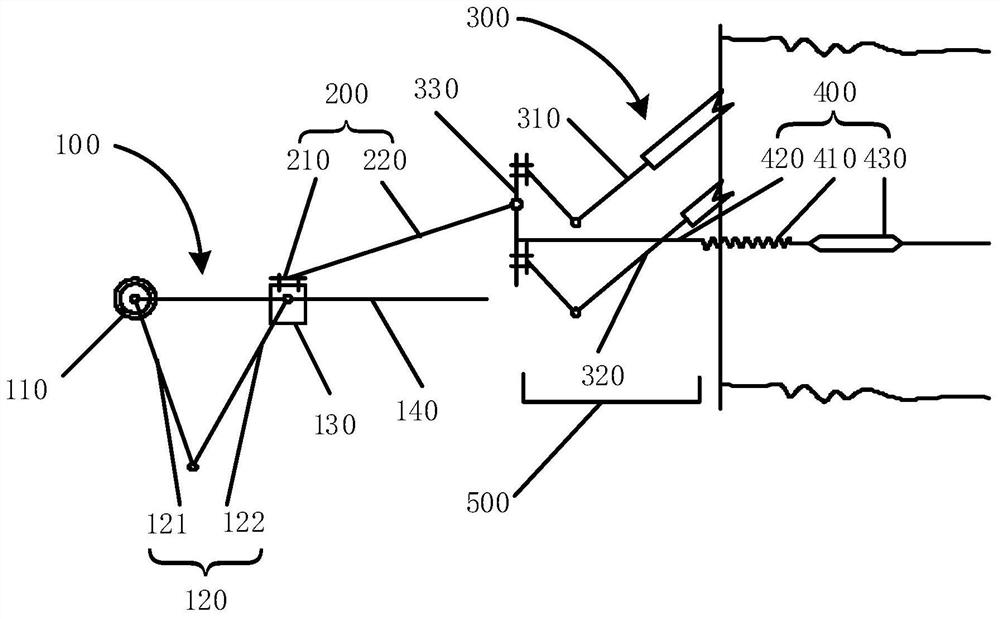

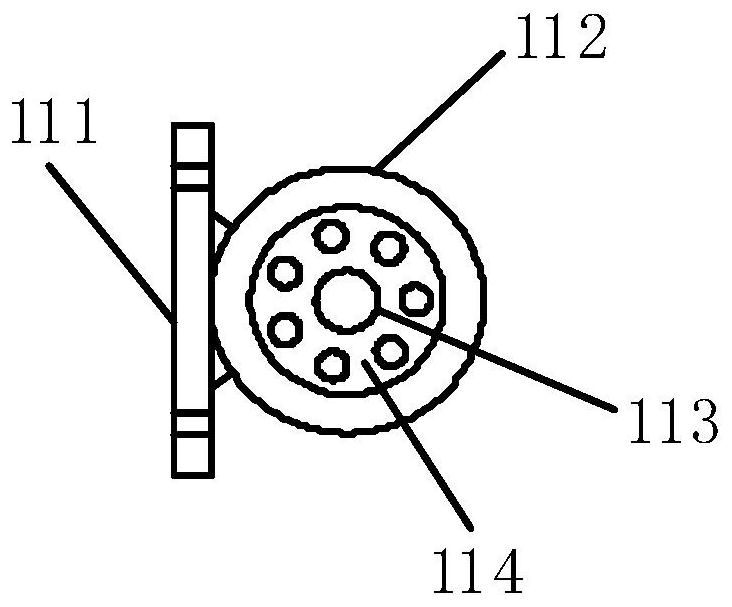

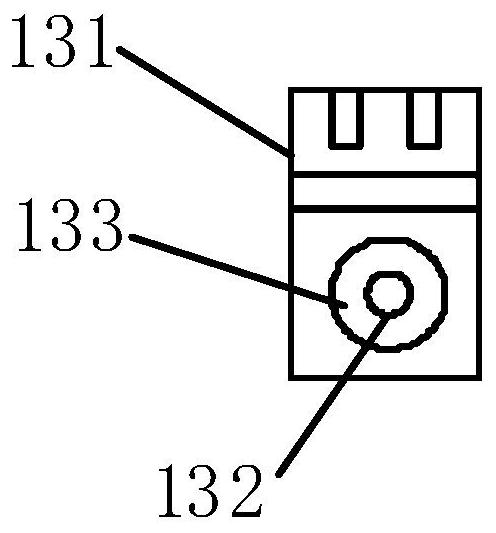

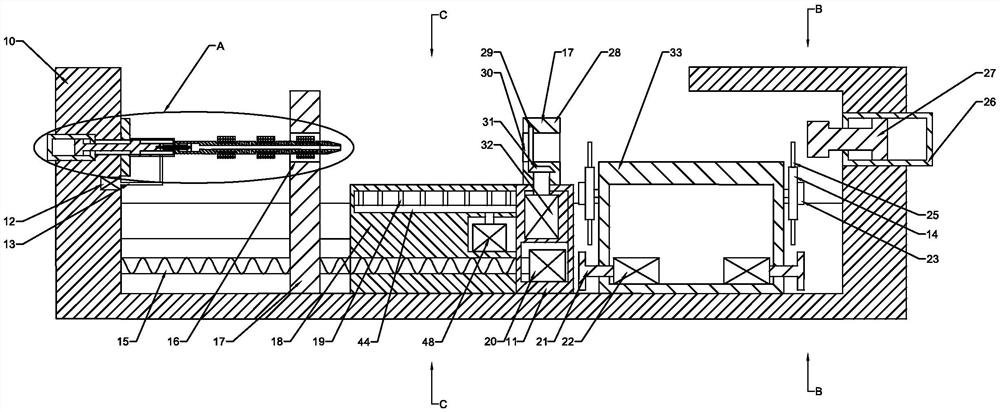

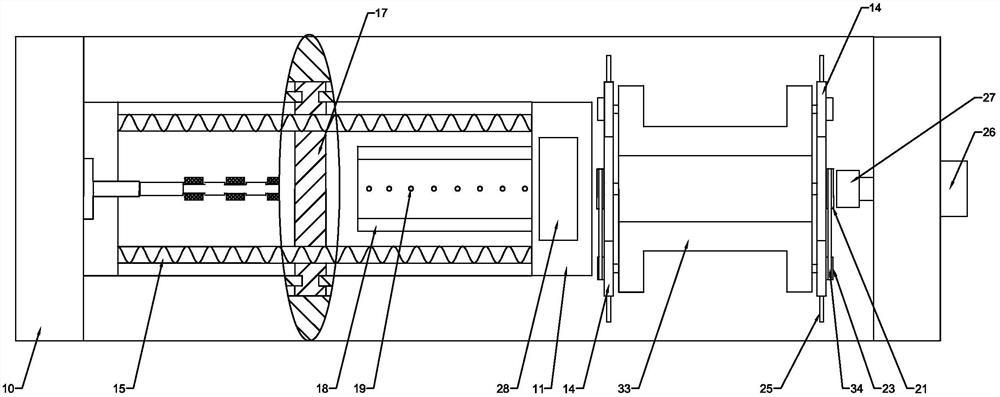

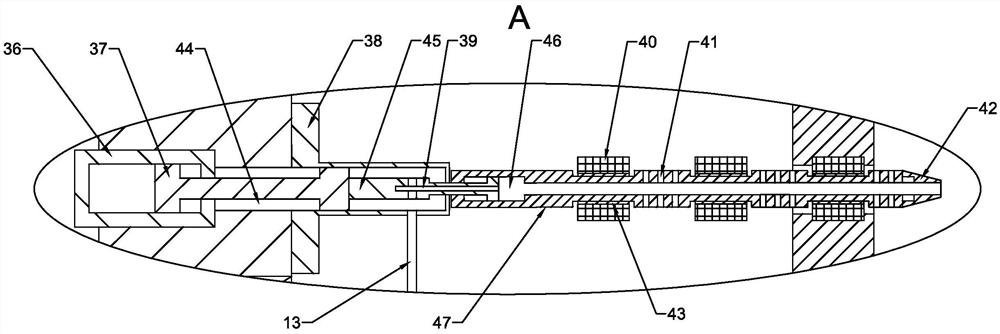

Water floating refuge collecting device

The invention relates to a water floating refuge collecting device, belongs to the field of water environment protection auxiliary equipment, and in particular relates to a river (lake) water floating refuge pollutant collecting device and a using method thereof. The invention aims at providing an automatic water floating refuge collecting control device, solving the problem of manual fishing operation. The water floating refuge collecting control device comprises a dirt removing part, a control part, a filter part and an operating part, wherein through comprehensive application of control technologies such as electric machinery, continuous automatic operations of cleaning, filtering, recovering, transporting and the like of water floating refuge are realized. The water floating refuge collecting device has the advantages that time and labor are saved, operation efficiency is increased, and practical value and popularization value are good. The water floating refuge collecting device can be used in the fields of production and life when being arranged on a boat body.

Owner:金子钒

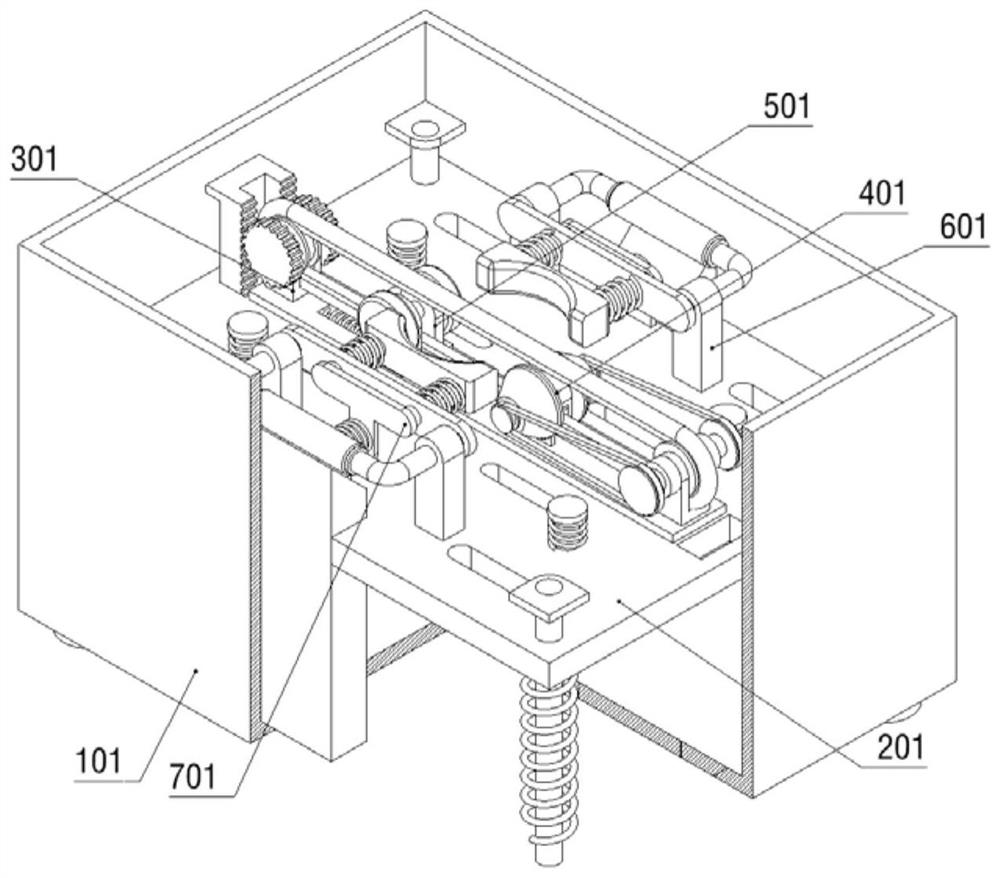

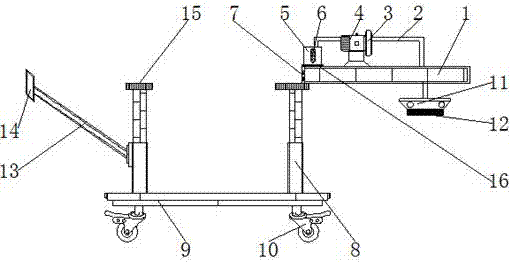

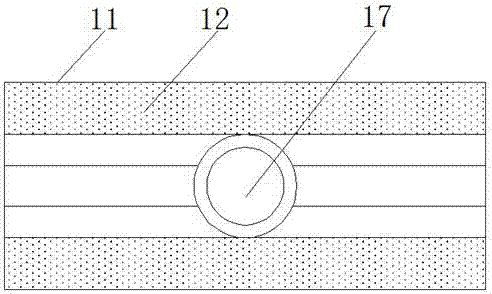

Ironclad motor cast-aluminum rotor end surface burr cleaning device

InactiveCN107370306AMeet clean upPrevent adhesionEdge grinding machinesGrinding drivesCouplingDrive motor

The invention discloses an ironclad motor cast-aluminum rotor end surface burr cleaning device, which comprises a slideway, a driving gear, a toothed belt, a driven gear, a driving motor A, a screw rod, a driving motor B, a lifting table, a high-pressure suction fan, a circular wheel and grinding heads, wherein a plurality of groups of sliding blocks are arranged on a sliding groove in a sliding mode; a rotor placement groove is opened in the upper surface of each sliding block; the output shaft of the driving motor B is connected with the screw rod through a coupler; the lifting table is arranged on the screw rod in a threaded mode; the lower side of the lifting table is provided with a fan cover; the upper side of the lifting table is provided with the high-pressure suction fan; the output shaft of a rotation motor is provided with the circular wheel in a rotating mode; and the lower side of the circular wheel is fixedly provided with a plurality of groups of grinding heads. While the device grinds rotor end surface burrs, the ground burrs can also be absorbed, burr scrap can be prevented from being attached to the surface of the rotor as much as possibly, the problem of single motor noise caused by various friction noise in the case of final assembly can be effectively avoided, and the production qualification rate of the motor can be improved.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

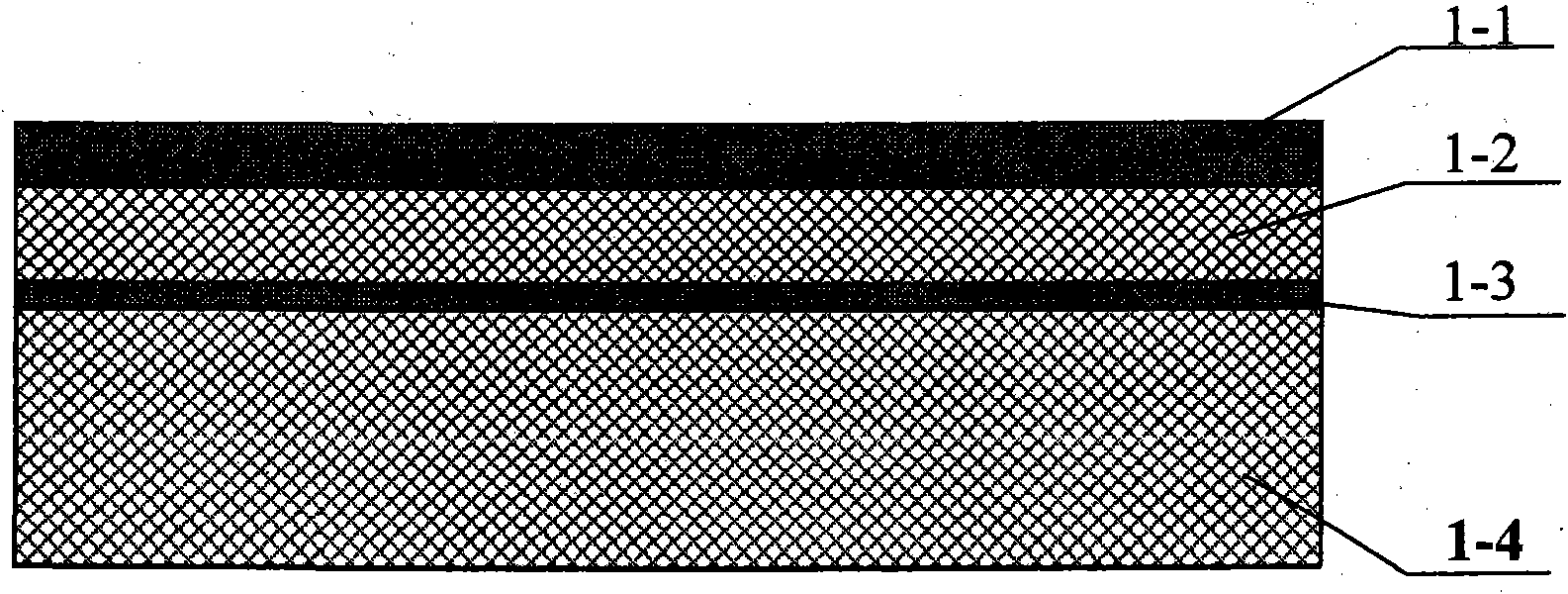

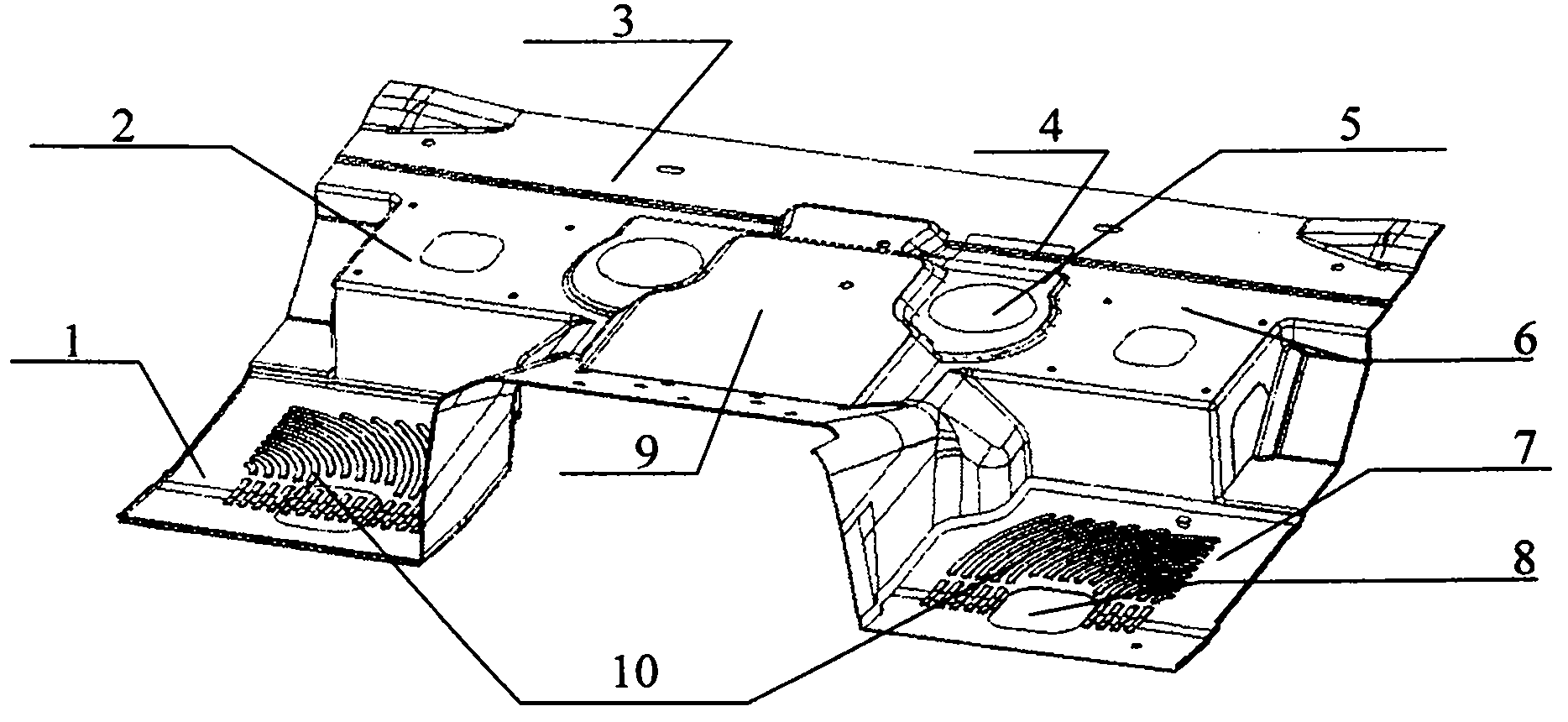

Method for producing automotive sound-absorption and heat-insulation integrated carpet

ActiveCN101830188ASolve sound absorption and heat insulationAddress personalizationVehicle arrangementsLayered productsPunchingHazardous substance

The invention relates to a method for producing an automotive sound-absorption and heat-insulation integrated carpet and belongs to the technical field of automotive interior decorations. In the method, an environmentally-friendly 3.5 millimeter (including 0.8 millimeters of a toughening layer, 2.5 millimeters of a foaming layer and 0.2 millimeter of a bottom film protective layer) PVC foamed leather is mainly used and subjected to heating, baking, vacuum forming, cooling forming, 8 millimeter cotton-based sound-absorption and heat-insulation carpet compression and lamination, shearing, hole making, punching and inspection to produce a finished product. The method solves and improves the indexes, such as sound absorption, heat insulation, dust prevention, attractive appearance and easy cleaning, of the automotive carpet and makes the automotive carpet reach international advanced level-III and meet the design requirements on environmental protection, attractive appearance, comfortableness, sound absorption and heat insulation of an automotive cab. In a plastic absorption process, a pneumatic pre-feeding device is used to ensure the thickness of the foamed leather on the highly-stretched part of the large section of the product, so the overall quality of the product is improved, the quality consistency of the product is guaranteed, the production efficiency is improved greatly and the labor intensity is relieved greatly. The compression and lamination of the sound-absorption and heat-insulation carpet improve the sound and heat insulation performance of the product and make the appearance of the product smooth and elegant and touch comfortable. In the while production process of the product, no harmful matter is produced, and the product is an environmentally-friendly product.

Owner:XIAN TIANRUI AUTOMOBILE INTERIORS

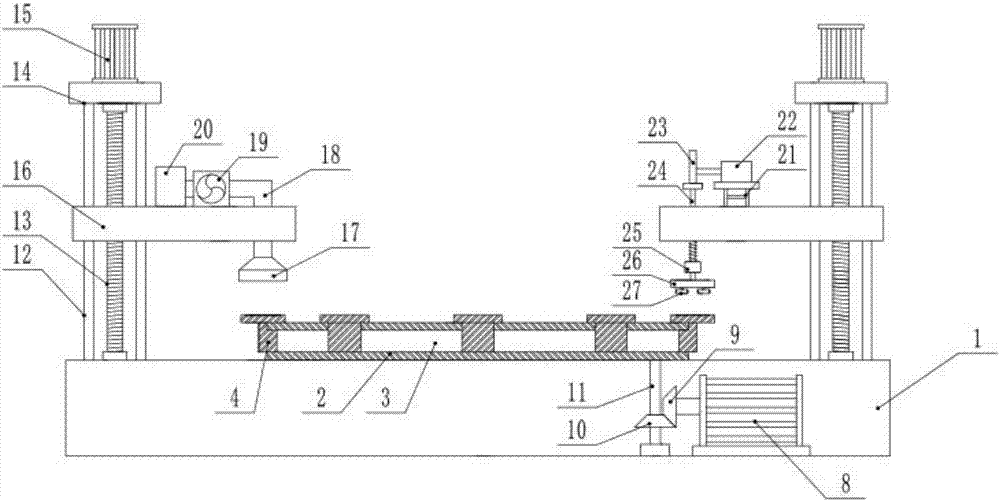

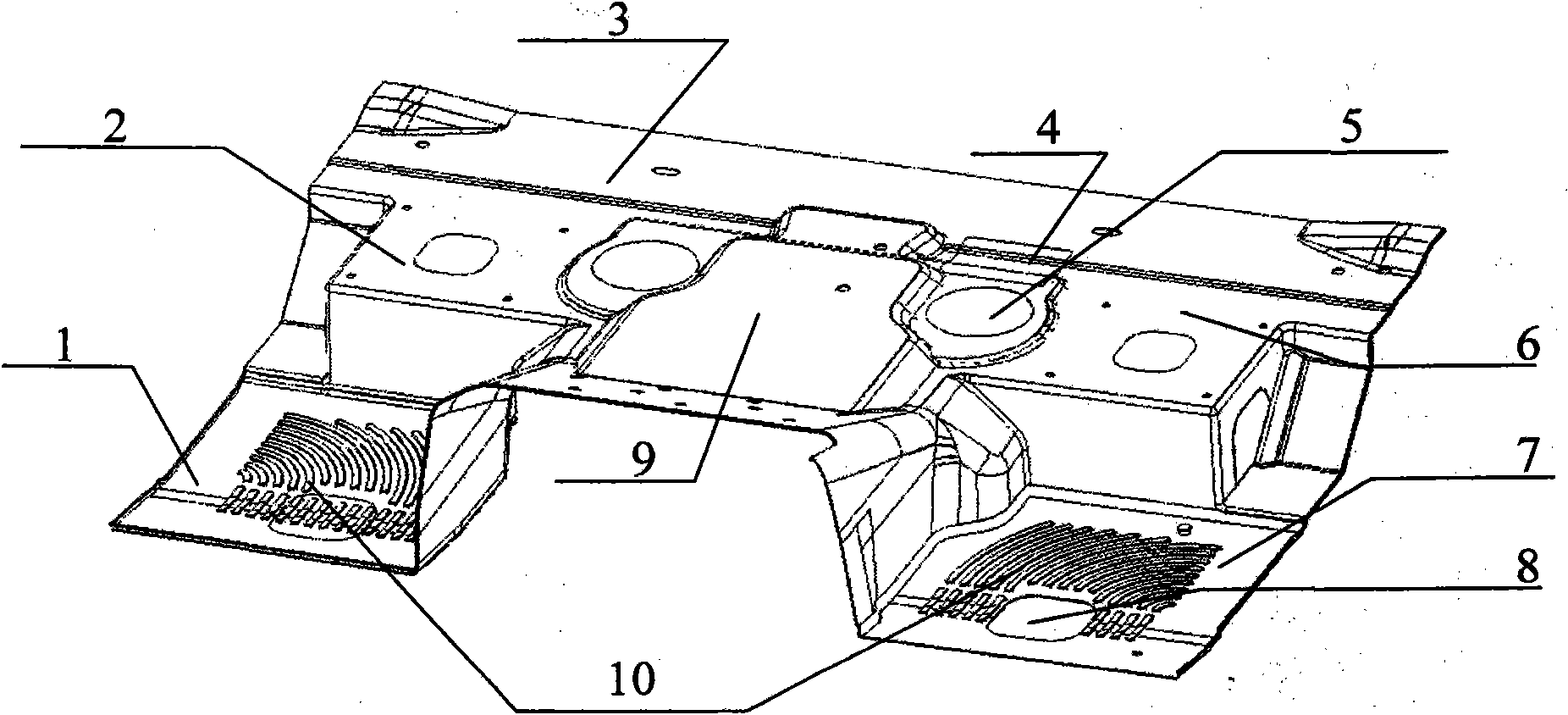

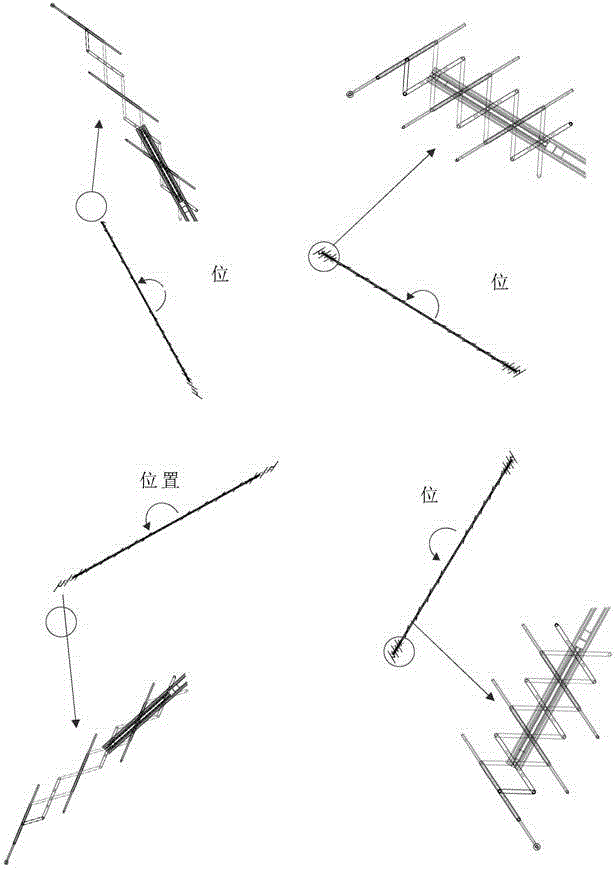

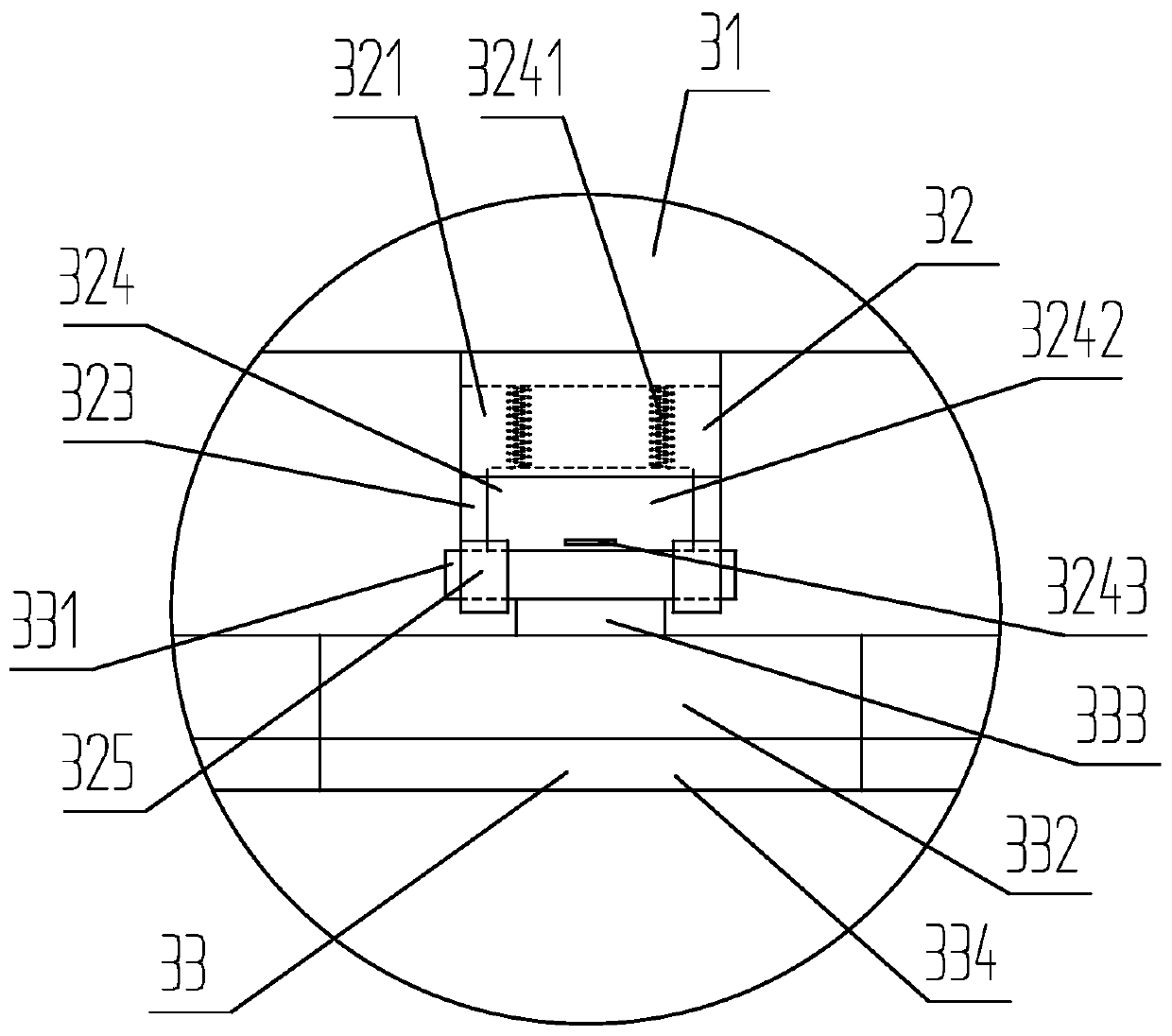

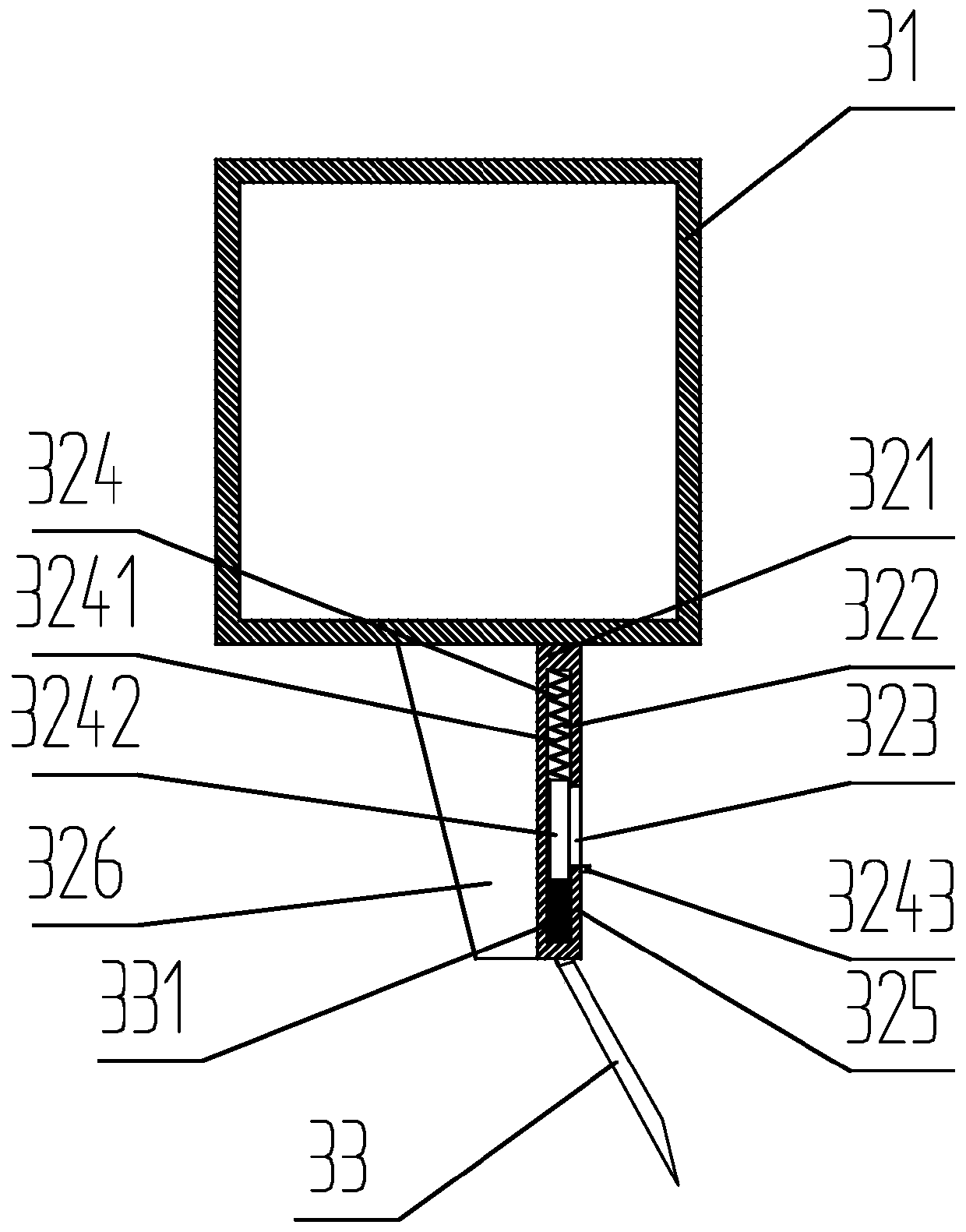

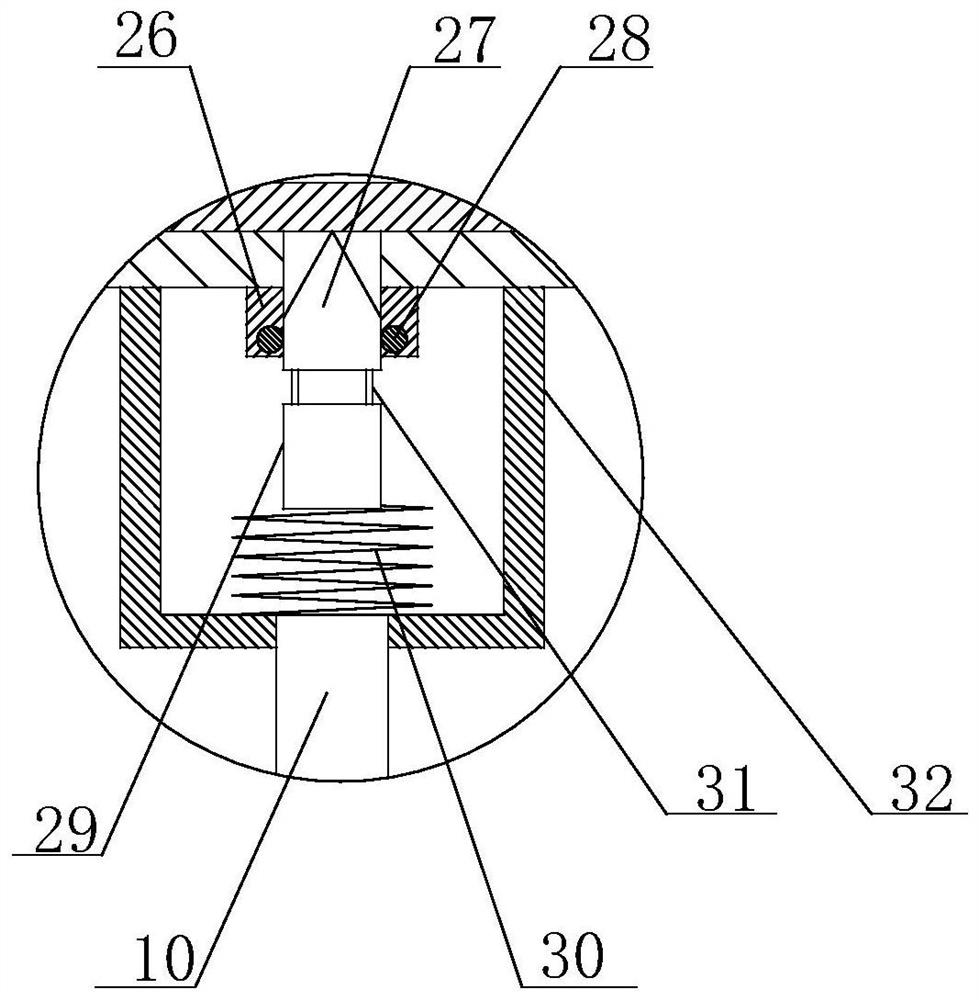

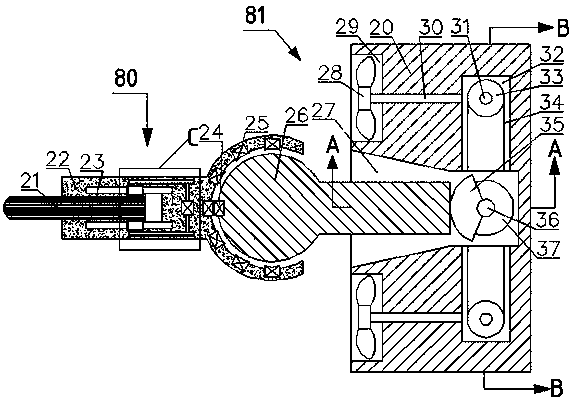

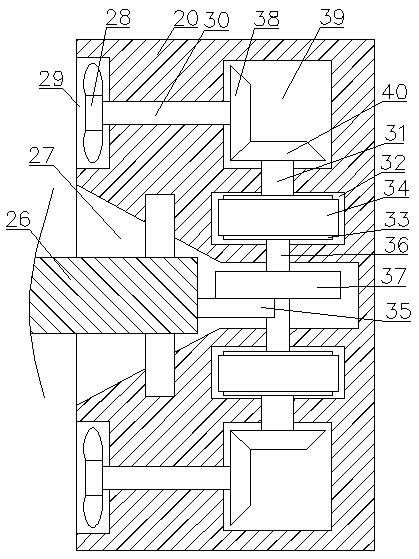

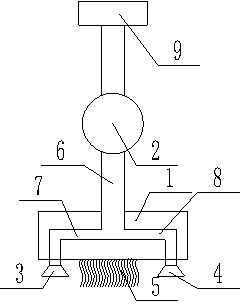

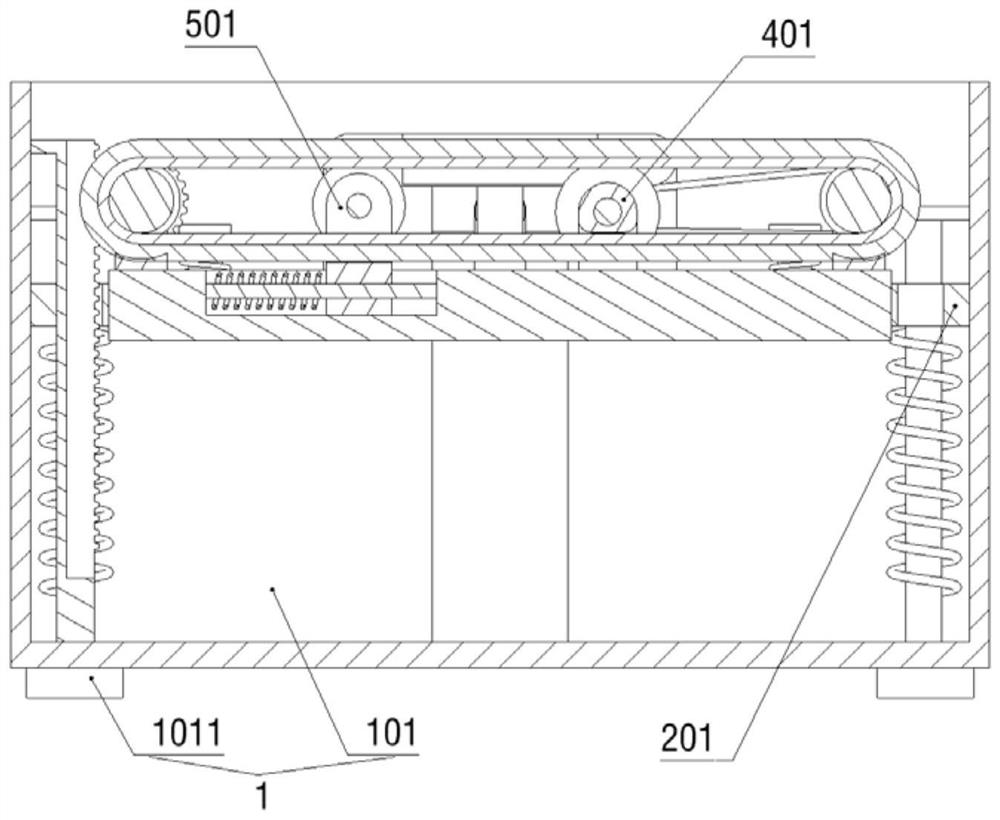

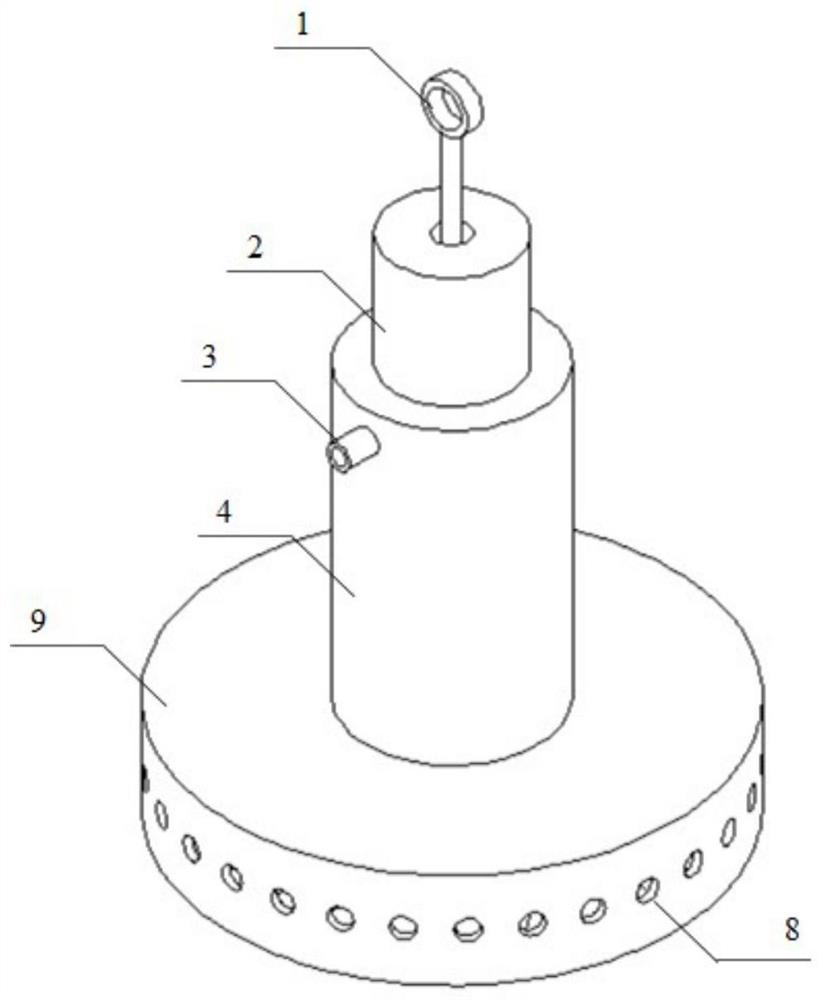

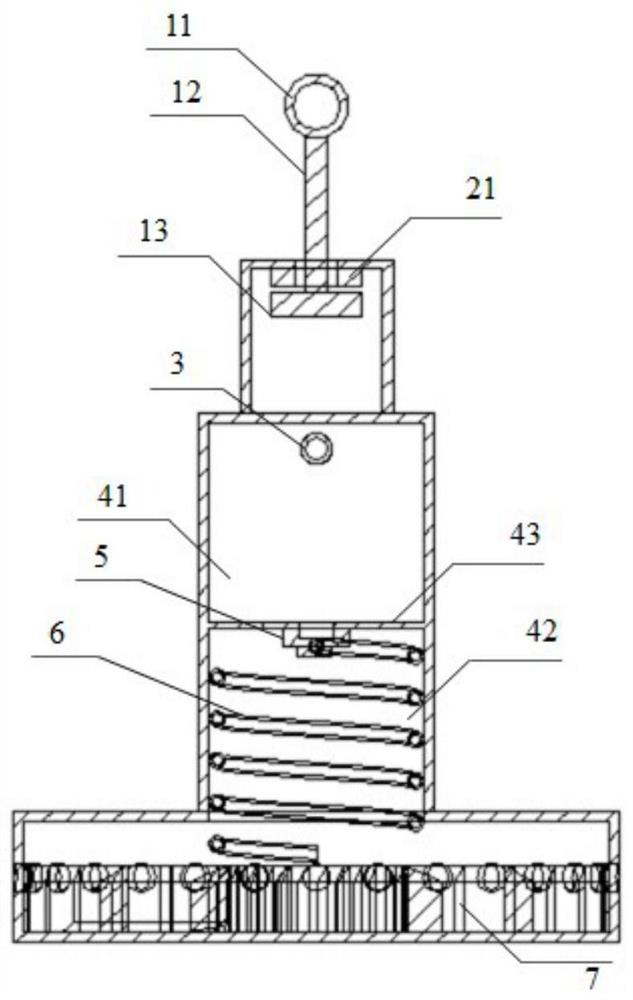

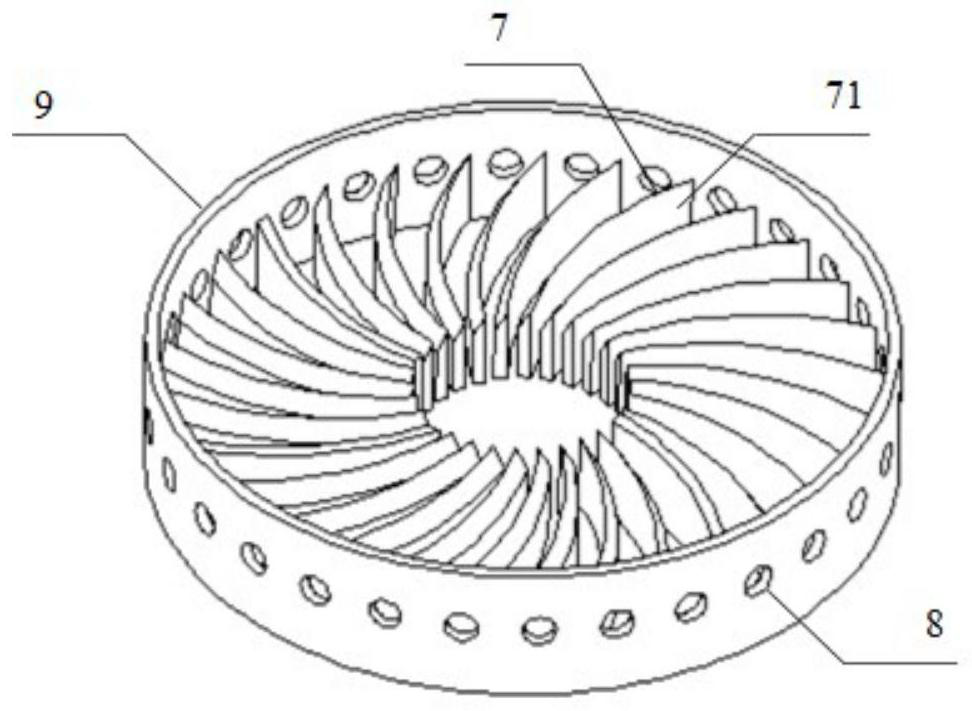

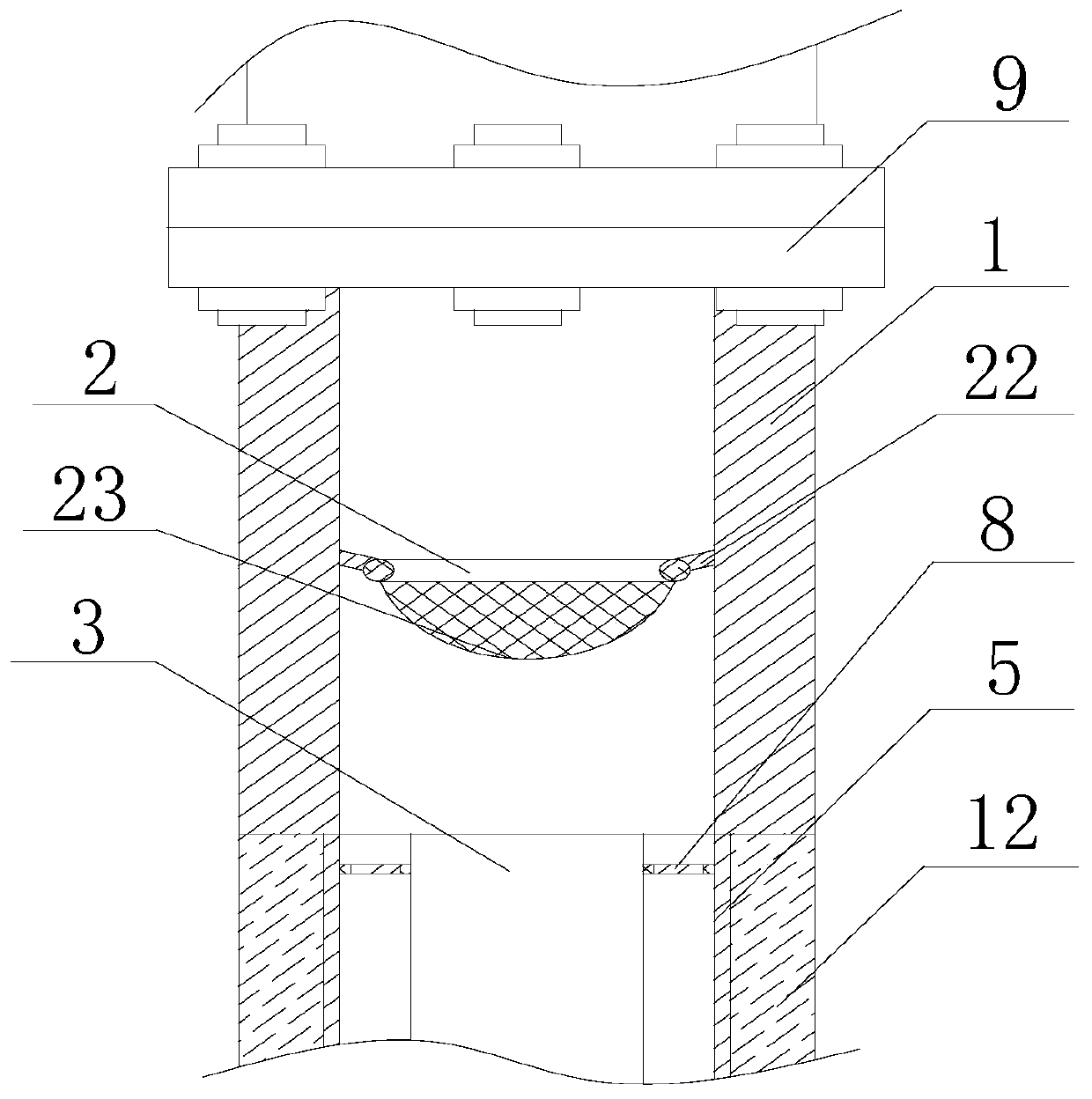

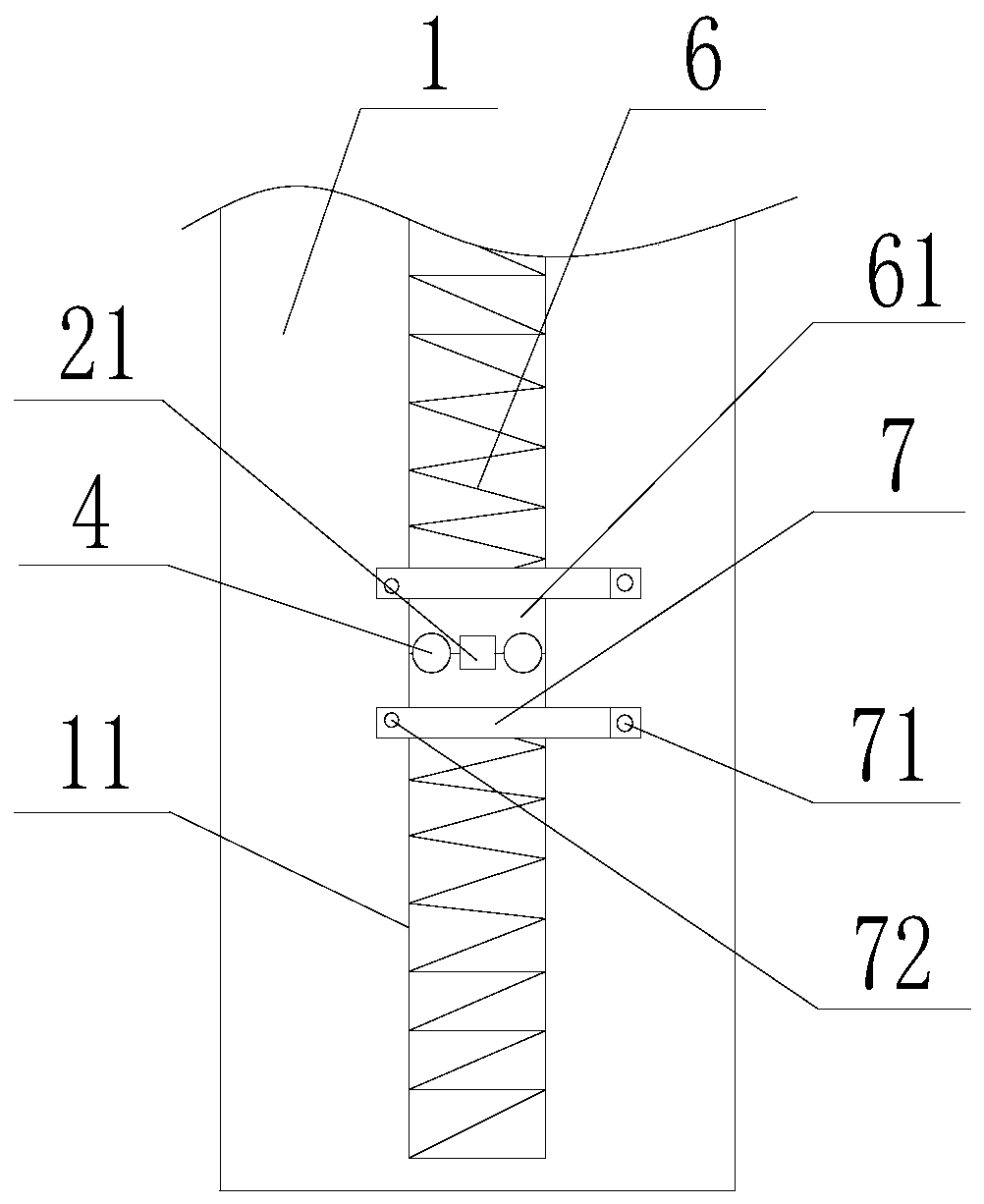

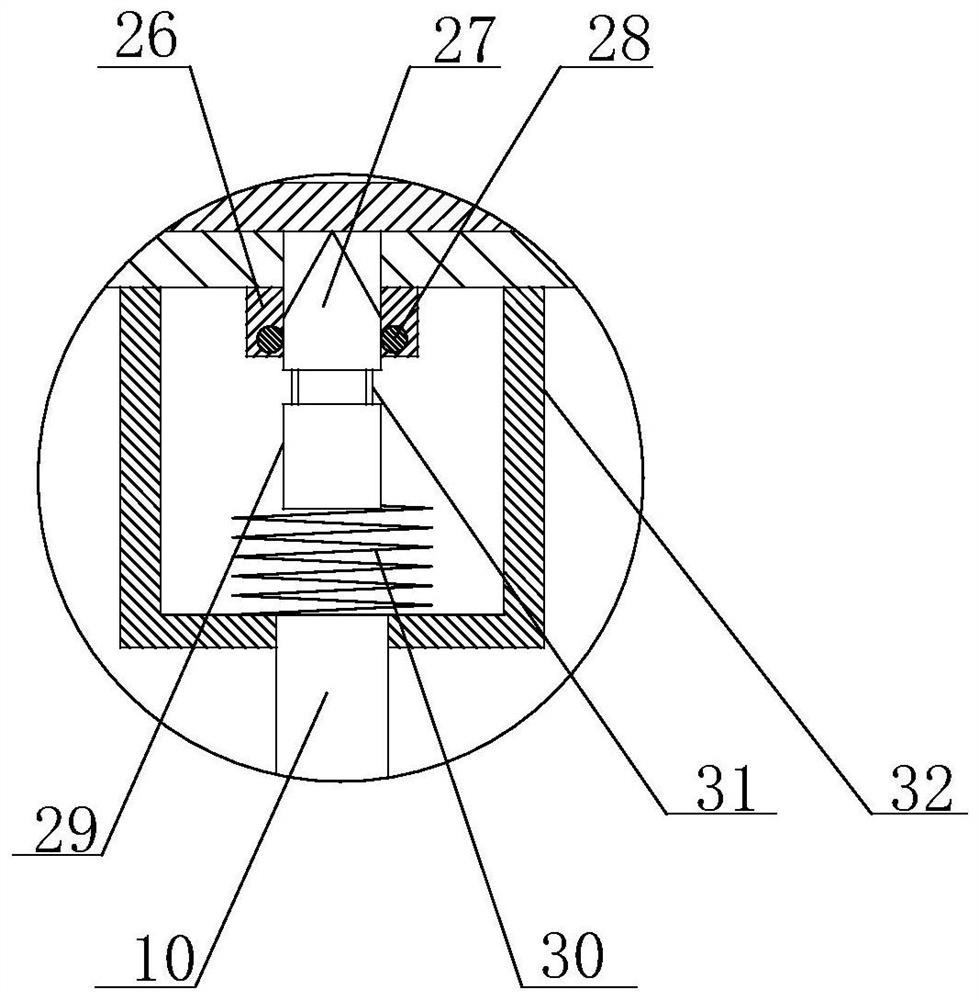

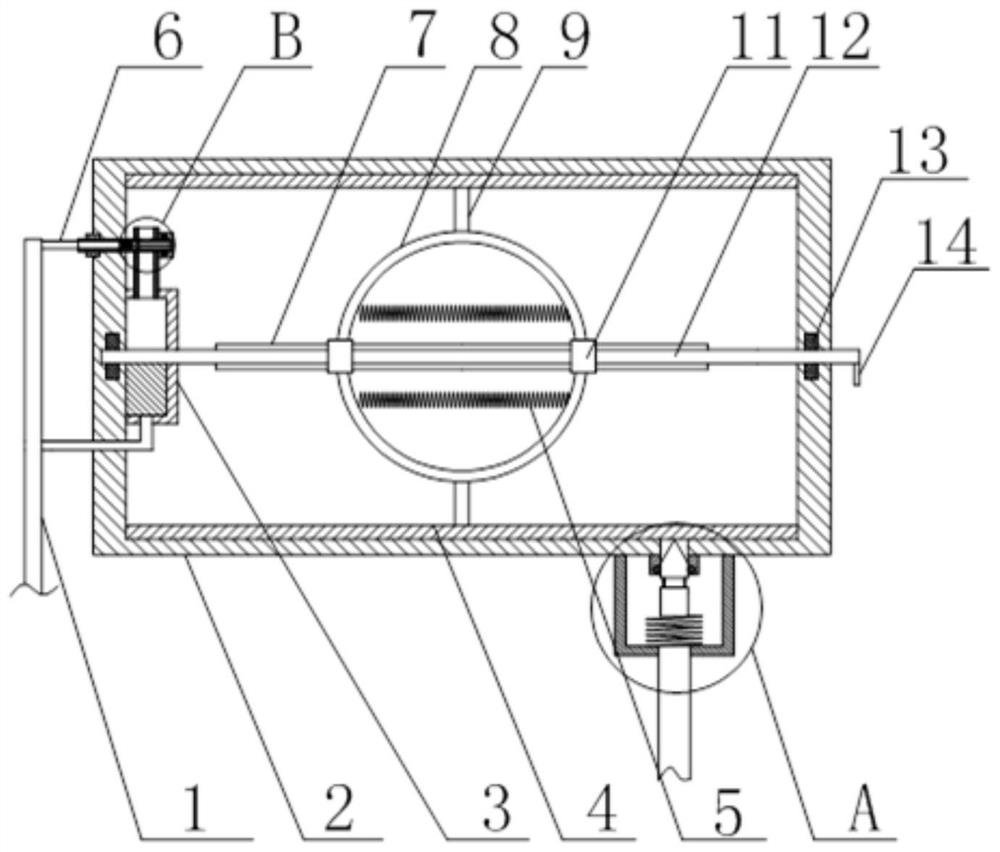

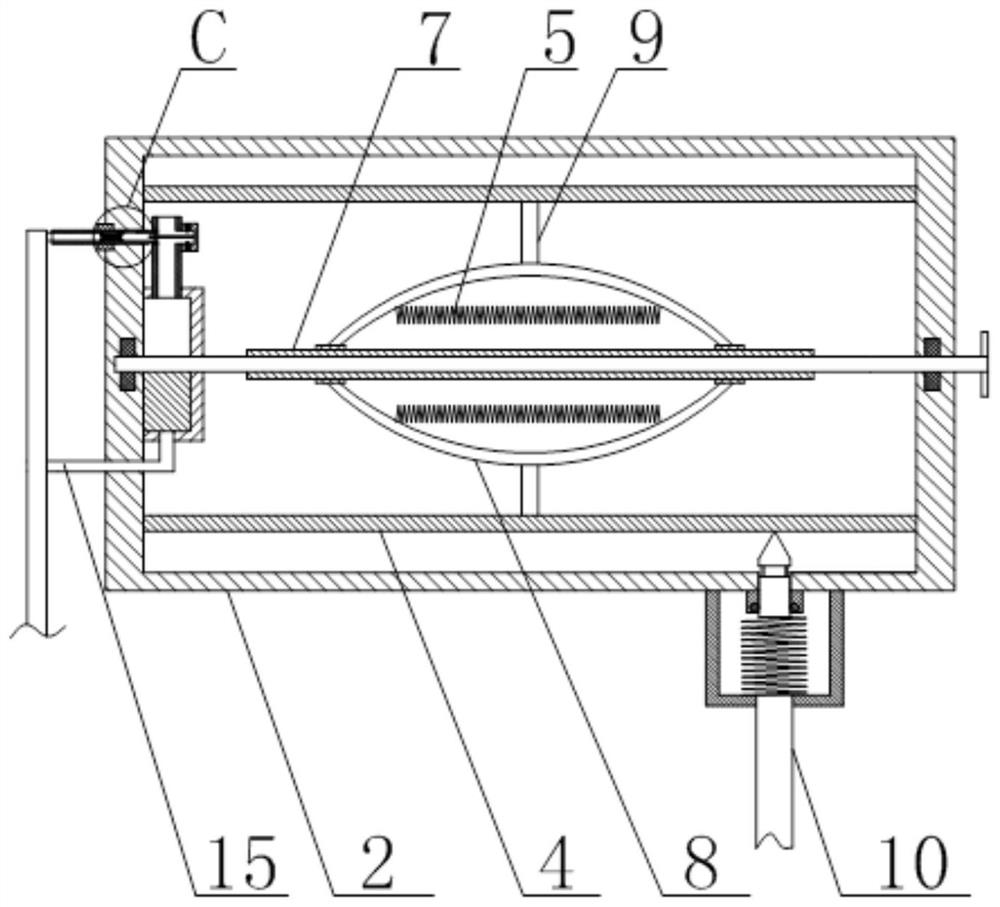

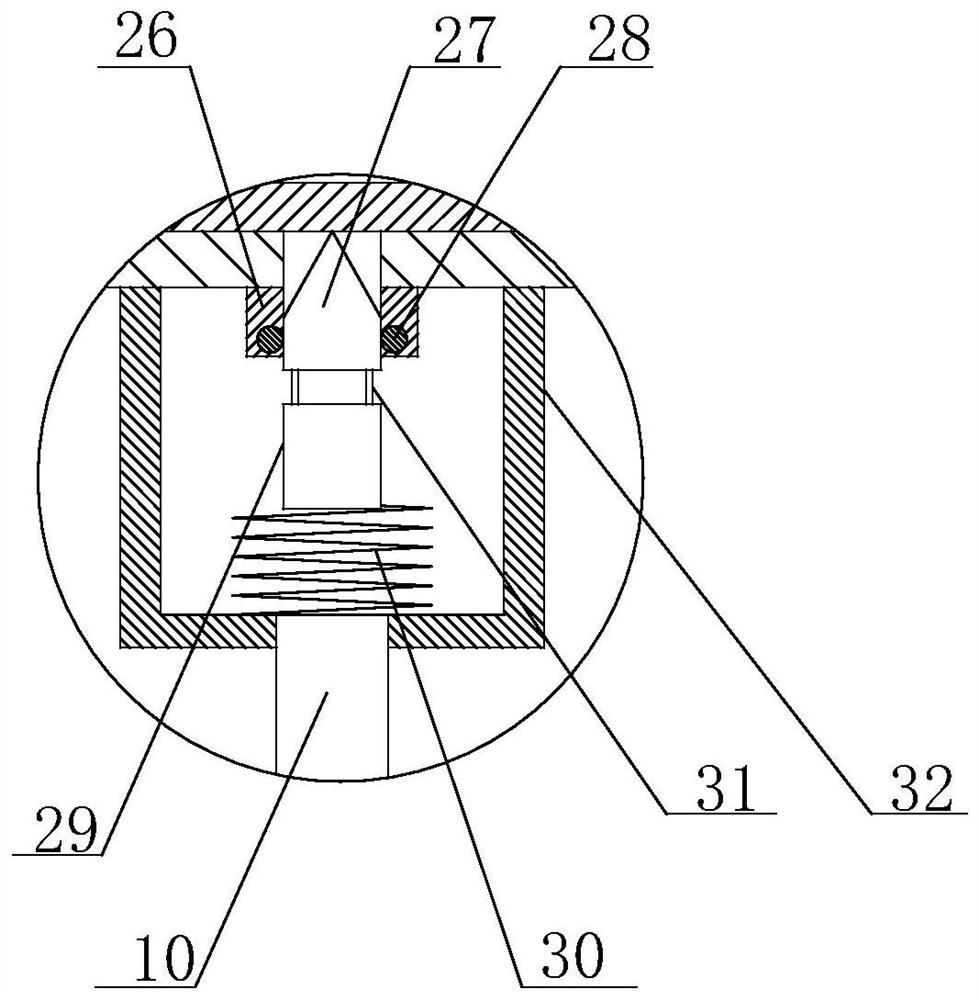

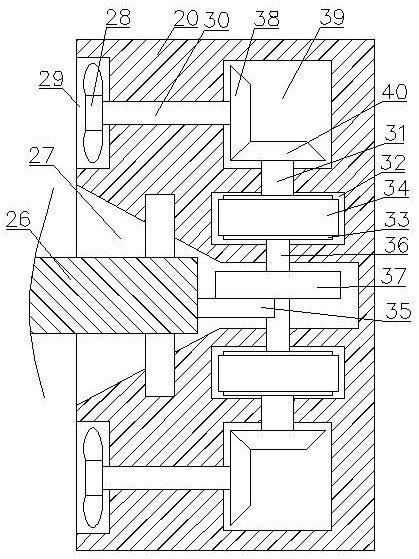

Automatic telescopic scraping arm for square/regular polygon settling basin

InactiveCN104941267AMeet clean upImprove the problem that it cannot be applied to the rectangular poolSedimentation separationEngineeringSettling basin

The invention relates to an automatic telescopic scraping arm for a square / regular polygon settling basin. The automatic telescopic scraping arm comprises a fixed scraping arm part installed on a main shaft and an automatic telescopic scraping arm part installed at the arm end of the fixed scraping arm. The fixed scraping arm is composed of a main shaft (1), a main-shaft assembly (2), a scraper plate (3), a fixed scraping arm (4), a scraper plate joint bar (5), a mud-guide tank scraper plate (6) and a middle shaft (7). The automatic scraping arm is composed of an end contact first roller (11), an end contact second roller (10), an end contact third roller (9), a tension spring (11), a scraper plate anti-drag hole (13), a first automatic scraper plate (14), a second automatic scraper plate (15), a third automatic scraper plat (16), an end contact roller (17), a scraper plate anti-drag hole (18) and a linkage (19). The automatic telescopic scraping arm for the square / regular polygon settling basin can perform circular motion when driven by the main shaft, and the tops of the scraping arms stick close to the wall of the settling basin. Without extra power, sludge on the square / regular polygon settling basin can be scraped off in all directions such that the settling basin has no blind angle of sludge.

Owner:CHANGZHOU UNIV

Garbage and fine sand separating device used for sandbeach

The invention discloses a garbage and fine sand separating device used for a sandbeach. The garbage and fine sand separating device comprises a body. A screening cavity is formed in the body, an eccentric wheel cavity is formed in the upper side of the screening cavity, a power cavity is formed in the back side of the eccentric wheel cavity, a sliding cavity is formed in the upper side of the screening cavity, a T-shaped plate is slidably connected in the sliding cavity, a sand shoveling spring is connected between the T-shaped plate and the bottom wall of the sliding cavity, and a sand shoveling plate is fixedly arranged on the lower side of the sand shoveling spring. A hydraulic motor is started to extrude the T-shaped plate downward so as to push the sand shoveling plate downward to adjust a sand digging depth. A hanging buckle is arranged on the front side of the body and the device can be directly hung to a tow hook of a dune buggy, so that the sandbeach is cleaned by means of power of the dune buggy, the resources are saved to a certain extent, and discharge of pollution is reduced.

Owner:YUYAO XINZHI NEW ENERGY TECH CO LTD

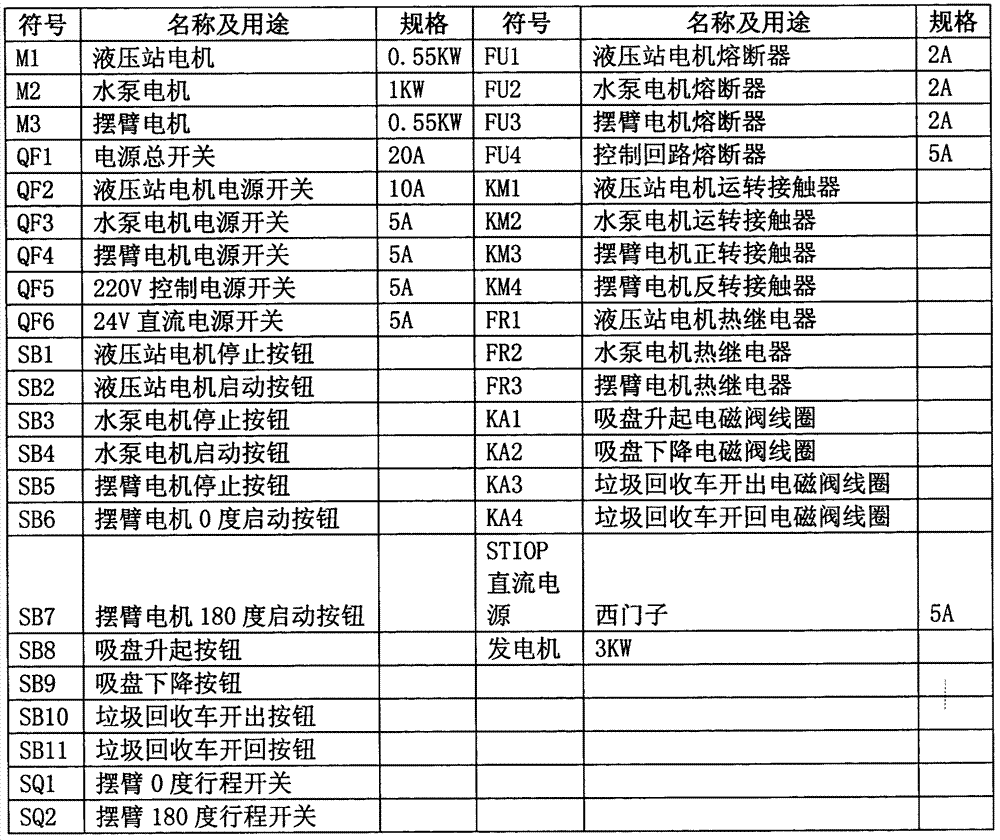

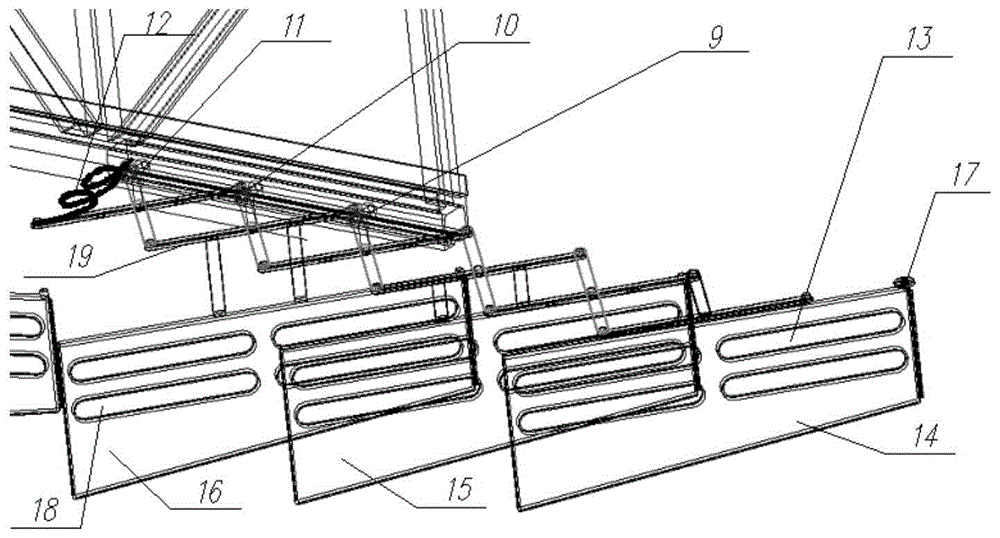

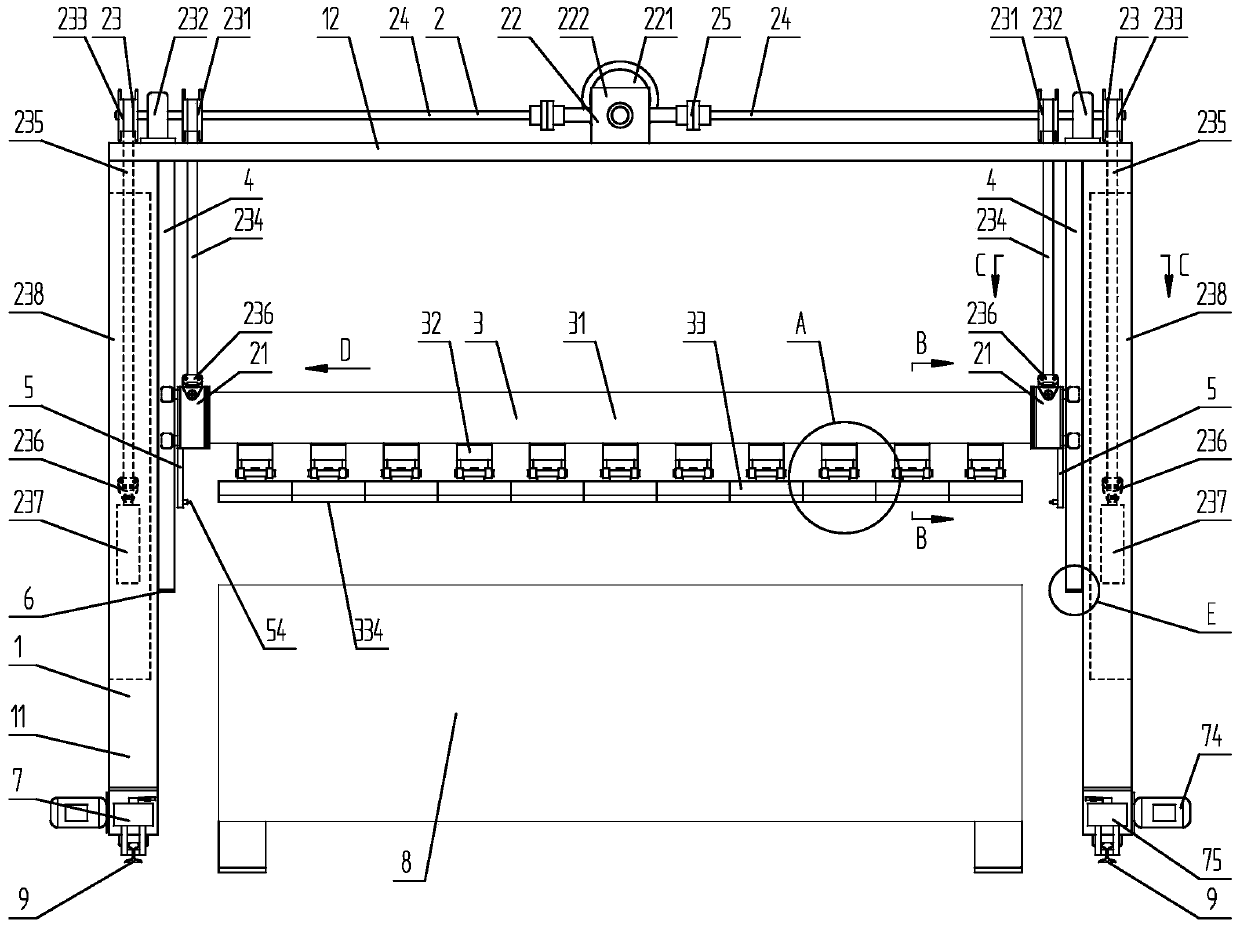

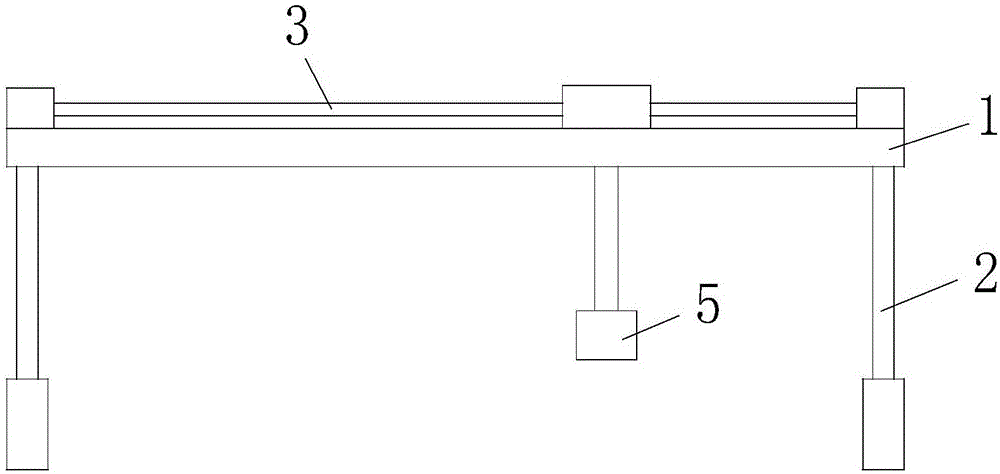

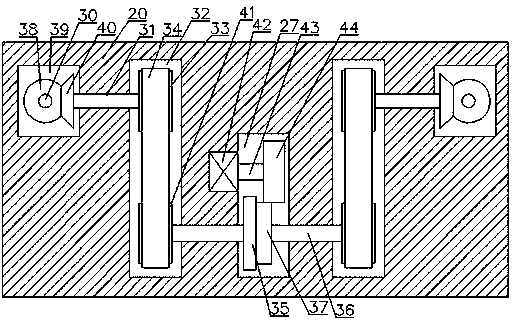

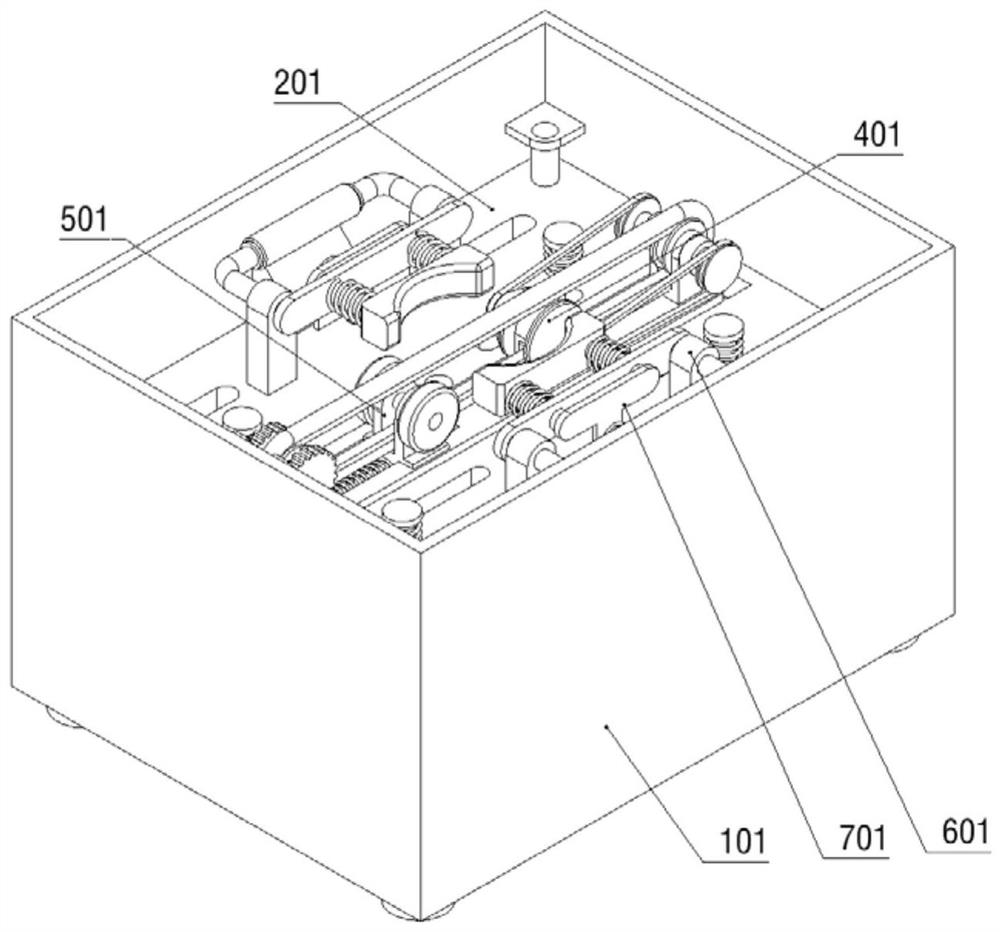

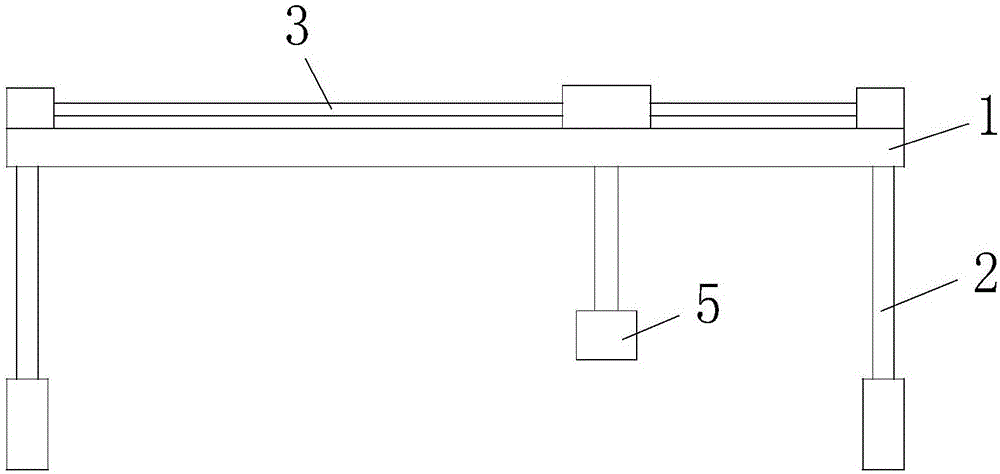

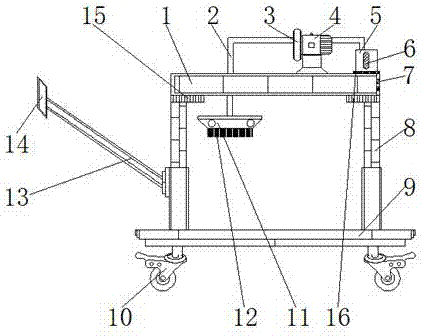

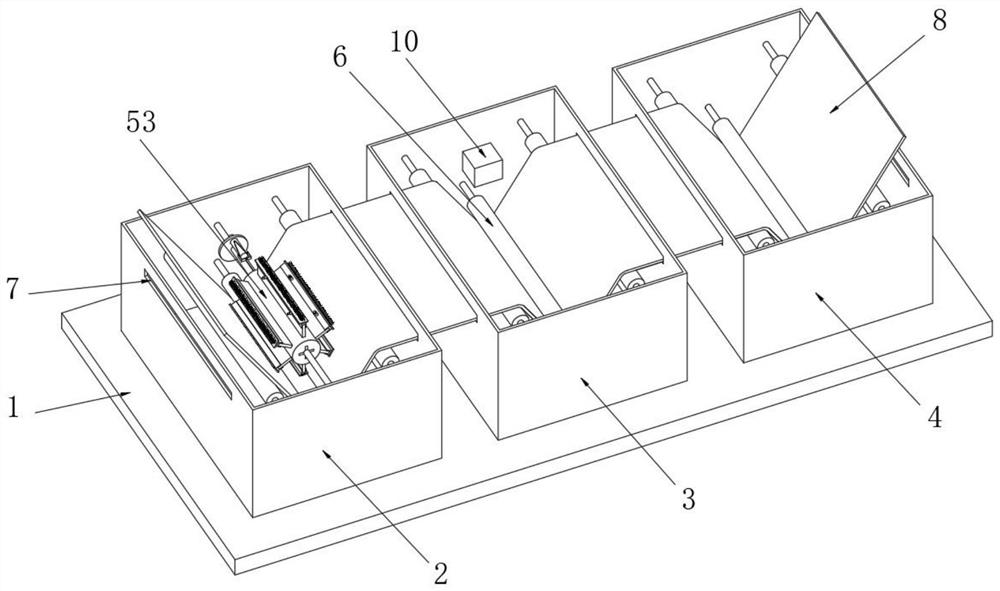

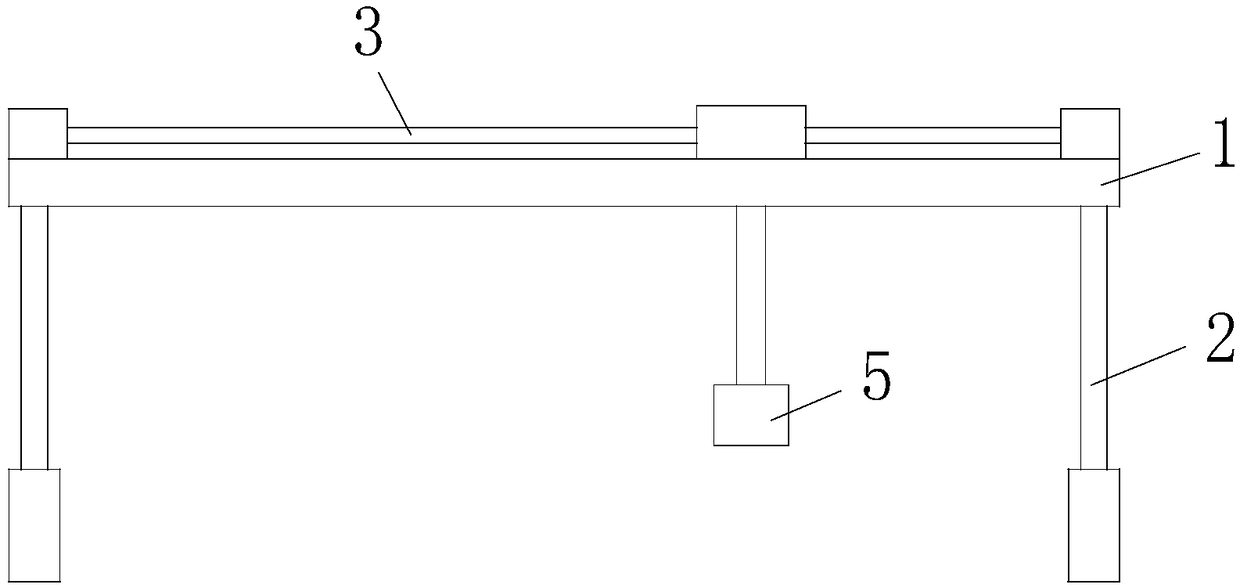

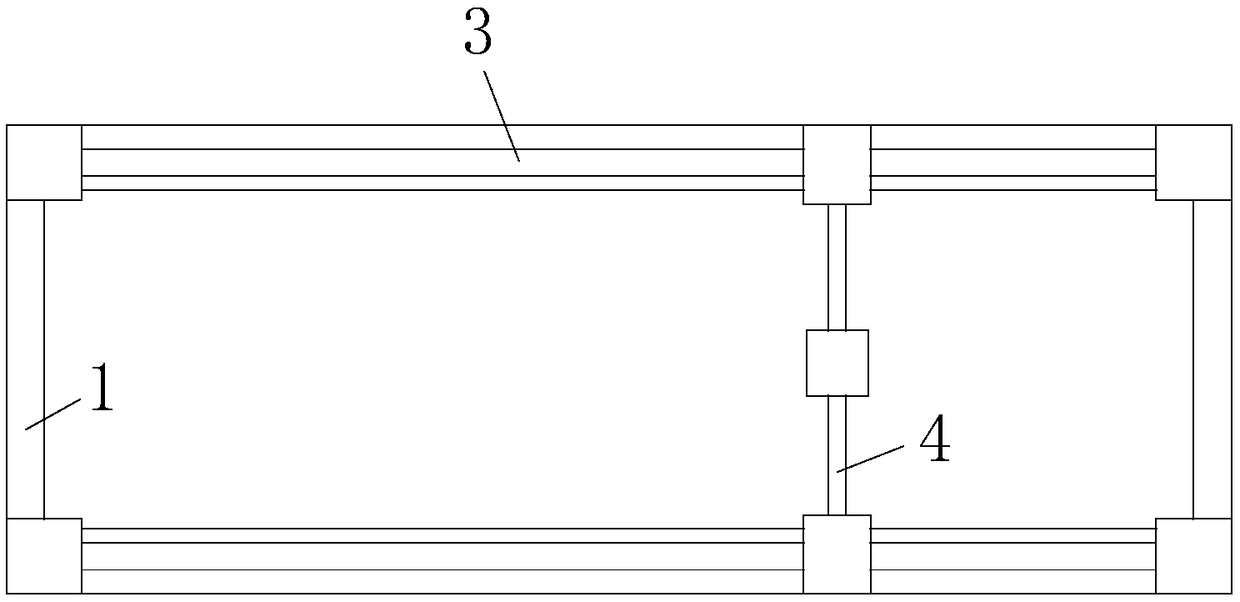

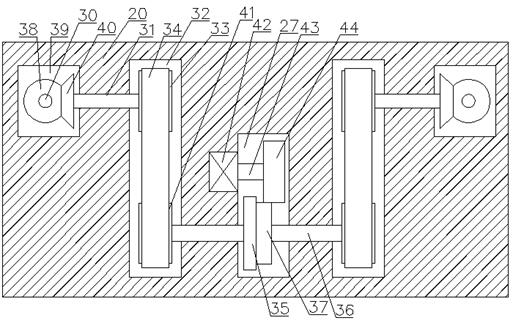

Table top cleaning equipment of fixing type prefabricated component mold table

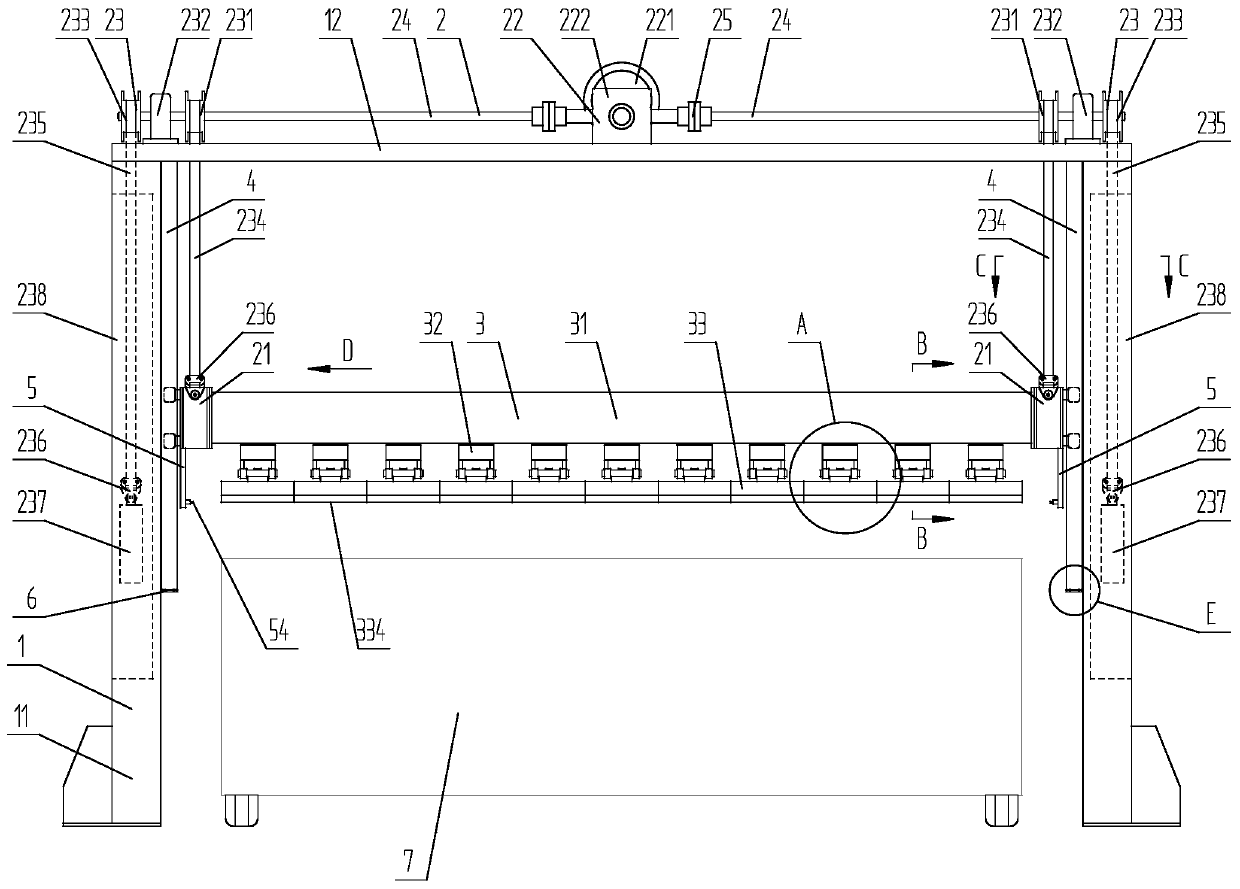

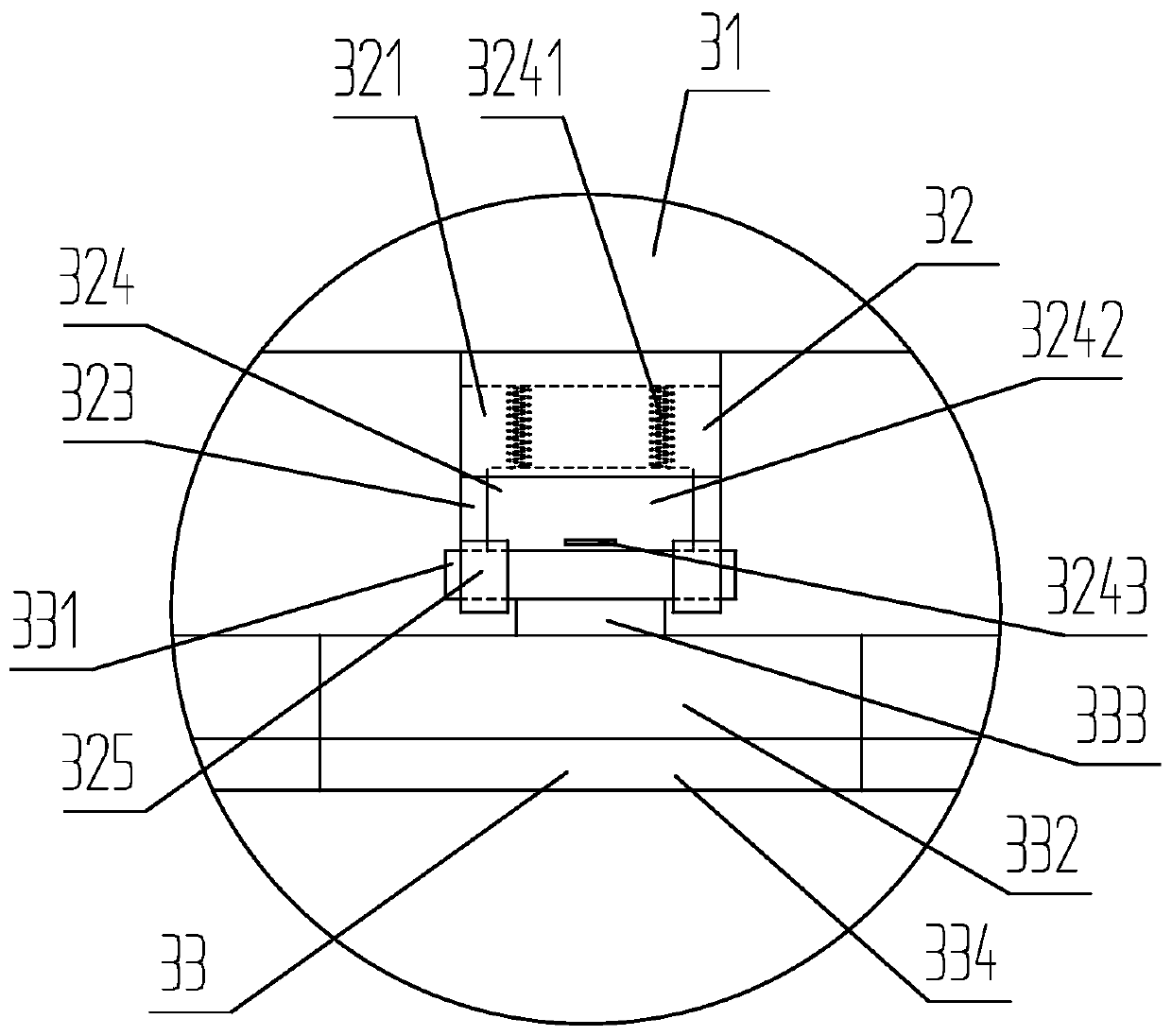

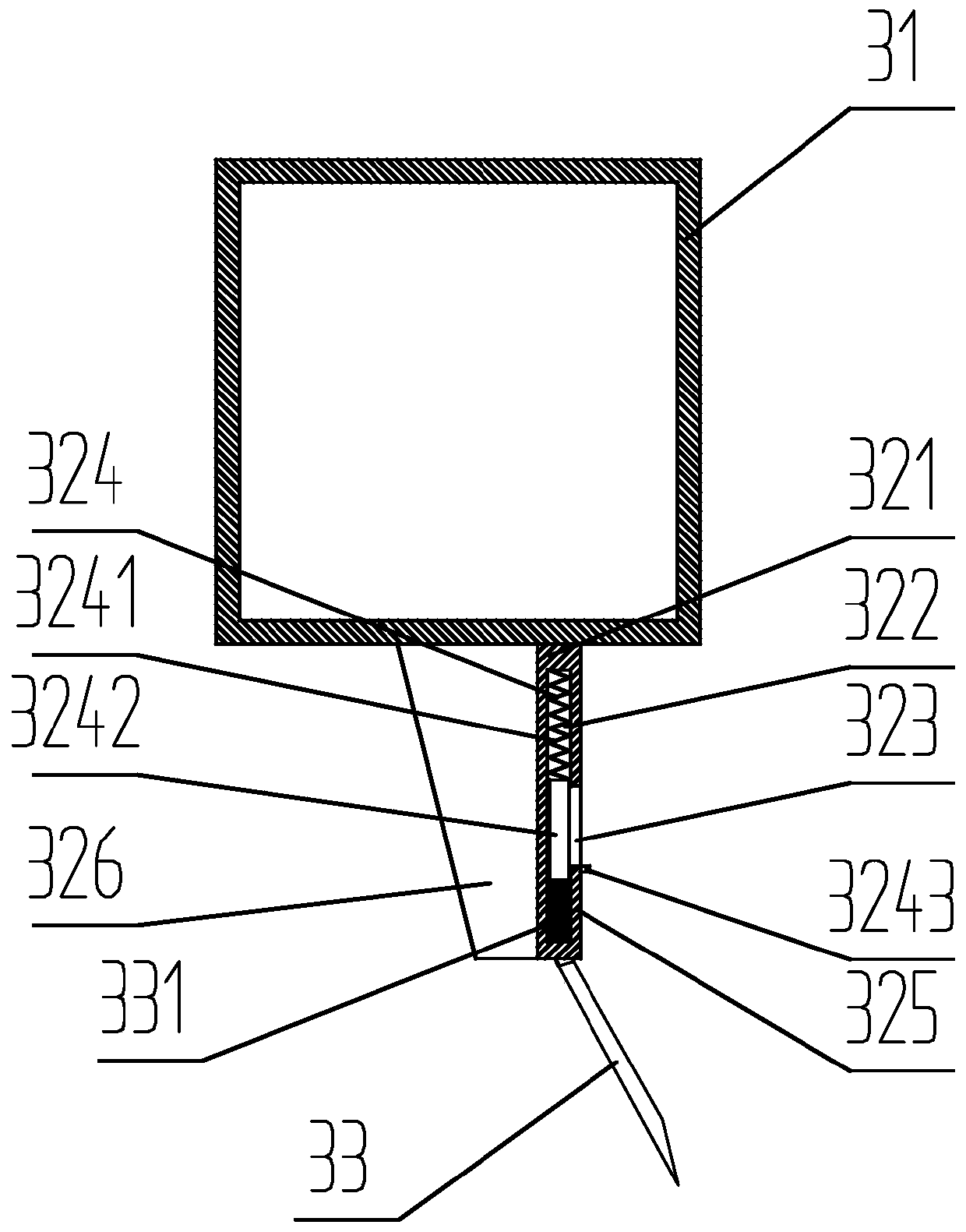

ActiveCN110694957AMeet clean upEasy to disassemble and replaceAuxillary shaping apparatusCleaning using toolsPortal frameKnife blades

The invention discloses table top cleaning equipment of a fixing type prefabricated component mold table. The equipment comprises a frame body, a lifting transmission device and a tool rest assembly;the frame body adopts the portal frame structure formed through overlapping of stand columns and a cross beam; trolley moving guiding rails are mounted on the inner side walls of the two stand columnsthrough welding; trolley moving limiting assemblies are mounted at the lower ends of the trolley moving guiding rails; the lifting transmission device is fixedly mounted on the frame body and comprises two moving trolleys symmetrically glidingly mounted on the trolley moving guiding rails; the tool rest assembly is connected with the two moving trolleys; the lifting transmission device pulls thetwo moving trolleys to move up and down, so that the tool rest assembly rises and falls; and traveling mechanisms are in flange connection at the lower ends of the stand columns. By the aid of the equipment, residual cement clinker on the fixing type prefabricated component mold table is cleaned automatically, so that the cleaning working efficiency is greatly improved; blades adopt the quick-connection structures and are convenient to mount, dismount and replace; and the tool rest assembly can rise and fall, so that cleaning work of the prefabricated component mold tables in different heightsis realized.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

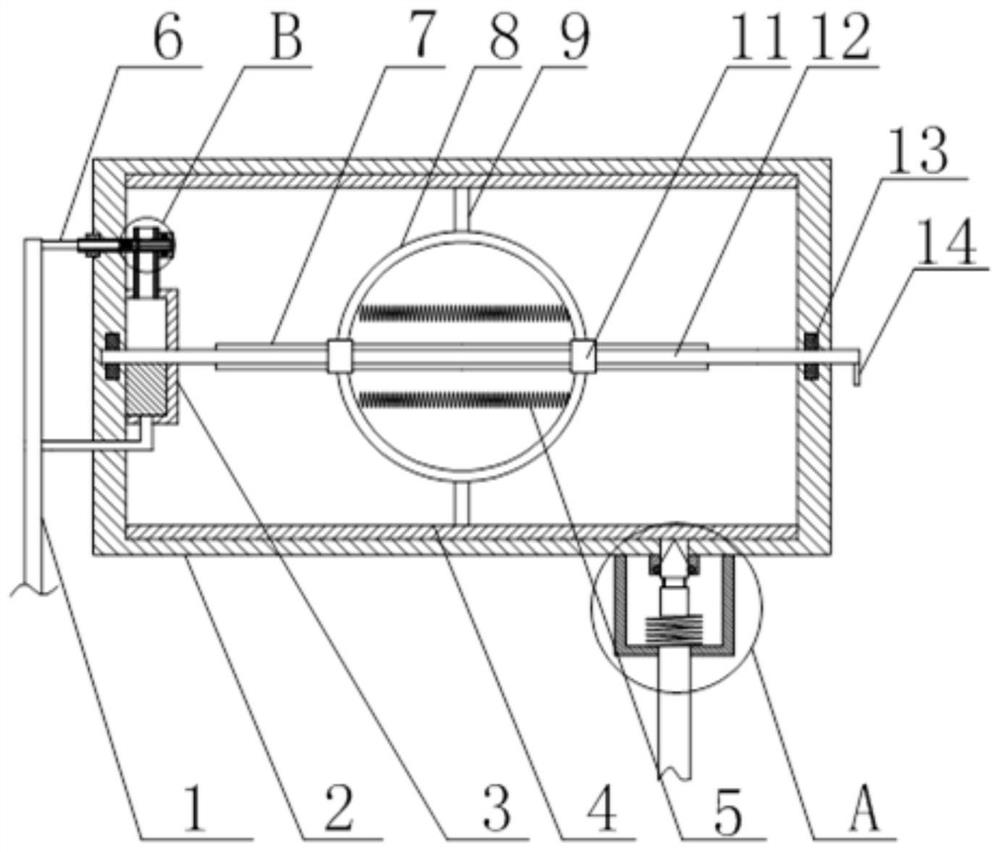

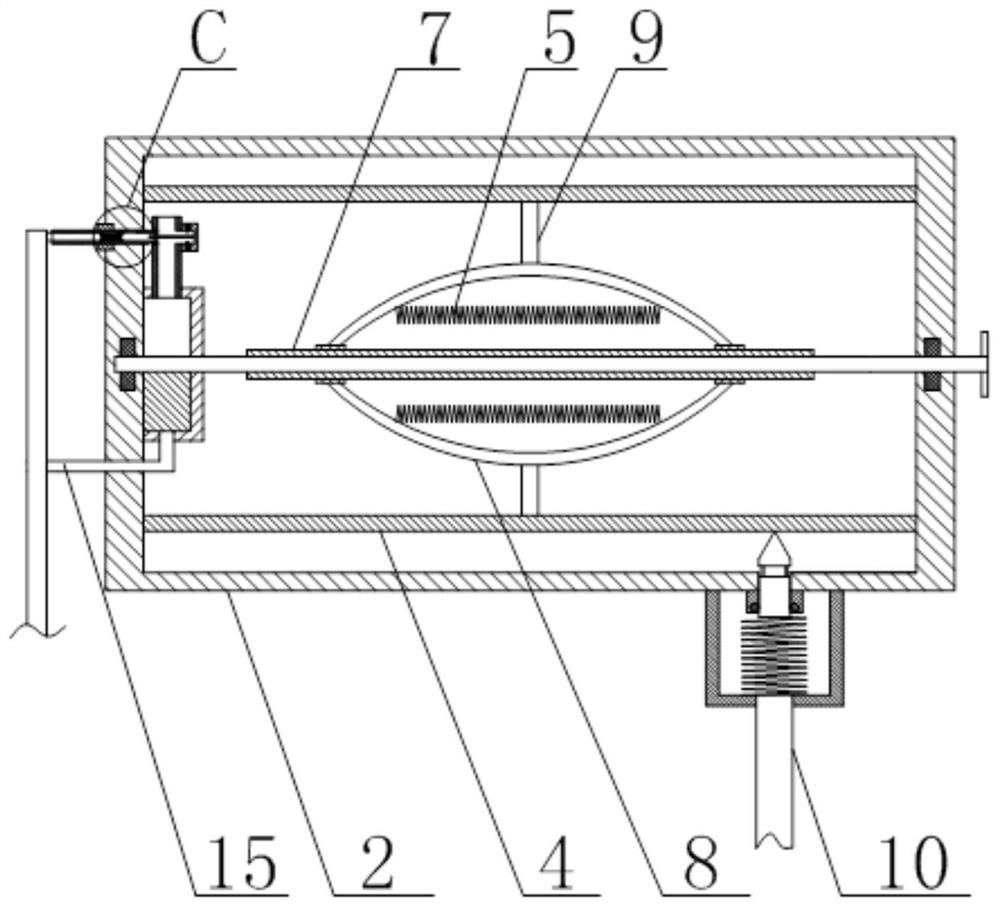

Method for cleaning incrustation of solar water heater

ActiveCN111765654AImprove stabilityQuick Auto Auto CleanupSolar heating energySolar heat collector controllersPhysicsSolar water

The invention discloses a method for cleaning incrustation of a solar water heater. The solar water heater comprises a water storage tank of a cylindrical structure, a drainage pipe and a water inletpipe are arranged on the water storage tank, a fixed box of a cylindrical structure is arranged on the inner wall of the water storage tank, a rotating shaft is arranged in the water storage tank, anarc-shaped plate is arranged on the rotating shaft, a connecting rod is further arranged on the arc-shaped plate, and scrapers are arranged on the connecting rod; a first blade and a plurality of second blades are arranged in the fixed box, a water outlet pipe is arranged at the top of the fixed box, and a water inlet pipe is arranged at the bottom of the fixed box; a connecting block is further arranged between the drainage pipe and the water storage tank, a cavity is formed in the connecting block, the drainage pipe communicates with the cavity, a fourth elastic piece and a connecting pipe are further arranged in the cavity, one end of the fourth elastic piece is connected with the inner wall of the cavity, and the other end of the fourth elastic piece is connected with the connecting pipe; and the water storage tank is also provided with a drain outlet communicating with the cavity of the connecting block, a plurality of supporting rods are arranged at the tail end, located in the water storage tank, of the connecting pipe, one ends of the supporting rods are connected with the connecting pipe, and plugging rods of conical structures are arranged at the other ends of the supporting rods.

Owner:陕西专壹知识产权运营有限公司

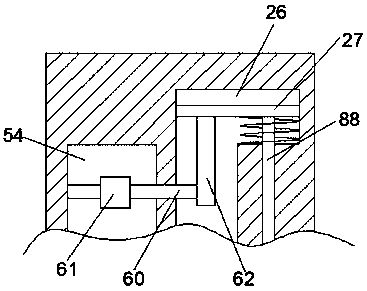

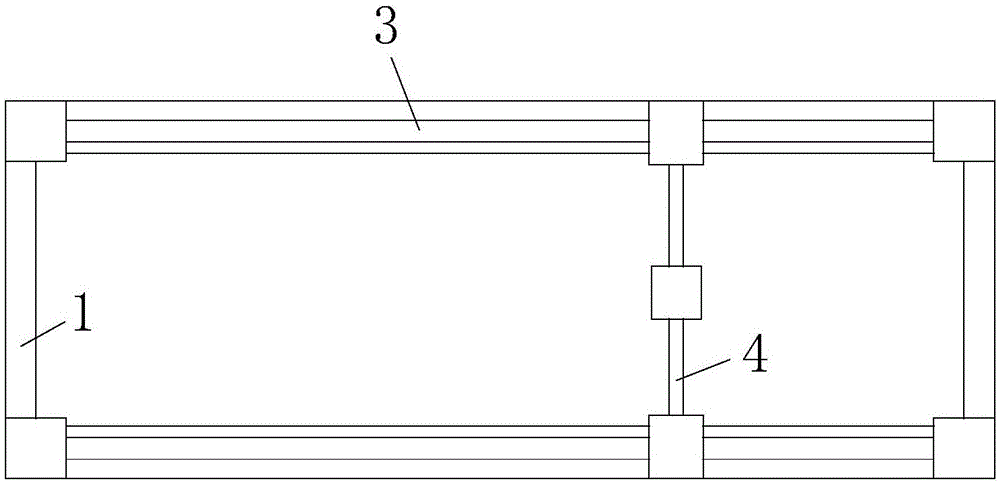

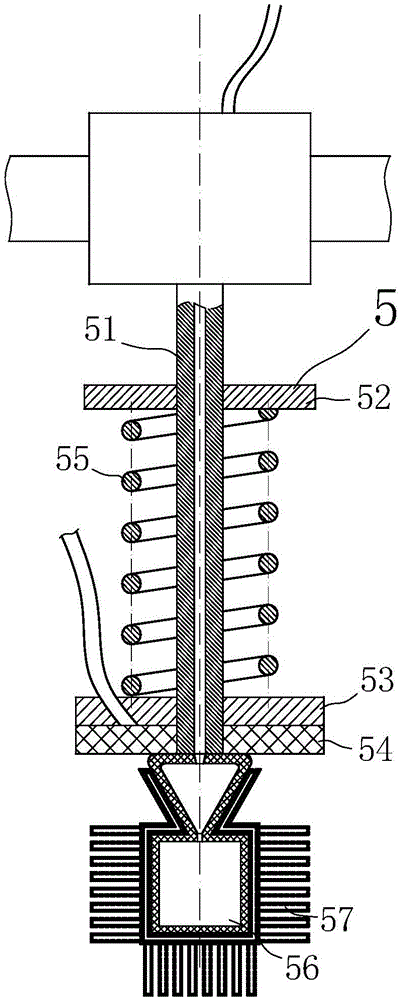

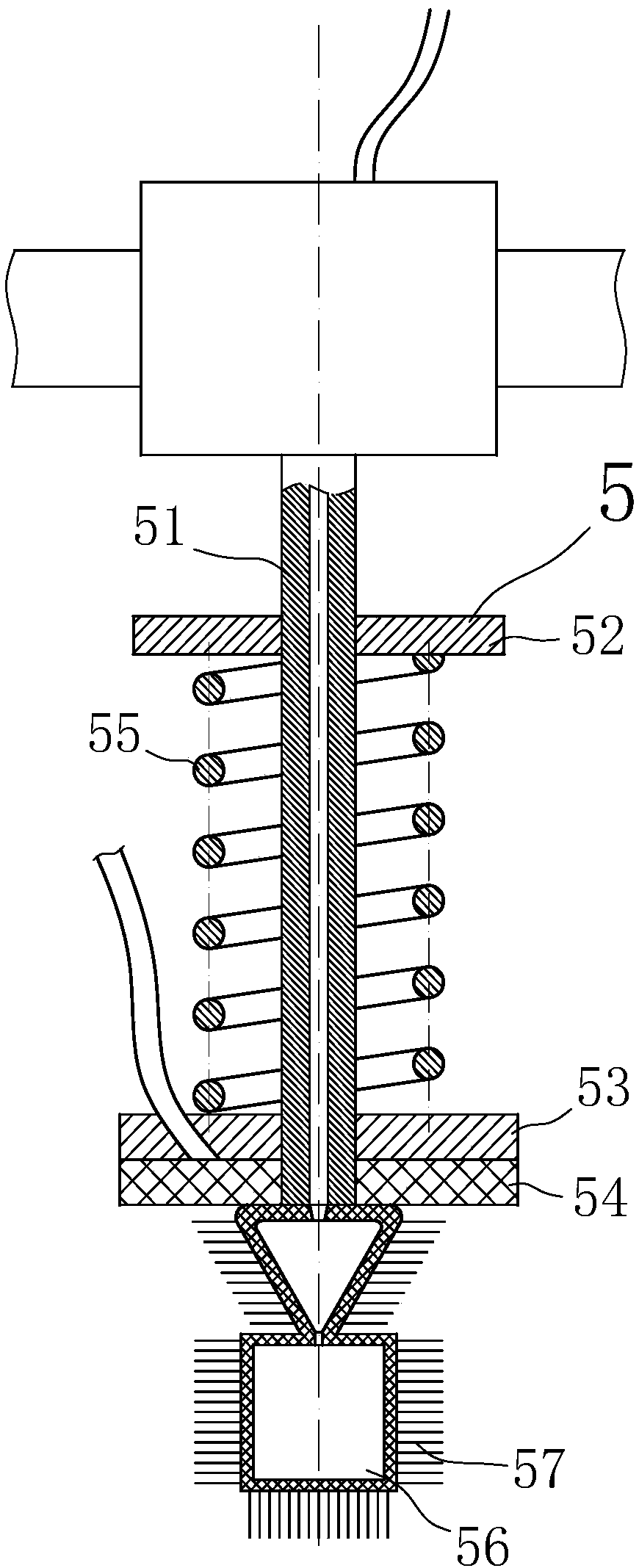

Mechanical keyboard automatic cleaning robot

ActiveCN106552779AImprove cleaning efficiencyClean fitCleaning using toolsCleaning using gasesEngineeringSlide plate

The invention relates to the field of computer cleaning, in particular to a mechanical keyboard automatic cleaning robot. The mechanical keyboard automatic cleaning robot comprises a main frame, a bottom hoisting device, a left-right moving device and a front-back moving device. The mechanical keyboard automatic cleaning robot further comprises a cleaning body; the cleaning body includes a cleaning main pipe, a top fixed plate, a lower slide plate, a top brush sponge, a spring, a cleaning cavity and a cleaning terminal; the cleaning cavity includes an upper cavity and a lower cavity; the upper cavity is totally a conical cavity structure with large top and small bottom; and the lower cavity is totally a cube cavity structure. The mechanical keyboard automatic cleaning robot is high in cleaning and brushing efficiency, can be more matched with the gap shape of a mechanical board through the structural design of the upper cavity and the lower cavity to perform the targeted cleaning of the side walls of the mechanical keyboard, and is better in cleaning effect.

Owner:宁阳县鑫农农村发展有限公司

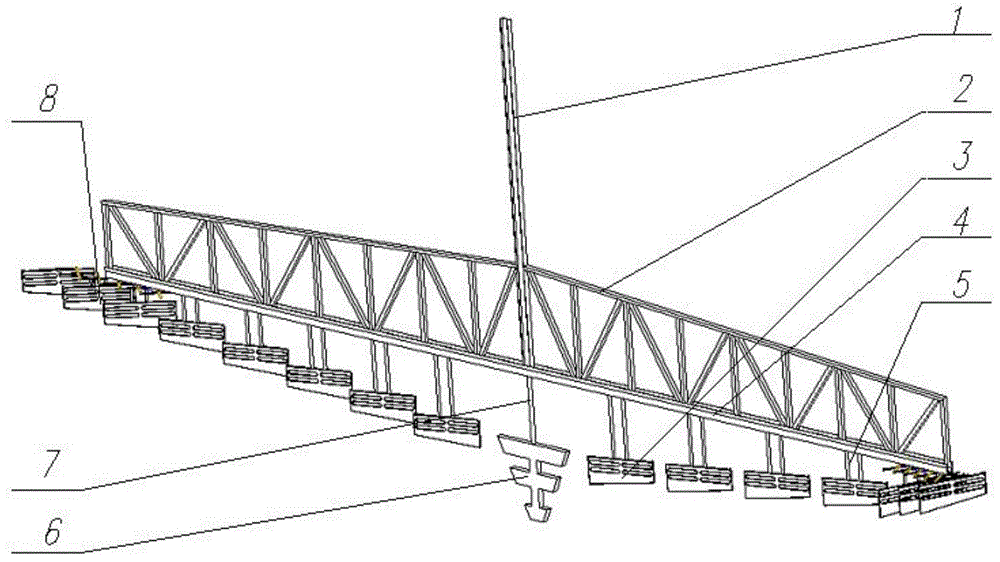

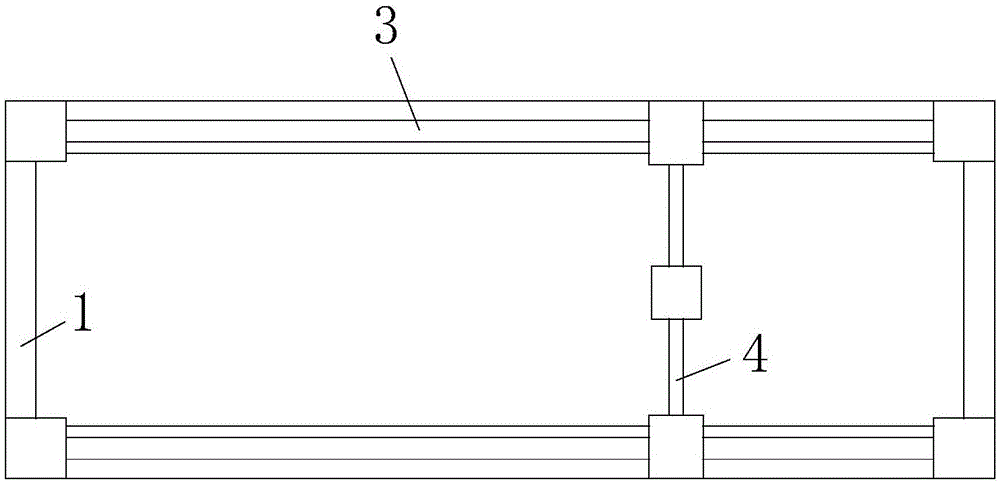

Table board clearing equipment for flowing type prefabricated part mould tables

ActiveCN110696177AMeet clean upImprove cleaning efficiencyMouldsAuxillary shaping apparatusStructural engineeringKnife blades

The invention discloses table board clearing equipment for flowing type prefabricated part mould tables. The equipment comprises a framework body, a lifting transmission device and a cutter frame assembly. The framework body is of a door-shaped framework structure formed by overlapping stand columns and cross beams. Trolley moving guide rails are installed on the inner side walls of the two standcolumns in a welded manner correspondingly. Trolley moving limiting assemblies are installed at the lower ends of the trolley moving guide rails. The lifting transmission device is fixedly installed on the framework body. The lifting transmission device is fixedly installed on the framework body. The lifting transmission device comprises two motion trolleys symmetrically installed on the trolley moving guide rails. The cutter frame assembly is connected with the two motion trolleys. The lifting transmission device pulls the two motion trolleys to move up and down so that the cutter frame assembly can do up and down lifting motion. The equipment automatically clears residual cement slag on the flowing type prefabricated part mould tables, the clearing work efficiency is improved greatly, arapid connecting structure is adopted in a blade, assembling, disassembling and replacing are convenient, the cutter frame assembly can be lifted up and down, and the flowing type prefabricated part mould tables of different heights can be cleared.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

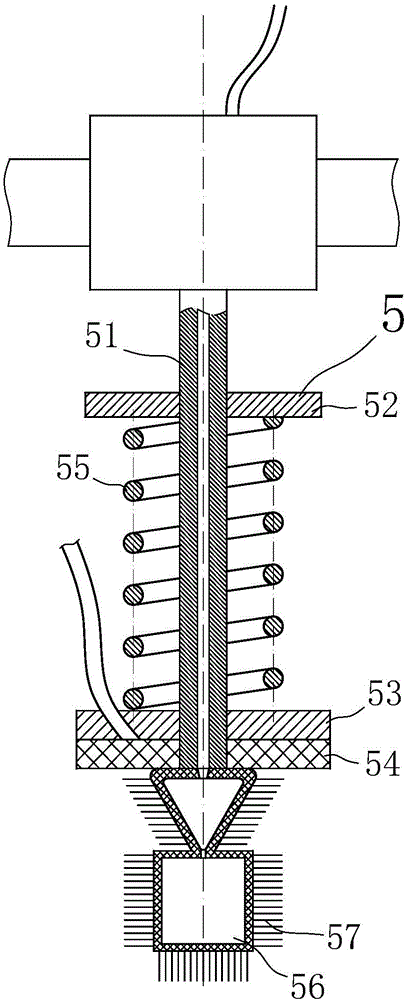

Cleaning machine for cleaning engraving waste

ActiveCN111016509AIncrease flexibilityIncrease cleaning intensityHand artistic toolsDirt cleaningElectric machineryFan blade

The invention discloses a cleaning machine for cleaning engraving waste. The cleaning machine comprises a machine body, wherein a brushing head base is rotatably arranged on the left side surface of aswinging rod. When the cleaning machine is used for cleaning, a first motor is started to drive a driving shaft, a first gear, a fan blade gear base and a fan blade gear to rotate; the flexibility ofthe brushing head rotation is improved through the spherical rotation, so that the cleaning at various angles during engraving can be met, and the all-round cleaning on complex engraving is realized;a brushing head which can slide left and right is designed, so that the cleaning of engraved holes can be realized, the deep cleaning is realized, and the cleaning intensity is high; and the fan blade is designed, so that waste cleared out can be blown away through the rotation of the fan blade, and the condition that blowing the waste in other ways causes the damage of engraving finished products is avoided.

Owner:阜南县中泰工艺品有限公司

Special dust removal device for solar warning street lamp

InactiveCN104384155AImprove dust removal efficiencyMeet clean upCleaning using toolsCleaning using gasesEngineeringEnvironmental geology

The invention discloses a special dust removal device for a solar warning street lamp. The dust removal device comprises a casing, a brush and a dust collector, wherein the dust collector is connected to the upper part of the casing through a dust suction pipe; the brush is fixed on a lower surface of the casing; a left dust suction pipe and a right dust suction pipe are arranged in the casing; an upper end opening of the left dust suction pipe and an upper end opening of the right dust suction pipe are both connected with a lower end opening of the dust suction pipe; a left sucking disc is mounted at a lower end opening of the left dust suction pipe; a right sucking disc is mounted at a lower end opening of the right dust suction duct; the brush is positioned between the left sucking disc and the right sucking disc. Through the manner, the dust removal device has the advantages that the dust collector and the brush are used cooperatively, so that the dust removal efficiency is greatly improved, and the requirement for cleaning of a large amount of dust accumulated on solar panels exposed to the air for a long time is satisfied.

Owner:SUZHOU FEIMI PHOTOELECTRIC CO LTD

Medicated bath device for preventing hoof diseases for animal husbandry and veterinary

PendingCN114831773AClean up thoroughlySafe and stable useClimate change adaptationVeterinary washing devicesAnimal scienceMedicine

The invention provides a medicated bath device for preventing hoof diseases for animal husbandry veterinarians, and relates to the technical field of veterinary instruments. The mounting soaking part is fixedly connected with a sliding lifting part; the sliding lifting part is fixedly connected with an inter-hoof cleaning device; a linkage friction device is mounted on the sliding lifting part; a sliding propelling part is mounted on the sliding lifting part; two linkage clamping devices are fixedly connected to the sliding lifting part; the two linkage clamping devices are symmetrically mounted; the two linkage clamping devices are respectively connected with a positioning device in a sliding manner; the comprehensiveness of medicated bath can be effectively improved, cleaning is more thorough, the linkage between the structures is high, and use is safer and more stable; the problems that according to an existing medicated bath device for preventing hoof diseases of animal husbandry and veterinary medicine, cleaning is not efficient enough, hoof cannot be matched correspondingly, splashing and safety accidents are caused, the overall linkage performance is poor, and the medicated bath cleaning quality is low are solved.

Owner:侯万天

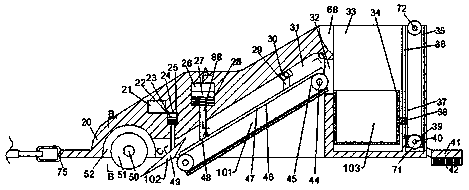

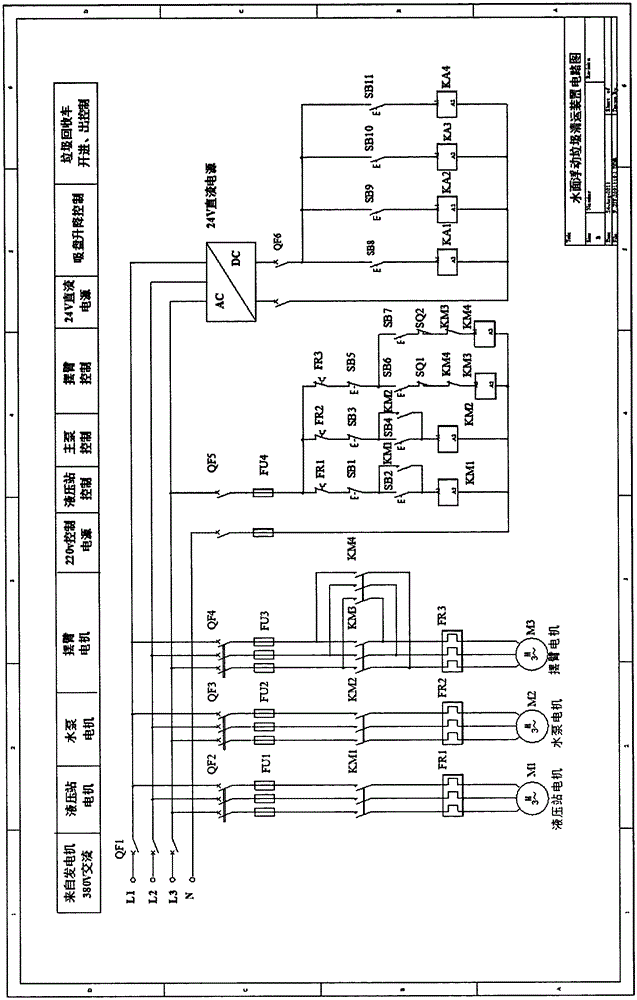

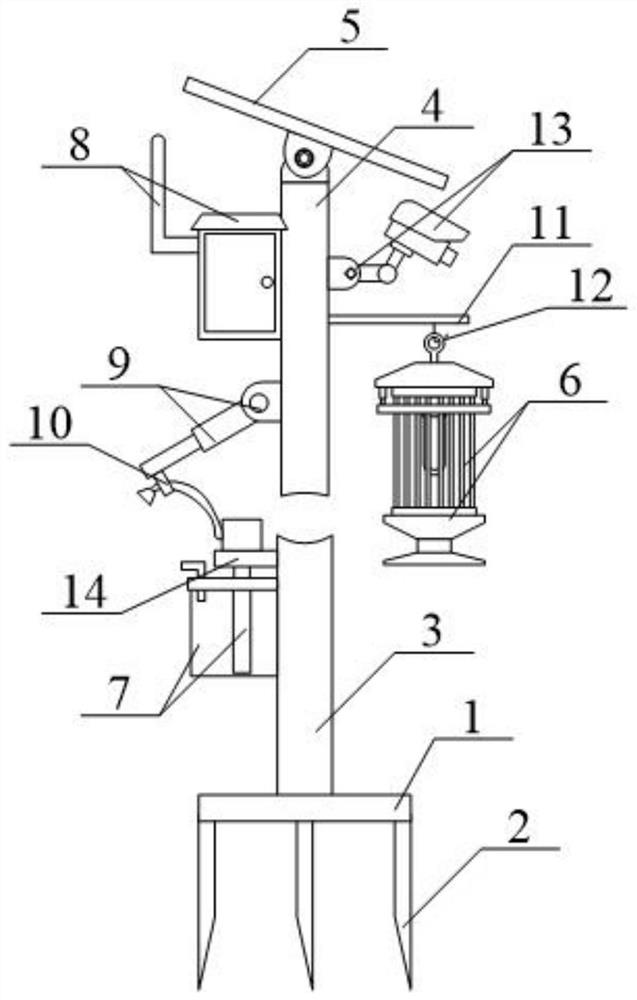

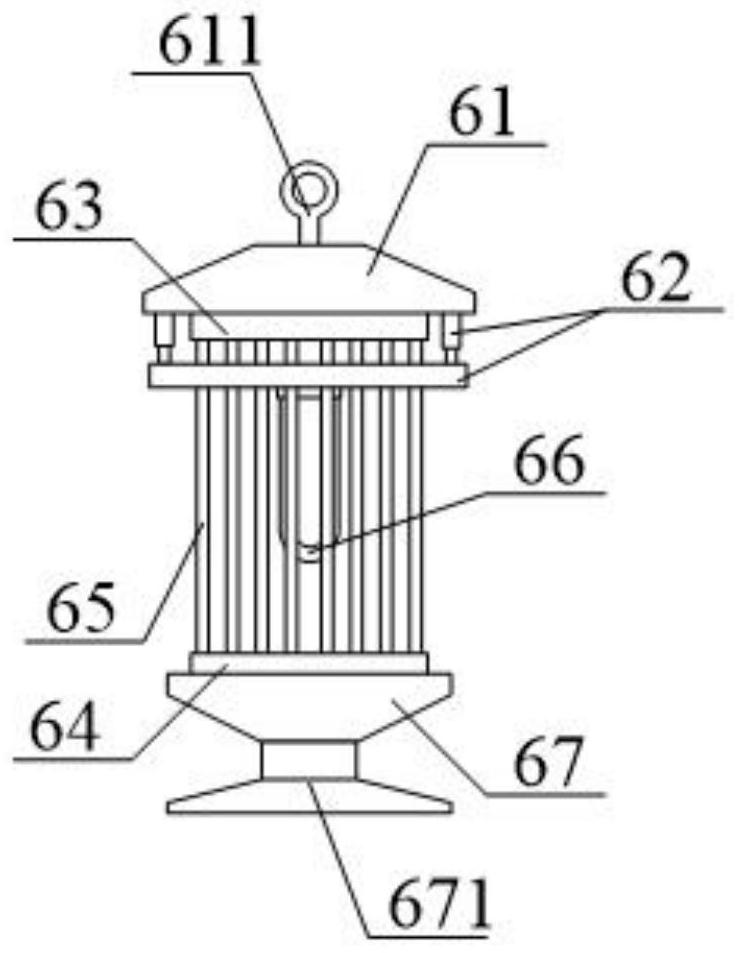

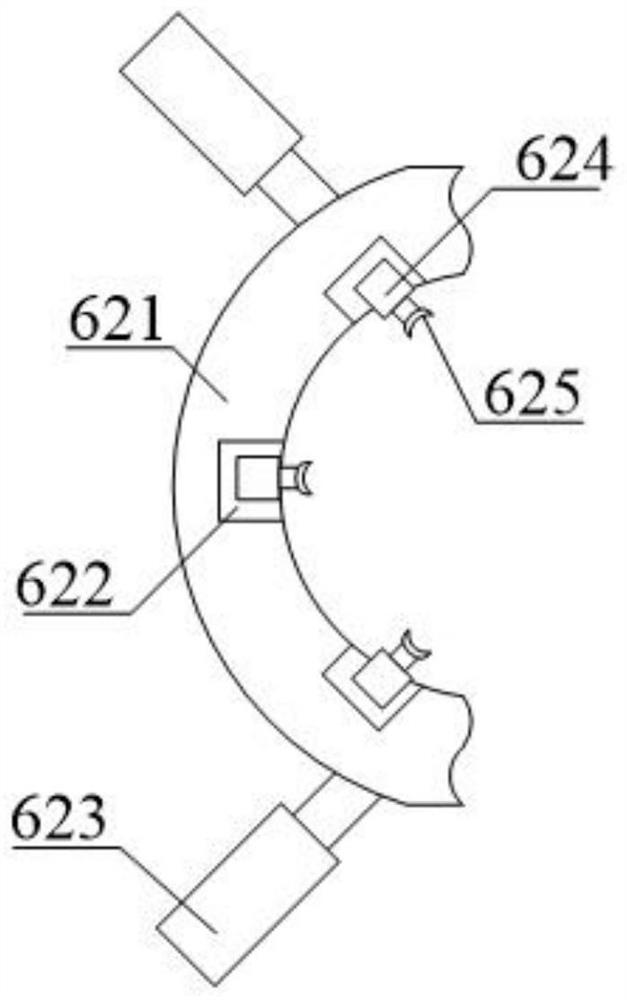

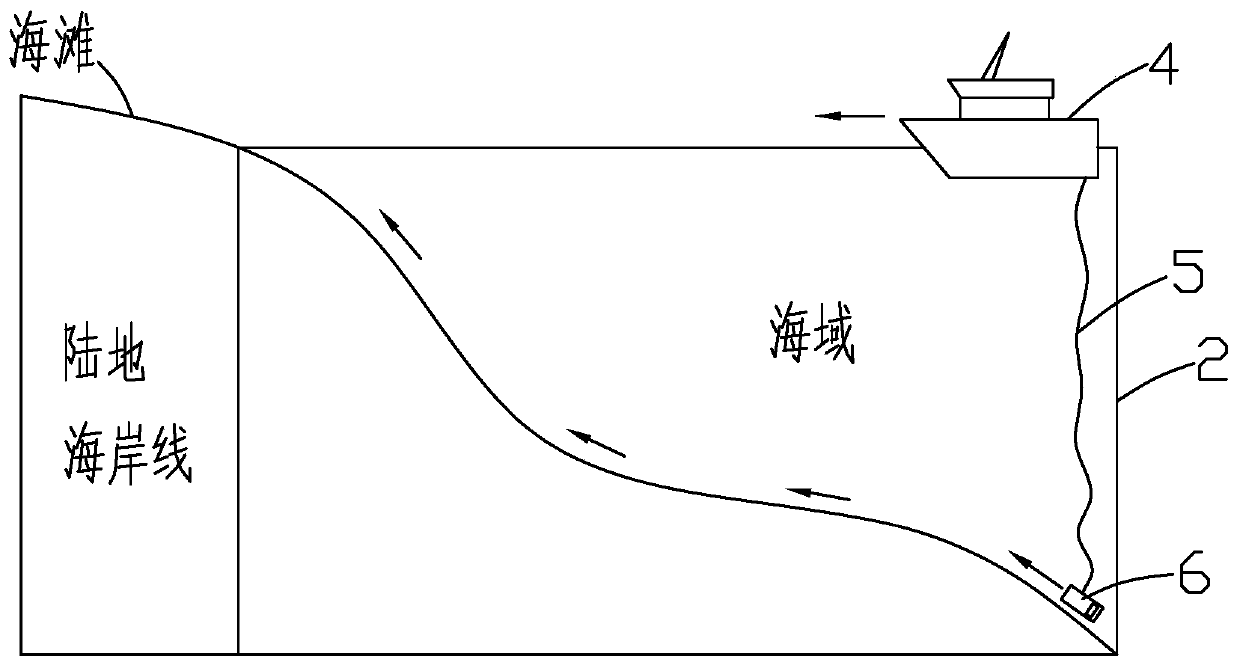

A device for cleaning floating garbage on the water surface

InactiveCN102953361BSimple structureEasy to operateWater cleaningAutomatic controlEnvironmental engineering

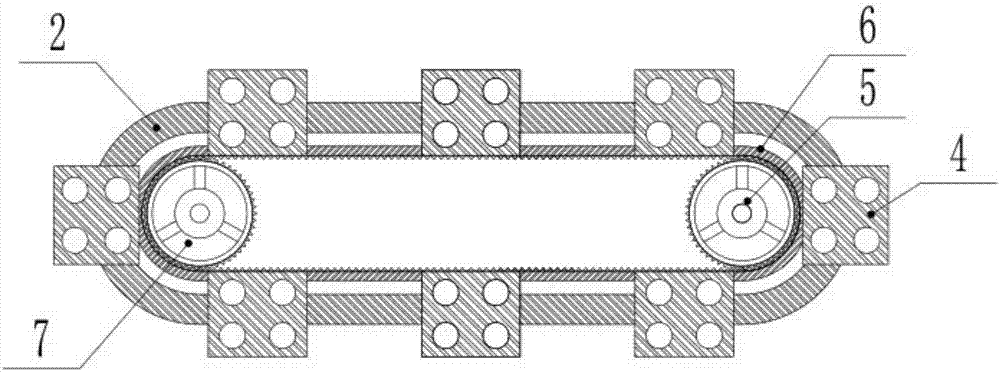

The name of the invention is a device for cleaning floating garbage on the water surface, which belongs to the field of auxiliary equipment for water environment protection, and in particular relates to a device for cleaning floating garbage pollutants on the surface of rivers (lakes) and a method for using the device. The invention aims to provide an automatic control device for cleaning floating garbage on the water surface to solve the problems existing in manual salvage operations. It includes four parts: cleaning part, control part, filtering part and operation part. Through the comprehensive application of electrical machinery and other control technologies, continuous automatic operations such as cleaning, filtering, recycling and transportation of floating garbage on the water surface are realized. The device saves time and effort, improves operation efficiency, and has good practical value and popularization value. The device is installed on the hull and can be used in various fields of production and life.

Owner:金子钒

Paddy field shrimp culture pest control device based on visual monitoring

PendingCN114431205APlay the role of counterweight gripImprove stabilityRenewable energy machinesClosed circuit television systemsAnimal scienceVisual monitoring

The invention provides a rice field shrimp culture pest control device based on visual monitoring, which comprises a support base plate, a fixed drill rod, a lower support pipe, an upper support pipe, a solar panel, a pest trapping and killing lamp assembly, a pest spraying pipe assembly, a control box assembly, a telescopic rod, a constraint clamping ring, a suspension arm rod, a fixed lifting hook, a visual monitoring camera and a mounting support plate, the fixed drill rods are respectively in bolted connection with the lower part of the supporting base plate; the lower supporting pipe is welded to the middle position of the upper portion of the supporting base plate. An electromagnetic buckle is controlled to be opened, a cleaning scraper is attached to the outer side of a high-voltage power grid column, and lifting of a lifting rod is controlled, so that pest corpses attached to the surface of the high-voltage power grid column are cleaned, and the pest removal efficiency is improved; the device utilizes the visual monitoring camera to realize monitoring and removal of pest control, is simple and convenient to operate, can realize remote control, utilizes solar energy to supply power, and is suitable for prevention and treatment of rice field pest control.

Owner:无为市陵海农业发展有限公司

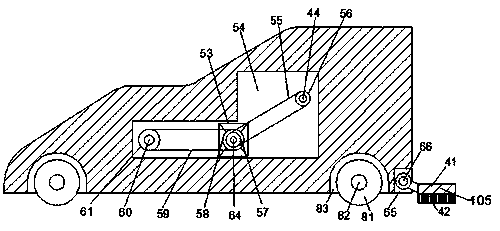

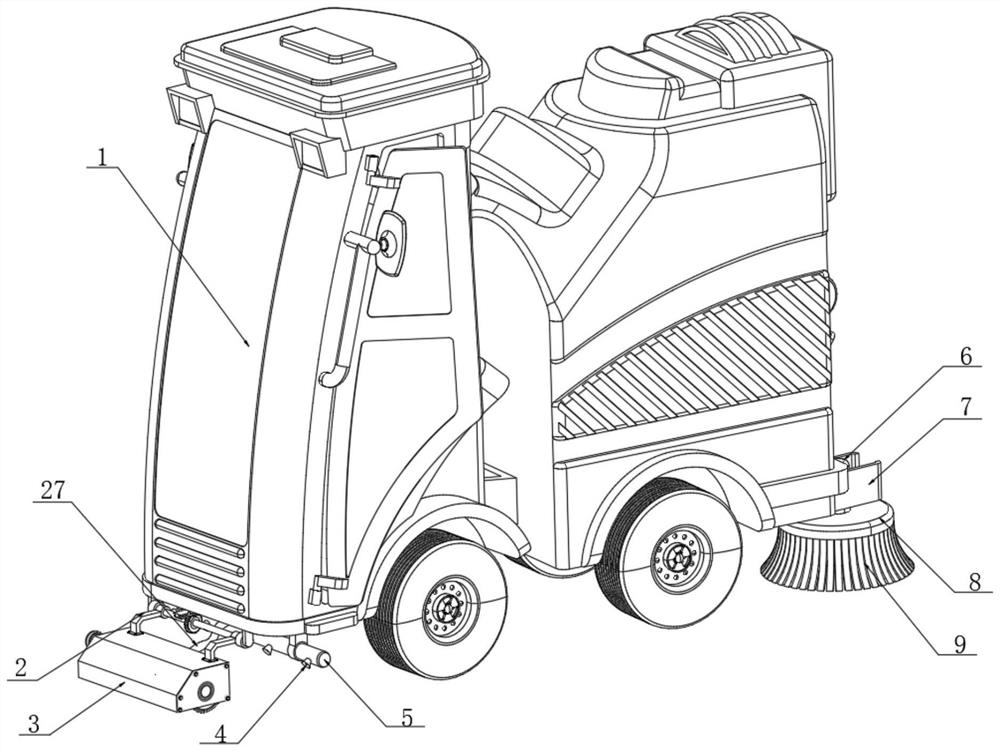

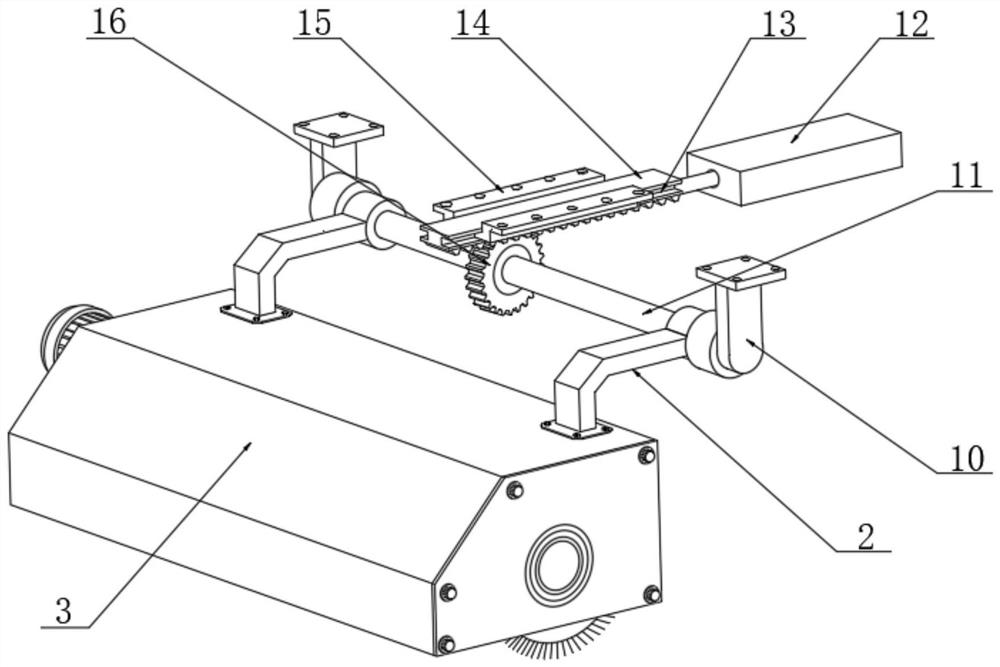

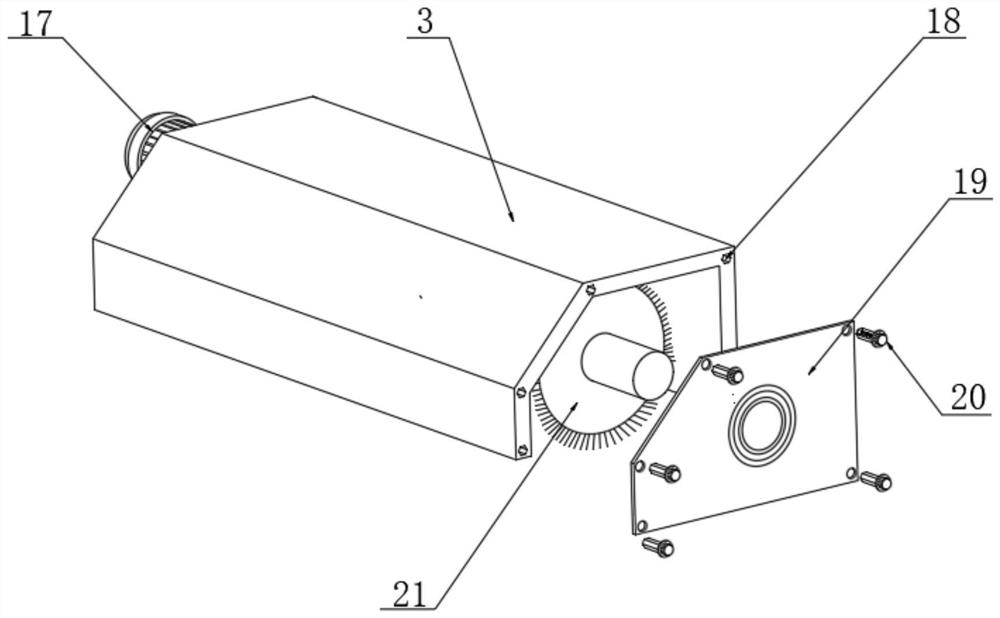

Road surface sweeping equipment for municipal construction

ActiveCN112695688AMeet clean upQuick disassemblyClimate change adaptationRoad cleaningEnvironmental resource managementRoad surface

The invention relates to the technical field of municipal construction, in particular to road surface sweeping equipment for municipal construction, a sweeping part is arranged on the front side of a vehicle body, the vehicle body and the sweeping part are connected through a self-adaptive angle adjusting mechanism, and a flushing part is arranged at the position, located on the rear side of the sweeping part, below the vehicle body; and washing mechanisms are symmetrically arranged at the tail end of the vehicle body. The road surface sweeping equipment is ingenious in design and refined in structure, the sweeping part can automatically change along with the change of the road gradient through the self-adaptive angle adjusting mechanism, high adaptability is achieved, the requirement for cleaning work of any complex road surface is met, practicability is improved, the end plates can be conveniently disassembled and assembled through the rapid disassembling and assembling mechanism, the sweeping roller can be conveniently replaced, and the maintenance difficulty is reduced; in addition, tools are not needed for disassembly and assembly, convenience and rapidness are achieved, the adjusting mechanism changes the spraying angle of the water spraying head by rotating the water spraying pipe, the roadside flushing effect is improved, and the problem of water resource waste caused by back-and-forth flushing is avoided.

Owner:博信达建设集团有限公司

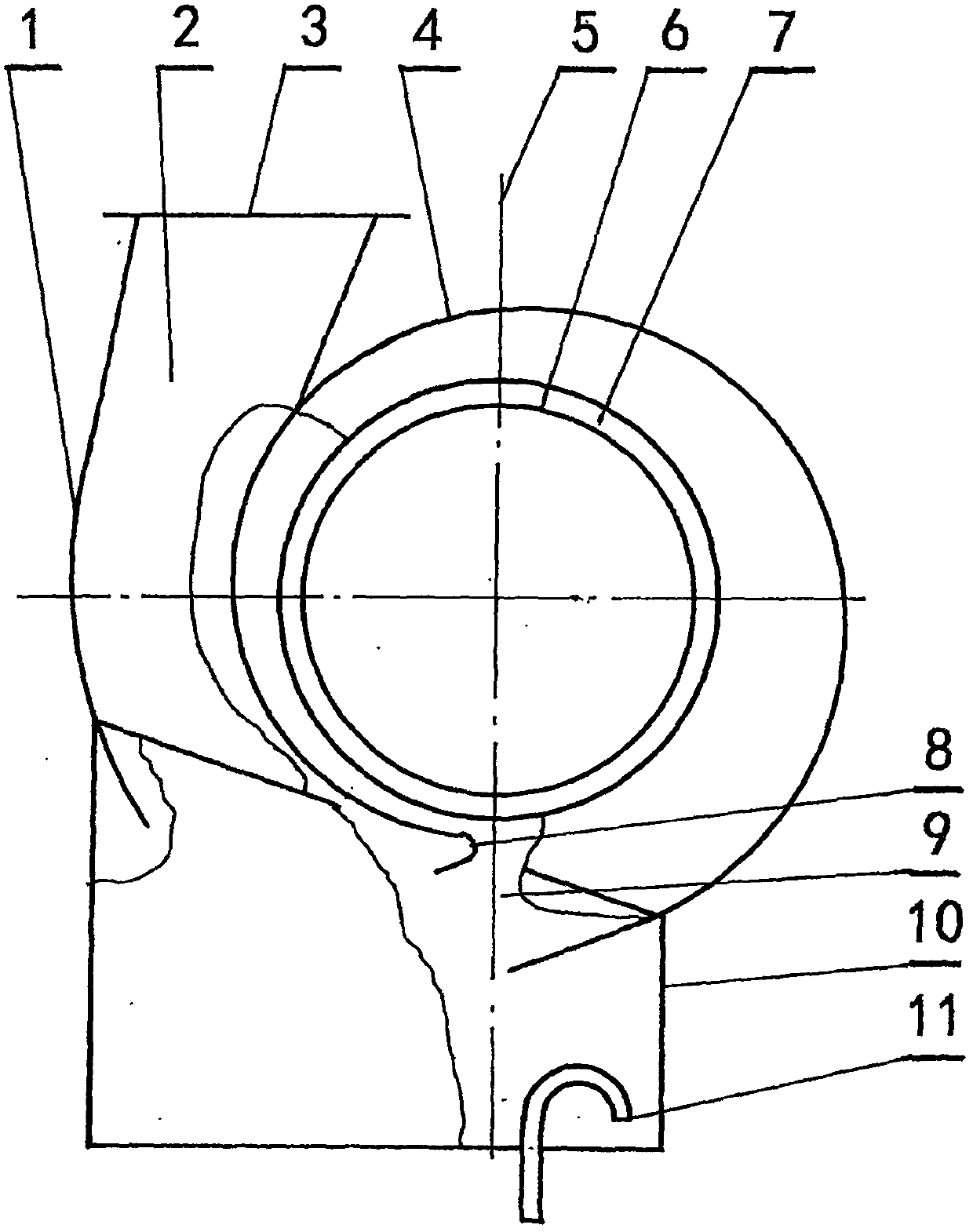

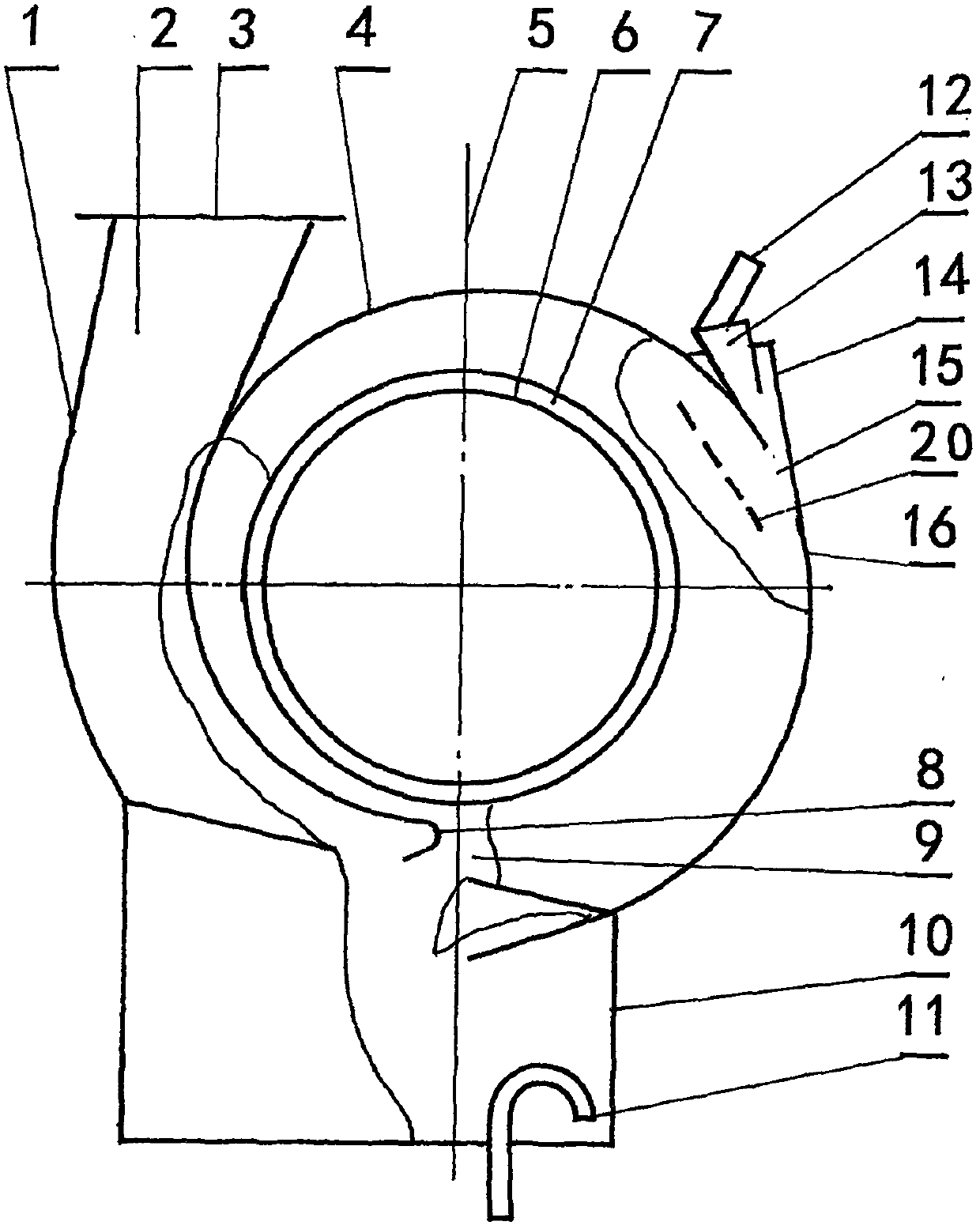

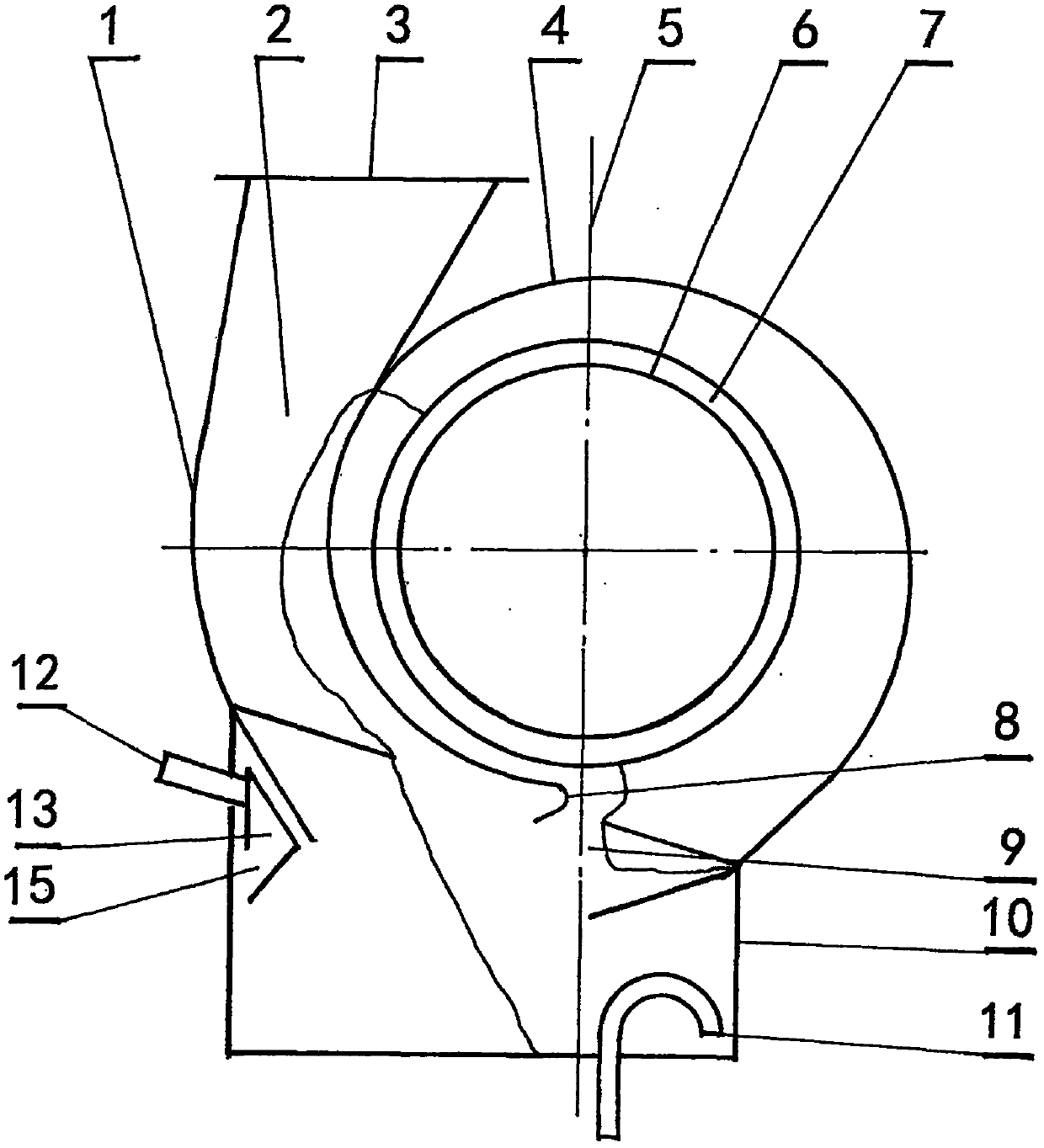

Centrifugal fan provided with centrifugal force separation device

ActiveCN109915389AImproved separation efficiency and qualityCircumference optimizationPump componentsRadial flow pumpsImpellerCentrifugal fan

The invention relates to a centrifugal fan for separating oil smoke, purifying air and dirt. The centrifugal fan is to mainly solve the problem that an existing centrifugal fan is not provided with aseparation device under the action of centrifugal force, or the technical difficulty of poor separation efficiency of the separation device. According to the technical scheme, the centrifugal fan comprises a fan shell, an impeller and a separation device, wherein the separation device is composed of an annular separation plate, an induced draft guide pipe, a separation box body and a blowdown water seal pipe; the annular separation plate is an annular body with opening formed in two opposite ends; the openings of the annular body are formed in a manner that a fan outlet is inverted at the inner upper end of the separation box body; one end of the annular separation plate is combined with the upper end of one side of the separation box body; the other end of the annular separation plate isarranged at the upper end of the separation box body and is provided with a spiral tongue; an induced draft pipe is combined with the outer side of the annular separation plate and the upper end of the other side of the separation box body is provided with an induced draft pipe outlet; the bottom of the separation box is provided with a pollution discharge water seal pipe; the width of the annularseparation plate is consistent with the thickness of the fan shell; and a fan inlet and a wind wheel are arranged in the middle of the annular separating plate

Owner:关云龙

Mechanical keyboard dust sucking working platform

ActiveCN106419741AImprove cleaning efficiencyFit cleaningSuction cleaner storing devicesSlide plateConical cavity

The invention relates to the field of computer cleaning, and particularly relates to a mechanical keyboard dust sucking working platform which comprises a main rack, a bottom lifting device, a left-to-right movement device and a front-to-back movement device, and further comprises a cleaning main body, wherein the cleaning main body comprises a cleaning main tube, a top fixing plate, a lower sliding plate, top brush sponge, a spring, a cleaning cavity and a cleaning terminal, wherein the cleaning cavity comprises an upper cavity and a lower cavity; the upper cavity is of a conical cavity structure of which the upper part is large and the lower part is small overall; the lower cavity is of a cube cavity structure overall; the cleaning terminal comprises a dust sucking cavity, a dust sucking tube and a dust sucking hole. The mechanical keyboard dust sucking working platform is high in cleaning and brushing efficiency, moreover, due to the structural design of the upper cavity and the lower cavity, gaps of a mechanical keyboard can be specifically cleaned according to the shapes of the gaps of the mechanical keyboard, and the mechanical keyboard dust sucking working platform is relatively applicable to cleaning on side walls of the mechanical keyboard, therefore, the mechanical keyboard dust sucking working platform is relatively good in cleaning effect.

Owner:DONGGUAN WULIAN ELECTRONICS TECH

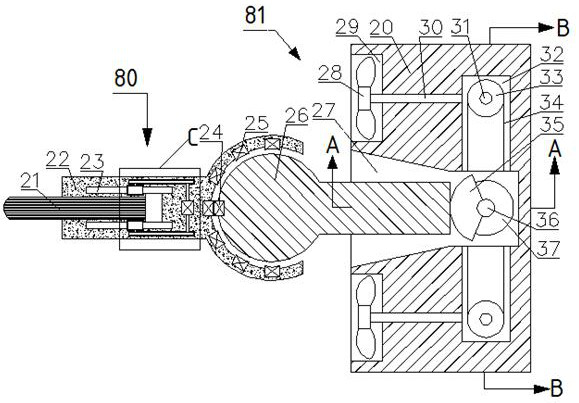

Microfiber leather edge scraping device

ActiveCN113894007AAdjust the horizontal positionMeet clean upLiquid surface applicatorsTextile/flexible product manufactureCrankEngineering

The invention relates to the technical field of microfiber leather production, in particular to a microfiber leather edge scraping device. The microfiber leather edge scraping device comprises a crank sliding rod mechanism, a connecting mechanism and a scraper mechanism; the crank sliding rod mechanism is connected with the scraper mechanism through the connecting mechanism, and the crank sliding rod mechanism is provided with a sliding path in the horizontal direction and used for adjusting the horizontal position of the scraper mechanism; one end of the connecting mechanism is connected with the crank sliding rod mechanism, the other end is connected with the scraper mechanism, and the connecting mechanism is used for driving the scraper mechanism to move in the horizontal direction; and the scraper mechanism comprises a scraper connected to the position away from the connecting mechanism, the scraper is used for cleaning away slurry flowing out of the side face of base cloth, the scraper mechanism is provided with an angle adjusting structure, and the angle adjusting structure is used for adjusting the mounting angle of the scraper. According to the technical scheme, the scraper can adjust the horizontal position and angle along with the change of the position of the base cloth, and the slurry flowing out of the base cloth is cleaned away in time.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

Self-rotating type heat shield rapid cleaning device and using method

InactiveCN113070298AStressfulBlow evenlyPolycrystalline material growthHollow article cleaningInlet valveEngineering

The invention discloses a self-rotating type heat shield rapid cleaning device and a using method. The device comprises a hook assembly, a first cavity, a second cavity and a third cavity; the hook assembly penetrates through one end face of the first cavity and is rotationally connected with the first cavity; the other end face of the first cavity is fixedly connected with one end face of the second cavity; the other end face of the second cavity is fixedly connected with one end face of the third cavity; the second cavity comprises an argon cavity, an exhaust cavity and a partition plate fixed between the argon cavity and the exhaust cavity; the side face of the argon cavity is fixedly connected with an air inlet valve; the exhaust cavity communicates with the third cavity; a thermoswitch control valve is fixedly connected to the partition plate, and the thermoswitch control valve is fixedly connected with a rotary exhaust passage; and a turbo type air guide disc is fixedly connected in the third cavity; and two or more exhaust holes are formed in the side face of the third cavity. By using the device, silicon powder on the inner wall of a heat shield can be cleaned up, and the influence of falling of the silicon powder on coil base crystallization during crystal pulling is avoided.

Owner:宁夏协鑫晶体科技发展有限公司

Colored-spun-yarn equipment cleaning device convenient to move

The invention discloses a colored-spun-yarn equipment cleaning device convenient to move. The colored-spun-yarn equipment cleaning device convenient to move comprises a flat plate, a rotating shaft, an air suction base and a pulling rod. A pipe is arranged on the flat plate, an air suction machine is connected to the right end of the pipe, a motor is installed on the right side of the air suction machine, a waste box is arranged at the right portion of the motor, an viewing opening is formed in the surface of the waste box in an embedded mode, a pipe opening is formed in the upper surface of the waste box in an embedded mode, a supporting block is installed at the bottom end of the waste box, a sliding groove is formed in the supporting block in an embedded mode, the flat plate is connected to the left end of the rotating shaft, the bottom end of the flat plate is connected with supporting columns through magnetic blocks, a base is installed at the bottom ends of the supporting columns, universal wheels are connected below the base, the pipe is connected to the upper end of the air suction base, hairbrushes are arranged on the air suction base, an air suction opening is formed in the inner sides of the hairbrushes, and a handle is connected to the left end of the pulling rod. The colored-spun-yarn equipment cleaning device convenient to move can adjust the height of the cleaning device according to the different heights of a colored-spun-yarn device.

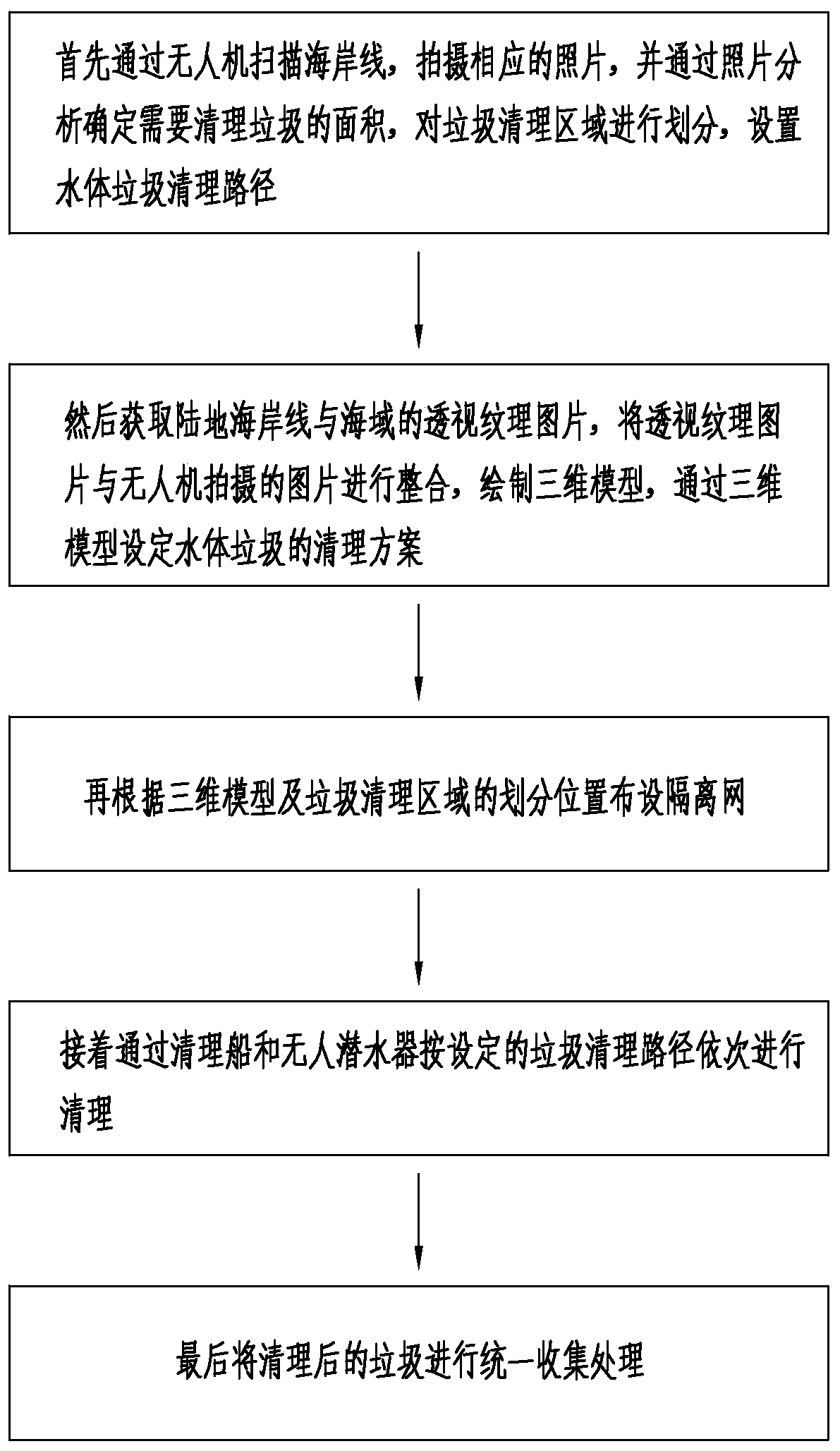

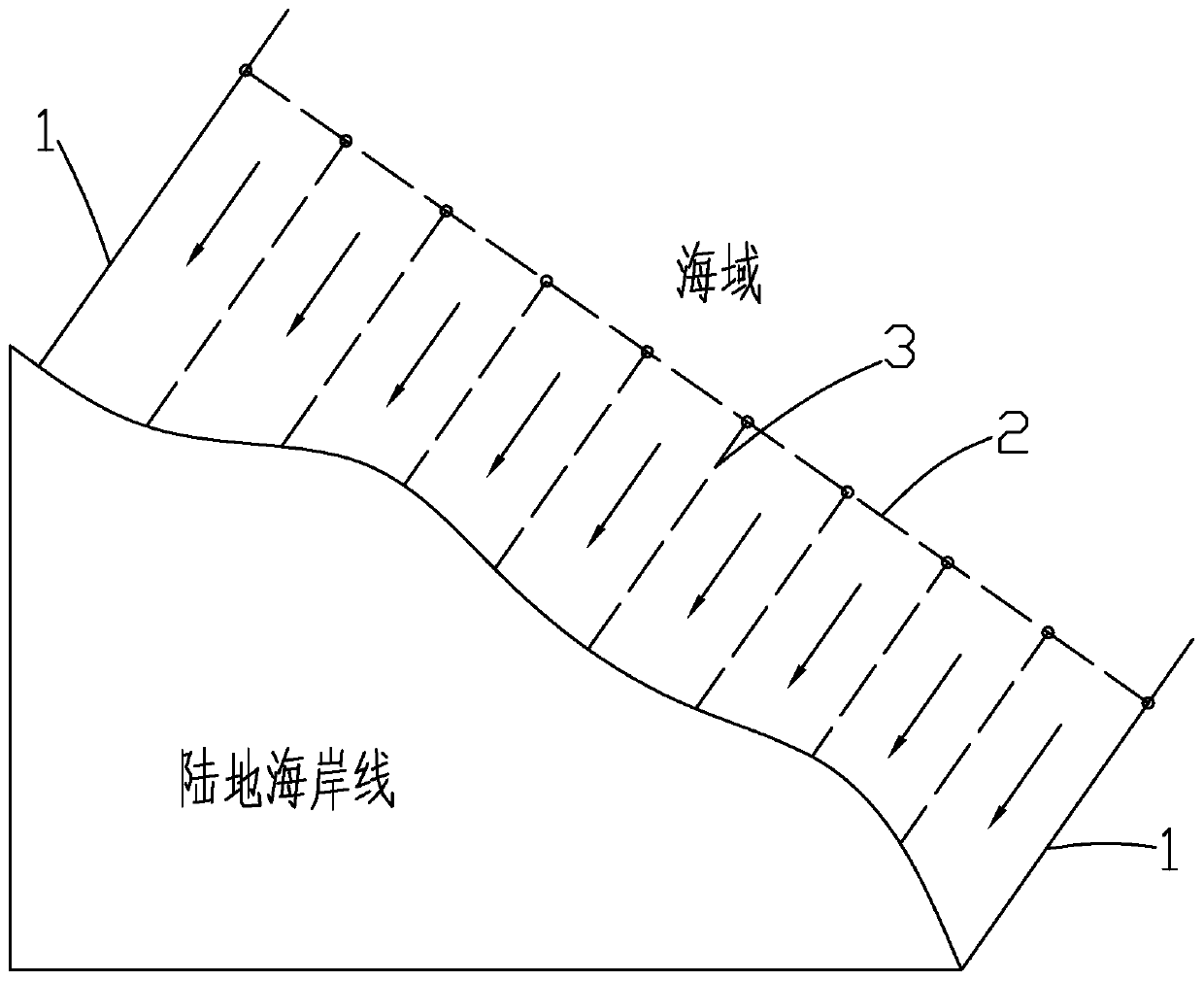

Coastline water body garbage rapid cleaning method

ActiveCN111501701AMeet clean upLow costImage analysisWater cleaningEnvironmental engineeringThree dimensional model

The invention discloses a coastline water body garbage rapid cleaning method. The coastline water body garbage rapid cleaning method comprises the following steps of firstly shooting a picture of a corresponding coastline, determining the area of garbage needing to be cleaned through picture analysis, dividing a garbage cleaning area, setting a water body garbage cleaning path, then obtaining perspective texture pictures of a land coastline and a sea area, integrating the perspective texture picture with a picture shot by a drone, drawing a three-dimensional model, arranging an isolation net according to the three-dimensional model and the division position of the garbage cleaning area, sequentially cleaning the garbage through a cleaning ship and an unmanned submersible according to a setgarbage cleaning path, and finally uniformly collecting and treating the cleaned garbage. The rapid water body garbage cleaning method is suitable for cleaning different coastline water body garbage,compared with a traditional fishing mode, the efficiency is higher, the water body garbage cleaning cost is reduced, meanwhile, the water body garbage in the corresponding sea area can be removed, and the coastline garbage cleaning requirements of different gradients and sections are met.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

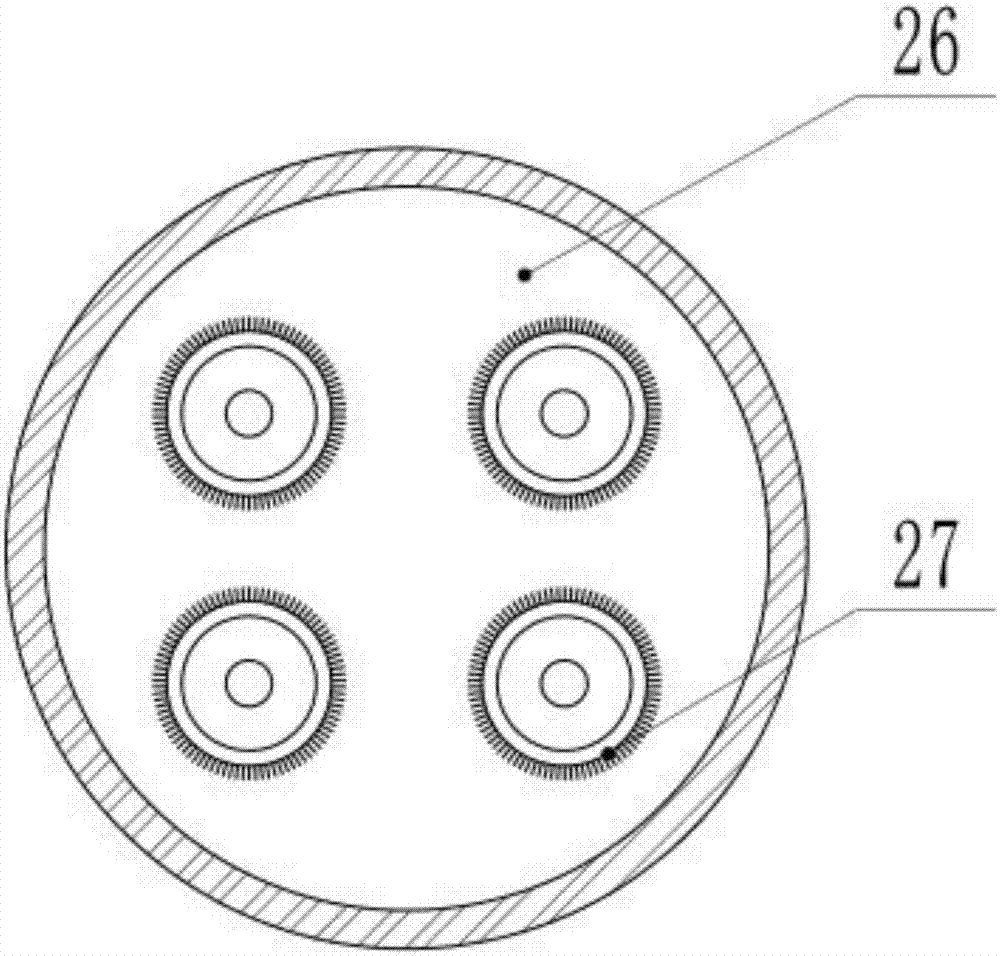

Pipeline inner and outer wall maintenance system

PendingCN113843225AReduce manual operation costsMeet clean upHollow article cleaningStructural engineeringPipe

The invention belongs to the field of pipe treatment, and relates to a pipeline inner and outer wall maintenance system. The pipeline inner and outer wall maintenance system comprises a rack, a pipe inner wall cleaning device is arranged on the left side wall of the rack, and is used for cleaning chippings and water falling into a pipe during cutting, a feeding device is arranged on the right sidewall of the rack, and is used for pushing in the pipe manually placed on a feeding opening. A belt wheel drives a push rod to achieve automatic feeding, in the pipe moving process, through rotation, compressed gas is sprayed out below the pipe to clean the surface of the pipe, after the pipe moves to a certain position, a cleaning rod is pushed into the pipe, due to rotation of the pipe, the inner wall of the pipe and a brush on the cleaning rod rub, multiple air holes formed in the cleaning rod spray out compressed gas to the inner wall, and cleaning of the interior of the pipe is achieved.

Owner:高家洪

Heating method of boiler for exploitation of offshore shale gas

InactiveCN110360588AMeet ventilationAvoid cloggingSolid removalLump/pulverulent fuel feeder/distributionOil processingExhaust pipe

The invention discloses a heating method of a boiler for exploitation of offshore shale gas. The heating method comprises the following steps: 1) coal is added to the boiler, exhaust gas produced during combustion of coal flows out through gas exhaust pipes at the top and is exhausted through air exhaust pipes, the volume of the added coal accounts for 2 / 3 that of the boiler, and the flow rate ofa fan in each air exhaust pipe is 350-450 m<3> / h; 2) coal is added to the boiler in time; 3) an interlayer is arranged in a petroleum refining tank, the temperature of the inside of the petroleum refining tank can be controlled by adding water at different temperatures to the interlayer, and the inside of the petroleum refining tank is controlled to be within a certain temperature; 4) the air exhaust pipes are cleared regularly; dirt on inner walls of the air exhaust pipes is cleared through an impurity removing device, the lower part of each air exhaust pipe is connected with the corresponding gas exhaust pipe of the boiler, a fan is arranged at the upper part of each air exhaust pipe, and the upper part of each air exhaust pipe is connected with an air discharging pipe through a flange.With the adoption of the heating method, the problem that exhaust gas in existing air exhaust systems cannot be discharged sufficiently is solved.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

A method for cleaning solar water heater scale

ActiveCN111765654BQuick Auto Auto CleanupEasy dischargeSolar heating energySolar heat collector controllersWater storageWater storage tank

The invention discloses a method for cleaning scale of a solar water heater, which comprises a water storage tank with a cylindrical structure. The water storage tank is provided with a drain pipe and a water inlet pipe. There is a rotating shaft inside, and an arc-shaped plate is arranged on the rotating shaft, and a connecting rod is arranged on the arc-shaped plate, and a scraper is arranged on the connecting rod; the first blade and several second blades are arranged in the fixed box, and the top of the fixed box is arranged There is a water outlet pipe, and the bottom of the fixed box is provided with a water inlet pipe; there is also a connecting block between the drain pipe and the water storage tank, and a cavity is provided in the connecting block, the drain pipe is connected with the cavity, and a fourth elastic member is also provided in the cavity and the connecting pipe, one end of the fourth elastic member is connected to the inner wall of the cavity, and the other end is connected to the connecting pipe. The water storage tank is also provided with a sewage outlet connected to the connection block cavity, and the connecting pipe is located at the end of the water storage tank. A plurality of support rods, one end of the support rods is connected with the connecting pipe, and the other end is provided with a sealing rod of conical structure.

Owner:陕西专壹知识产权运营有限公司

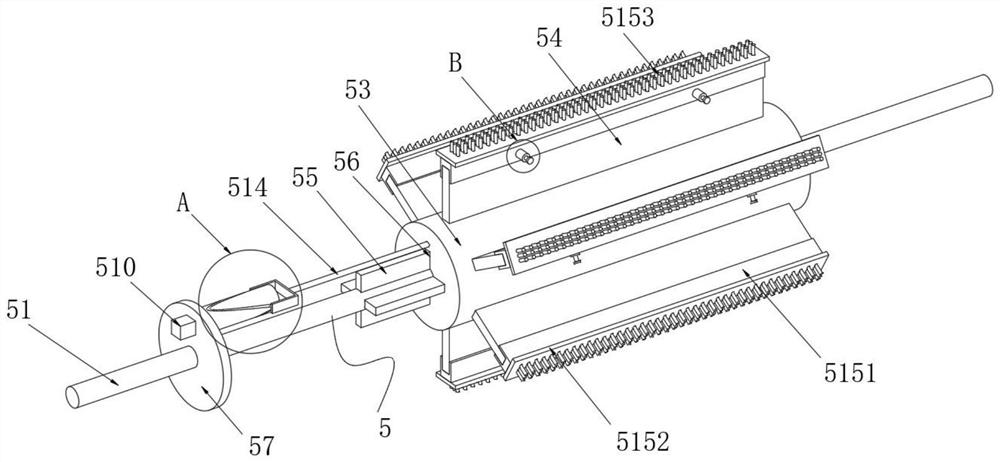

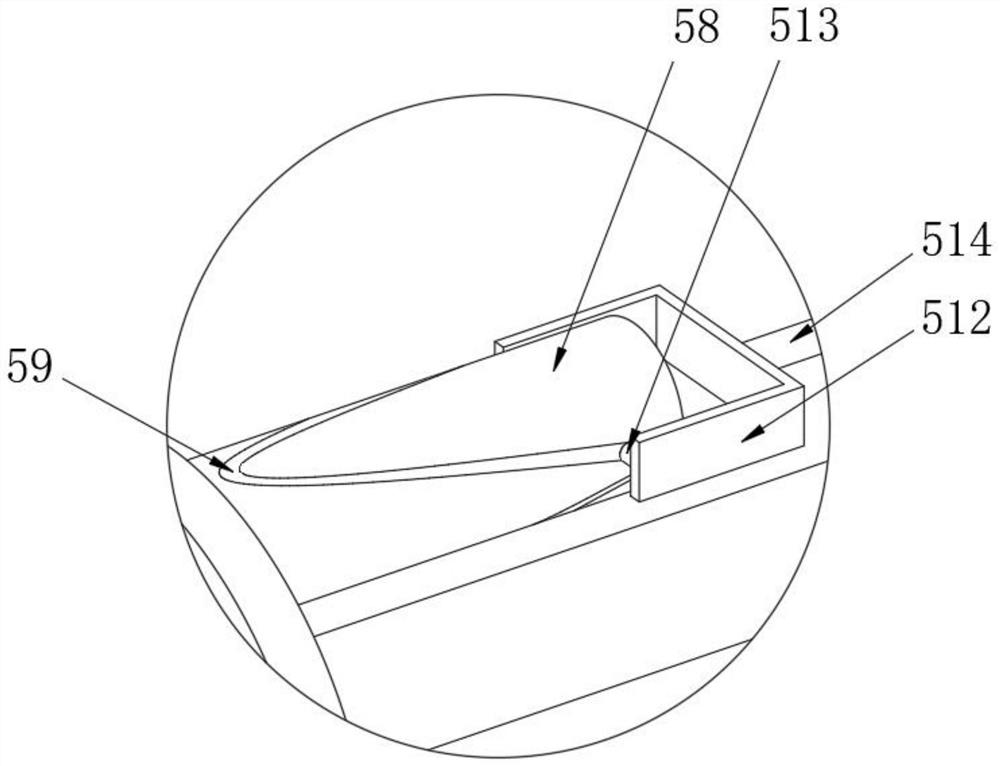

Desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment

PendingCN113914045AMeet clean upImprove efficiencyLiquid/gas/vapor treatment machines driving mechanismsSucessive textile treatmentsProcess engineeringWoven fabric

The invention discloses a desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment, and relates to the technical field of cloth production. The desizing, scouring and bleaching one-bath process system comprises a bottom plate, a desizing bin, a scouring bin and a bleaching bin are fixedly connected with the top of the bottom plate in sequence from left to right, and a reciprocating stirring mechanism is arranged in the desizing bin; and the reciprocating stirring mechanism comprises a rotating rod rotationally connected between the front side and the rear side of the inner wall of the desizing bin, and the rear end of the rotating rod penetrates through the desizing bin and extends to the rear side of the desizing bin. According to the desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment, by arranging the reciprocating stirring mechanism, desizing liquid is stirred and mixed by a stirring paddle, full desizing of the desizing liquid on the surface of the fabric is facilitated, through the front-back-side reciprocating motion of a stirring wheel, the stirring wheel drives the stirring paddle and bristles to movably clean the surface of the cloth, cleaning of the surfaces of the cloth with different widths is met, and the desizing efficiency of the cloth is greatly improved.

Owner:佛山市顺德金纺集团有限公司

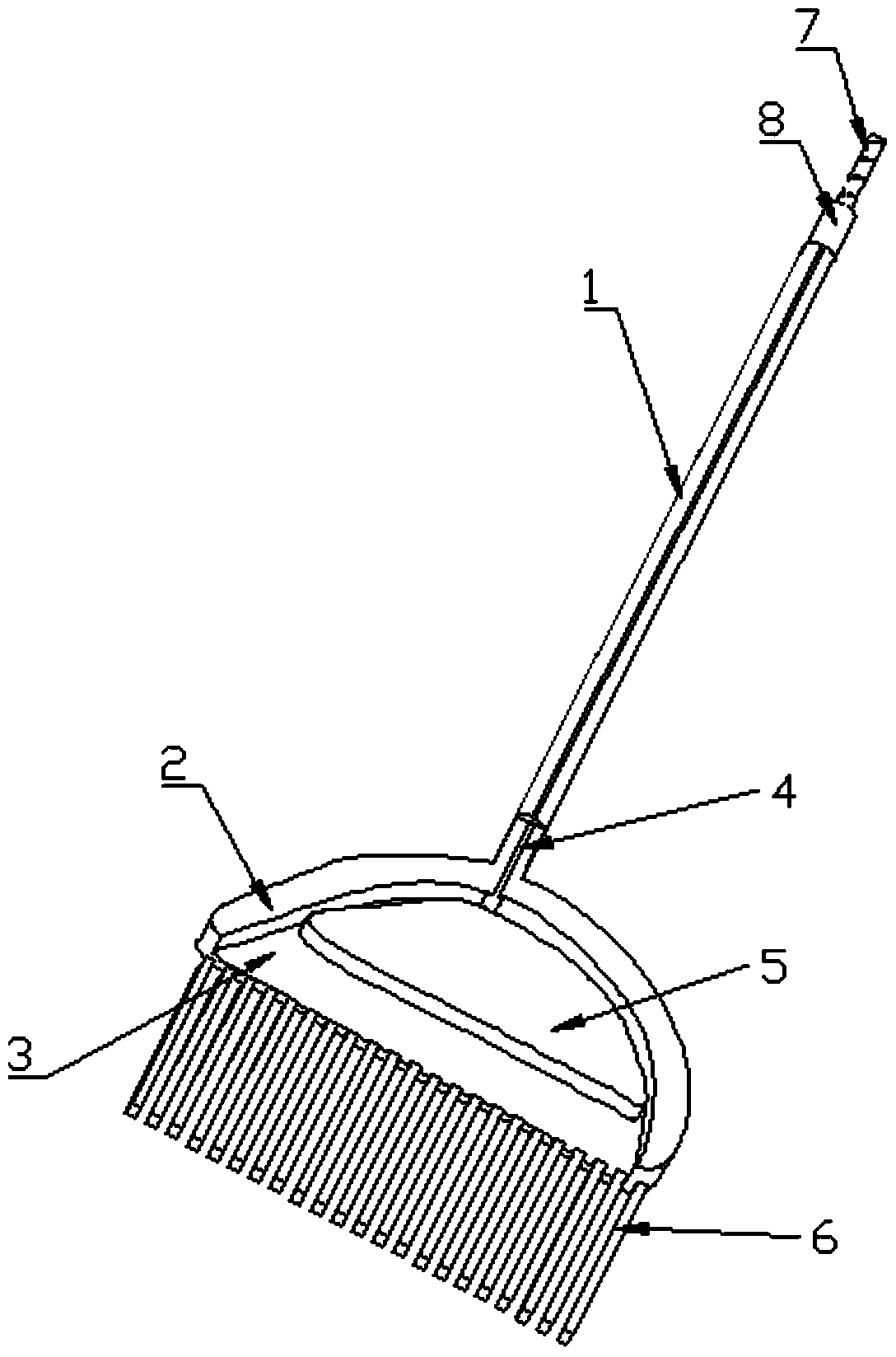

A quick cleaning device

The invention provides a rapid cleaning device, which comprises a broom rod, a broom rack, a second cleaning body and broom heads, wherein each of the broom heads is constituted by parallel distribution of strip-shaped bodies which are made from soft fiber materials; the bottom of the broom rod is connected to the broom rack; the broom heads are fixed to two sides of the bottom surface of the broom rack, and between the two broom heads, a cleaning groove is formed in the bottom surface of the broom rack; the second cleaning body is arranged in the cleaning groove; a shield, which is made from a fiber material, covers the outer surface of the second cleaning body; a rod passing hole, from which the broom rod runs through, is formed in the top surface of the broom rod; the rod passing hole communicates with the cleaning groove; a movable rod is arranged in the rod passing hole; one end of the movable rod is arranged at the upper part of the top surface of the broom rod; and the other end of the movable rod is connected to the second cleaning body. The rapid cleaning device disclosed by the invention can meet basic cleaning demands; and meanwhile, the rapid cleaning device can also achieve the purpose of cleaning waste hung on the broom heads.

Owner:山东益客食品产业有限公司

A mechanical keyboard automatic cleaning robot

ActiveCN106552779BImprove cleaning efficiencyClean fitCleaning using toolsCleaning using gasesSlide plateConical cavity

The invention relates to the field of computer cleaning. Specifically, it is an automatic cleaning robot for mechanical keyboards, which includes a main frame, a bottom lifting device, a left and right movement device and a front and rear movement device. The invention also includes a cleaning main body; the cleaning main body includes a cleaning main pipe, a top fastener Plate, lower slide plate, top brush sponge, spring, cleaning chamber and cleaning terminal; the cleaning chamber includes an upper chamber and a lower chamber. The upper chamber is a conical cavity structure with a large top and a small bottom, and the lower cavity is a cubic cavity structure. The cleaning efficiency of the present invention is high, and the structural design of the upper cavity and the lower cavity enables the present invention to better fit the shape of the mechanical keyboard gap to clean the mechanical keyboard gaps more specifically and more closely to the side wall of the mechanical keyboard. This makes the cleaning effect of the present invention better.

Owner:宁阳县鑫农农村发展有限公司

Solar water heater with scale cleaning function

ActiveCN111765655AChange spacingChange the bendSolar heating energySolar heat collectors safetySolar waterWater storage tank

The invention discloses a solar water heater with a scale cleaning function. The solar water heater comprises a water storage tank of a cylindrical structure, a drainage pipe and a water inlet pipe are arranged on the water storage tank, a fixing tank of a cylindrical structure is arranged on the inner wall of the water storage tank, a rotating shaft is arranged in the water storage tank, an arc-shaped plate is arranged on the rotating shaft, a connecting rod is further arranged on the arc-shaped plate, and a scraper blade is arranged on the connecting rod; a first blade and a plurality of second blades are arranged in the fixing tank, a water outlet pipe is arranged at the top of the fixing tank, and a water inlet pipe is arranged at the bottom of the fixing tank; and a connecting block is further arranged between the drainage pipe and the water storage tank, a cavity is formed in the connecting block, the drainage pipe is in communication with the cavity, a fourth elastic piece and aconnecting pipe are further arranged in the cavity, one end of the fourth elastic piece is connected with the inner wall of the cavity, the other end of the fourth elastic piece is connected with theconnecting pipe, the water storage tank is also provided with a drain outlet communicated with the cavity of the connecting block, a plurality of supporting rods are arranged at the tail end, locatedin the water storage tank, of the connecting pipe, one ends of the supporting rods are connected with the connecting pipe, and plugging rods of conical structures are arranged at the other ends of the supporting rods.

Owner:ZHANGJIAKOU TIANYANG SOLAR WATER HEATER CO LTD

A cleaning machine for cleaning up carving waste

ActiveCN111016509BIncrease flexibilityMeet clean upHand artistic toolsDirt cleaningEngravingDrive shaft

Owner:阜南县中泰工艺品有限公司

Flushing type wet wipe used for cleaning fruit and vegetables, and production method thereof

InactiveCN110331050AMeet clean upAvoid cloggingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium bicarbonatePesticide residue

The invention belongs to the technical field of wet wipe manufacturing, and more specifically discloses a flushing type wet wipe used for cleaning fruit and vegetables, and a production method thereof. The flushing type wet wipe used for cleaning fruit and vegetables comprises a wet wipe solution and non-woven fabric; the non-woven fabric comprises two layers, and the wet wipe solution is uniformly sprayed onto the surface of the non-woven fabric. The wet wipe solution comprises, by weight, lemon essential oil of 0.2%-0.6%, tea tree essential oil of 0.2%-0.6%, glycerin of 0.2%-0.6%, tea saponin of 1.5%-3.5%, sodium chloride of 2.5%-7.0%, mint extract of 1.2%-2.3%, Green Core Pesticide Degrading Enzyme of 0.6%-1.3%, sodium bicarbonate of 1.2%-3.5 %, amino acid surfactant 0.8%-1.7%, and thebalance pure water. The flushing type wet wipe is capable of solving problems in the prior art that, in growth and transportation process of fruit and vegetables, pesticide residue in fruit wax on surfaces and fruit and vegetables influences body health of consumers, conventional wet wipe technology is not capable of solving the problem, and in picnics, because of lack of washing equipment, it isimpossible to eat fruits.

Owner:ANHUI HANBON DAILY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com