Method for producing automotive sound-absorption and heat-insulation integrated carpet

A production method and carpet technology, which is applied in the field of automotive sound-absorbing and heat-insulating integral carpets, can solve the problems that the sound-absorbing and heat-insulating performance cannot be significantly improved, the production environment cannot be improved, and the overall appearance is affected, and the appearance is smooth and beautiful, The effect of reducing production costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

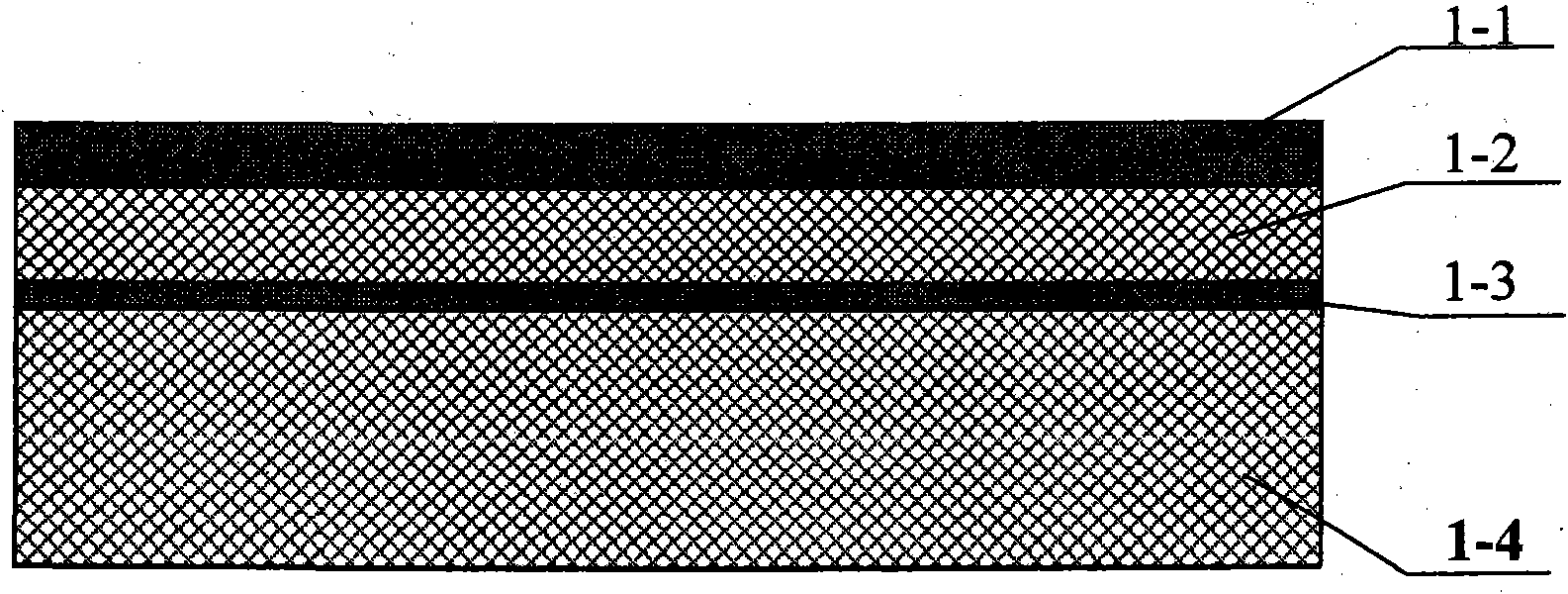

[0015] The production process steps of the automobile sound-absorbing and heat-insulating integral carpet of the present invention are as follows:

[0016] (1) Heating and baking: put the foamed leather into the oven to bake, the oven temperature setting: 320°C for the outer ring, 290°C for the inner ring, 270°C for the center, and the heating tube is 400mm away from the baking material tray; Baking time: 40°C seconds, reverse side 60 seconds;

[0017] (2) Suction molding: use the pre-feeding device to pre-feed and then suck, vacuum pressure setting: -0.04~-0.06Mpa, molding time 5 seconds;

[0018] (3) Cooling and shaping: Spray cooling water to cool the surface of the product rapidly, and increase the amount of cooling water for parts that are stretched greatly;

[0019] (4) Pressing and bonding: the back of the sound-absorbing and heat-insulating felt is covered with glue, and after positioning, it is pressed and bonded to the back of the foam leather;

[0020] (5) Cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com