Circuit board production equipment based on vacuum etching technology

A technology for production equipment and circuit boards, which is applied in the direction of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of reduced etching effect of circuit boards, high equipment cost, power consumption, and high requirements for the use environment, so as to improve maintenance efficiency, The effect of reducing the difficulty of maintenance and low requirements for the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

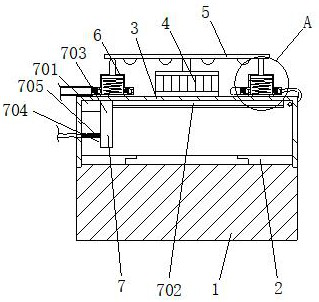

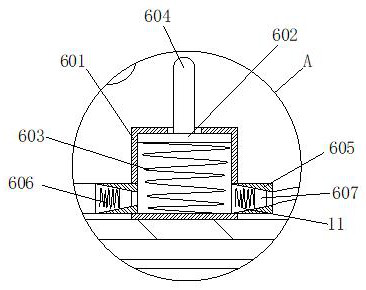

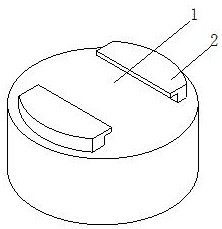

[0038] Example 1: Please refer to Figure 1-3 , the present invention proposes circuit board production equipment based on vacuum etching technology, including a base 1, a pallet 2, an etching cylinder 3, a rotating motor 4, a turntable 5, a vacuum device 6 and an etching device 7, and the base 1 and the etching cylinder 3 are all in the form of Cylinder and matching size, the bottom surface of the etching cylinder 3 is hollowed out, the clamping plate 2 is an inverted L-shaped body, the number of the clamping plates 2 is two and is opposite to the left and right, and the sides of the two clamping plates 2 facing away from each other are in the shape of Curved and compatible with the inner wall of the etching cylinder 3, the etching cylinder 3 is sleeved on the outer walls of the two clamping plates 2, the rotating motor 4 is fixedly installed on the top surface of the etching cylinder 3, the transmission shaft of the rotating motor 4 is fixedly connected with the turntable 5, ...

Embodiment 2

[0040] Example 2: Please refer to Figure 4-5 On the basis of Embodiment 1, the left side of the etching nozzle 703 is fixedly connected with a cleaning cylinder 704, the bottom surface of the cleaning cylinder 704 is hollowed out and the outer wall is provided with holes, the left side of the cleaning cylinder 704 is fixedly connected and communicated with a bellows 705, The left end of the corrugated pipe 705 on the cleaning cylinder 704 is fixedly connected with the inner wall on the left side of the etching cylinder 3, and the outer wall on the left side of the etching cylinder 3 is fixedly connected to the position of the corrugated pipe 705 on the cleaning cylinder 704 and is connected with a trachea. The right side air guiding column 605 on the side vacuum device 6 is fixedly connected and communicated, the left side air guiding column 605 on the left side vacuum device 6 is fixedly connected with a recovery pipe, and the right side air guiding column 605 on the left sid...

Embodiment 3

[0041] Embodiment 3: Please refer to Figure 6-8. On the basis of Embodiment 1, a reset mechanism 9 is provided on the right side of the etching cylinder 3. The reset mechanism 9 includes a bottom rod 901 and an insertion rod 902. The top surface of the bottom rod 901 is Holes are opened and socketed with the insertion rod 902, the bottom rod 901 is fixedly connected with the base 1, the insertion rod 902 is fixedly connected with the etching cylinder 3, the front of the insertion rod 902 is fixedly connected with a sector plate 903, and the front of the bottom rod 901 is fixedly connected with a cylinder C904, the inside of the cylinder C904 is hollow and there are round holes on the front and right sides, the inner wall of the back of the cylinder C904 is fixedly connected with the central axis 905, the outer wall of the central axis 905 is fixedly connected with the sleeve 906, and the outer wall of the sleeve 906 is located in the cylinder Outside C904, the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com