Mechanical keyboard dust sucking working platform

A technology for mechanical keyboards and working platforms, which is applied to vacuum cleaners, vacuum cleaner storage devices, cleaning equipment, etc., can solve the problems of time-consuming and laborious, mechanical keyboards are not waterproof, dust and stains are difficult to remove, and achieve good cleaning effect and practical effect. High cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

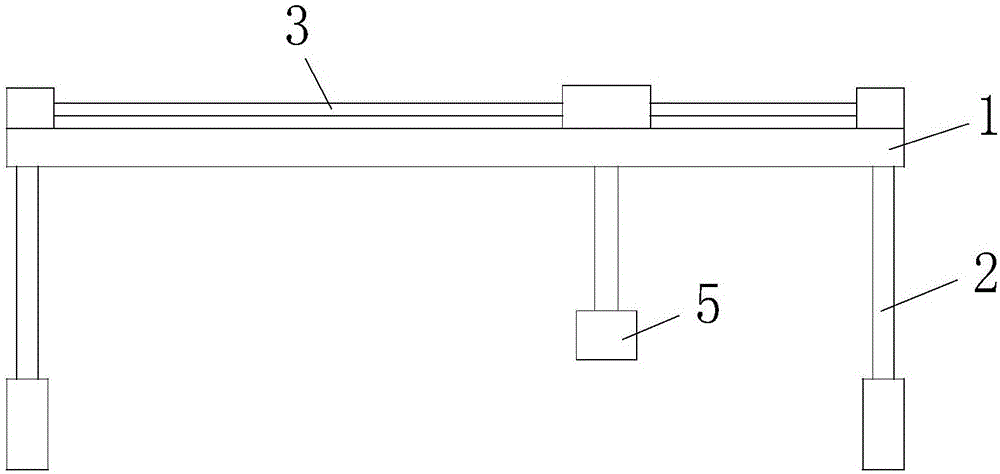

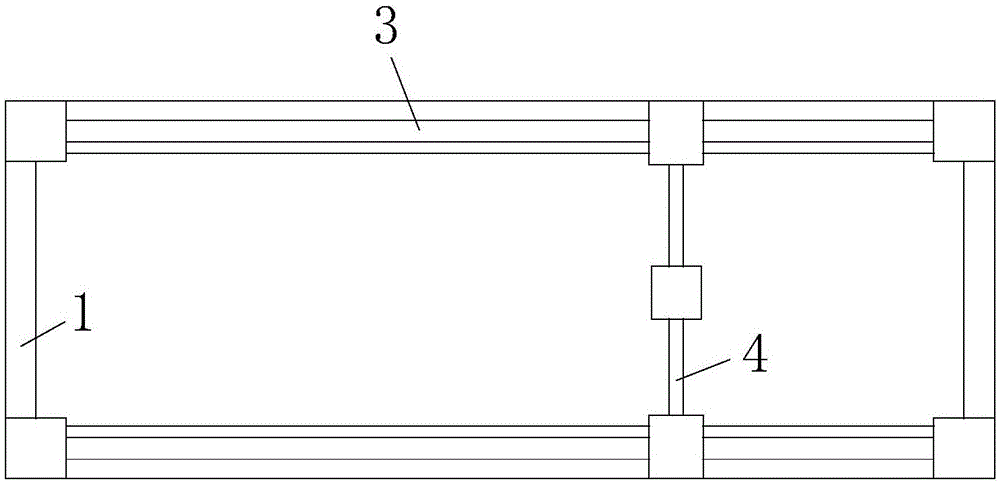

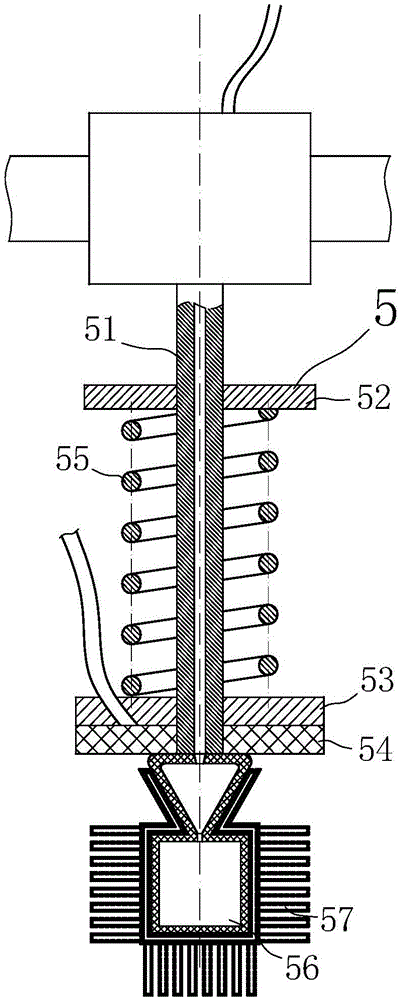

[0043] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a mechanical keyboard vacuuming work platform according to the present invention includes a main frame 1, a bottom lifting device 2, a left and right moving device 3 and a front and rear moving device 4. The main frame 1 is a square frame structure as a whole, and the main frame A PLC controller is installed on the frame 1, and the PLC controller is used to control the work of all electrical components and pneumatic components in the present invention. The bottom lifting device 2 is installed at the four corners of the main frame 1 bottom, and the top of the bottom lifting device 2 is connected to the main frame. The frame 1 is hinged, and the bottom lifting device 2 can be a cylinder, which is used to lift the main frame 1, so that the present invention can adapt to the needs of mechanical keyboards of different heights, and each part of the bottom lifting device 2 can ...

Embodiment 2

[0051] The difference between embodiment 2 and embodiment 1 is that the cleaning cavity 56 is a cubic cavity structure as a whole, because the key gaps of non-mechanical keyboards are generally cubic structure gaps, so this design enables the present invention to meet general conventional non-standard requirements. mechanical keyboard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com