Drum-type shot blasting machine

A shot blasting cleaning machine and drum type technology, which is applied to abrasive jet machine tools, used abrasive treatment devices, abrasive materials, etc., can solve the problems of waste projectile treatment cost, low cleaning efficiency, poor cleaning effect, etc., and shorten the cleaning time. The effect of time, increase cleaning intensity and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

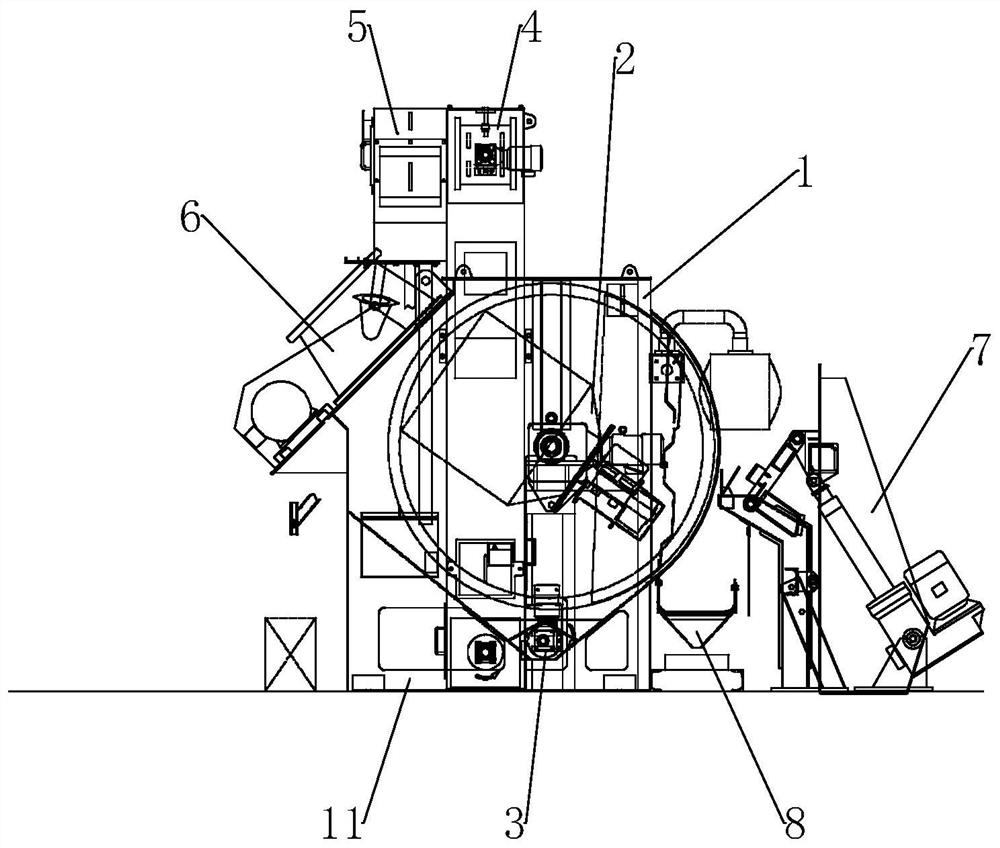

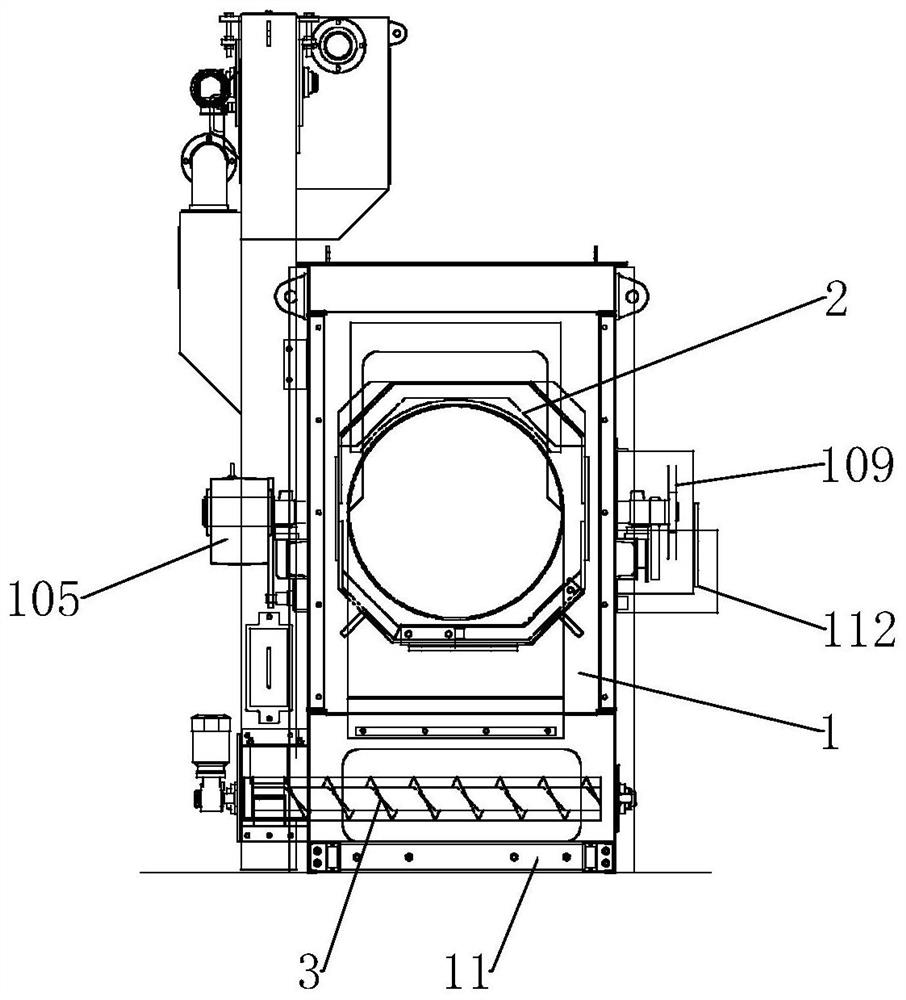

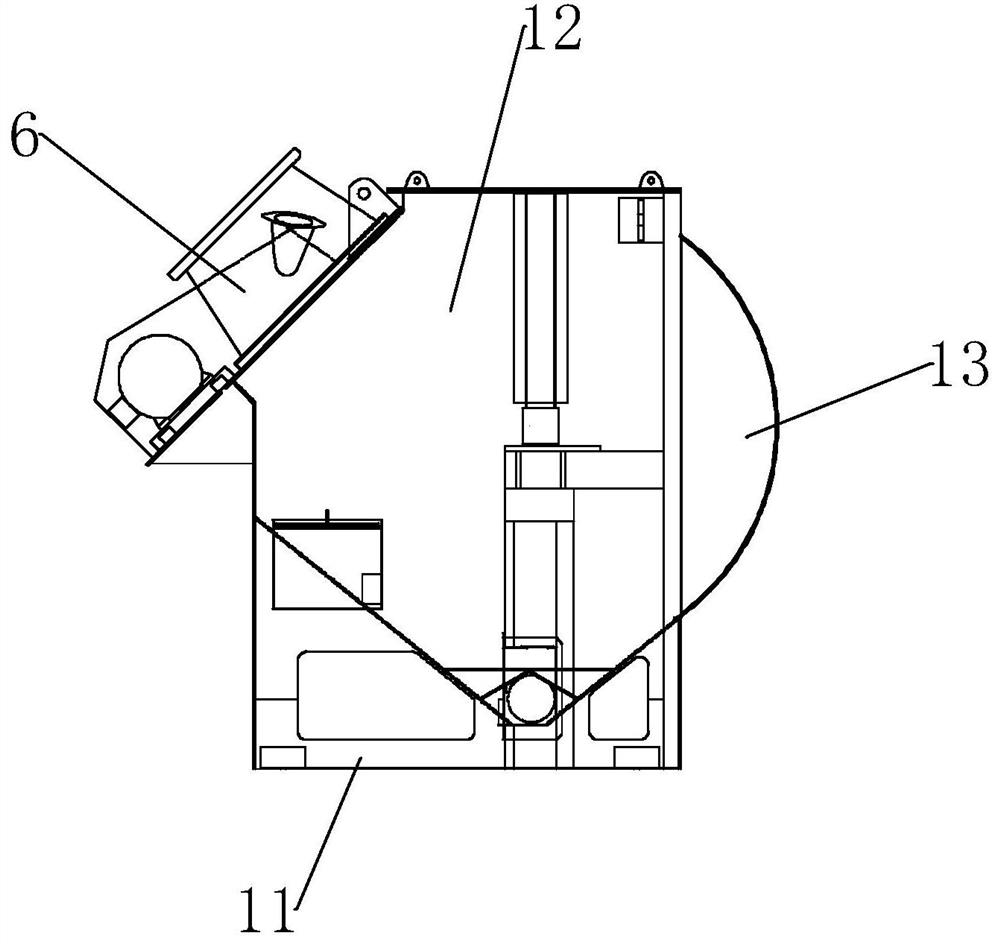

[0030] like Figure 1 to Figure 3 As shown, a drum-type shot blasting machine includes a shot blasting chamber 1, a shot blasting device 6, a screw conveyor 3, an elevator 4, a separator 5, a shot feeding device, a dust removal system and an electric control system. The shot blasting chamber 1 includes a chamber body 12, which is fixedly installed on the chamber body support 11 directly below it, and a screw conveyor 3 is fixedly installed below the chamber body 12, and the hopper in the screw conveyor 3 is facing the chamber body 12, and the screw conveyor The conveying end of the device 3 corresponds to the position of the hoist 4 and is connected to the lower end of the hoisting pipeline. The hoist 4 is arranged on one side of the chamber body 12, and the projectile outlet of the hoist 4 is connected with the projectile inlet of the separator 5, and the separator 5 is fixedly installed On the side of the hoist 4, its projectile outlet is connected to the shot supply device,...

Embodiment 2

[0037] In another embodiment of the present invention, the composition and connection relationship between the various components are the same as those in the above-mentioned embodiment 1, the only difference is: the inclination angle of the first turning plate 115 is 30°, and the second turning plate 116 The angle of inclination is 30°, and the angle of inclination of the third turning plate 117 is 5°.

Embodiment 3

[0039] In another embodiment of the present invention, the components and connections between the components are the same as those in Embodiment 1 above, the only difference is that the inclination angle of the first turning plate 115 is 40°, and the second turning plate 116 The angle of inclination is 40°, and the angle of inclination of the third turning plate 117 is 15°.

[0040] The working principle is as follows: the electronic control system is controlled by the circuit connection, the swing reducer 105 operates and rotates, and drives the drum 101 to swing to the loading station. The push rod 705 stretches out to lift the hopper 701. Under the action of the hopper turning arm 703, the hopper 701 turns over and pours the workpiece to be cleaned into the drum 101; At this time, the opening of the drum 101 is facing the shot blasting port of the shot blasting device 6, and the protective cover door 110 covers the long opening on the front side wall 13 of the chamber body;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com