Electroplating device for circuit board production

An electroplating device and circuit board technology, which is applied to electrical components, electrical components, printed circuits, etc., can solve problems affecting the factory's work allocation to employees, lack of circuit board cleaning mechanisms, and circuit board dust accumulation, etc., to achieve good fixing effect, Simple fixing operation and the effect of increasing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

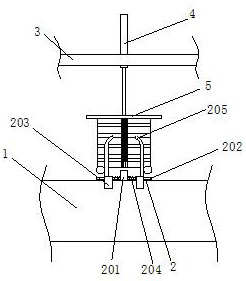

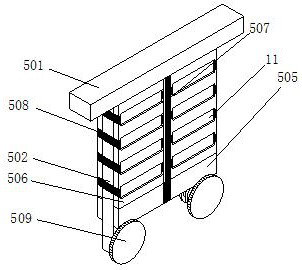

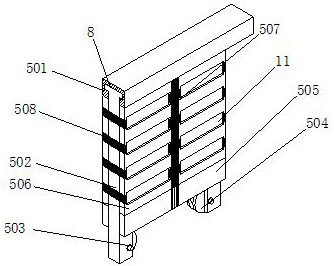

[0041] Example 1: Please refer to Figure 1-5 , an electroplating device for circuit board production, comprising an electroplating tank 1, a transmission mechanism 2, a transmission line 3, a telescopic device 4 and a clamping mechanism 5, the transmission mechanism 2 is arranged on the electroplating tank 1, and the transmission line 3 is arranged on the transmission mechanism 2 Above, telescopic equipment 4 is arranged on conveying line 3, conveying line 3 and telescopic equipment 4 are existing known technologies, do not repeat them here, clamping mechanism 5 is arranged on the drive shaft of telescopic equipment 4, clamping mechanism 5 includes a top plate 501, a side plate 502, a rotating shaft 503 and a clamp ring 504. The top surface of the top plate 501 is fixedly connected with the transmission shaft of the telescopic device 4. The bottom surface of the top plate 501 is provided with a chute 8, and the cross-sectional surface of the chute 8 is convex , the top of the...

Embodiment 2

[0042] Embodiment 2: Please refer to the electroplating tank 6-7 in the figure. On the basis of the first embodiment, a feeding box 6 is arranged on one side of the electroplating tank 1, and the feeding box 6 includes a box body 601, which is also provided on the front side of the box body 601 There is a transmission mechanism 2, and the top surface of the box body 601 is provided with a placement groove 12 on the rear side of the transmission mechanism 2. The back side of the placement groove 12 is provided with a hole and is sleeved with a push rod 602. The push rod 602 is an I-shaped body. The back end of the rod 602 is fixedly connected with a spring B603, and the front end of the spring B603 is fixedly connected with the back of the box body 601. The top surface of the box body 601 is provided with a telescopic slot A13 on both sides of the transmission mechanism 2, and a cylinder is sleeved in the telescopic slot A13. 604, the cylinder 604 is a cylinder with a hollowed-o...

Embodiment 3

[0043] Embodiment 3: Please refer to Figure 8-10 of the electroplating tank. On the basis of Embodiment 2, a dust removal mechanism 7 is arranged in the arrangement hole 11. The dust removal mechanism 7 includes an air bag 701. The air bag 701 is a hollowed-out semi-cylindrical body. The top surface and the bottom surface are respectively fixedly connected with the top surface and the bottom surface of the arrangement hole 11. The bottom end of the back of the airbag 701 is fixedly connected with a slide plate B703, and the top end of the back surface of the airbag 701 is fixedly connected with a slide plate A702. Together, the front of the skateboard A702 is equidistantly provided with ventilation holes A16, and the front of the skateboard B703 is provided with a ventilation hole B17 at the position corresponding to the ventilation hole A16. The height of the ventilation hole B17 is ten times the height of the ventilation hole A16. A through groove B15 is opened, and the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com