Patents

Literature

30results about How to "Increase cleaning intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

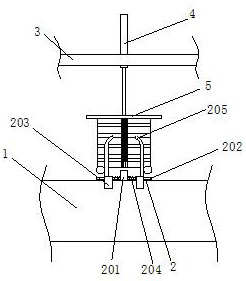

Textile thread lubrication device

InactiveCN111304847AAccelerate oil wetting efficiencyKeep cleanTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingEngineeringEnvironmental geology

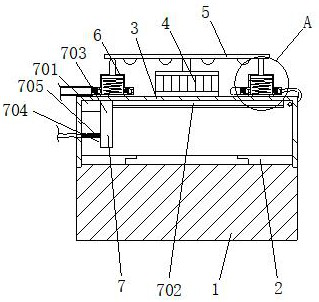

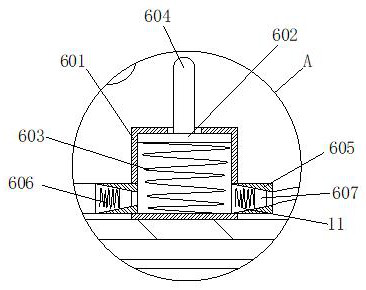

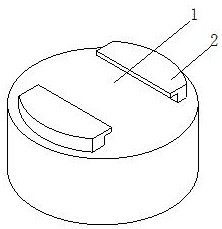

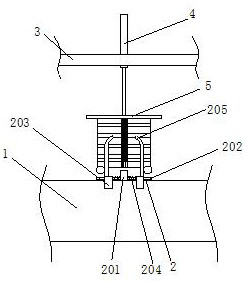

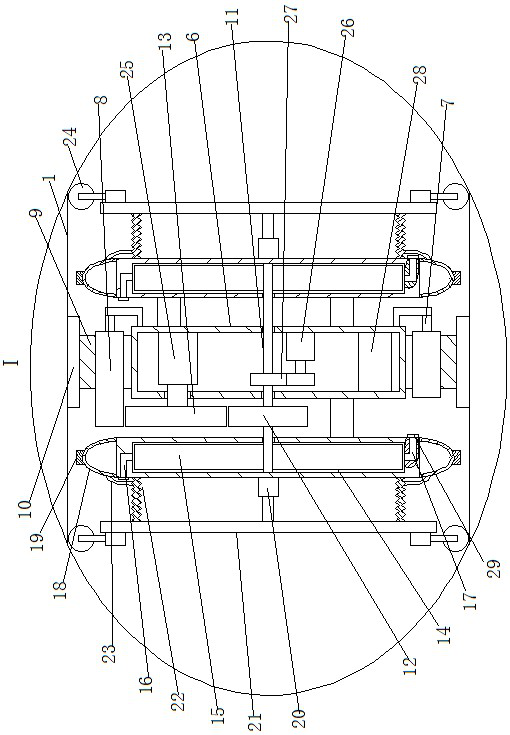

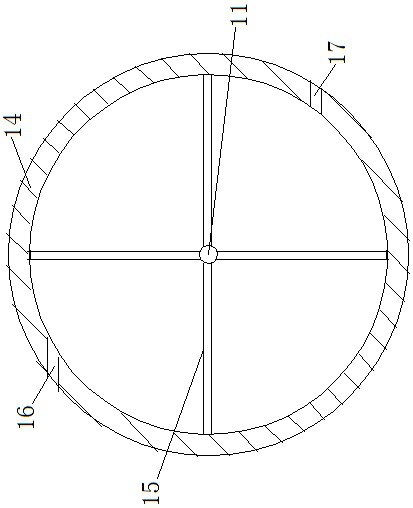

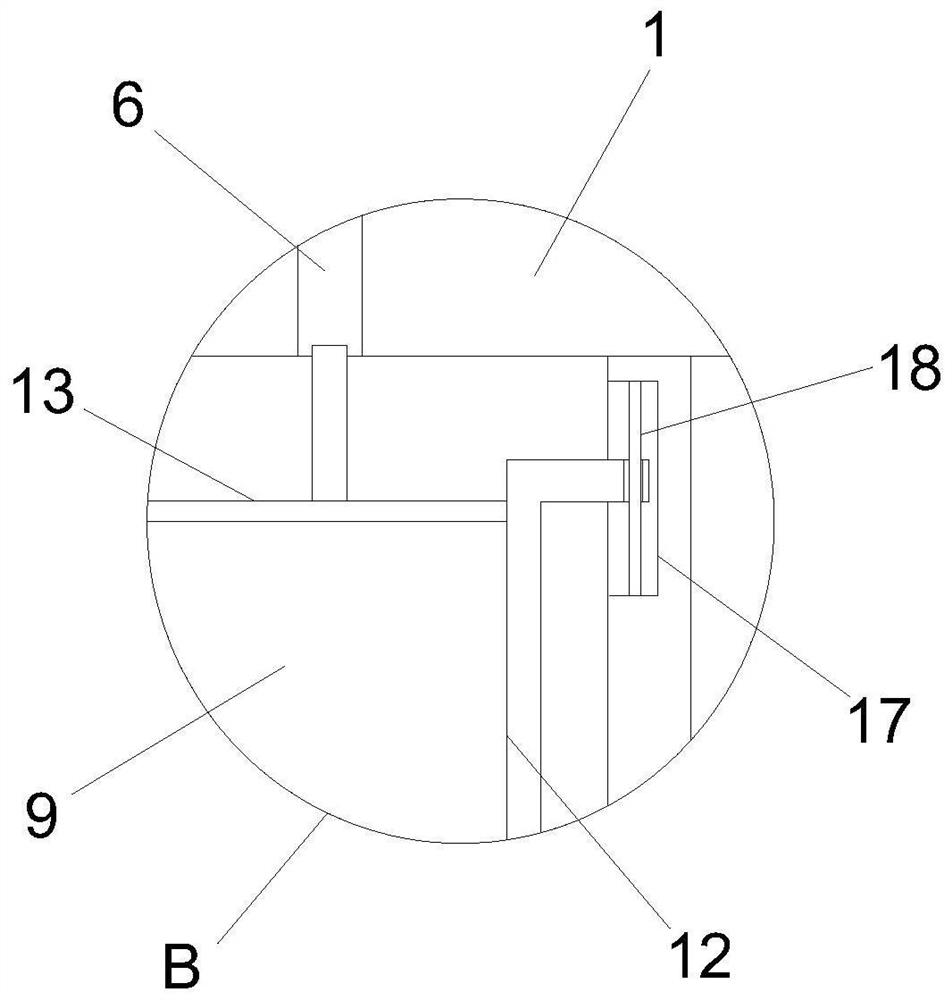

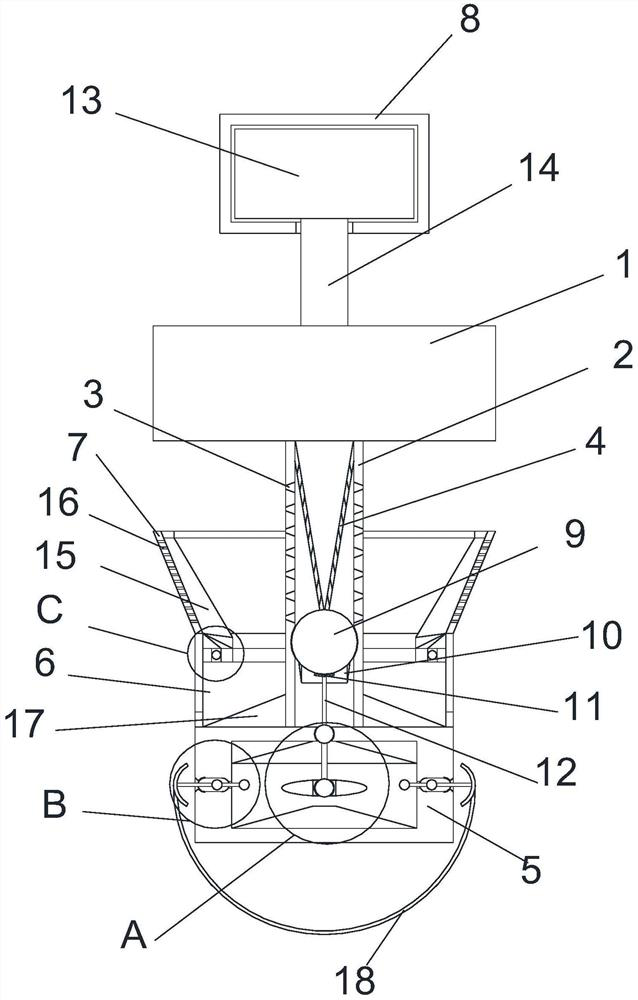

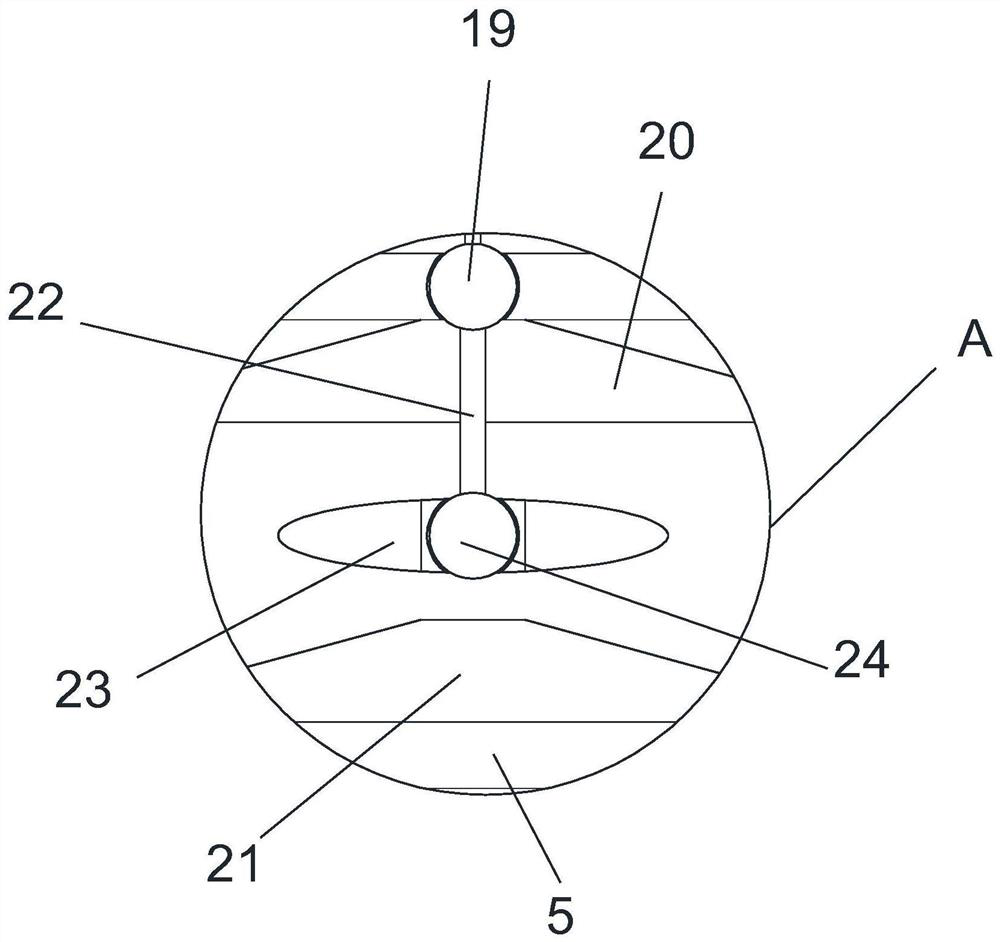

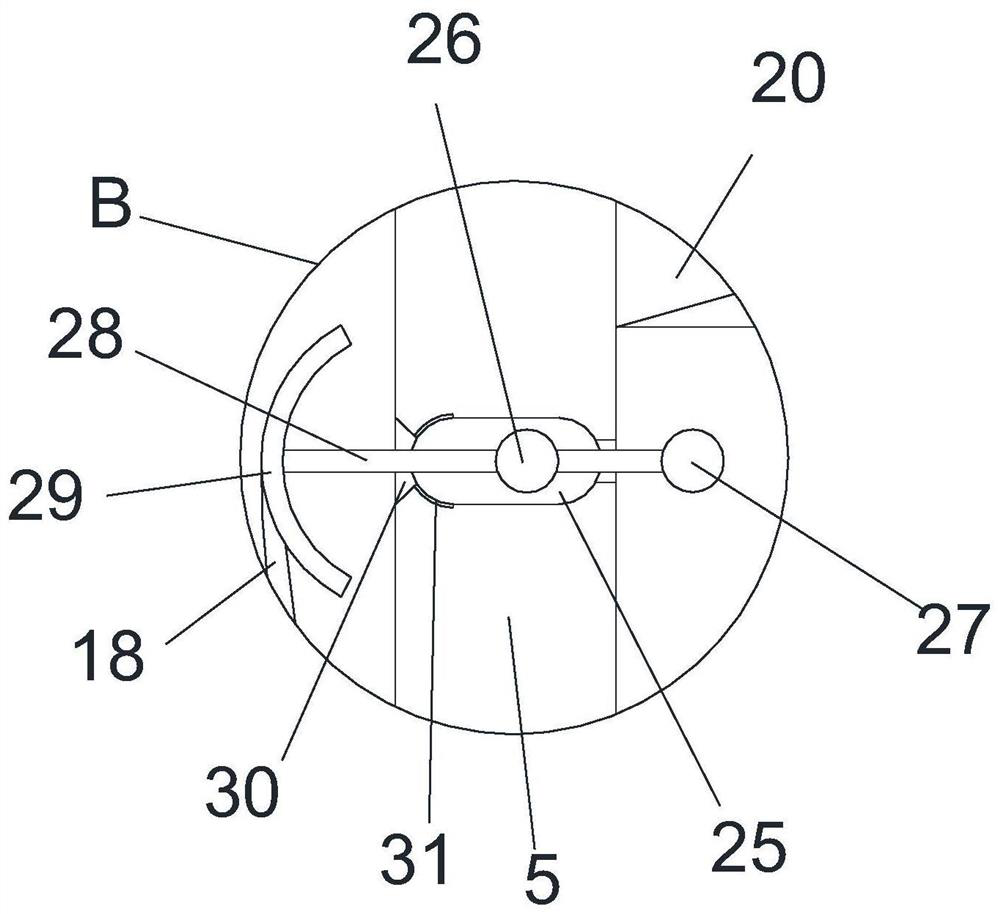

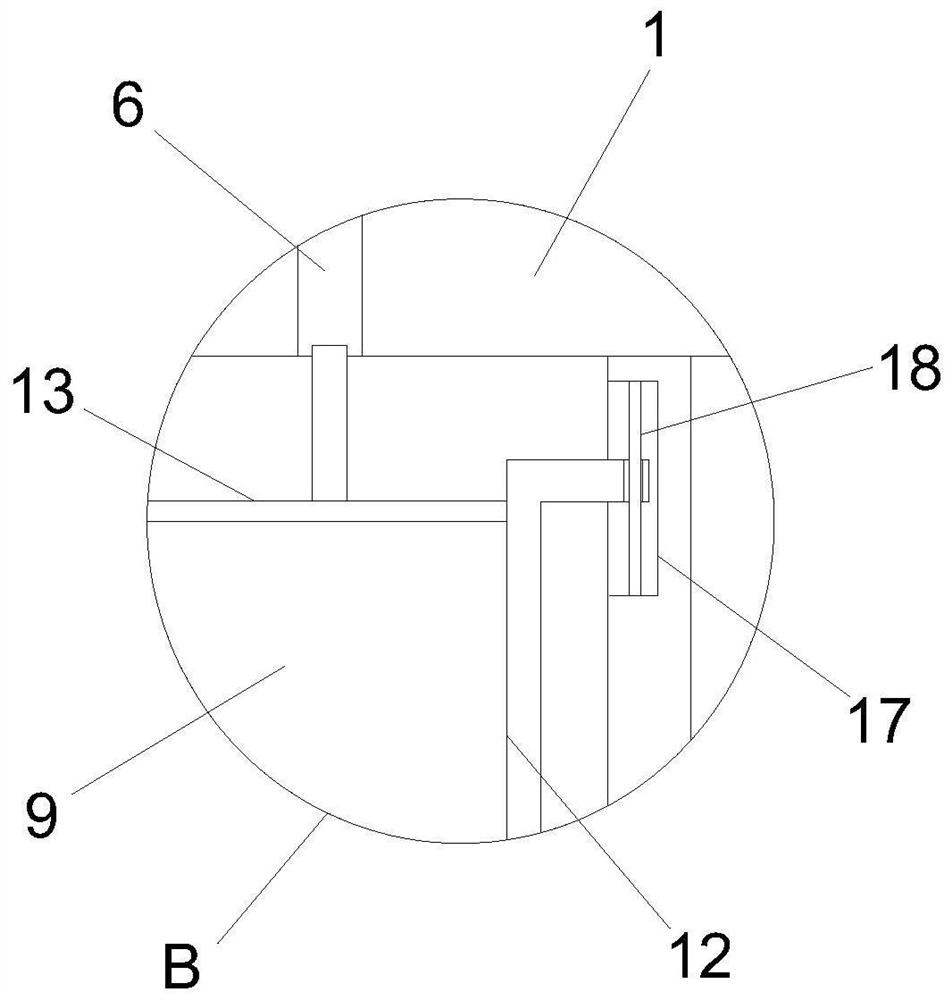

The invention discloses a textile thread lubrication device. The textile thread lubrication device comprises a base; a box body is fixedly connected to the upper end of the base; a heating box is fixedly connected to the upper end of the box body; a first circular ring is fixedly connected to the lower end of the heating box; a cylinder is slidably connected to the inner wall of the first circularring; a plurality of springs are symmetrically and fixedly connected to the inner wall of the cylinder; one end, away from the inner wall of the cylinder, of the plurality of springs is fixedly connected with an arc-shaped plate in a hollow structure; and the first circular ring is provided with an oil guiding device for inputting oil in the arc-shaped plate. According to the textile thread lubrication device provided by the invention, the cylinder drives the arc-shaped plate to rotate, so that the oil in the heating box flows into the arc-shaped plate through the oil guiding device, and flows out from an oil guiding hole, thus comprehensive oil infiltration is carried out on textile threads, the oil infiltration efficiency on the textile threads with different thicknesses is accelerated,and the oil can be heated through a heating plate, so that the situation that the circulation of the oil is affected due to the solidification of the oil when the weather is cold, so that the oil infiltration efficiency of the textile threads is affected is avoided.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

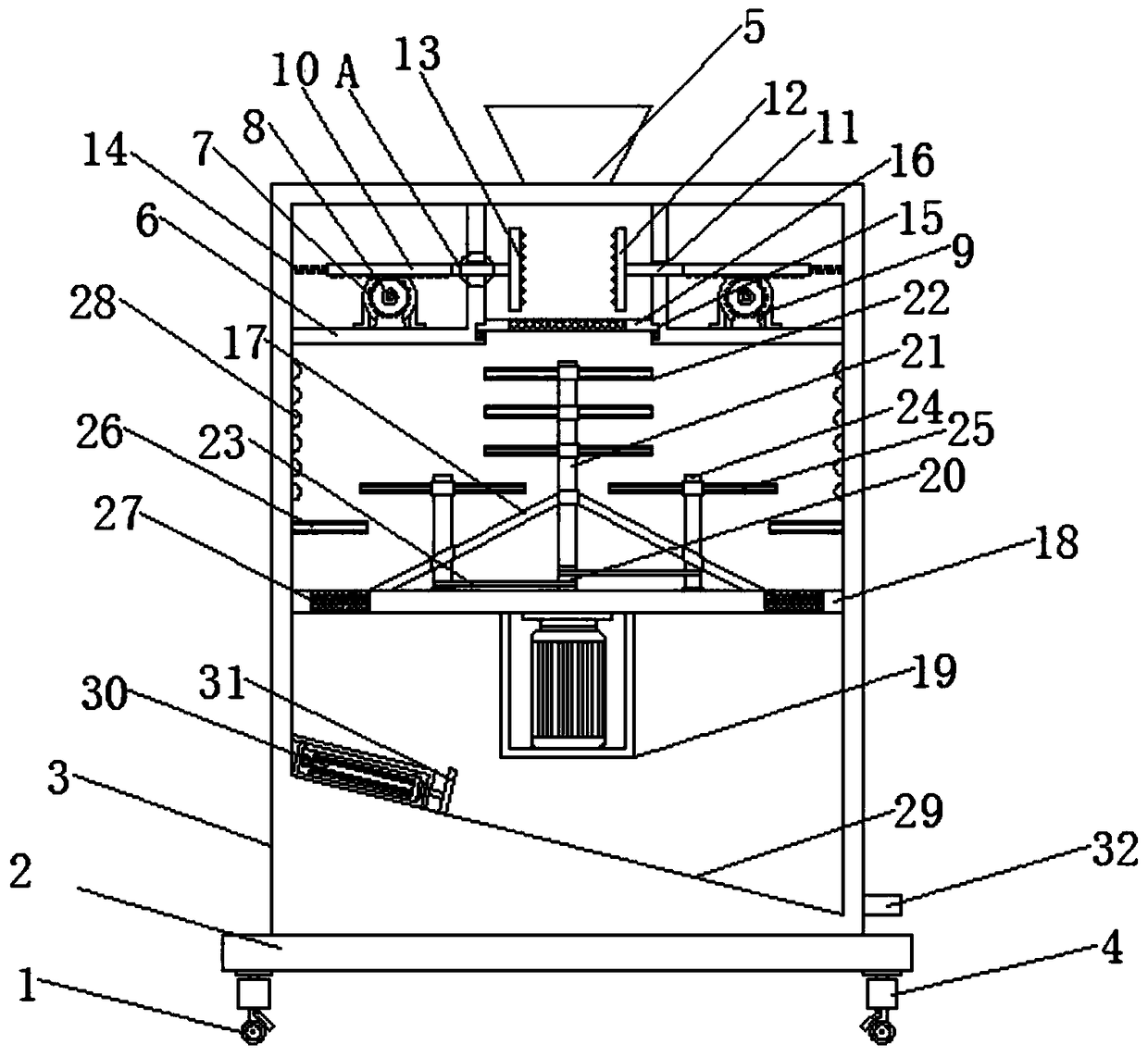

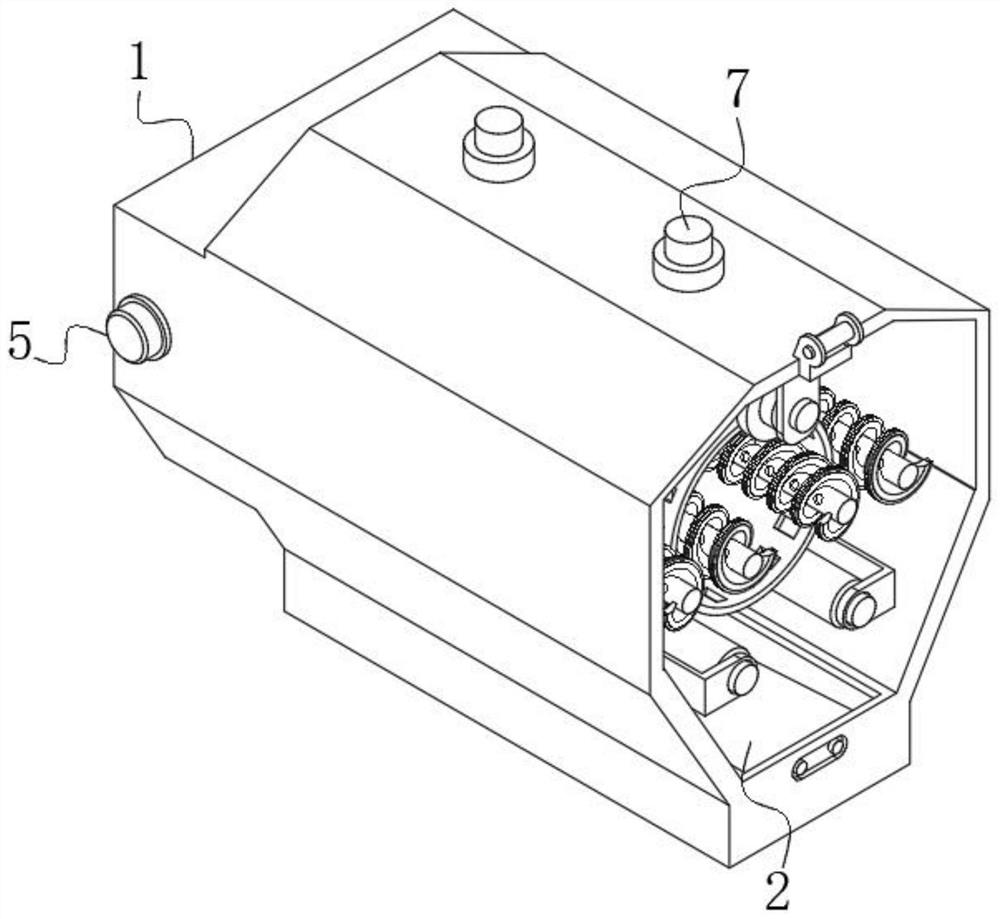

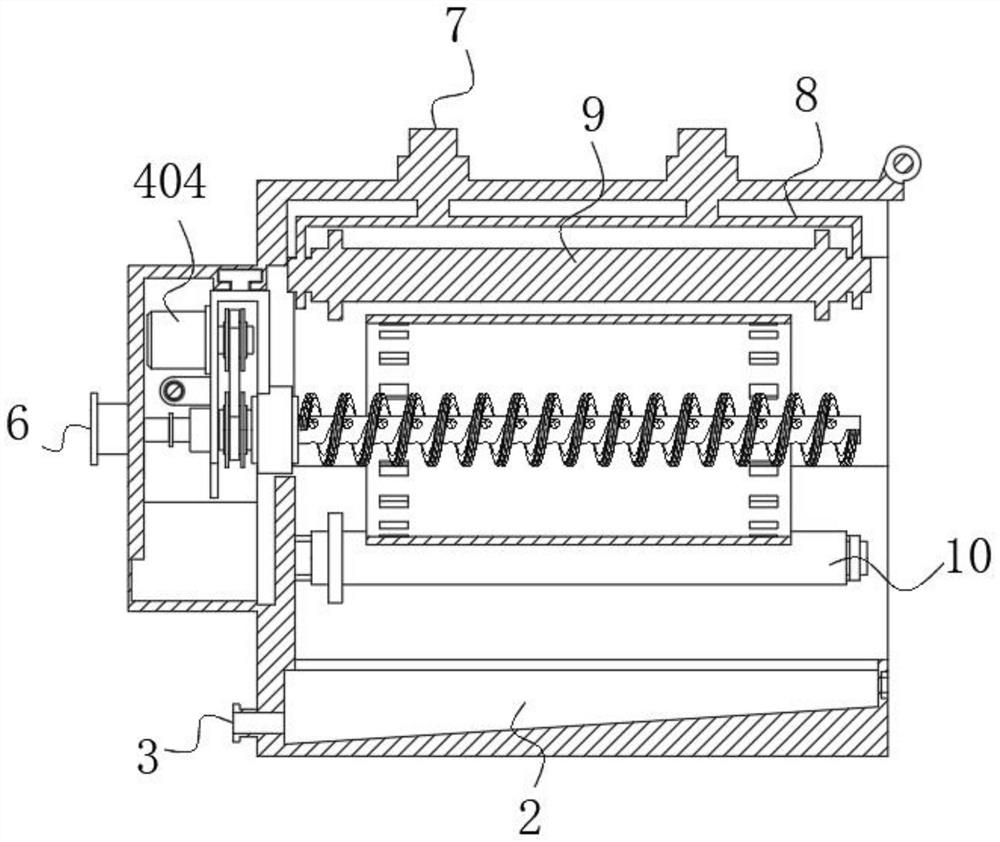

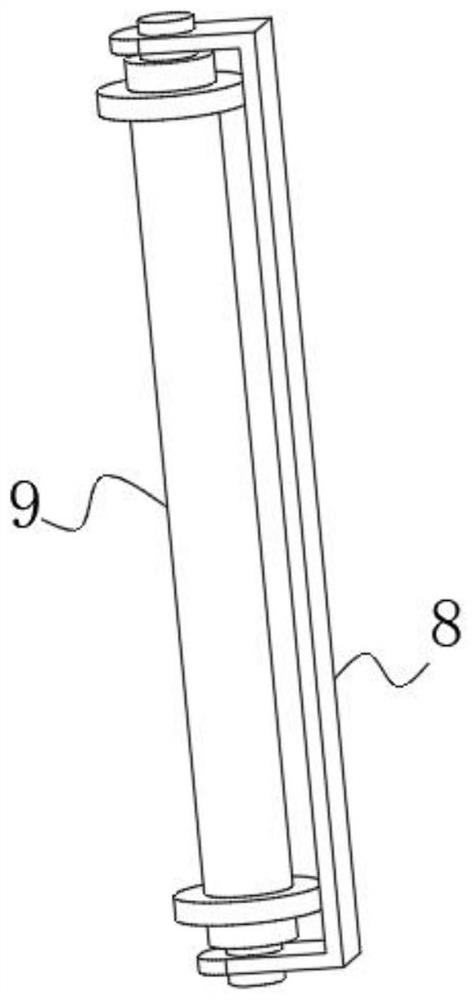

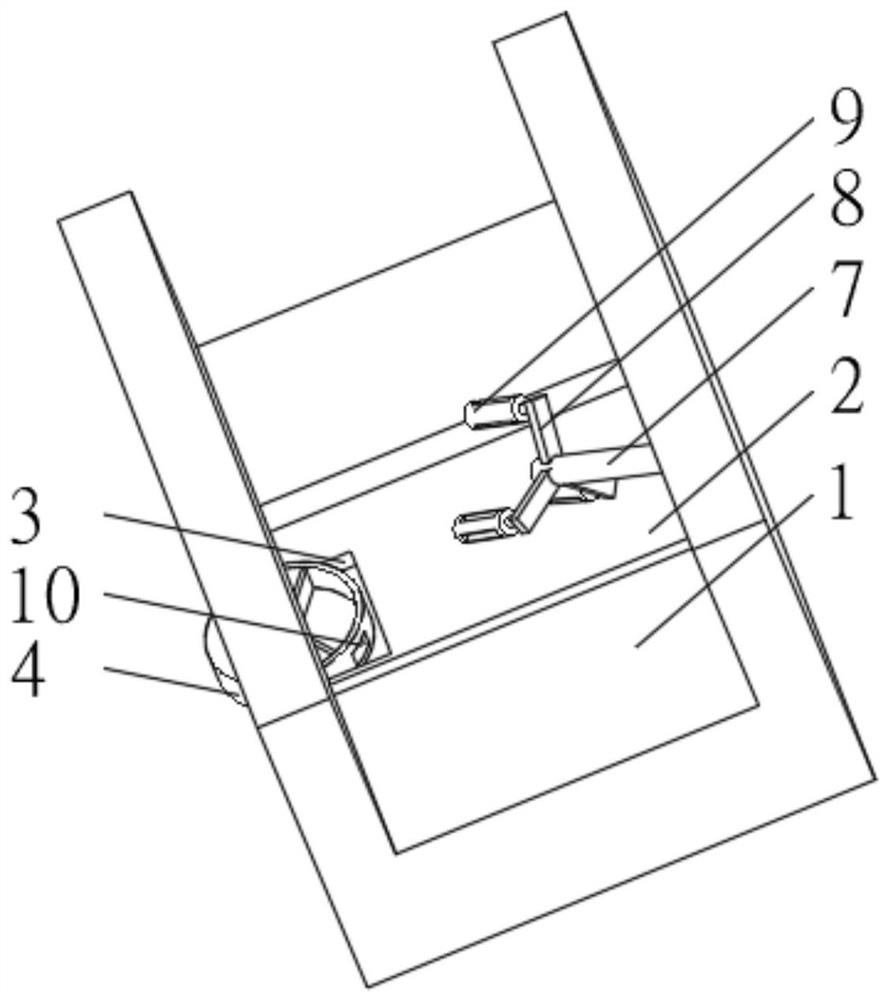

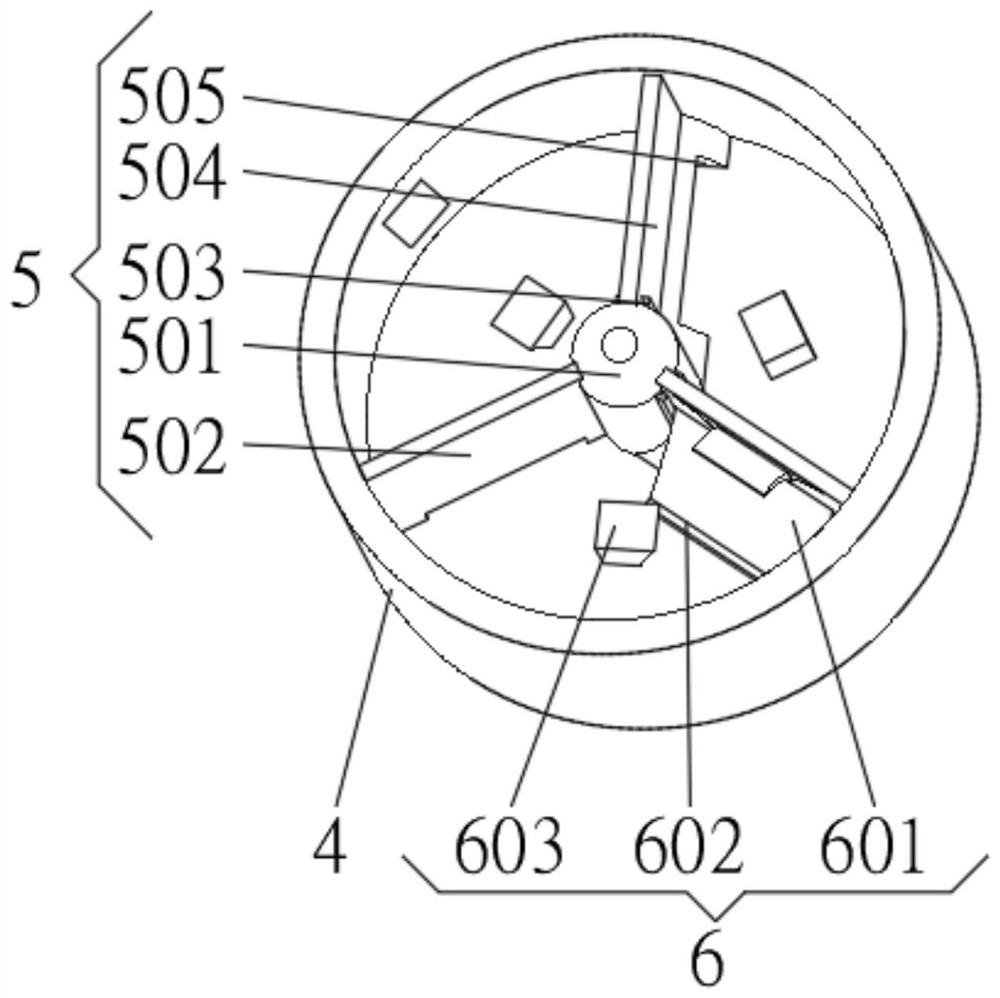

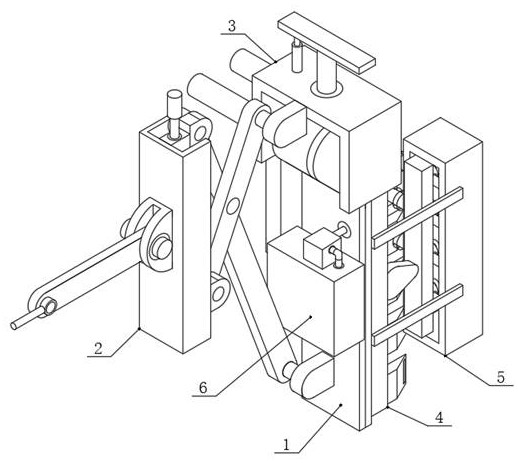

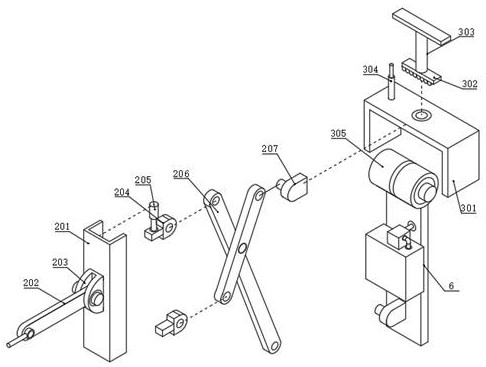

Smashing device for food detection

PendingCN108844795AEasy to achieve primary crushingAchieve primary crushingPreparing sample for investigationTesting foodDrive shaftEngineering

Owner:冒志华

Circuit board production equipment based on vacuum etching technology

ActiveCN112203429AImprove cleanlinessAvoid quality lossConductive material chemical/electrolytical removalEtchingElectric machinery

The invention relates to the technical field of etching, and discloses circuit board production equipment based on a vacuum etching technology. The equipment comprises a base, two clamping plates, anetching cylinder, a rotating motor, a turntable, a vacuum device and an etching device, and is characterized in that the bottom surface of the etching cylinder is in a hollow state, the clamping plates are inverted L-shaped bodies, and the two clamping plates are opposite to each other left and right; the surfaces, deviating from each other, of the two clamping plates are curved and are matched with the inner wall of the etching cylinder, the vacuum device and the etching device are both arranged on the etching cylinder, and through arrangement of the vacuum device, a vacuum effect is formed in the whole etching cylinder by utilizing a continuous air exhaust effect, so that dust and the like in the base are powerfully extracted, and the etching efficiency is improved. Therefore, dust in the base or on the circuit board before etching and smoke and impurities generated by chemical reaction in the etching process are removed, the cleanliness of the circuit board after etching is improved, the problem that the quality of the circuit board is reduced due to the fact that the smoke and the impurities such as the dust participate in the etching process is solved, and compared with an existing cleaning mechanism on an etching machine, the cleaning range is more comprehensive, and the cleaning force is stronger.

Owner:东莞感恩蚀刻科技有限公司

Water conservancy pipeline desilting device

InactiveCN114247711AQuick dredgingImprove practicalityHollow article cleaningElectric machineryStructural engineering

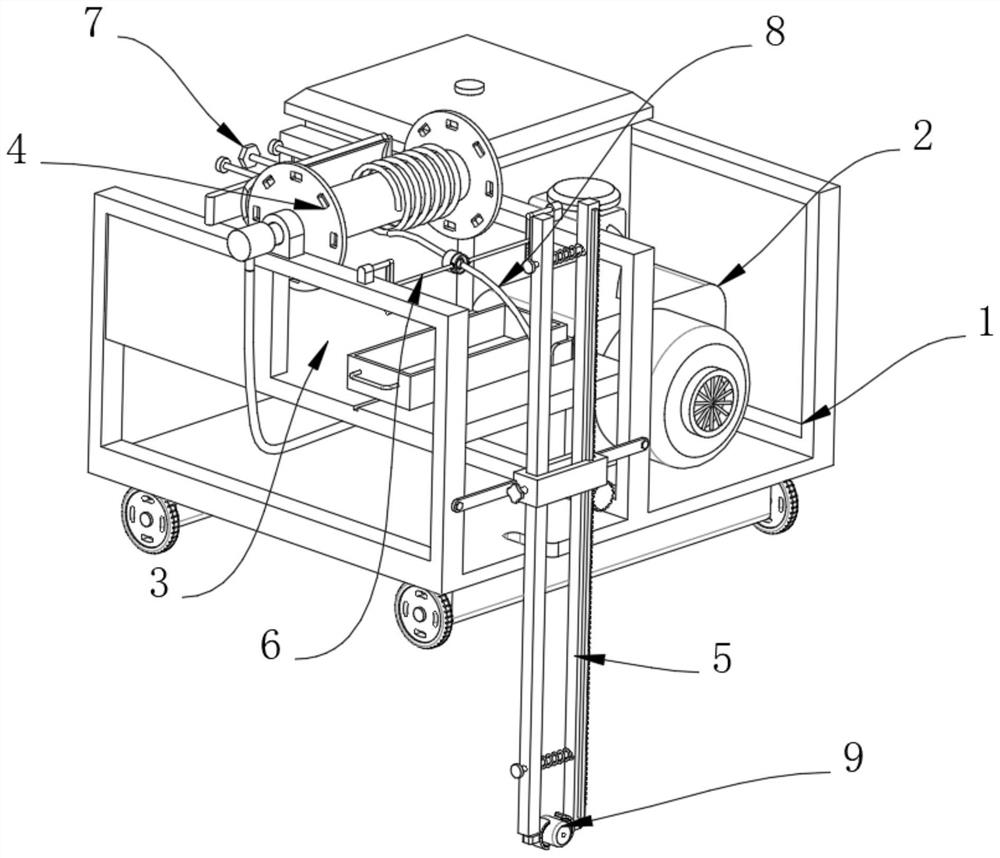

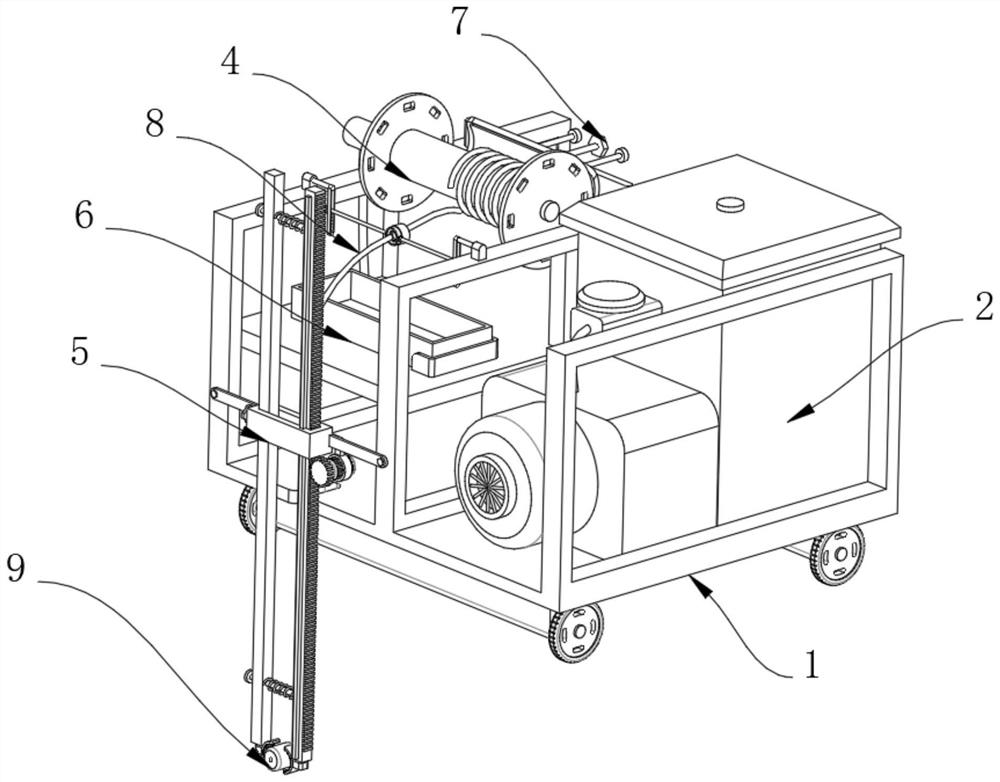

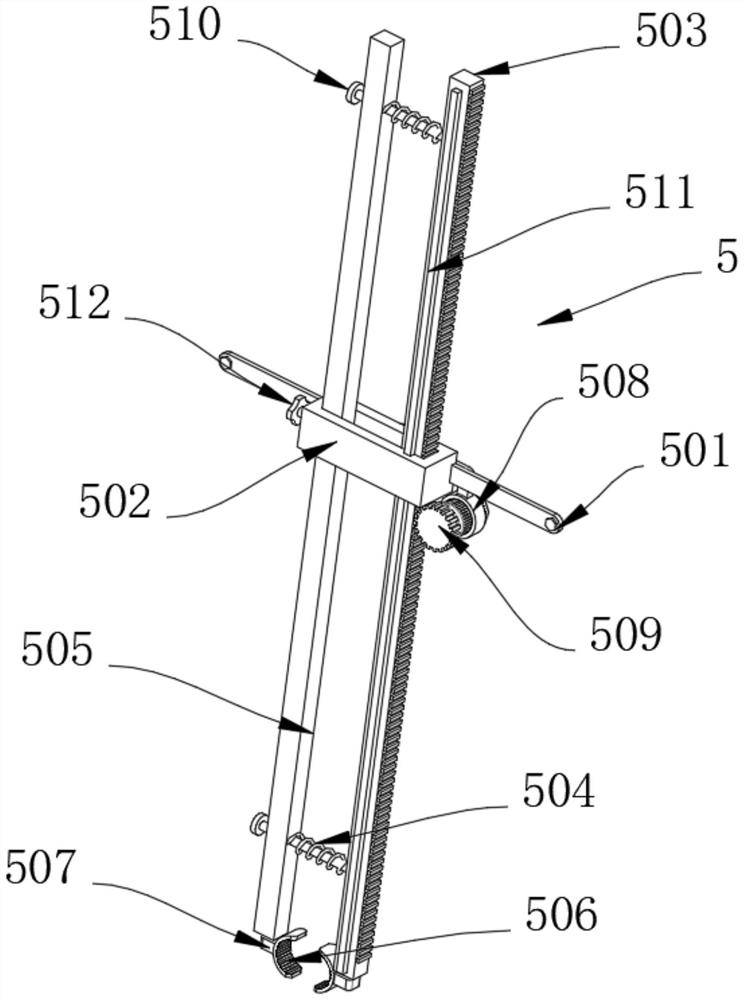

The invention provides a water conservancy pipeline desilting device, and relates to the technical field of desilting equipment, the water conservancy pipeline desilting device comprises a rack and a conveying structure, the upper end of the rack is provided with a machine body, the surface of the rack is fixedly connected with a partition plate, the upper end of the rack is provided with a pipe winding device, and the arc surface of the pipe winding device is wound with a water pipe; one end of the water pipe is installed on the machine body, a spray head is installed at the other end of the water pipe, a conveying structure is arranged on the surface of the machine frame and comprises two fixing plates, the two fixing plates are fixedly connected to the surface of the machine frame, and the ends, close to each other, of the two fixing plates are fixedly connected with a square frame. A rack is slidably connected to the inner wall of the square frame, and a motor is fixedly connected to the side, close to the rack, of the square frame. According to the water conservancy pipeline dredging device, the problem that when a water conservancy pipeline below a small wellhead is subjected to dredging treatment, a water pipe and a spray head are inconvenient to quickly move to the position of the pipeline, and inconvenience is brought to operators is solved.

Owner:关蕾

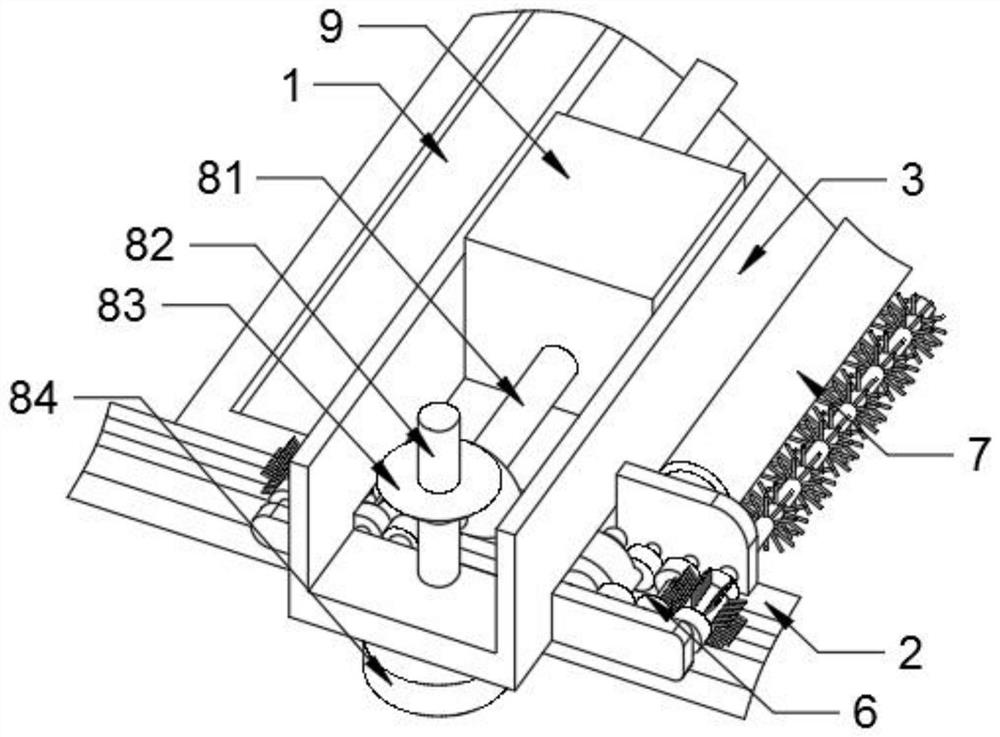

Ship bottom organism cleaning device

ActiveCN113650750AAchieving fit and adaptabilityHigh control precisionVessel cleaningHullsStructural engineeringCam

The invention discloses a ship bottom organism cleaning device, and belongs to the technical field of ships, the ship bottom organism cleaning device comprises a base, connecting plates are fixedly connected to two ends of one side of the base, a mounting plate is arranged on one side of the base, a knocking mechanism is fixedly connected between the connecting plates, and a cam is arranged on one side of the knocking mechanism. According to the cleaning device, the first electric push rod extends to drive a rod body on one side of the transmission rod to push the base to relatively deflect through the top transmission roller, so that the relative deflection angle can be adjusted, and the control capacity of the relative angle of traditional cleaning is effectively improved; the second electric push rod can be shortened to pull the fixing plate to drive the limiting plate to be attached to limiting teeth on the outer wall of the limiting roller downwards through the first sliding rod for limiting, control over the relative deviation angle of the base is achieved, cleaning and attaching fit at the same angle in a part of areas are met, and the attaching adaptability to the curvature of the outer vertical face of the ship body is effectively achieved.

Owner:南通宇合睿船舶科技有限公司

Electroplating device for circuit board production

ActiveCN112165785ASolve the problem that the height must have certain requirementsAvoid wastingConductive pattern polishing/cleaningElectrical componentsDrive shaftEngineering

The invention relates to the technical field of electroplating, and discloses an electroplating device for circuit board production, which comprises an electroplating bath, a transmission mechanism, aconveying line, telescopic equipment and a clamping mechanism, the transmission mechanism is arranged on the electroplating bath, the conveying line is arranged above the transmission mechanism, thetelescopic equipment is arranged on the conveying line, and the clamping mechanism is arranged on a transmission shaft of the telescopic equipment. The clamping mechanism comprises a top plate, two side plates, a rotating shaft and a clamping ring, the top surface of the top plate is fixedly connected with a transmission shaft of the telescopic equipment, sliding grooves are formed in the bottom surface of the top plate, the two side plates are connected with the sliding grooves in a sleeving mode, through grooves A and movable grooves are formed in the corresponding surfaces of the two side plates, and holes are formed in the back surfaces of the movable grooves; the rotating shaft is sleeved in the holes; the front face end of the rotating shaft is fixedly connected with the clamping ring; by arranging the clamping mechanism, the clamping process before electroplating of the circuit board can be carried out from a low position, and the problem that a clamp of an existing electroplating device is high in installation position, so that certain requirements for the height of staff must be met is solved.

Owner:台山市图今智控技术有限公司

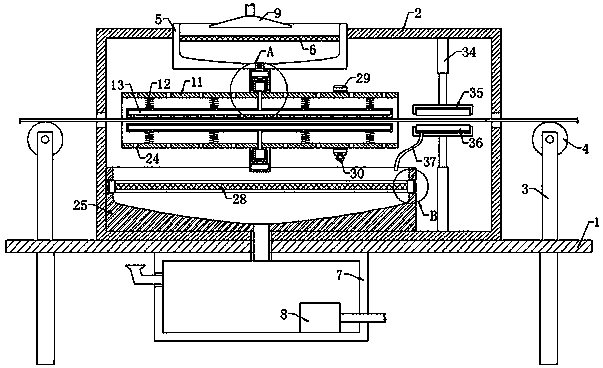

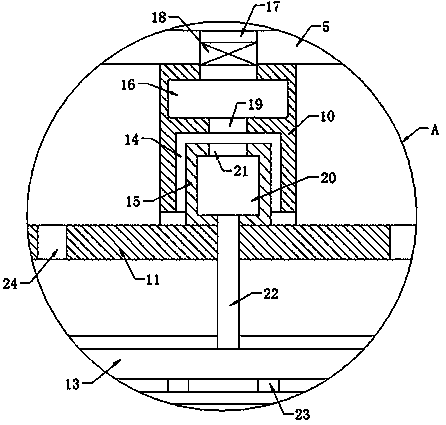

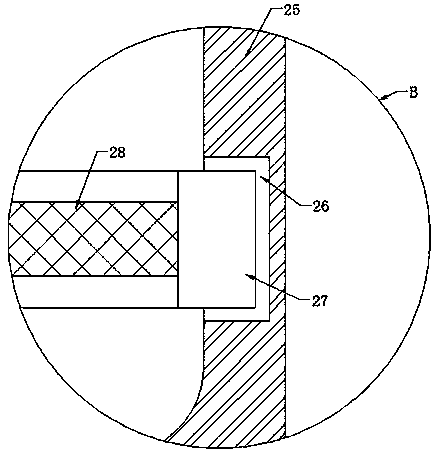

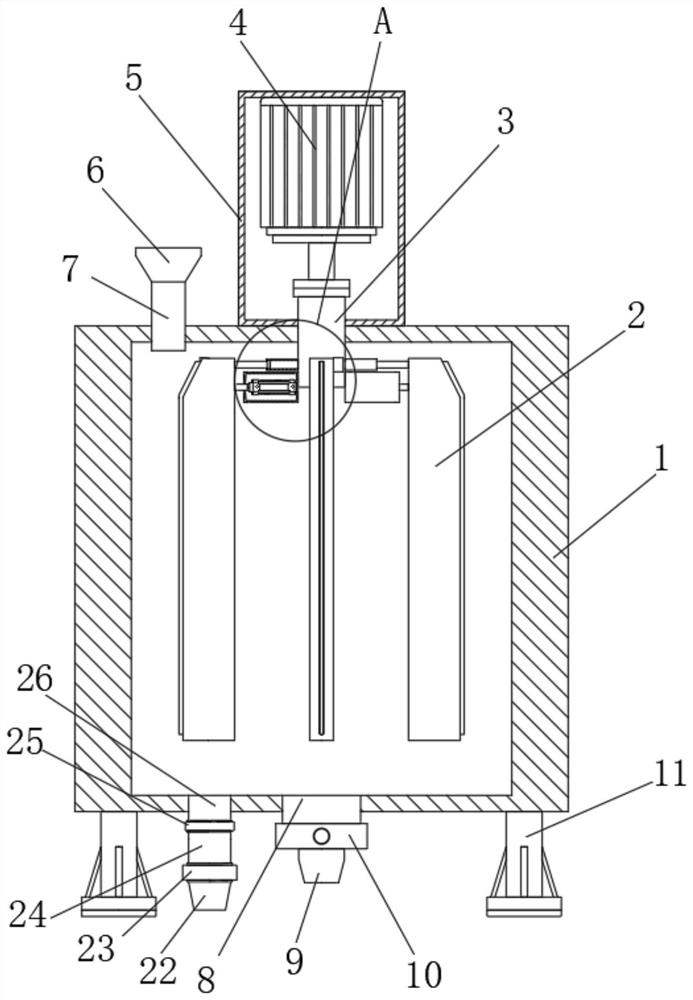

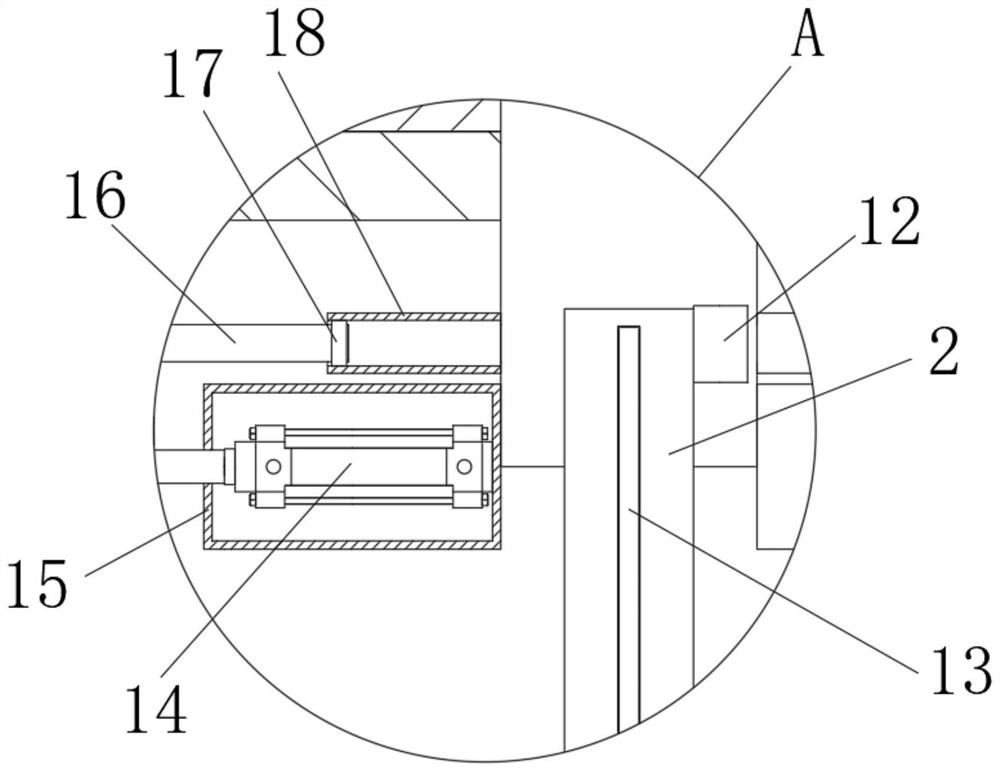

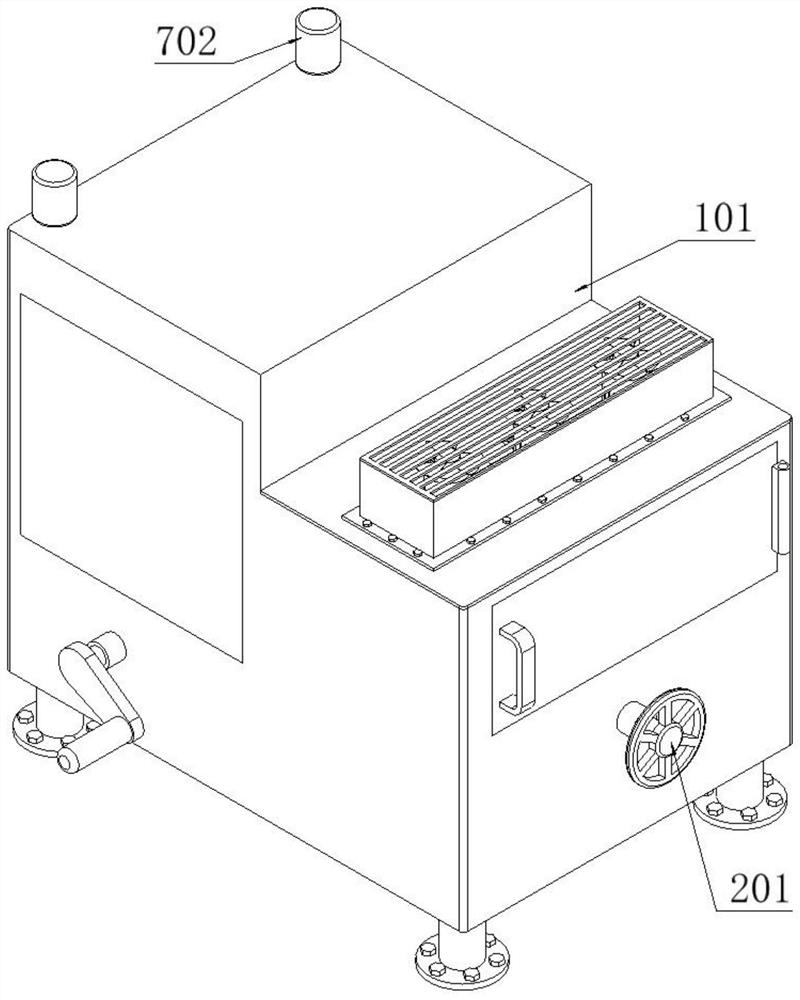

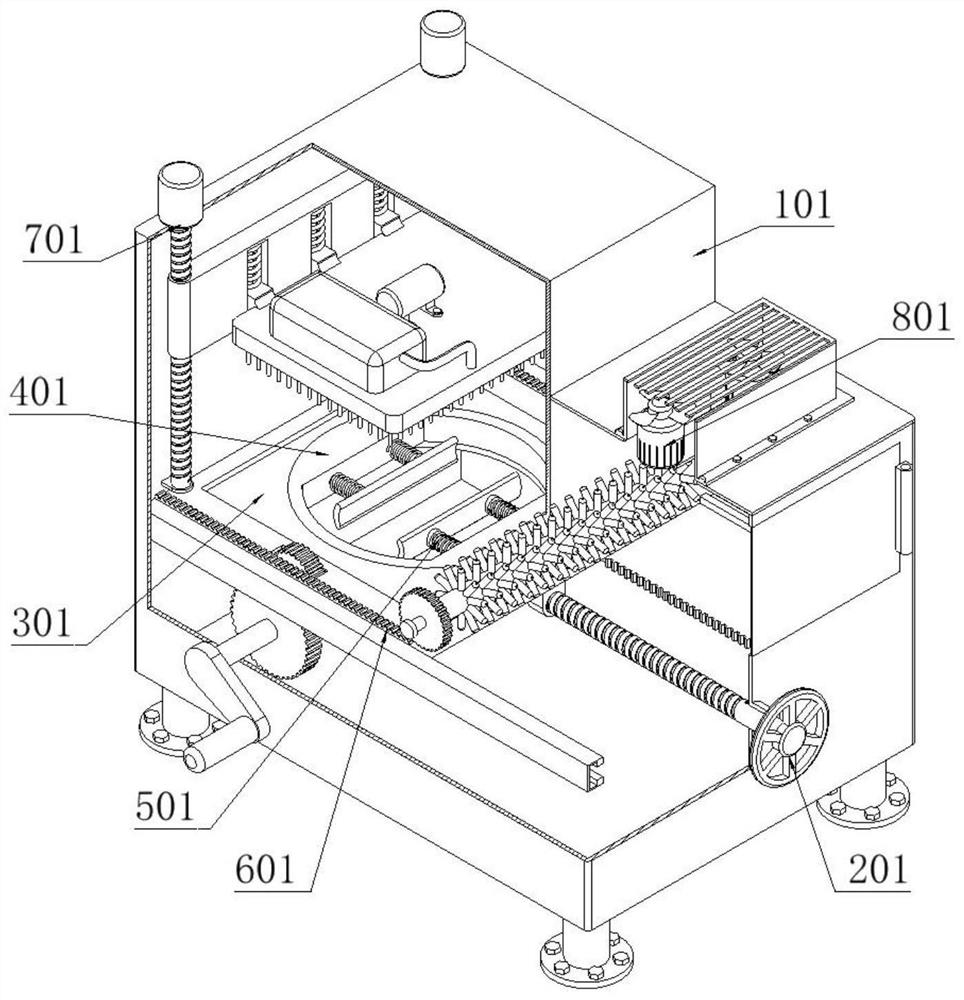

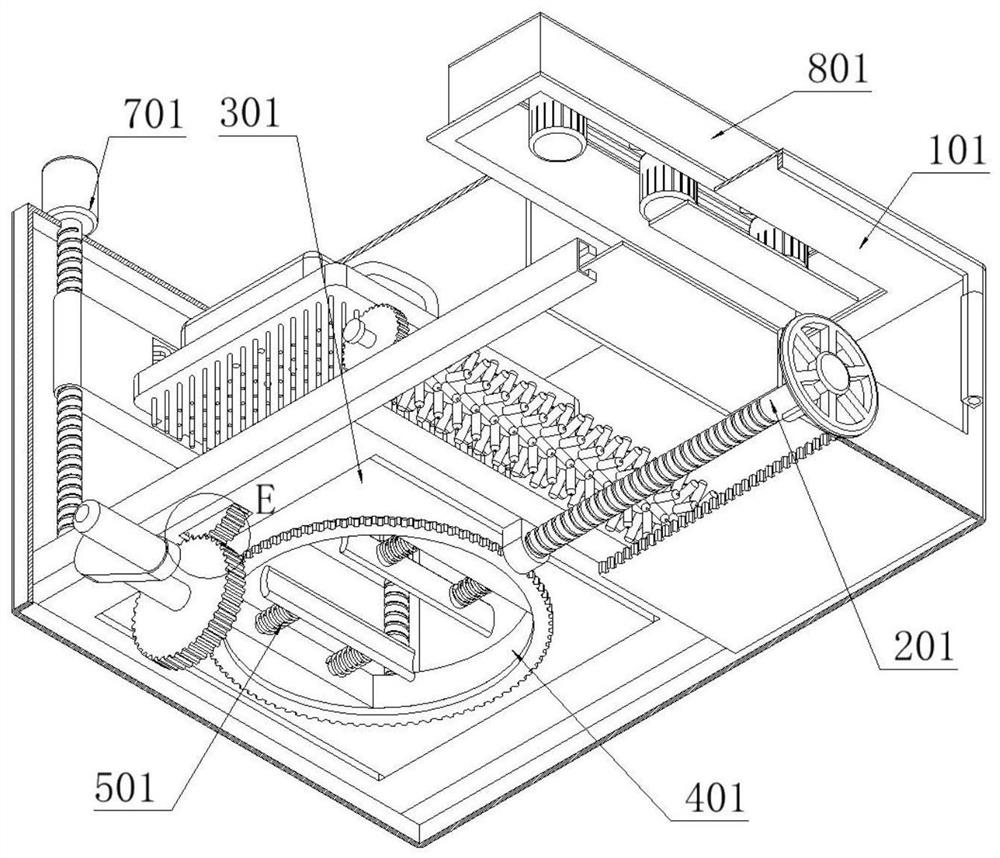

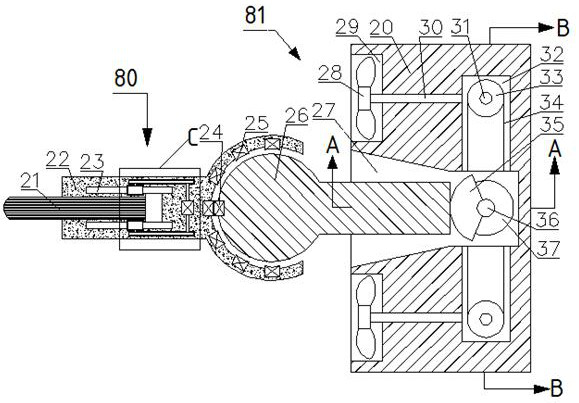

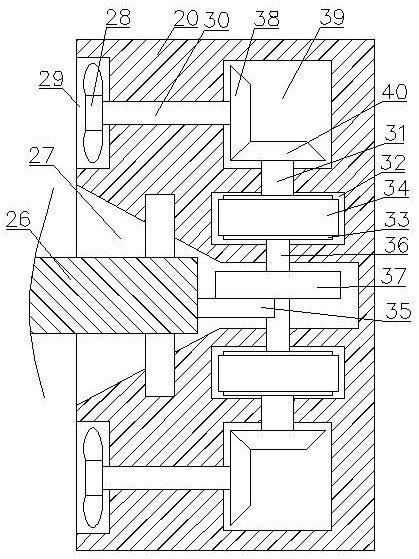

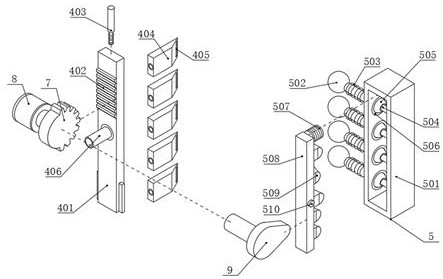

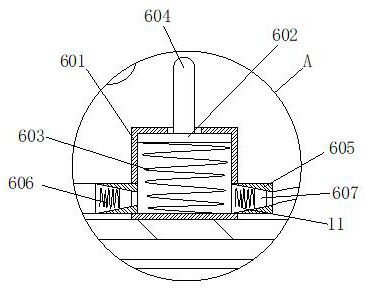

Efficient conductive slurry production device

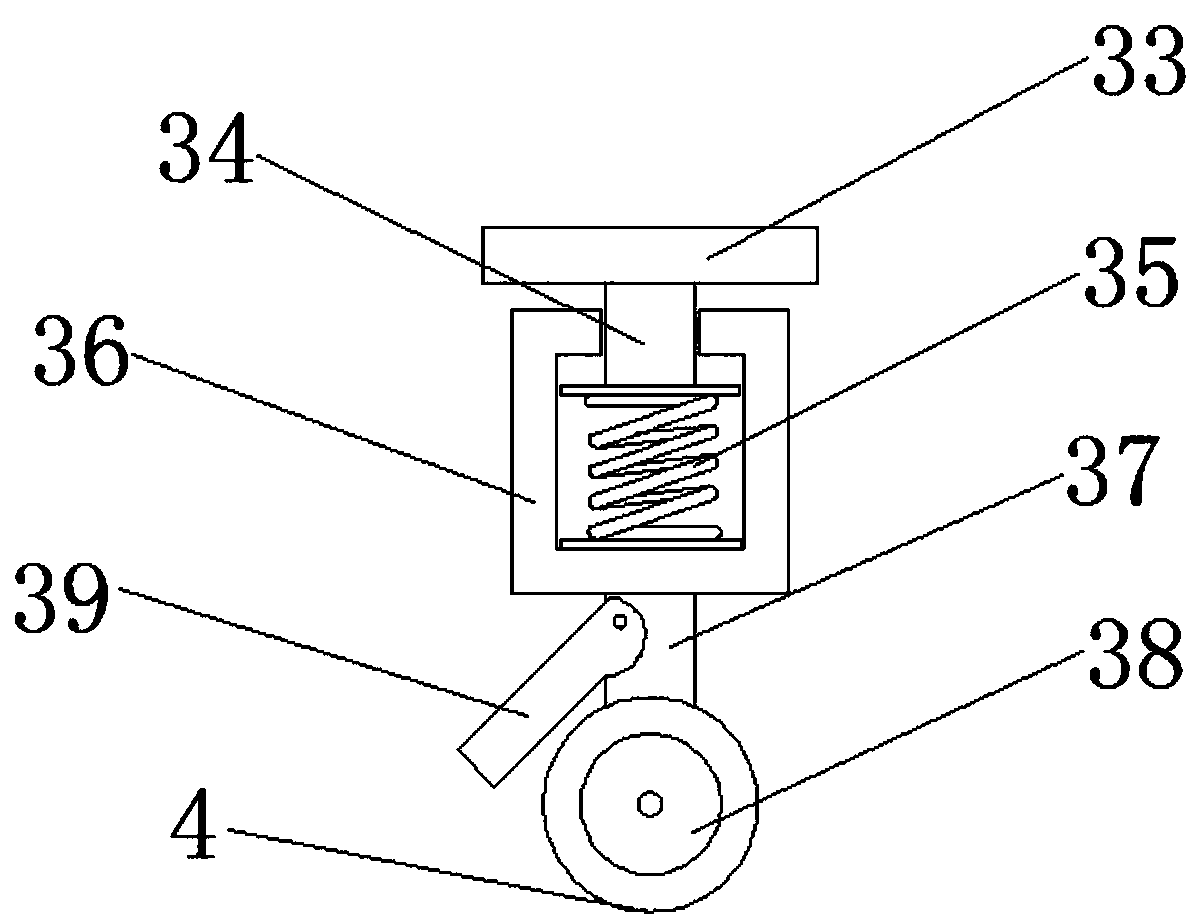

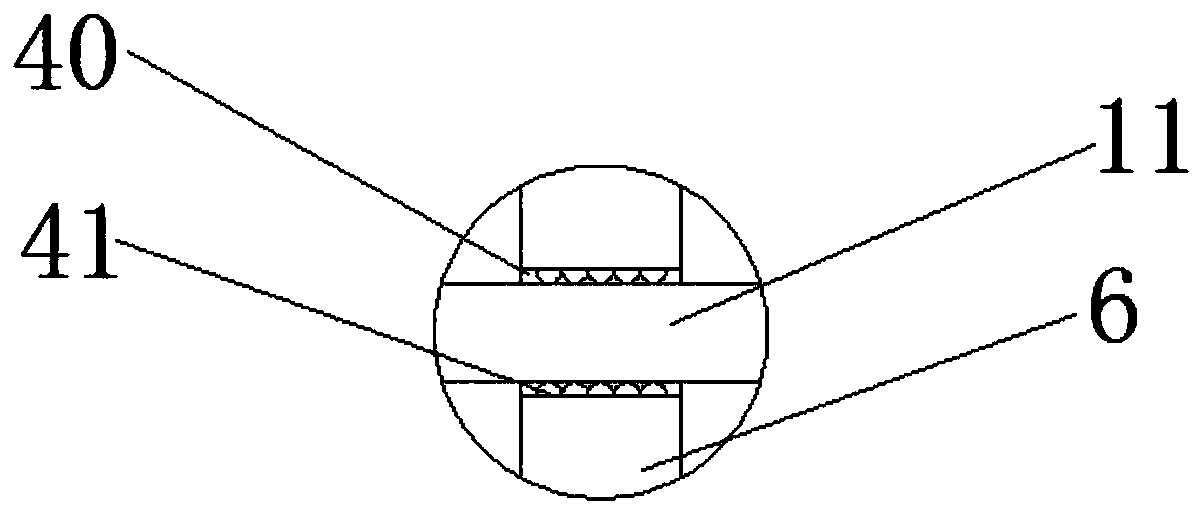

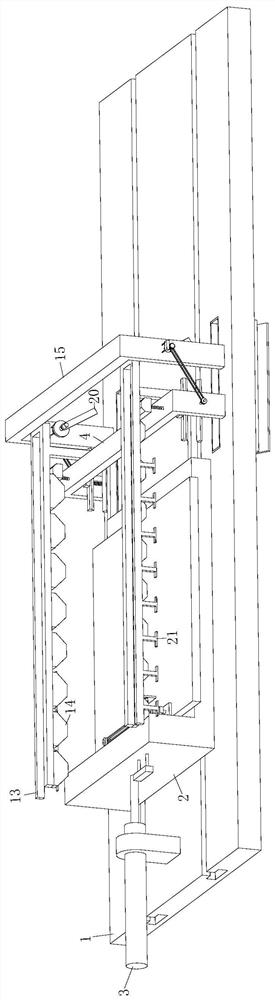

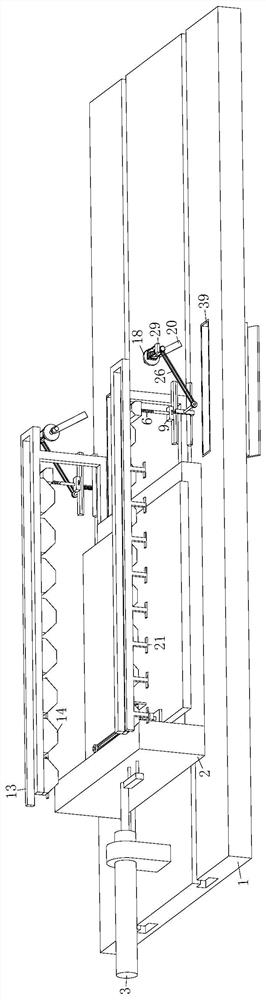

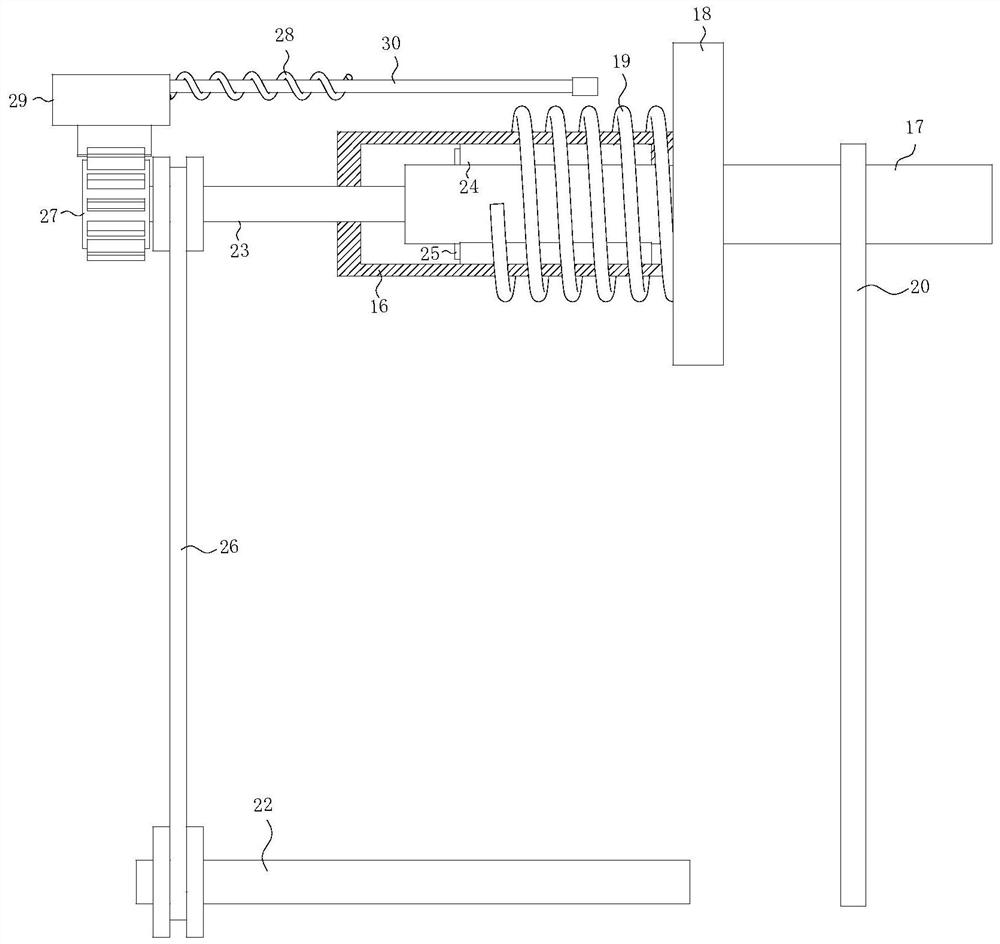

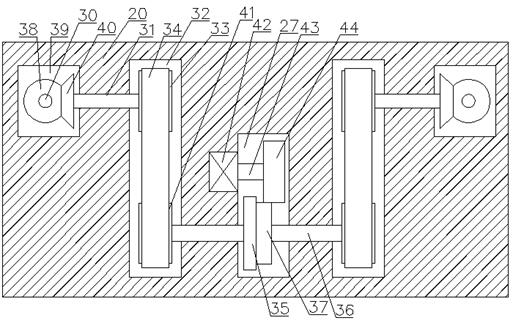

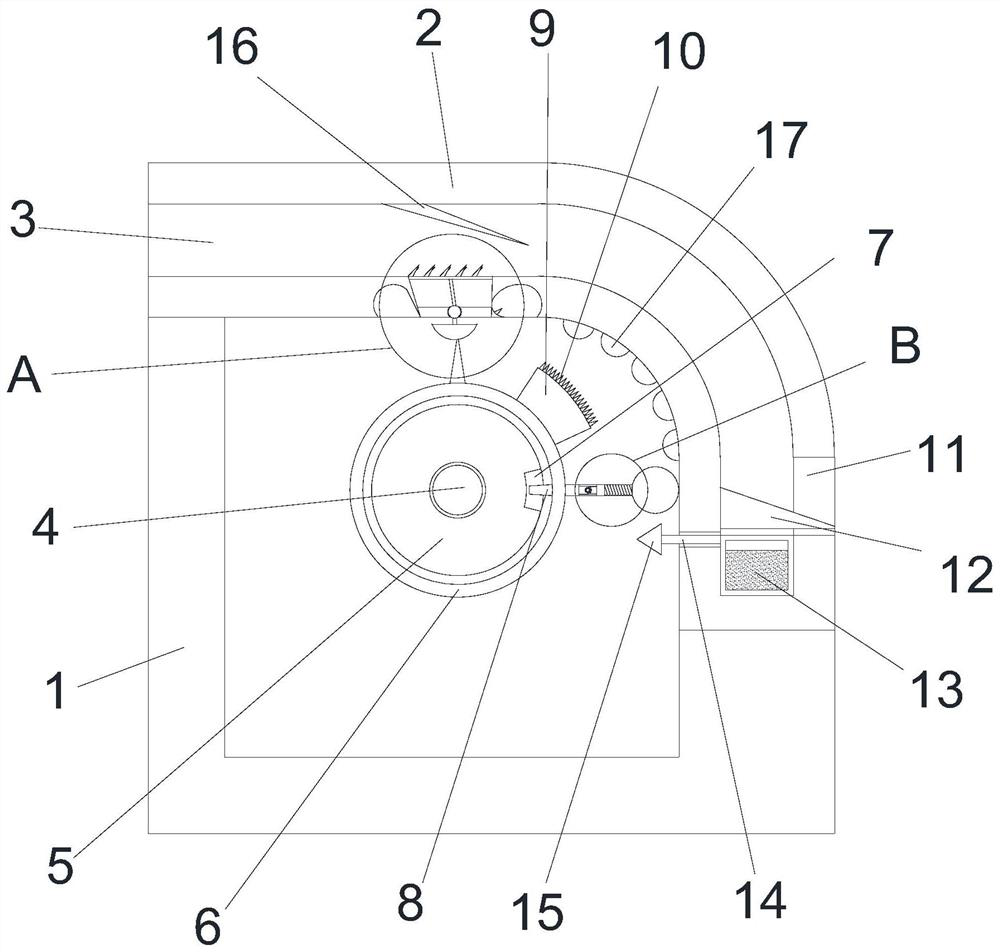

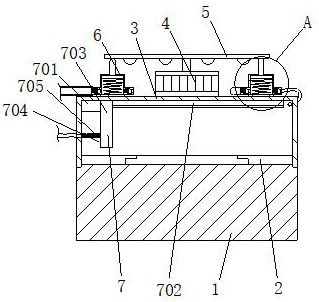

InactiveCN112892369AImprove cleaning efficiencyIncrease cleaning intensityTransportation and packagingRotary stirring mixersElectric machineGear wheel

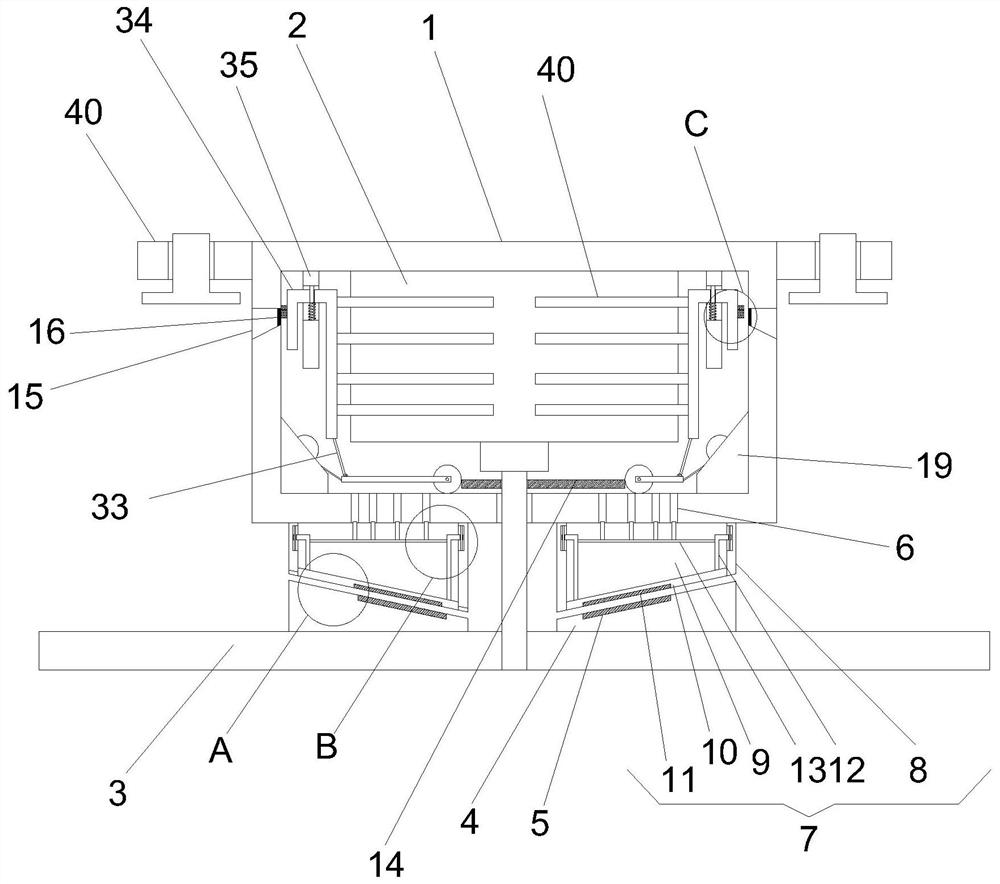

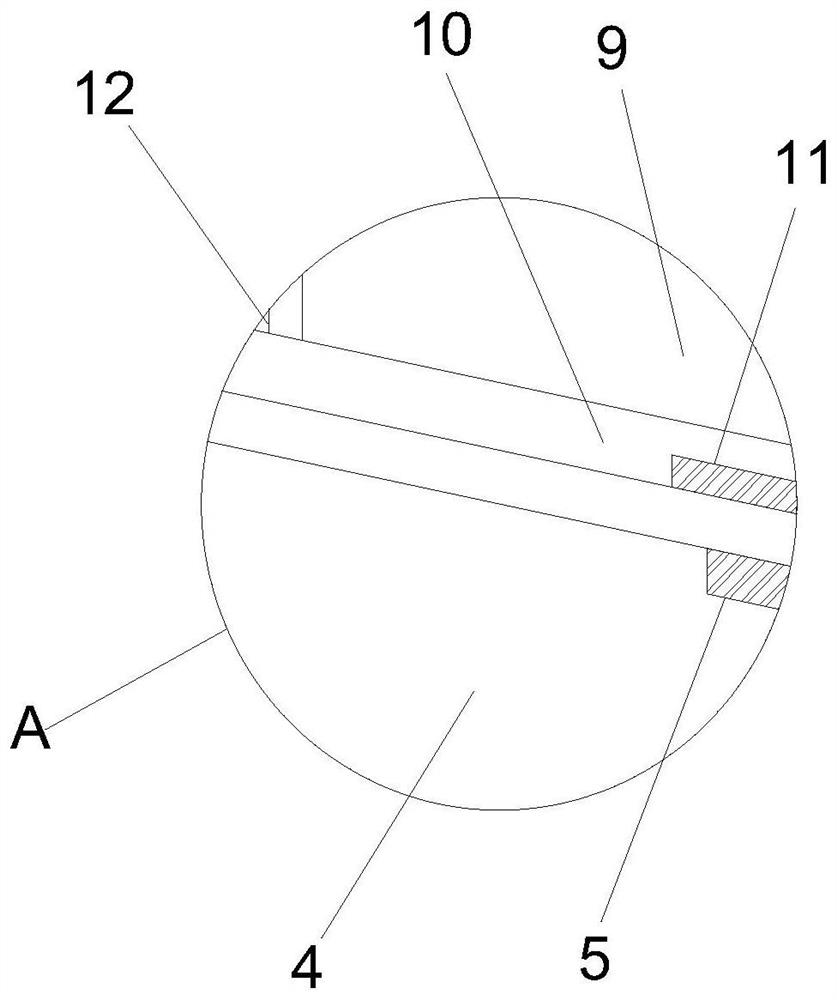

The invention provides an efficient conductive slurry production device, which comprises a stirring device, a case is fixedly connected to the outer wall of the top of the stirring device, and a rotating motor is fixedly mounted on the inner wall of the top of the case. The production device is equipped with a telescopic air cylinder, a sleeve, a telescopic rod, a seal ring, a rotating motor, a connecting shaft, a rotating gear, a scraping plate and the like, in order to conveniently clean the inner wall of the stirring device, an output shaft of the telescopic air cylinder drives a stirring rod to move towards the inner wall of the stirring device, then an output shaft of the rotating motor drives the rotating gear to rotate, the rotating gear moves the scraping plate out of the stirring rod, and the output shaft of the rotating motor drives the stirring rod to rotate, the inner wall of the stirring device is cleaned, then a proper amount of water and a cleaning agent are poured for stirring and scouring, cleaning of the inner wall can be completed, the cleaning efficiency is high, the cleaning strength is large, and the sleeve and the telescopic rod are used for supporting and fixing the stirring rod and carrying out force dividing on an output shaft of the telescopic air cylinder.

Owner:无锡东恒新能源科技有限公司

Cleaning device for welded circuit board

InactiveCN113522807ASafe to usePrevent splashDrying gas arrangementsDirt cleaningRotational axisEngineering

Owner:深圳市建宏达照明电路有限公司

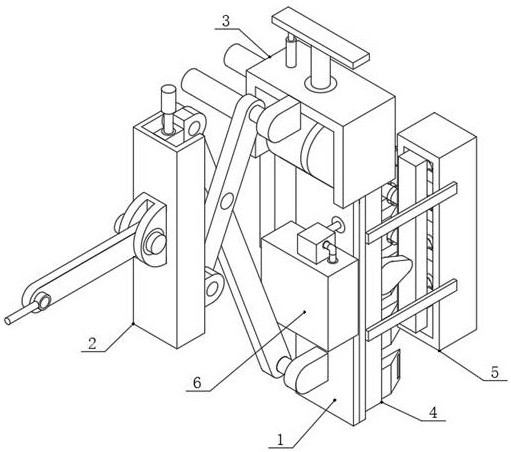

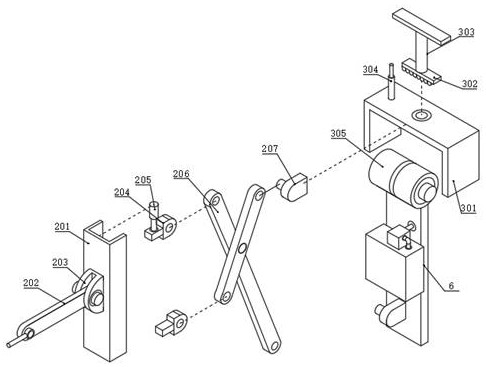

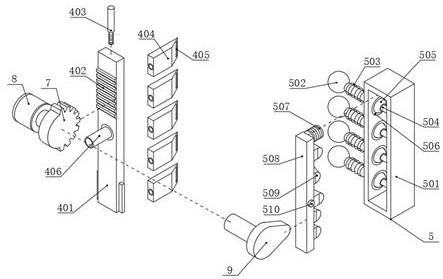

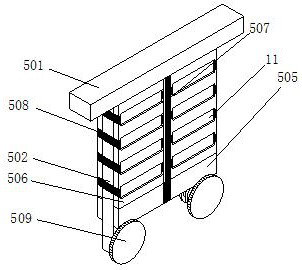

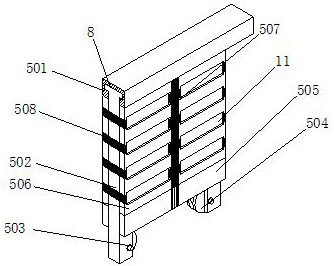

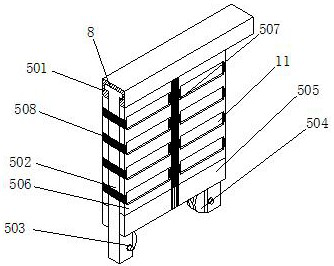

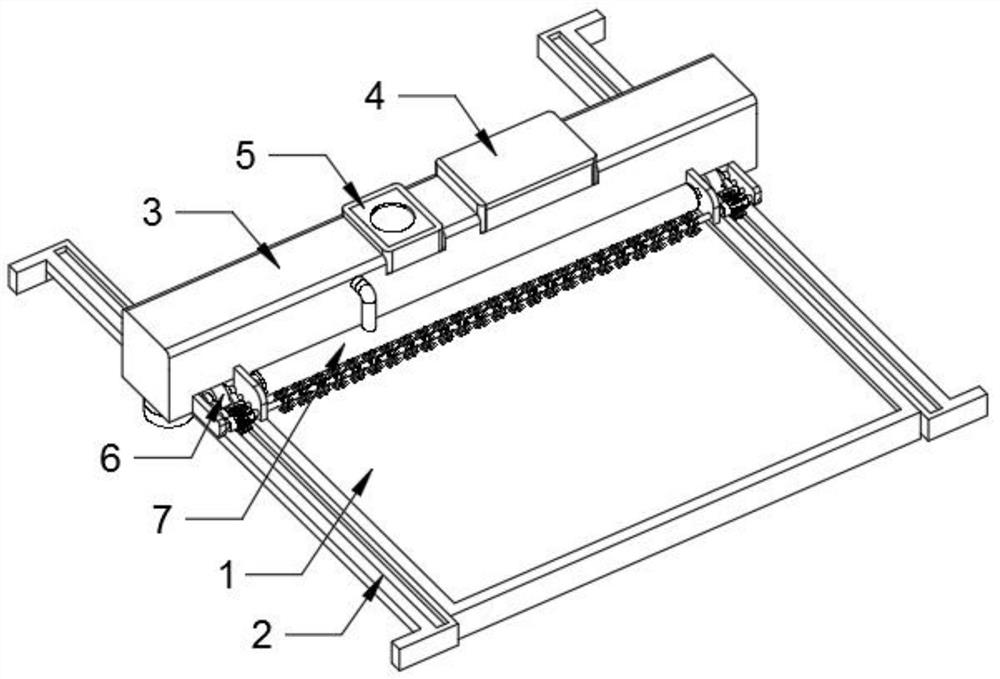

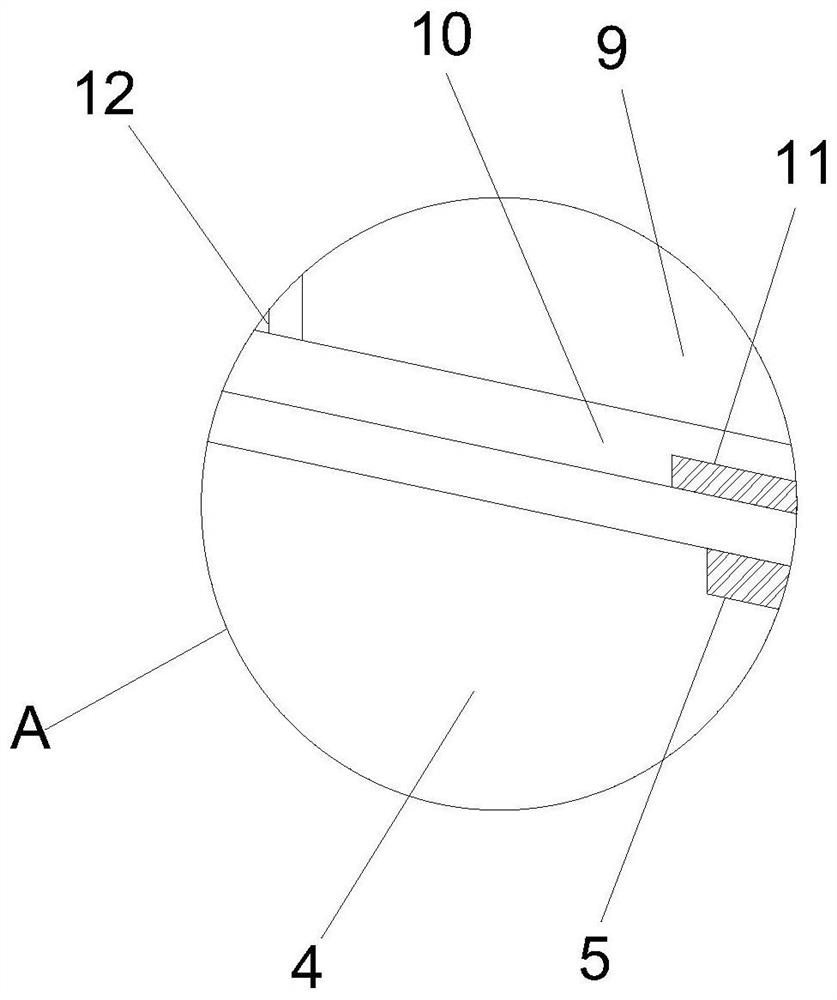

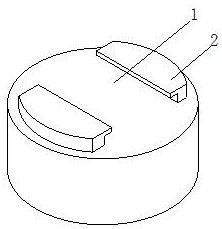

Adjustable automatic cleaning device for accumulated material at edge of side plate

ActiveCN113500666AIncrease cleaning intensityImprove aestheticsPlastic recyclingProfiling/shaping machinesMechanical engineeringWood plank

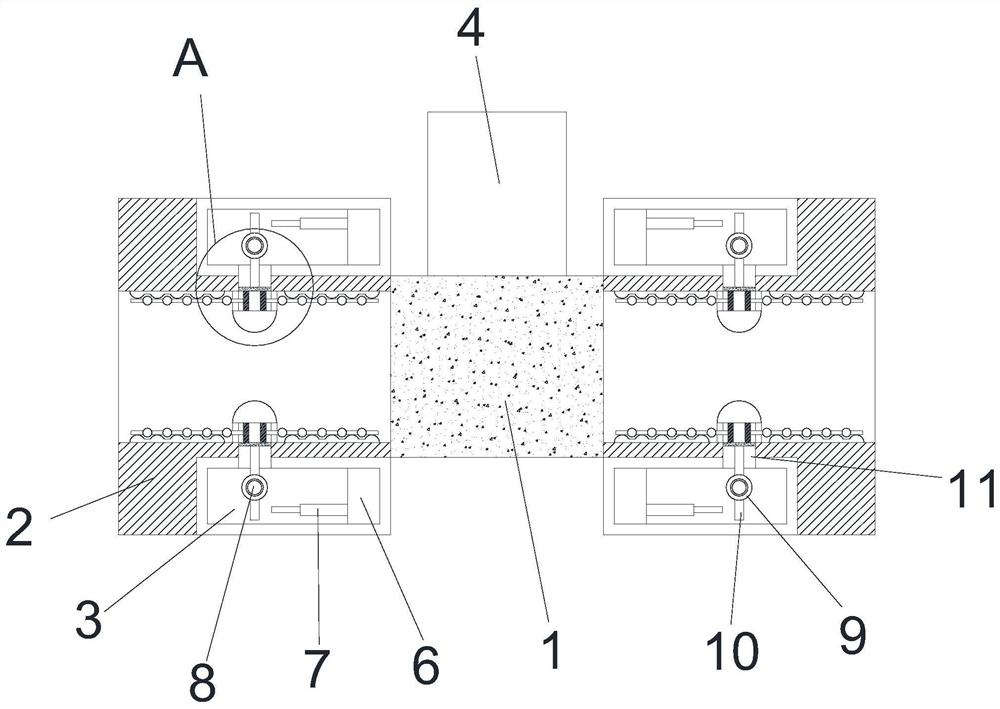

The invention discloses an adjustable automatic cleaning device for accumulated material at an edge of a side plate in the technical field of wood board processing. The adjustable automatic cleaning device comprises a mounting plate, an L-shaped push plate is slidably connected to the top end of the mounting plate, an air cylinder is fixedly connected to the left end of the L-shaped push plate, the air cylinder is fixedly connected to the top end of the mounting plate, a positioning mechanism is arranged at the top end of the L-shaped push plate, and a shearing mechanism and a scraping mechanism are arranged at the top end of the mounting plate. By arranging the shearing mechanism, wood difficult to remove on a side edge plate is sheared and cut up, the adhesive force between the wood and the side edge plate is reduced, then residual wood at the side edge plate is scraped away through the scraping mechanism, the cleaning strength of the side edge plate is improved, and the attractiveness of a wood plate is improved; and meanwhile, the device does not need to be manually cleaned, so that the labor intensity is reduced, and the working efficiency is improved.

Owner:安徽建鑫新型墙材科技有限公司

An electroplating device for circuit board production

ActiveCN112165785BSolve the problem that the height must have certain requirementsProblems affecting accumulation in the plating tankConductive pattern polishing/cleaningElectrical componentsDrive shaftEngineering

The invention relates to the technical field of electroplating, and discloses an electroplating device for circuit board production, including an electroplating tank, a transmission mechanism, a conveying line, telescopic equipment and a clamping mechanism, the transmission mechanism is arranged on the electroplating tank, and the conveying line is arranged on the transmission mechanism Above, telescopic equipment is set on the conveying line. The clamping mechanism is set on the transmission shaft of the telescopic equipment. The clamping mechanism includes a top plate, a side plate, a rotating shaft and a clamp ring. The top surface of the top plate is fixedly connected with the transmission shaft of the telescopic equipment. The top plate The bottom surface is provided with a chute, the number of side plates is two and both of them are socketed with the chute, and the corresponding surfaces of the two side plates are provided with a through groove A and a movable groove, and a hole is opened on the back of the movable groove and the rotating shaft is socketed in the hole , the front end of the rotating shaft is fixedly connected with a clamp ring. Through the setting of the clamping mechanism, the clamping process of the circuit board before electroplating can be carried out from a low position, which solves the problem that the height of the staff must be affected by the high installation position of the fixture in the existing electroplating device. Certainly asked questions.

Owner:台山市图今智控技术有限公司

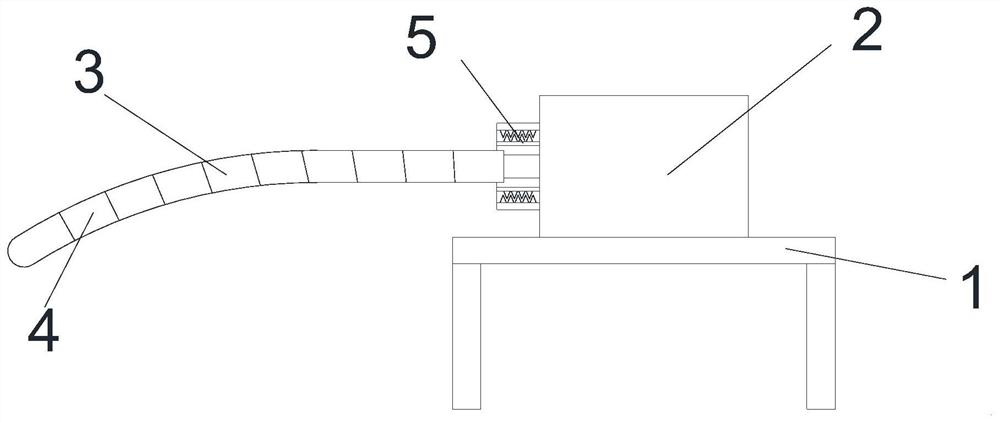

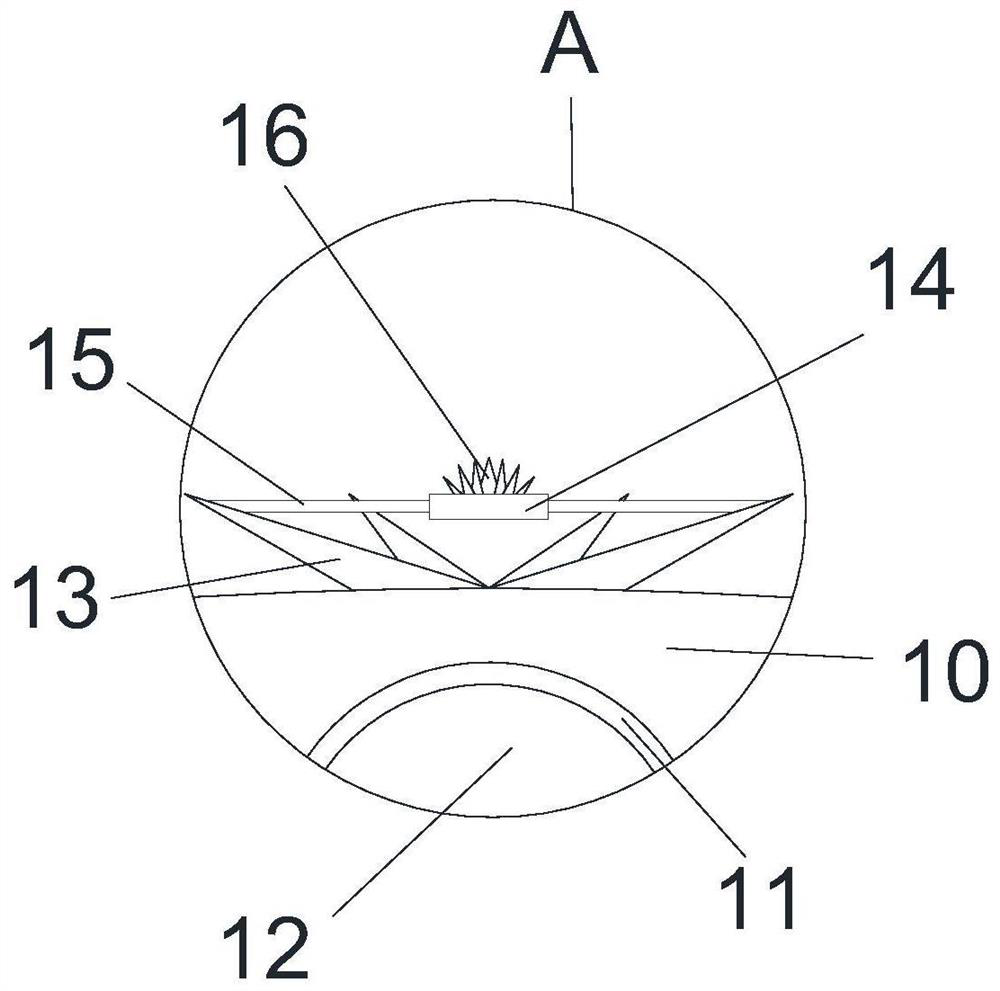

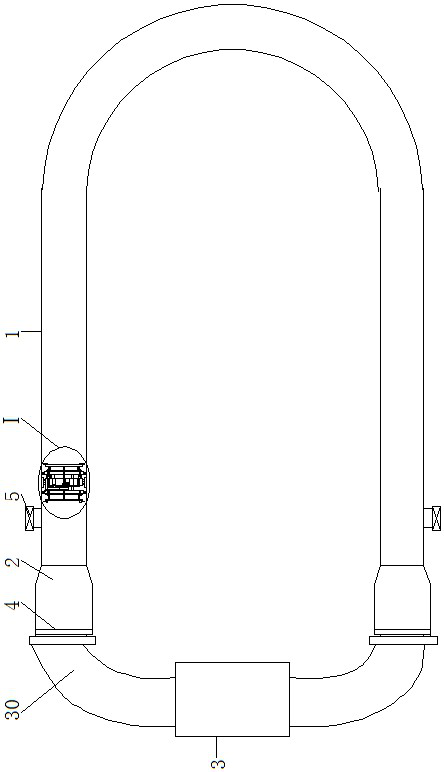

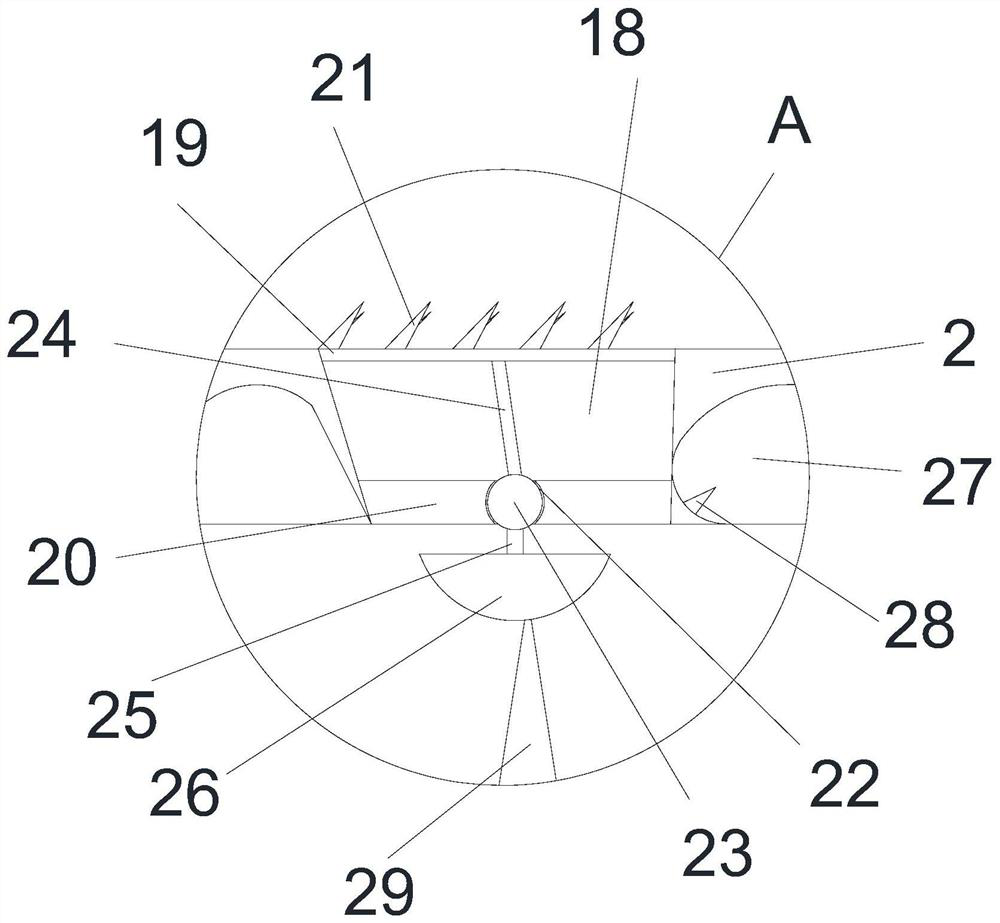

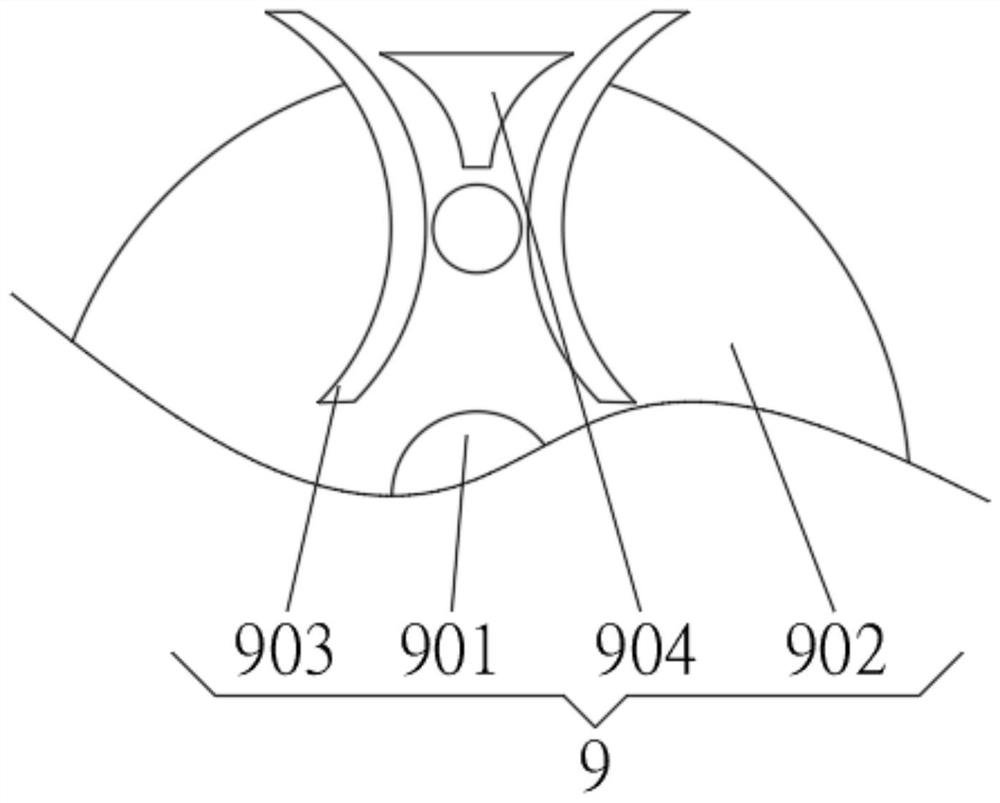

Pig intestine cleaning device

ActiveCN112616897AImprove cleaning efficiency and cleaning intensityEasy to break awayAnimal intestine cleaningEngineeringAnatomy

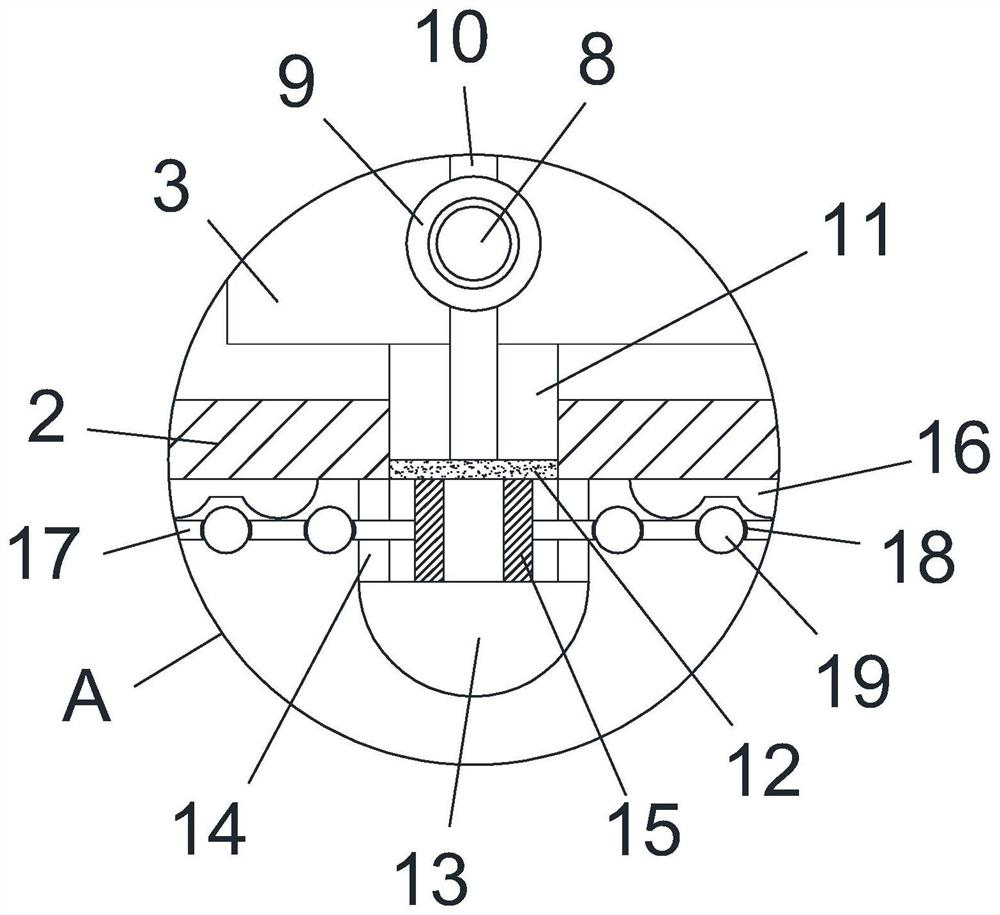

The invention discloses a pig intestine cleaning device, and relates to the field of food processing. The pig intestine cleaning device comprises a base, wherein an equipment box is fixedly mounted at the top of the base; control equipment is arranged in the equipment box; a cleaning shaft is arranged at the left end of the equipment box; the cleaning shaft comprises a segmented pipe; and the cleaning shaft is formed by combining the segmented pipe in a circular arc-shaped bending manner. According to the pig intestine cleaning device disclosed by the invention, the rotating manner of the cleaning shaft is special, so that when the segmented pipe cleans the inner wall of a pig intestine, an adjusting plate on the outer wall of the segmented pipe is influenced by rotating force and slapping force of the inner wall of the pig intestine, and adaptive inclination angle adjustment is performed through a movable groove and a movable ball; and besides, the adjusting plate is influenced by centrifugal force, and the adjusting plate can generate local rotation on the movable ball, so that a cleaning scraping cone can perform nonlinear scratching treatment on dirt on the inner wall of the pig intestine, and the dirt on the inner wall of the pig intestine is easy to separate.

Owner:伊美特(安徽)环保科技有限公司

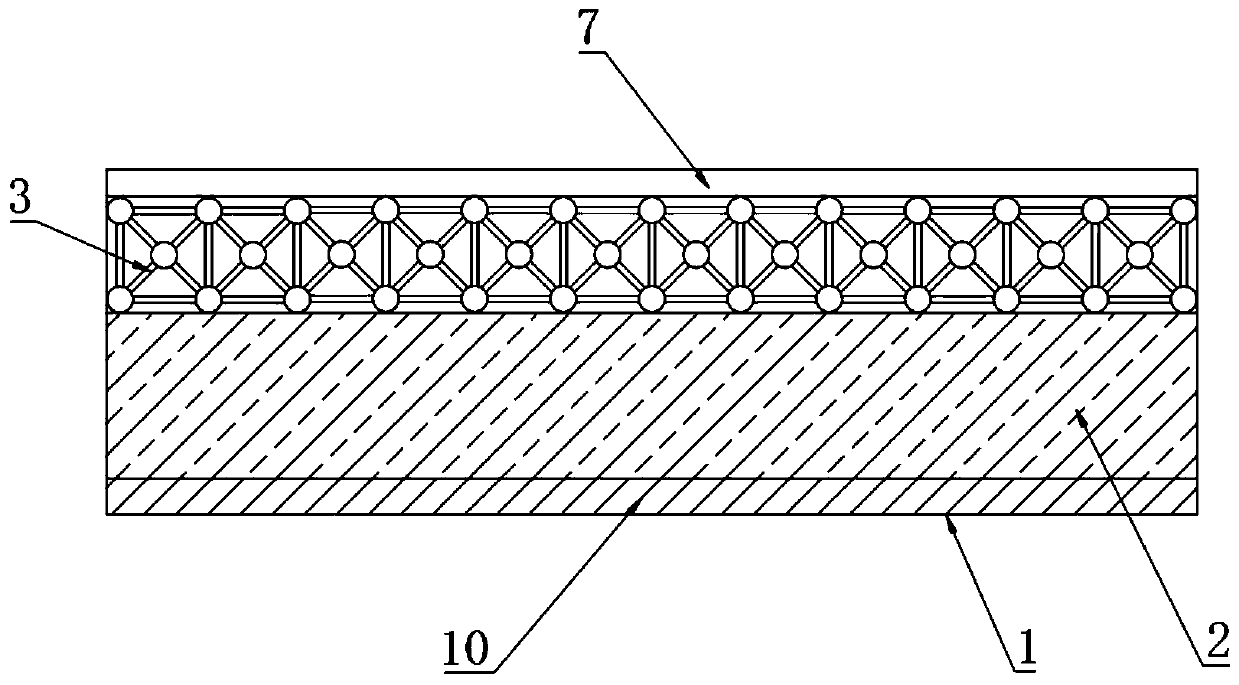

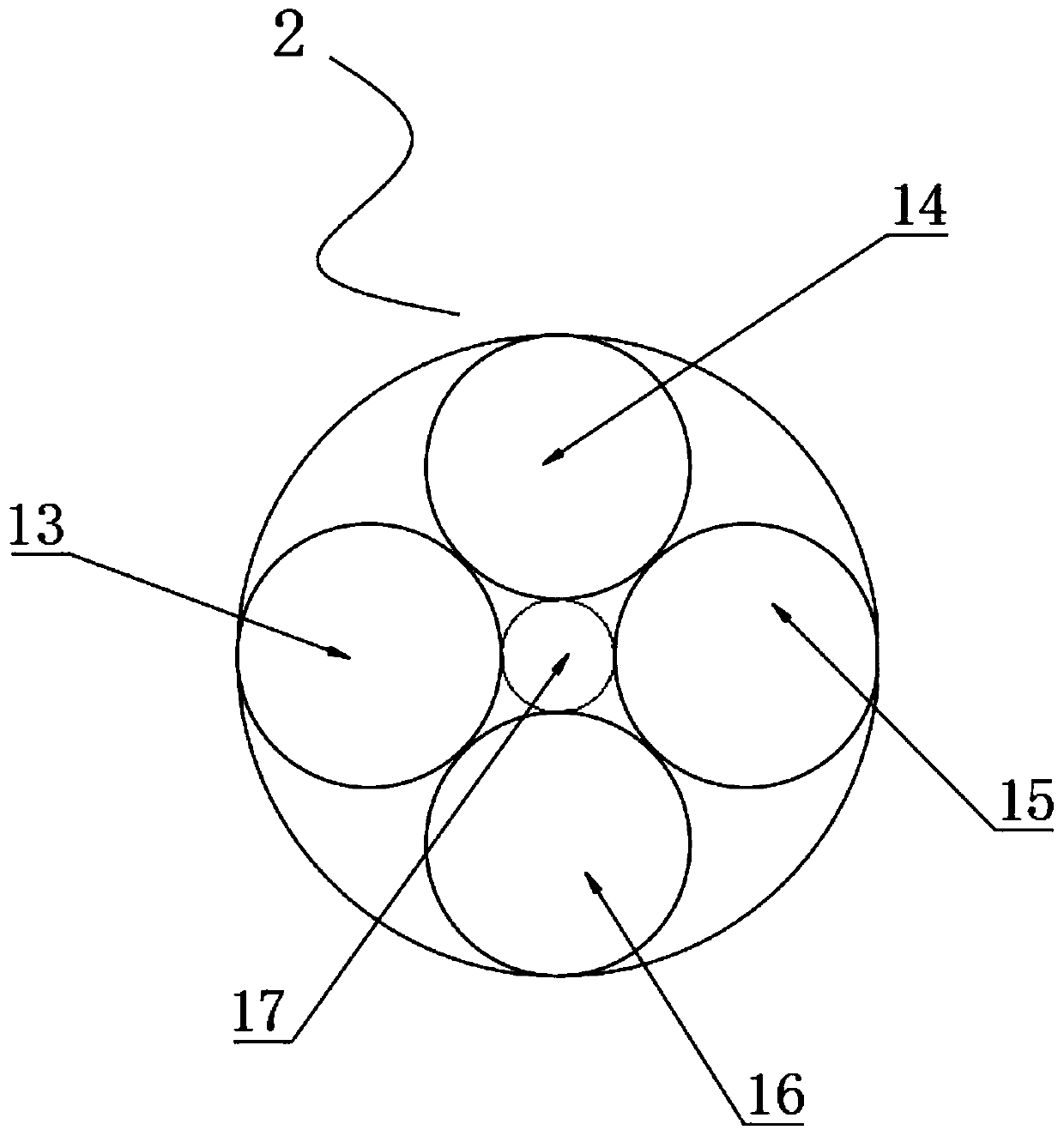

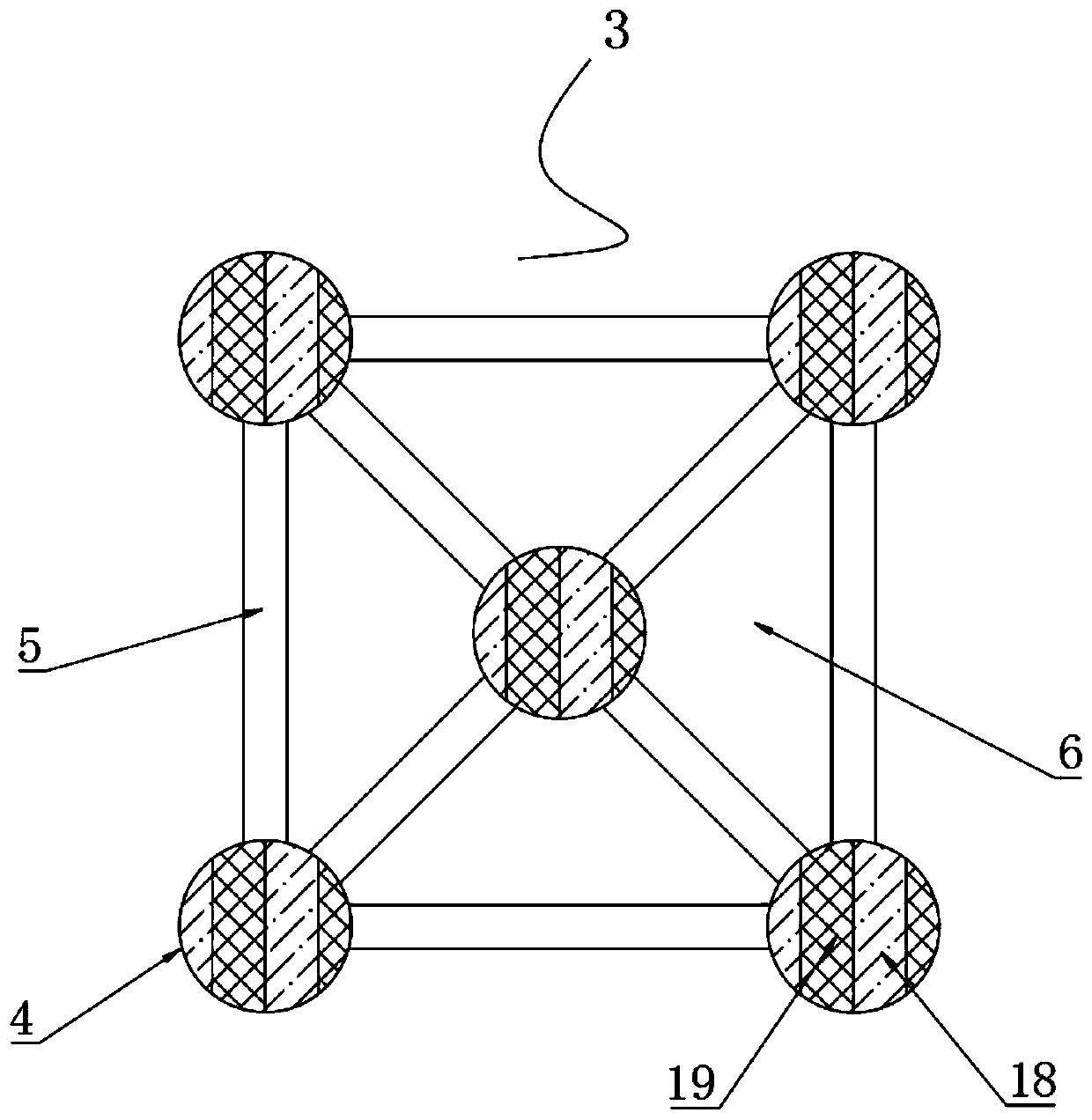

Flat comfortable fabric and bleaching and dyeing process thereof

InactiveCN111452449AEvenly distributedImprove water absorptionSynthetic resin layered productsCellulosic plastic layered productsFiberPolymer science

The invention discloses a flat comfortable fabric and a bleaching and dyeing process thereof. The fabric comprises a fabric body, wherein a matrix is arranged in and fixedly connected with of the fabric body; the top end of the matrix is fixedly connected with a breathable layer; water absorption balls fill in the breathable layer at equal intervals in a staggered manner; a connecting wire is fixedly arranged between and connected with every two water absorption balls; air vents are formed between the connecting wires; the top end of the breathable layer is fixedly connected with an outer layer; and the outer layer comprises viscose fibers and chemical fibers. The flat comfortable fabric is scientific and reasonable in structure and safe and convenient to use; the water absorption performance of the fabric is improved through pure cotton and terylene in the water absorption balls; multiple water absorption balls are fixedly connected and supported through the connecting lines, so the water absorption balls are evenly distributed in the fabric, and thus, the overall water absorption effect of the fabric is improved; in addition, the connecting lines are formed by weaving the polyurethane elastic fibers, so the elasticity and softness of the fabric are guaranteed; and meanwhile, the ventilation of the fabric is facilitated through the air vents.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

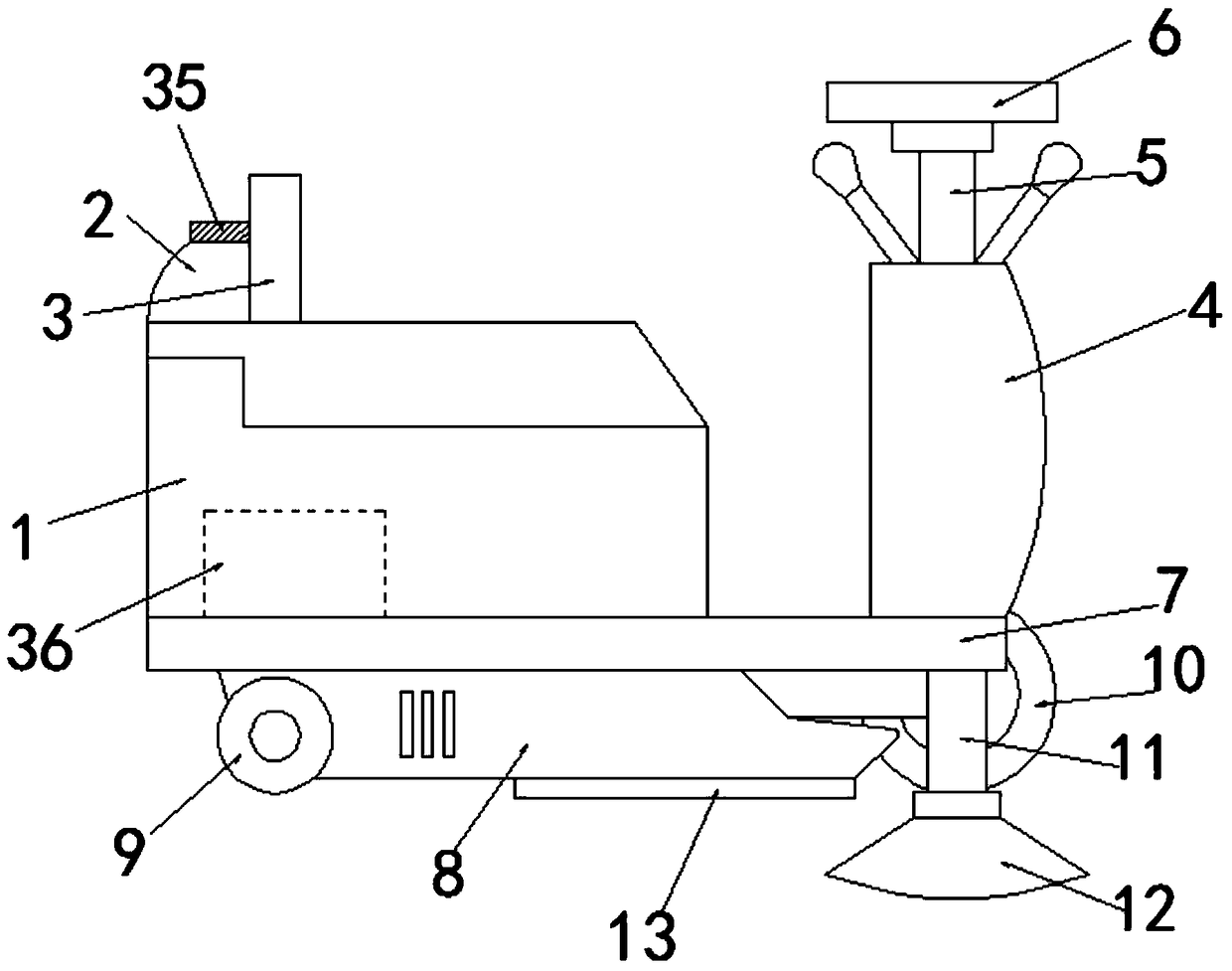

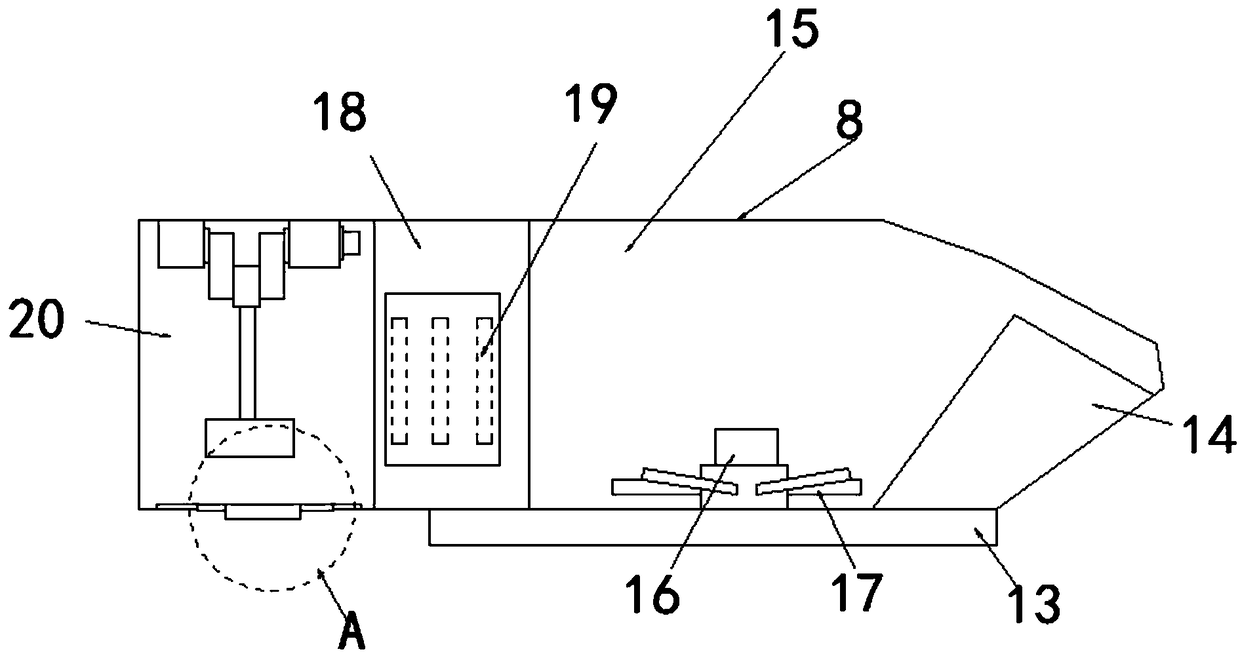

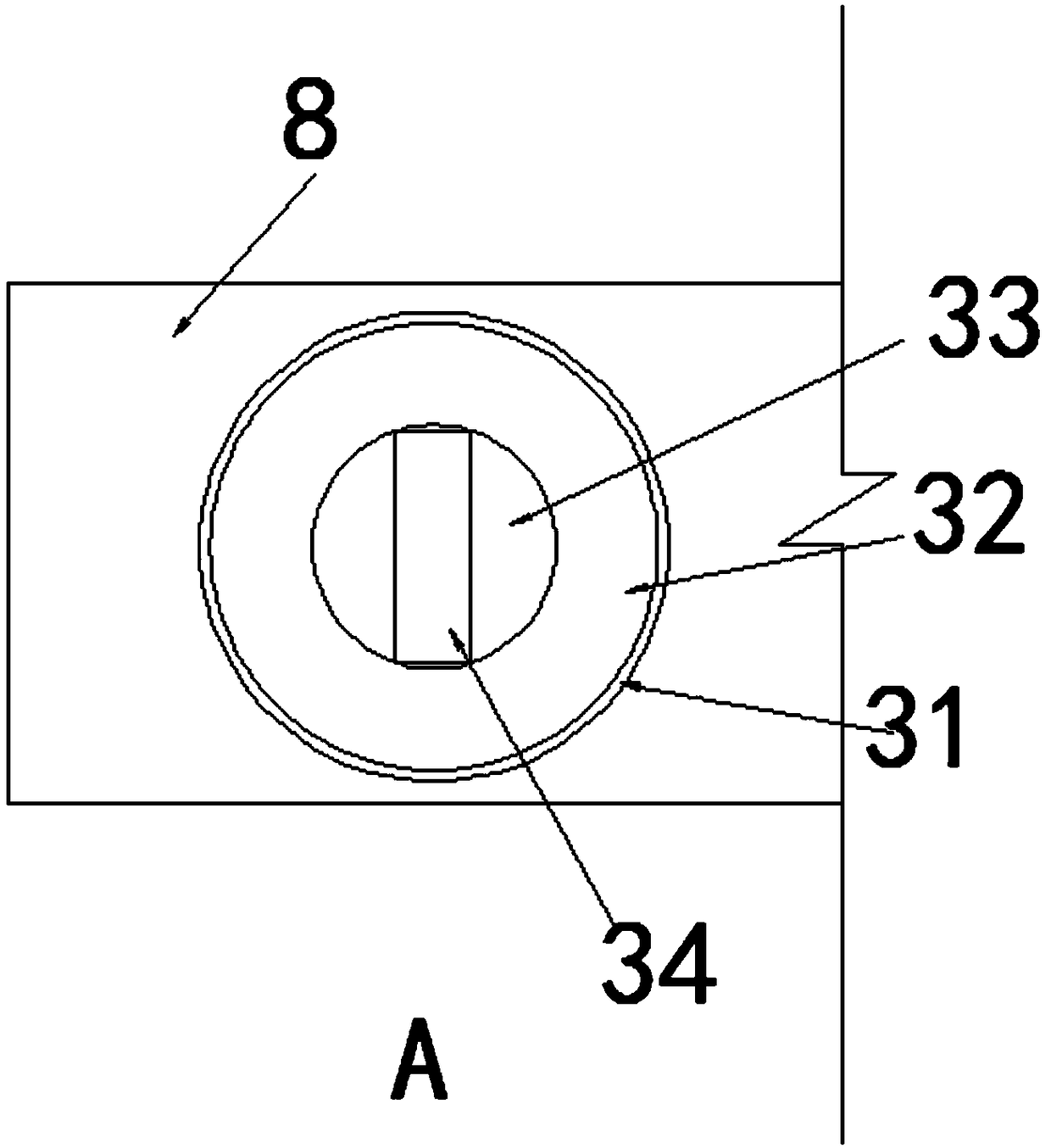

Energy-saving and eco-friendly sweeper capable of conveniently collecting dust

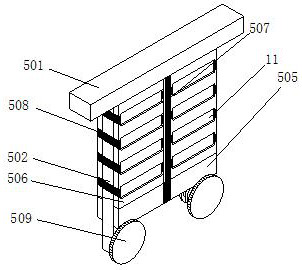

InactiveCN108720740AIncrease cleaning intensityEasy to collectCarpet cleanersFloor cleanersEngineeringSteering wheel

The invention discloses an energy-saving and eco-friendly sweeper capable of conveniently collecting dust. The sweeper comprises a box body, a backboard, a seat, a cabinet, a support rod, a steering wheel, a pedal, a collecting box, a back wheel, a front wheel, connecting rods and sweeping devices. Two ends of the top of the pedal are equipped with the box body and the cabinet. One side at the topof the box body is equipped with the backboard. One side of the backboard and one side close to the cabinet are provided with the seat. In addition, the bottom of the seat is fixed onto the other side at the top of the box body. The support rod is arranged at the top of the cabinet. The top of the support rod is equipped with the steering wheel. The connecting rods are arranged at two ends at oneside at the bottom of the pedal and located below the cabinet. The bottoms of the connecting rods are equipped with the sweeping devices. The front wheel is arranged in the middle on one side at thebottom of the pedal and located between the sweeping devices on two sides. The energy-saving and eco-friendly sweeper capable of conveniently collecting dust has the following beneficial effects: cleaning intensity of the sweeping machine is increased such that cleaning operation is performed more thoroughly.

Owner:吕寒肖

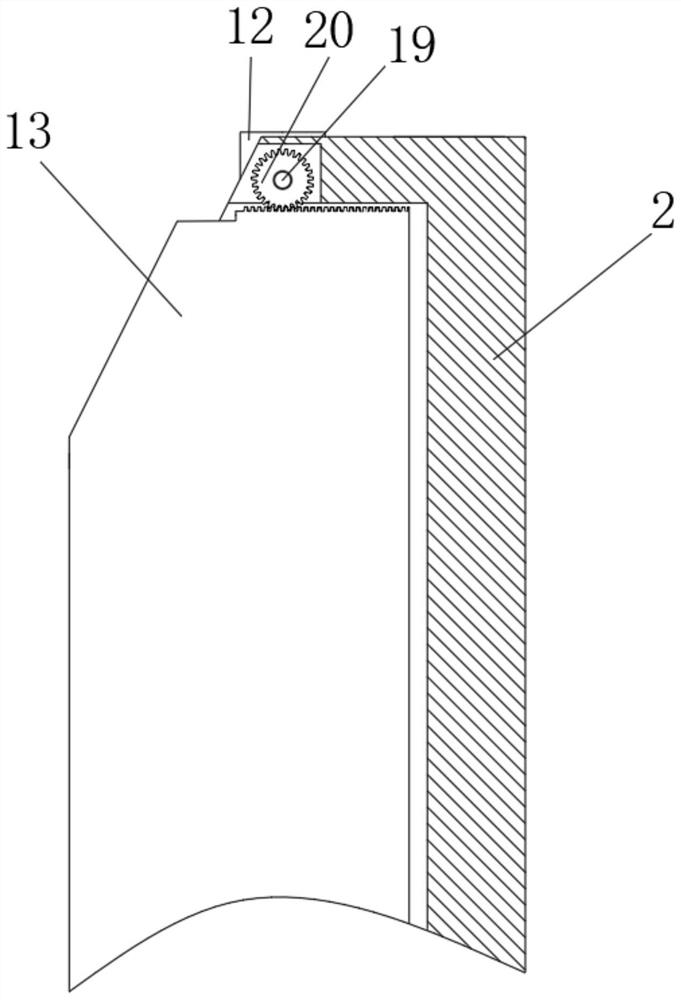

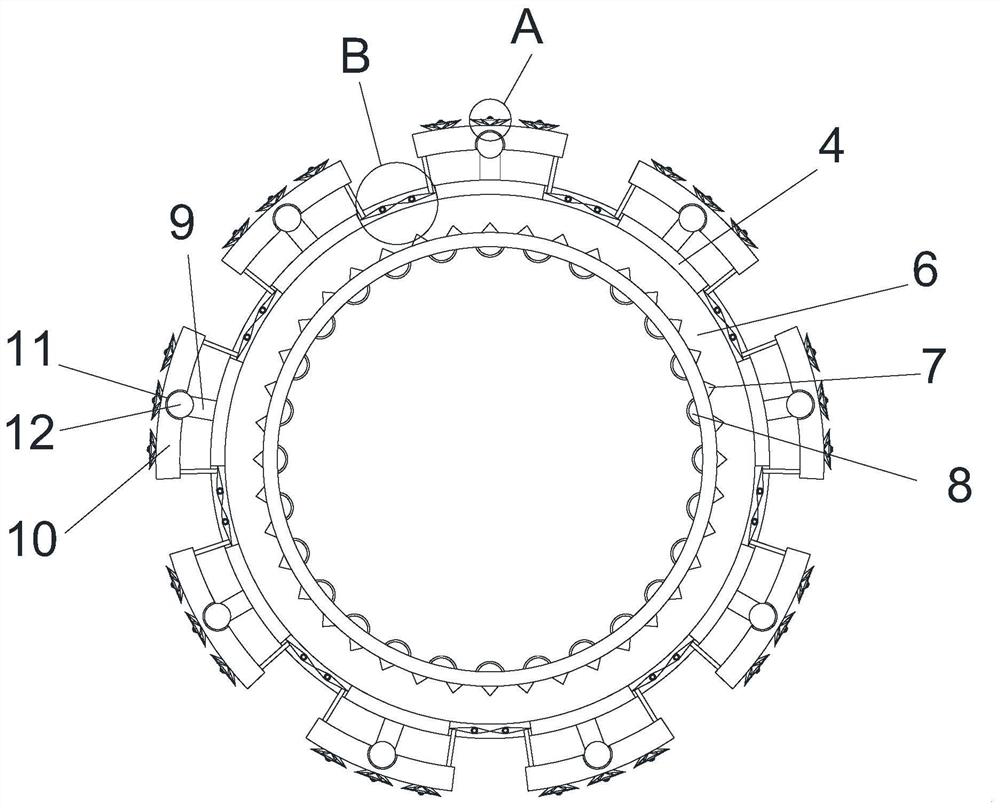

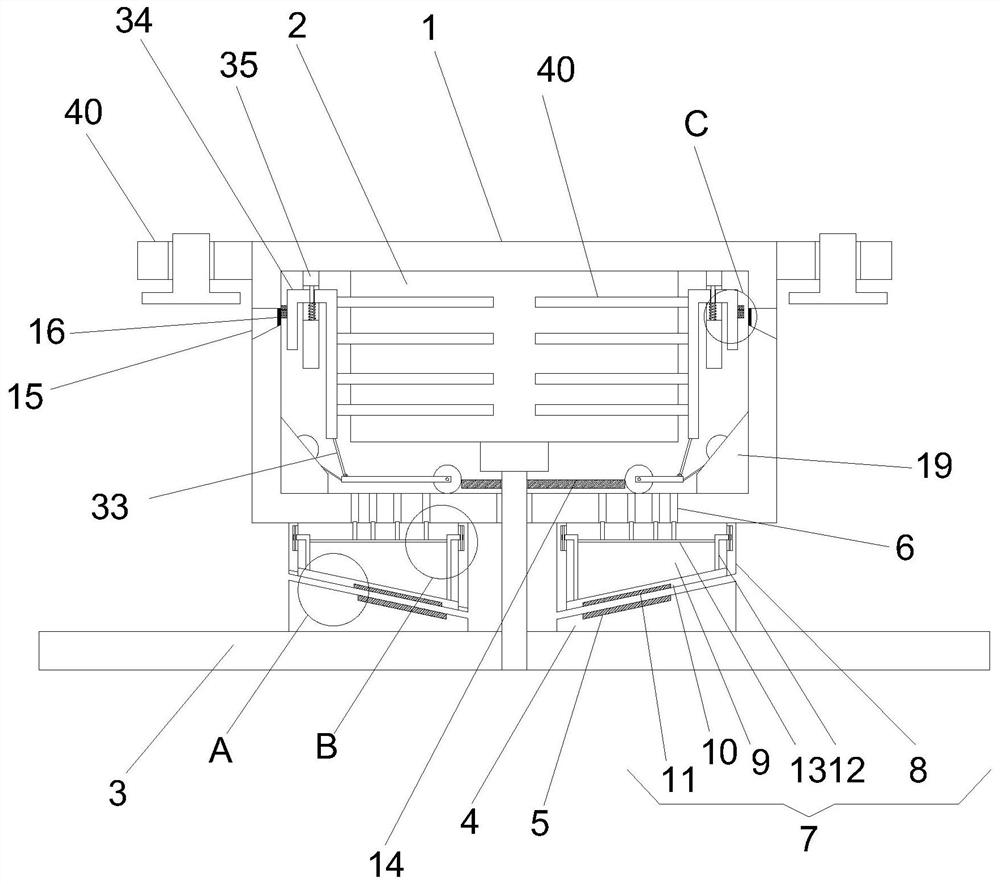

A cooling device with annular waterway based on 3D printing technology

ActiveCN112848287BIncrease water speedIncrease cleaning intensityAdditive manufacturing apparatusHollow article cleaningGear wheelWater cycling

A cooling device with an annular waterway based on 3D printing technology, including a conformal waterway. There are parking cavities at both ends of the conformal waterway. The outer end of the parking cavity is connected to a reversing water pump. There is a cleaning device for the inner wall of the waterway. The cleaning device for the inner wall of the waterway includes an installation box. The outside of the installation box is connected to the first shaft. There is a first gear outside the first shaft. A baffle is arranged on the wall, and a guide wheel assembly is arranged on the outside of the baffle. In the present invention, there are parking cavities at both ends of the conformal waterway, and the water flow can pass through the gap between the waterway inner wall cleaning device and the parking cavity to form a water cycle to take away the heat in the mold, and the water flow can push the waterway inner wall cleaning device along the Waterway walking can also drive the blades to scrape off the dirt on the inner wall of the waterway through the water flow, and the cooling effect of the conformal waterway can be further improved by reversing the direction of the water pump.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

A dust-proof asynchronous motor for a fan

ActiveCN112583222BImprove dust removal effectPlay the effect of automatic dust removalPump componentsDispersed particle filtrationInduction motorEngineering

A dust-proof asynchronous motor for a fan belongs to the technical field of asynchronous motors; it includes a motor box, the motor box is an internal hollow structure, fan blades are arranged under the motor box, and an asynchronous motor for driving the fan blades to rotate is arranged inside the motor box. Both sides of the chassis are provided with air intake holes connected to the motor box. In the present invention, a lower side plate, a magnetic sheet 1, an air outlet, an ash discharge device, a guide plate, a magnetic sheet 2, a guide rod and a dredging needle plate are provided at the same time. When the magnetic sheet one rotates with the fan blades and keeps getting closer to and away from the upper side plate, the repulsive force of the magnetic sheet pair and the second magnetic sheet alternates with the downward gravitational force between the second magnetic sheet, the guide rod and the dredging needle plate. At this time, the guide plate Continuously moving up and down inside the guide cavity, the guide plate continuously moves up and down inside the guide cavity, which has the effect similar to that of an exhaust fan. Heat dissipation has a promoting effect.

Owner:嵊州市玖和机电有限公司

Soup pot cleaning device

PendingCN112826411AEfficient scrubbingHigh impact strengthTableware washing/rinsing machine detailsWater flowEngineering

The invention discloses a soup kettle cleaning device, and relates to the technical field of soup kettles. The soup kettle cleaning device comprises a placing block, wherein the placing block is in a round block shape, a through pipe is fixedly installed at the bottom of the placing block, the through pipe is in a round pipe shape, cleaning holes are formed in the side wall of the through pipe in an annular gap mode, a water limiting plate is arranged in the through pipe, and a bottom cleaning box is fixed at the bottom of the through pipe. According to the soup pot cleaning device, through aiming type impact of water flow, a dislocation plate on the inner wall of a cleaning side rubber plate is affected by impact and rotates through a stress arc plate and a bearing, and meanwhile, the cleaning side rubber plate is also limited by flowing and impact of the water flow inside and outside; and when the cleaning side rubber plate rotates through the dislocation plate, the local position of the cleaning side rubber plate can be wrinkled, so the cleaning side rubber plate can effectively rub and clean the inner wall of the soup pot when cleaning the inner wall of the soup pot, and the effect of high-strength cleaning of the inner wall of the soup pot is achieved.

Owner:王锦举

Cleaning machine for cleaning engraving waste

ActiveCN111016509AIncrease flexibilityIncrease cleaning intensityHand artistic toolsDirt cleaningElectric machineryFan blade

The invention discloses a cleaning machine for cleaning engraving waste. The cleaning machine comprises a machine body, wherein a brushing head base is rotatably arranged on the left side surface of aswinging rod. When the cleaning machine is used for cleaning, a first motor is started to drive a driving shaft, a first gear, a fan blade gear base and a fan blade gear to rotate; the flexibility ofthe brushing head rotation is improved through the spherical rotation, so that the cleaning at various angles during engraving can be met, and the all-round cleaning on complex engraving is realized;a brushing head which can slide left and right is designed, so that the cleaning of engraved holes can be realized, the deep cleaning is realized, and the cleaning intensity is high; and the fan blade is designed, so that waste cleared out can be blown away through the rotation of the fan blade, and the condition that blowing the waste in other ways causes the damage of engraving finished products is avoided.

Owner:阜南县中泰工艺品有限公司

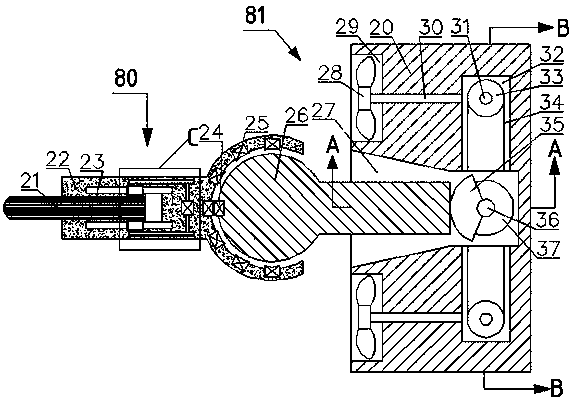

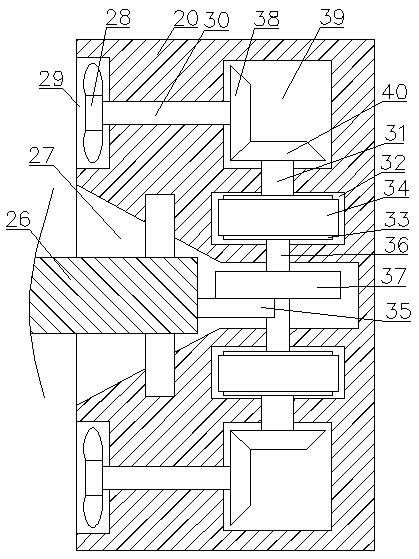

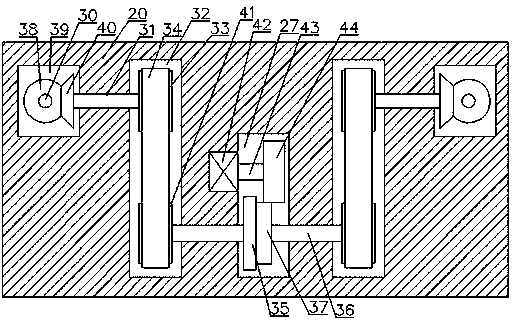

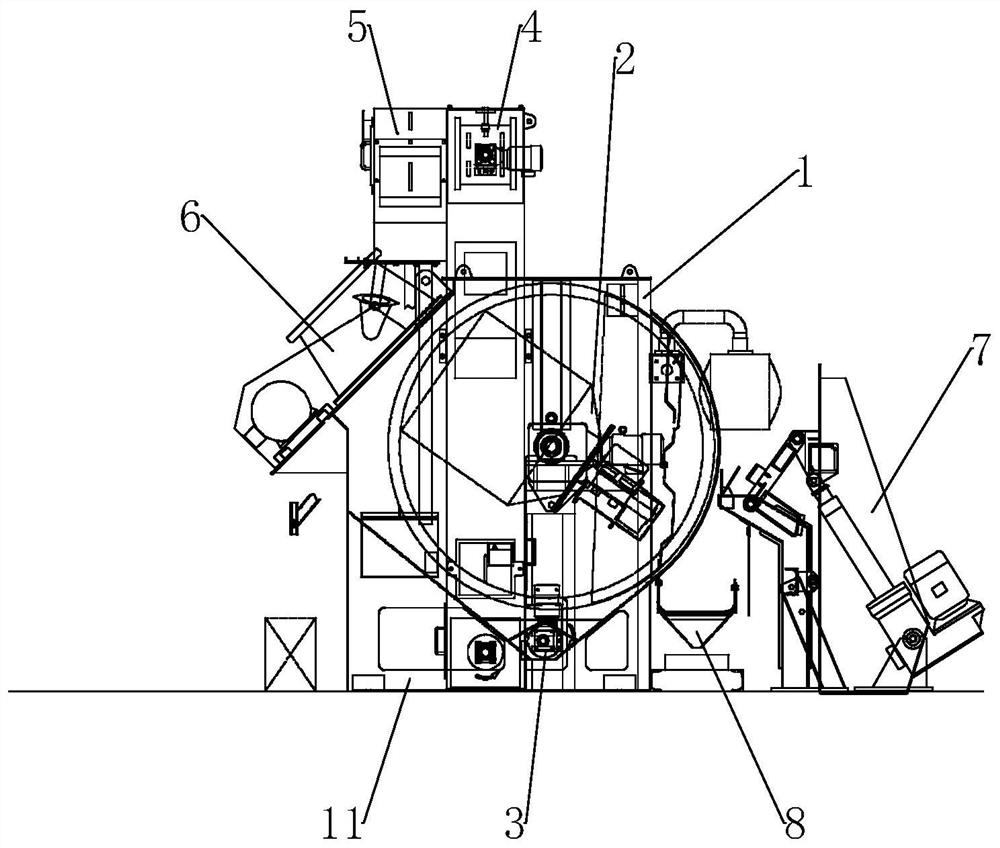

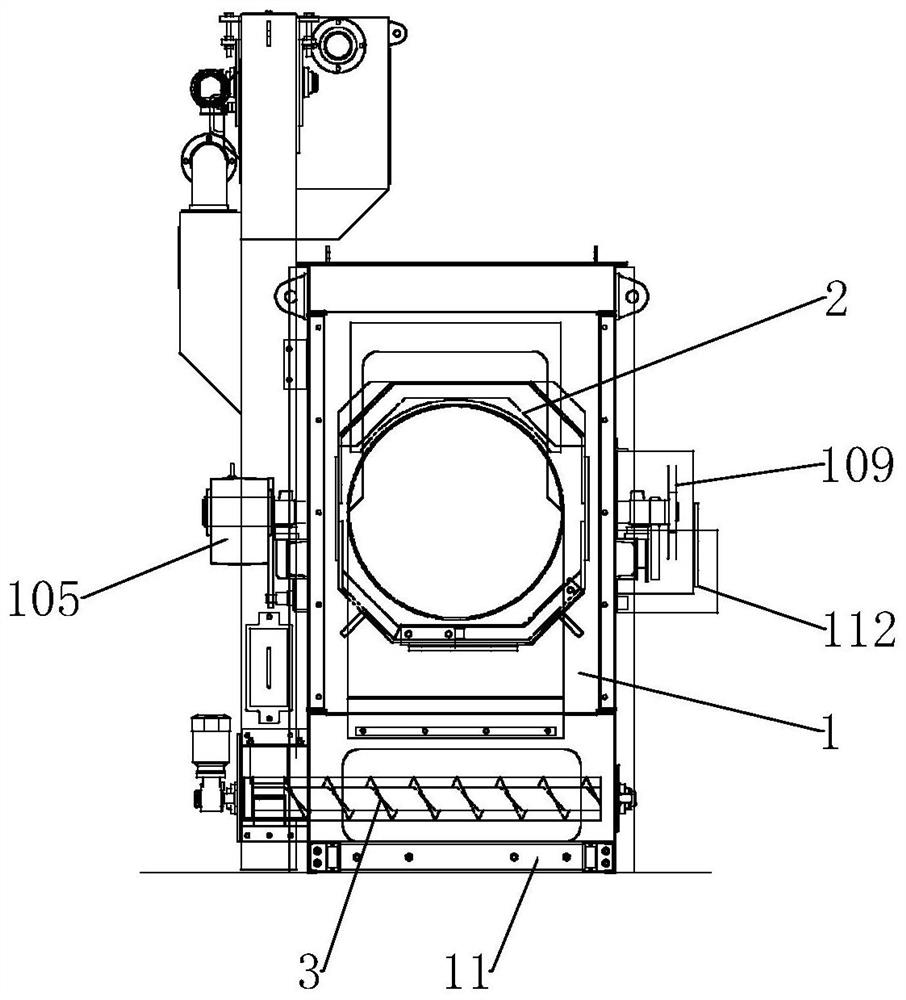

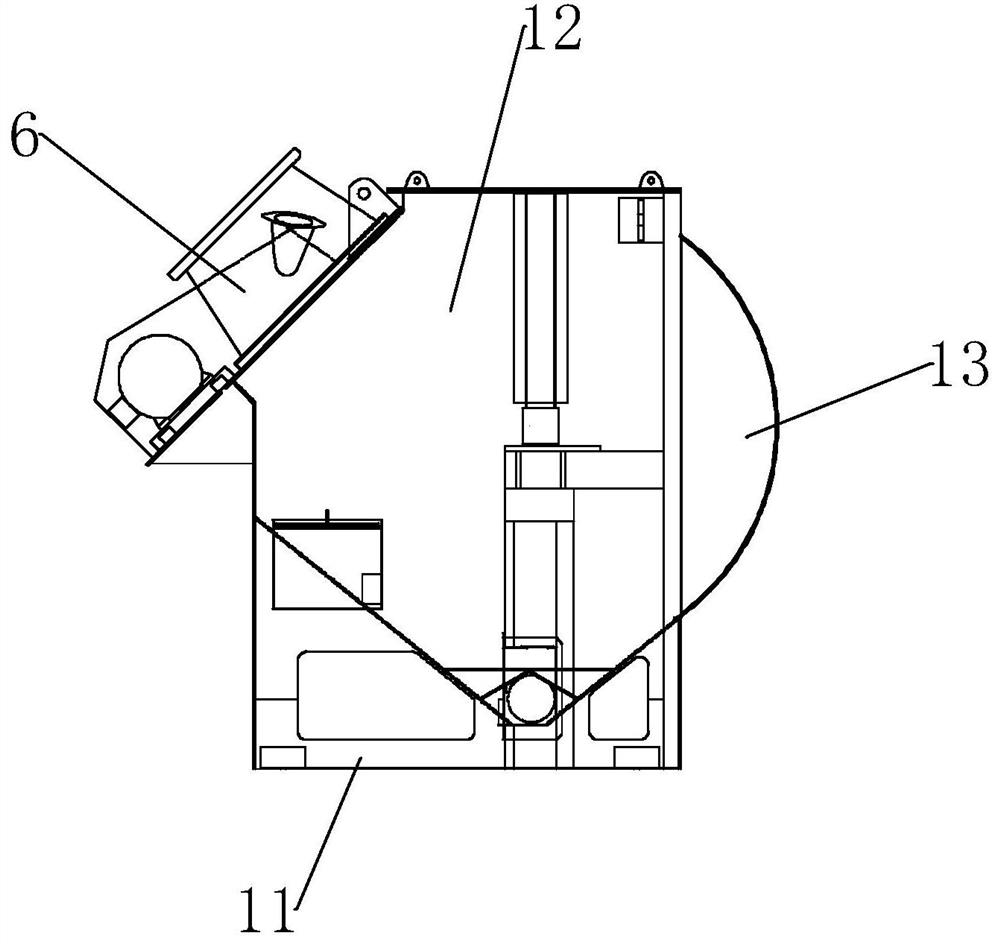

Drum-type shot blasting machine

PendingCN113799003AIncrease cleaning intensityReduce cleaning intensityAbrasive machine appurtenancesAbrasive blasting machinesDust controlStructural engineering

The invention discloses a drum-type shot blasting machine. The drum-type shot blasting machine comprises a shot blasting chamber, a shot blasting device, a spiral conveyor, a lifter, a separator, a shot supply device, a dust removal system and an electric control system. The shot blasting chamber comprises a chamber body; a long-strip-shaped opening is formed in the front side wall of the chamber body; the shot blasting device is fixedly installed at the upper inclined corner of the rear side of the chamber body; a drum, a drum support, a rotary speed reducer and a drum swing mechanism are installed in the chamber body; the drum support is rotationally installed in the chamber body; the drum is installed in the drum support; the rotary speed reducer is installed at the bottom of the drum support and connected with the drum so as to drive the drum to rotate; and the drum swing mechanism controls the drum to swing by different amplitudes. By the adoption of the drum-type shot blasting machine, the shot blasting strength can be effectively improved, the cleaning time of one shot blasting process is greatly shortened, the cleaning effect is achieved, and cost is reduced; and meanwhile, the drum-type shot blasting machine is simple in structure, batch feeding tasks can be completed, the damage to operators is reduced, the production efficiency is improved, and the requirement for semi-automatic production and machining is met.

Owner:QINGDAO ANTAI HEAVY IND MACHINERY +1

A cleaning machine for cleaning up carving waste

ActiveCN111016509BIncrease flexibilityMeet clean upHand artistic toolsDirt cleaningEngravingDrive shaft

Owner:阜南县中泰工艺品有限公司

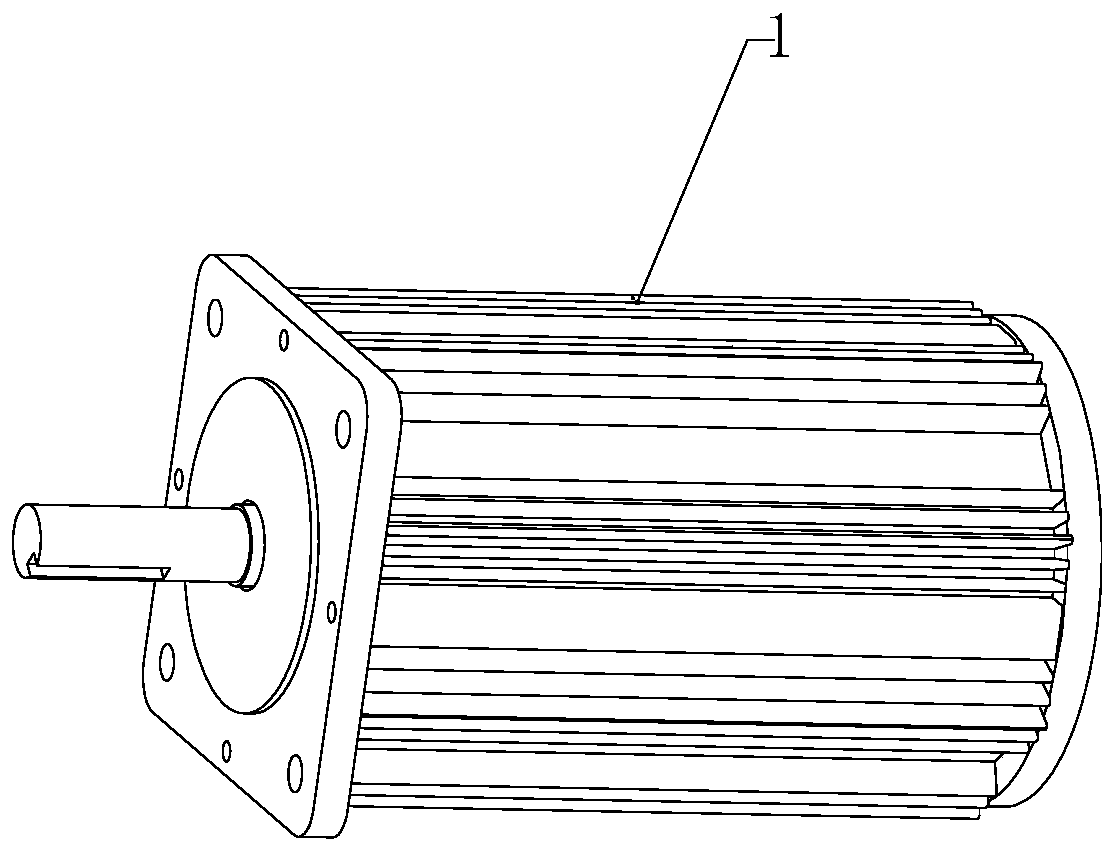

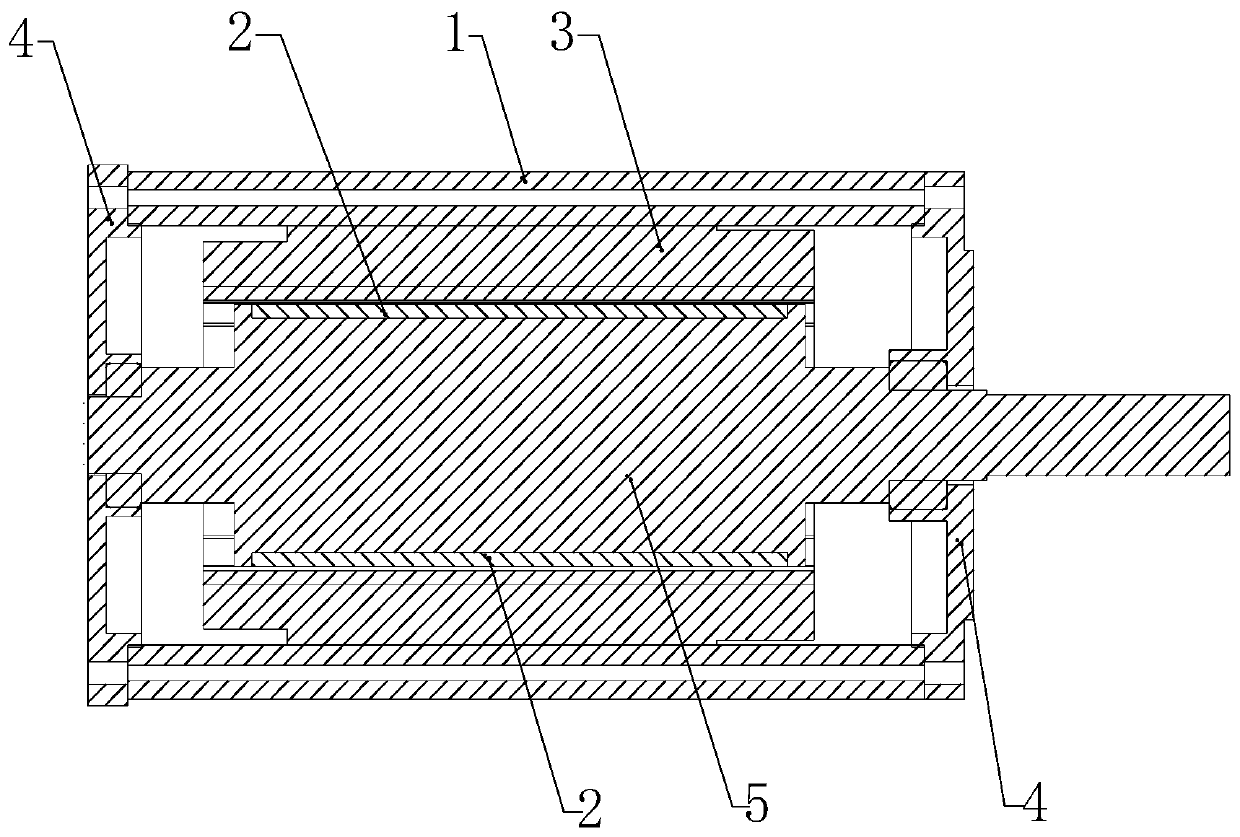

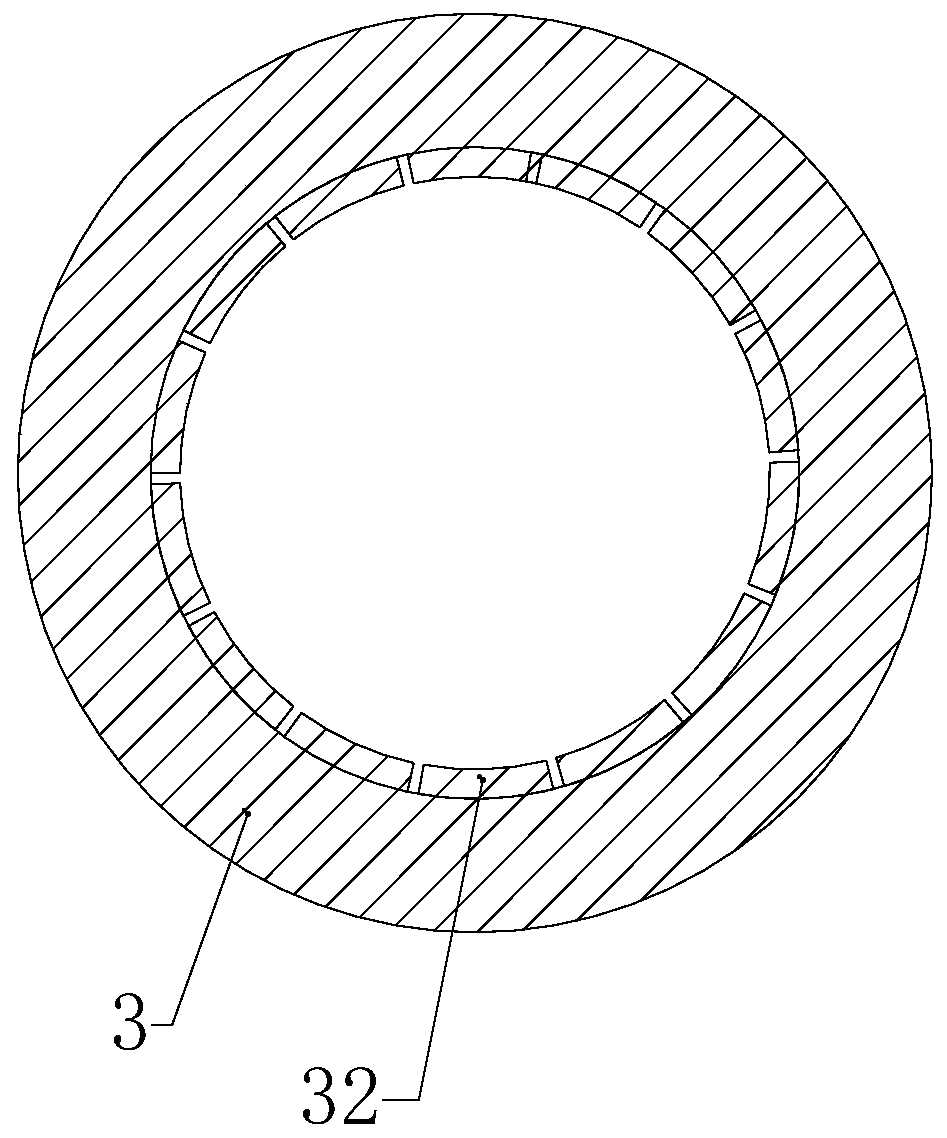

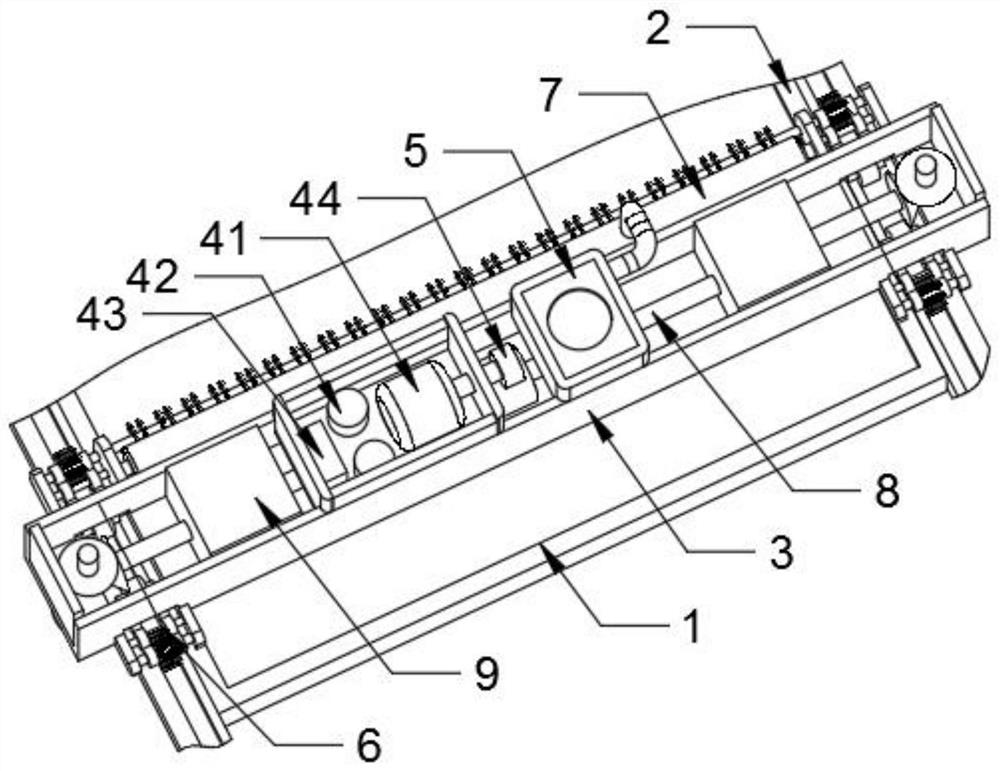

Special brushless motor for floor sweeper main brush and floor sweeper

The invention relates to a special brushless motor for a floor sweeper main brush. The special brushless motor comprises a shell, magnetic steel, a coil, a stator fixedly connected with the shell, endcovers arranged at the two ends of the shell, and a rotor arranged inside the stator, wherein the two ends of the rotor are arranged on the end covers through bearings; the magnetic steel is arrangedon the rotor; and the coil is arranged on the stator. The special brushless motor for the floor sweeper main brush is relatively small in volume, convenient for coil winding, relatively large in torque and relatively high in magnetic force. Moreover, a floor sweeper comprises a driving vehicle, two groups of floor sweeping devices are arranged on the vehicle body of the driving vehicle; each group of floor sweeping device comprises a lifting device, a mounting rack connected with the output end of the lifting device, a roller arranged on the mounting rack and the special brushless motor for the floor sweeper main brush, and the shell of the special brushless motor is fixedly arranged on the mounting rack; a collection box is further arranged between the two rollers; an exhaust fan is further arranged on the vehicle body; and the input end of the exhaust fan communicates with the collection box. The floor sweeper is good in sweeping effect.

Owner:SHANGHAI DALUE MOTOR MFG

Air blowing type solar panel surface foreign matter removing device

PendingCN113992141AImprove work efficiencyIncrease cleaning intensityPhotovoltaicsPhotovoltaic energy generationSurface cleaningEngineering

The invention relates to the field of solar panel surface cleaning, in particular to an air blowing type solar panel surface foreign matter removing device. The air blowing type solar panel surface foreign matter removing device comprises a photovoltaic panel, side frames and an integration box, the side frames are symmetrically fixed to the two sides of the photovoltaic panel, the integration box is arranged at the top of the photovoltaic panel, the two ends of the integration box are located on the surfaces of the side frames, an air guide pipe is arranged at the position, located on the surface of the photovoltaic panel, of the side edge of the integration box, exhaust holes are evenly formed in the surfaces of the air guide pipe, a draught fan is installed on the surface of the integration box, the exhaust end of the draught fan is connected with the air guide pipe, a driving device is installed in the integration box, a linkage device is installed in the integration box, and the driving device is connected with the linkage device. The integration box is driven by the driving device and the linkage device, so that the air guide pipe can reciprocate on the surface of the photovoltaic panel, airflow is driven by the draught fan, the airflow is sprayed out through the air guide pipe to clean dust on the surface of the photovoltaic panel, the surface of the photovoltaic panel is clean, and the working efficiency is high.

Owner:宋树华

Appliance cleaning device for construction site

ActiveCN112958500AIncrease cleaning intensityEasy to cleanCleaning using toolsDrive shaftArchitectural engineering

Owner:安徽富邦建设工程有限公司

Dustproof asynchronous motor for fan

ActiveCN112583222AImprove dust removal effectPlay the effect of automatic dust removalPump componentsDispersed particle filtrationPhysicsEngineering

Owner:嵊州市玖和机电有限公司

Valve with self-cleaning and anti-blocking functions

PendingCN113996607AWith self-cleaning anti-clogging functionEasy to cleanHollow article cleaningSuction forceEngineering

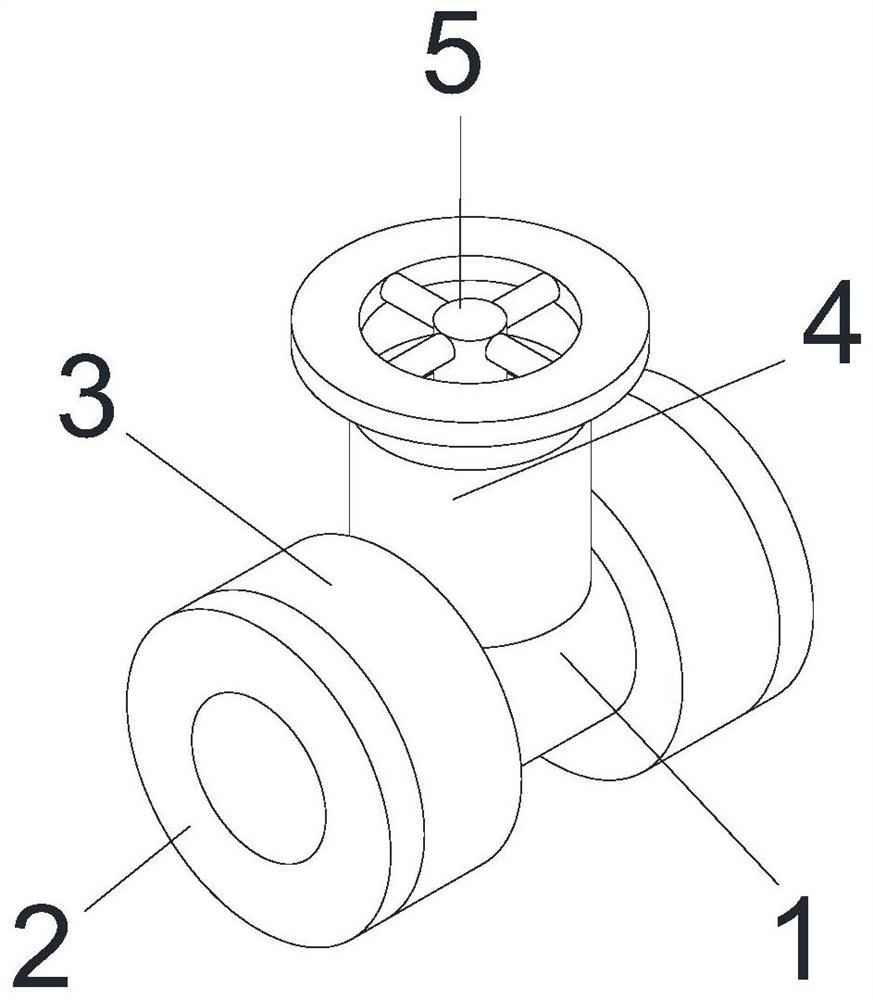

The invention relates to the technical field of valves, and discloses a valve with self-cleaning and anti-blocking functions, which comprises a valve pipe. Connecting pipes are fixedly mounted at the left end and the right end of the valve pipe, a control pipe is fixedly mounted at the top of the valve pipe, a control valve is arranged at the top of the control pipe, and a cleaning box is arranged on the connecting pipes. A telescopic vibration device is arranged at the end, close to the valve pipe, of the inner side of the cleaning box, and a telescopic vibration pipe is fixedly installed at the output end of the telescopic vibration device. According to the valve with the self-cleaning and anti-blocking functions,the fixed shaft is vibrated and impacted intermittently by the telescopic vibration pipe, so that the fixed shaft drives the adjusting rubber plate to vibrate, the adjusting rubber plate drives the breathing bag plate to perform adaptive deformation through the adjusting bag, the deformed breathing bag plate intermittently generates suction through the breathing holes in the breathing bag plate, loose and easily-gathered blockages such as sludge in the connecting pipe can be effectively dispersed, and therefore the cleaning effect on the valve is improved.

Owner:范振中

Cleaning device with good cleaning effect for electronic hardware shell production

InactiveCN113600519AEasy to cleanSimultaneous cleaningCleaning using toolsCleaning using liquidsWastewaterScrew thread

The invention provides a cleaning device with a good cleaning effect for electronic hardware shell production, and belongs to the technical field of cleaning devices. The cleaning device comprises a shell, a waste water discharging cavity is fixedly formed in the bottom of the shell, a waste discharging pipe communicating with the waste water discharging cavity is fixedly installed on the back face of the shell, a sliding groove is formed in the top of the inner surface of the shell, two symmetrically-arranged cleaning mechanisms are slidably connected to the inner wall of the shell through the sliding groove, and a lead screw driving module is fixedly installed between the inner surfaces of the shell; and a forward thread part and a reverse thread part are symmetrically arranged on the peripheral side face of the lead screw driving module, and the inner walls of the two cleaning mechanisms are connected with the forward thread part and the reverse thread part respectively. Through the design of the cleaning mechanisms, the device can efficiently complete the cleaning work of the hardware shell in an automatic mode; and when the device conducts cleaning, the inner wall and the outer wall of the outer shell can be cleaned at the same time, and the cleaning effect of the device on the shell is effectively improved by achieving the technical effects.

Owner:惠州聚鑫隆金属制品有限公司

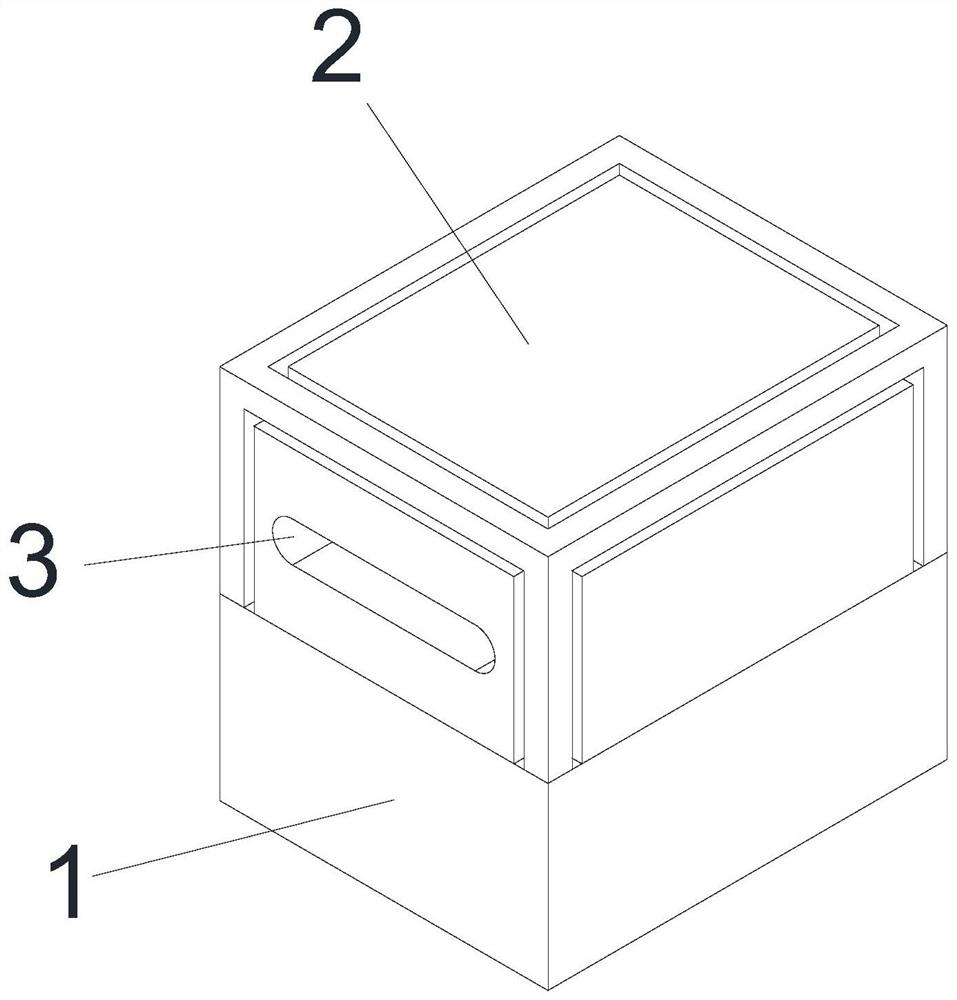

Outdoor water supply and drainage conveying channel

The invention discloses an outdoor water supply and drainage conveying channel, and relates to the technical field of water supply and drainage. The outdoor water supply and drainage conveying channel comprises a water supply channel, wherein a settling tank is formed in the bottom of the inner side of the water supply channel; a collecting tank is formed in the bottom of the inner side of the settling tank; a collecting box is installed at the bottom of the inner side of the collecting tank; the collecting box penetrates through the water supply channel and extends to the outside of the water supply channel; the end, located inside the water supply channel, of the collecting box is designed to be open; a collecting hole is formed in the side, located inside the water supply channel, of the collecting box; a collecting device is installed inside the collecting box; a scraping device is installed on one side of the collecting device; and the scraping device is in sliding connection with the bottom of the inner side of the collecting box. According to the outdoor water supply and drainage conveying channel, the purpose that internally settled particulate matter is accumulated in one place to be conveniently cleaned is achieved, water brought out when the internal particulate matter is cleaned is reduced, the possibility that the water is evaporated is reduced, and waste of water resources is reduced.

Owner:何兴树

A biological cleaning device for ship bottom

ActiveCN113650750BAchieving fit and adaptabilityHigh control precisionVessel cleaningHullsStructural engineeringCam

The invention discloses a biological cleaning device at the bottom of a ship, which belongs to the technical field of ships and comprises a base. Both ends of one side of the base are fixedly connected with connecting plates, and one side of the base is provided with a mounting plate. A knocking mechanism is fixedly connected between them, and a cam is arranged on one side of the knocking mechanism. In the present invention, the elongation of the first electric push rod drives one side of the transmission rod to push the base to deflect relative to each other through the top drive roller, so that the relative deflection angle can be adjusted, effectively improving the control ability of the relative angle of traditional cleaning, and the second electric push rod The working shortening of the rod can pull the fixed plate down through the first slide bar to drive the limit plate and the limit tooth on the outer wall of the limit roller to fit and limit, so as to realize the control of the relative offset angle of the base and meet the requirements of the same angle in some areas. Clean and fit, effectively realize the ability to fit and adapt to the curvature of the hull's exterior facade.

Owner:南通宇合睿船舶科技有限公司

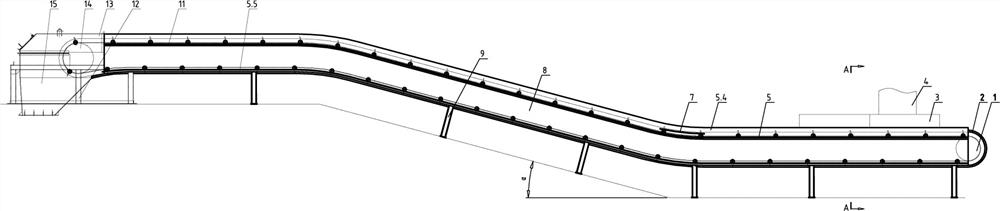

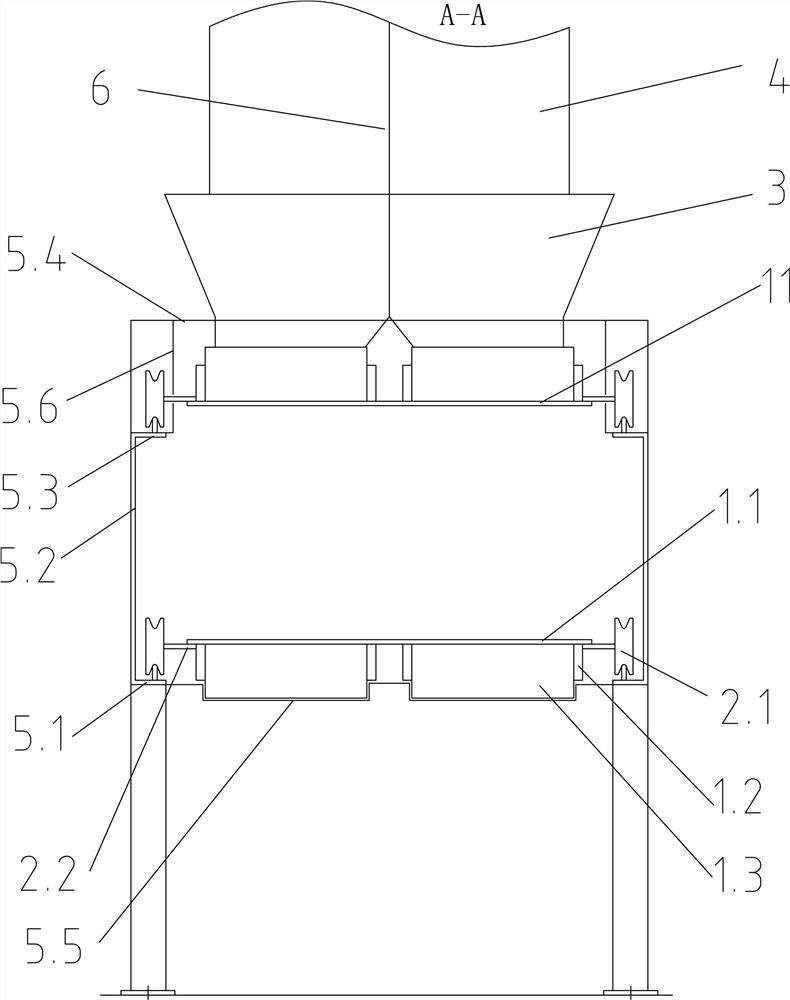

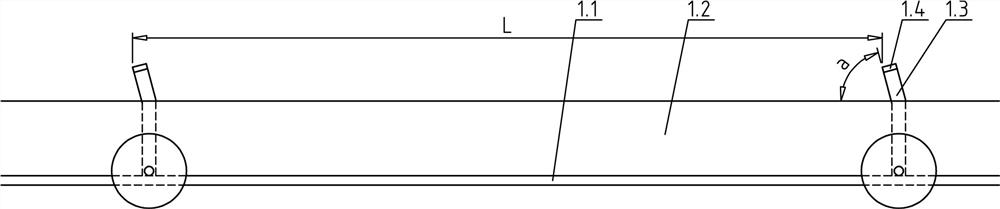

Conveying equipment for batching system

ActiveCN113928801AGuaranteed uptimeImprove lateral rigidityConveyorsSupporting framesAdhesive beltMachine

Conveying equipment for a batching system comprises a machine frame, a turnabout drum and a transmission drum are installed on the machine frame, and a multi-channel conveying rubber belt is wound between the turnabout drum and the transmission drum; the machine frame comprises main plate faces, and the main plate faces, lower plate faces and upper plate faces are welded to form the integrated machine frame and form rails; the left and right sides of the lower plate faces are connected with return receiving grooves, and the upper plate faces are connected with an upper sealing shell; the multi-channel conveying rubber belt comprises a base belt, a plurality of pairs of skirt flanges are longitudinally arranged on the base belt at intervals, transverse partition plates are arranged on the portion, between each pair of skirt flanges, of the base belt in the length direction at intervals, and walking wheels are arranged on the left side and the right side of the base belt and slide along the rails; and when the transverse partition plates run to a return section, materials in the return receiving grooves are cleaned. According to the conveying equipment for the batching system, different materials can be conveyed simultaneously, deviation of the rubber belt is avoided, and the materials at the return section can be automatically cleaned and returned.

Owner:HUBEI TIANYI MACHINERY CO LTD

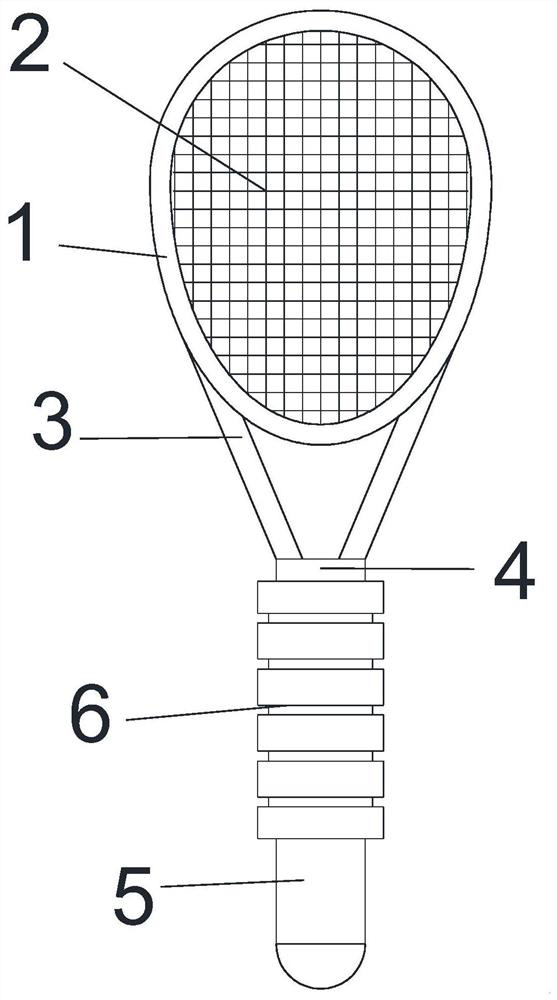

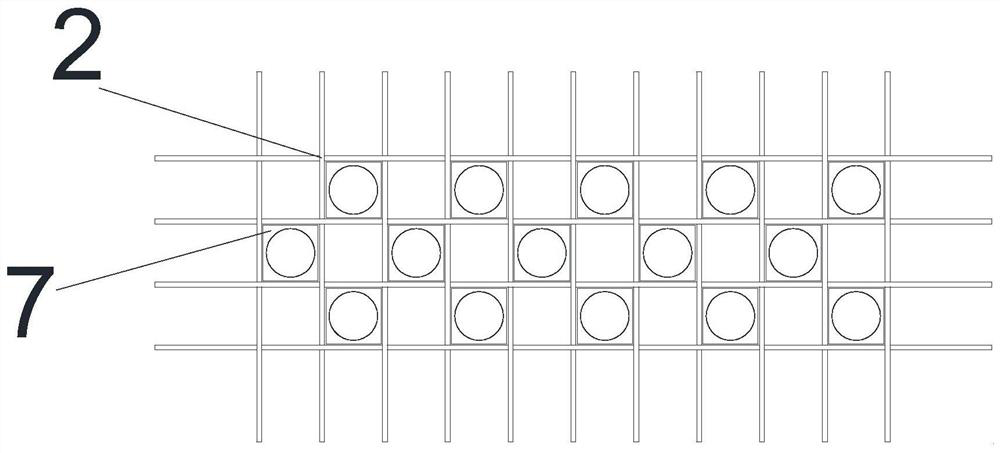

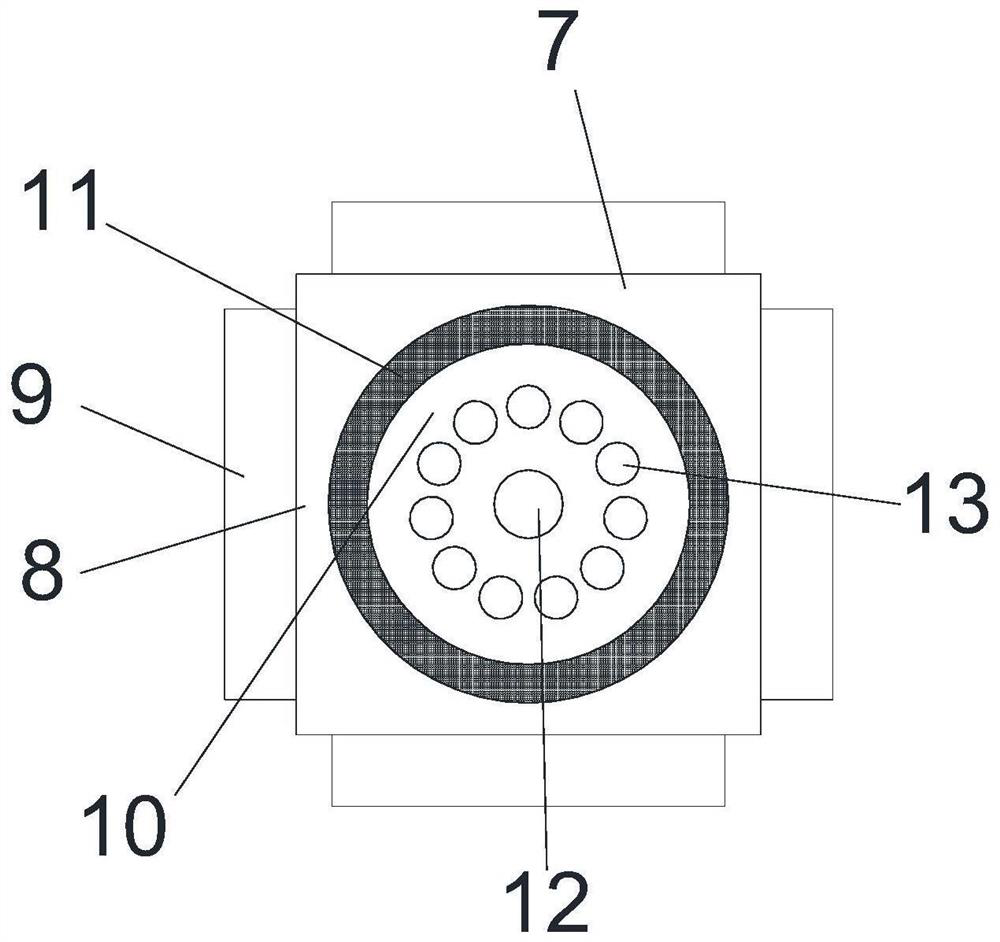

Tennis training racket

PendingCN112604249AAvoid cleaning difficultiesAvoid Cleaning Difficult SituationsBall sportsStringed racketsStructural engineeringMechanical engineering

The invention discloses a tennis training racket, and relates to the field of tennis rackets. The tennis training racket comprises a racket frame, a net is arranged in the racket frame, an adapter bracket is fixedly mounted at the bottom of the racket frame, an upper limiting connecting block is fixedly mounted at the bottom of the adapter bracket, and a lower limiting connecting block is arranged at the bottom of the upper limiting connecting block. According to the tennis training racket disclosed by the invention, when playing training is carried out, a cleaning block on the tennis net is impacted by a tennis ball, so that the tennis ball extrudes the corresponding surface of an air bag on the cleaning block through an impact force, the tennis ball is in contact with the inner side of a cleaning plate; the tennis ball wall and the cleaning layer on the inner side of the cleaning plate make contact with each other and rub each other, a cleaning layer on the inner side wall of the cleaning plate limits and interferes with plush on the tennis ball wall, impurities of the plush on the tennis ball wall are removed during beating, and the situation that a tennis ball is difficult to clean subsequently is avoided.

Owner:周杰龙

Circuit board production equipment based on vacuum etching technology

ActiveCN112203429BImprove cleanlinessAvoid quality lossConductive material chemical/electrolytical removalEtchingChemical reaction

The invention relates to the field of etching technology, and discloses circuit board production equipment based on vacuum etching technology, which includes a base, a clamping plate, an etching cylinder, a rotating motor, a turntable, a vacuum device and an etching device. The bottom surface of the etching cylinder is in a hollow state, and the clamping plate It is an inverted L-shaped body. The number of clamping plates is two and they are opposite to each other. The side of the two clamping plates facing away from each other is curved and matches the inner wall of the etching barrel. The vacuum device and the etching device are both installed on the etching barrel. , through the setting of the vacuum device, the continuous air extraction effect is used to form a vacuum effect in all the bases, so as to perform a strong extraction effect on the dust in the base, thereby removing the dust in the base or circuit board before etching, and etching The smoke and impurities generated by the chemical reaction during the process increase the cleanliness of the circuit board after the etching is completed, and avoid the problem of reduced quality of the circuit board caused by dust and other smoke and impurities participating in the etching process. Compared with the cleaning mechanism on the existing etching machine , the cleaning scope is more comprehensive and the intensity is stronger.

Owner:东莞感恩蚀刻科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com