Conveying equipment for batching system

A technology of conveying equipment and batching system, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of raising large dust, easy deviation of tapes, and difficulty in use, and achieves enhanced lateral rigidity and enhanced cleaning strength. , The effect of convenient replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

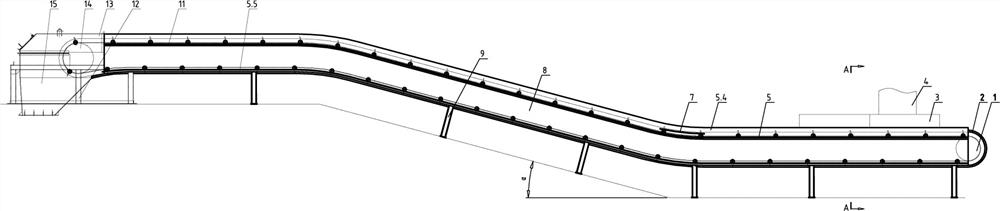

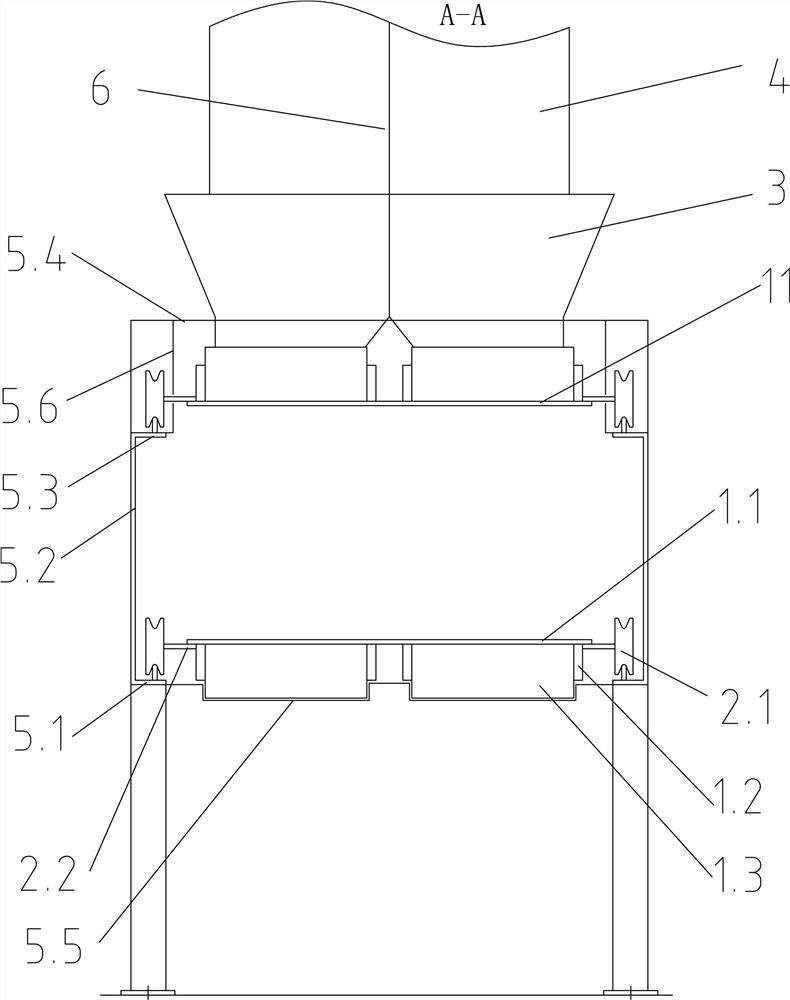

[0045] like Figure 1-2 As shown, a batching system conveying equipment includes a reversing drum 1, an arc-shaped machine trough 2, a material guide trough 3, a feed chute 4, a track 5, a partition 6, a pressing rail 7, a frame 8, and legs 9. Material 10, multi-channel conveying tape 11, head frame 12, head shield 13, drive roller 14, head funnel 15.

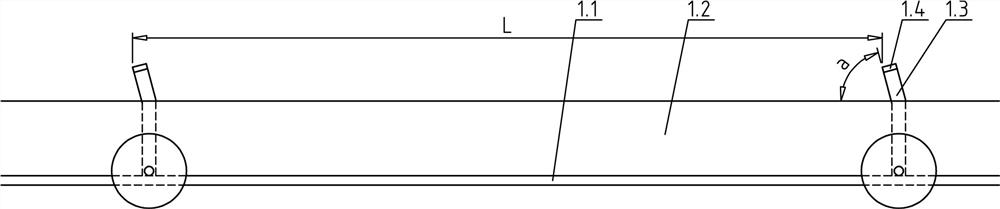

[0046] Specifically, such as Figure 3-4As shown, the multi-channel conveyor belt 11 includes a base belt 1.1, and a plurality of skirts 1.2 are vulcanized on the base belt 1.1. When the equipment batches and conveys two different materials at the same time, there are four skirt ribs 1.2, and each two groups of skirt ribs 1.2 form a set of conveying channels, and the distance between the two sets of conveying channels is B, separated from each other. A transverse partition 1.3 is arranged at every distance L in each group of conveying channels. The distance L is designed according to the conveying volume and equipment layout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com