A dust-proof asynchronous motor for a fan

An asynchronous motor, asynchronous motor technology, applied in asynchronous induction motors, electric components, machines/engines, etc., can solve the problems of dust accumulation, dust fall, inconvenient use, etc., to achieve the effect of improving the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

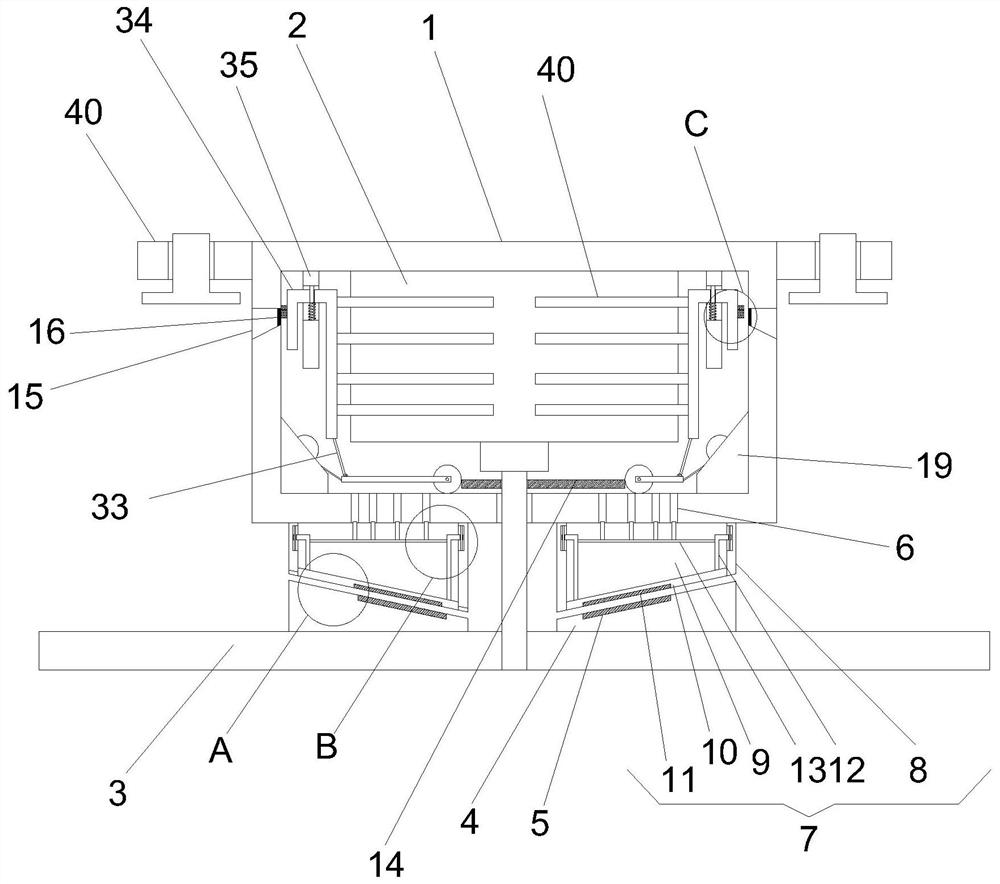

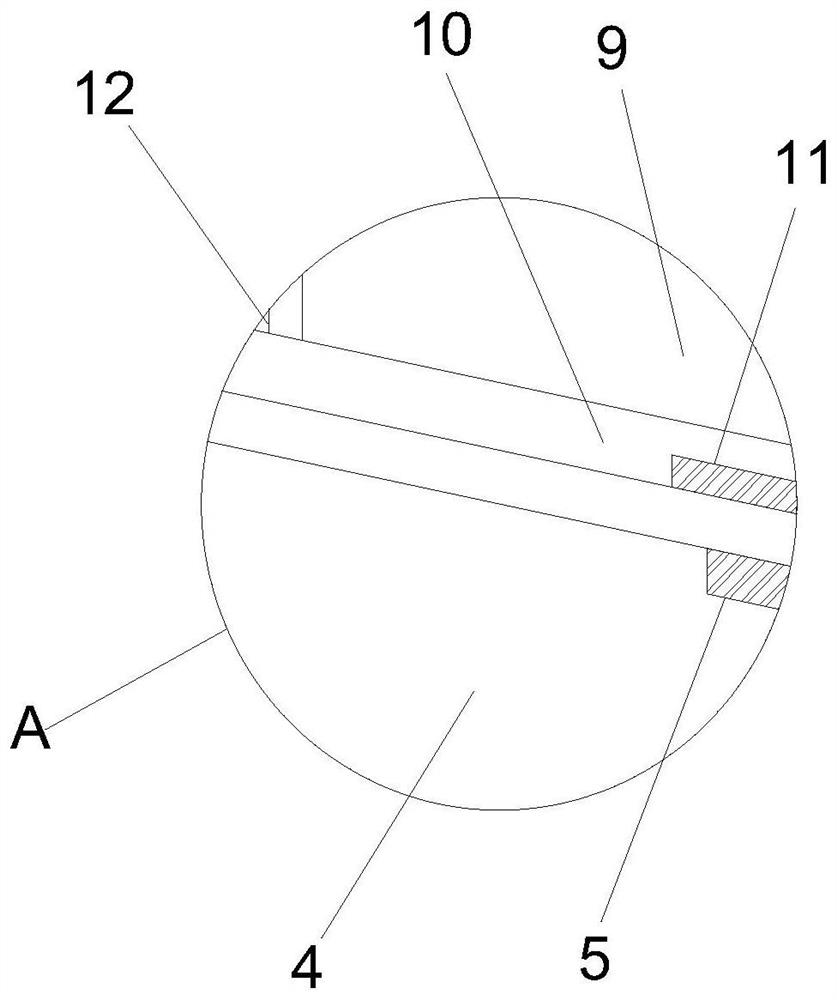

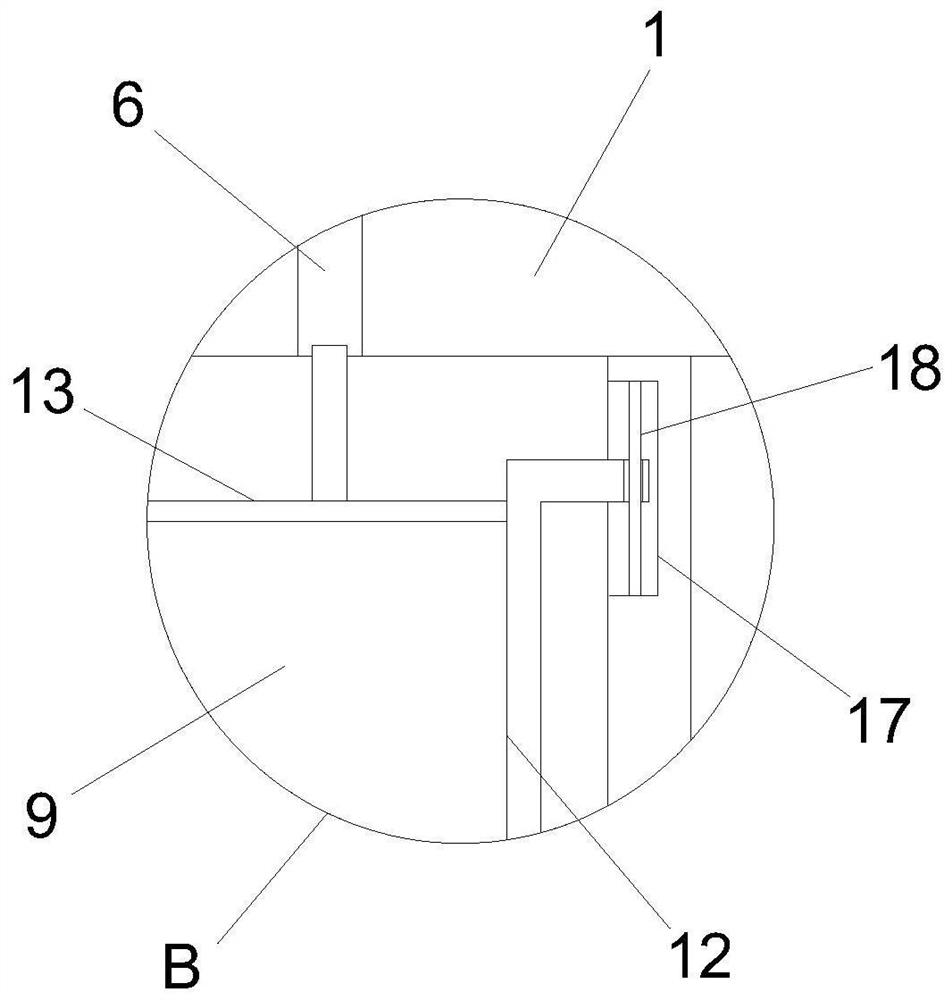

[0031] Example: see Figure 1-Figure 5 , a dust-proof asynchronous motor for a fan, comprising a motor box 1, the motor box 1 is an internal hollow structure, a fan blade 3 is arranged under the motor box 1, both fan blades 3 are rectangular structures, and the inside of the motor box 1 is arranged There is an asynchronous motor 2 that drives the fan blade 3 to rotate. The asynchronous motor 2 has an existing structure and will not be described here. The output shaft of the asynchronous motor 2 extends downward to the bottom of the motor box 1. The fan blades 3 are fixedly connected, and the two sides of the motor box 1 are provided with air intake holes 15 that communicate with the motor box 1. It is inclined downward toward the side far away from each other, and a filter screen 16 is fixedly installed inside the two air intake holes 15. The filter screen 16 is an existing structure and will not be described here. The bottom surface of the motor box 1 is provided with two set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com