Retractable dust-free wall grooving machine

A telescopic and slotting machine technology, which is applied in the direction of construction and building construction, can solve the problems of flying dust, air pollution, high labor intensity, etc., and achieve the effects of simple construction process, water saving and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

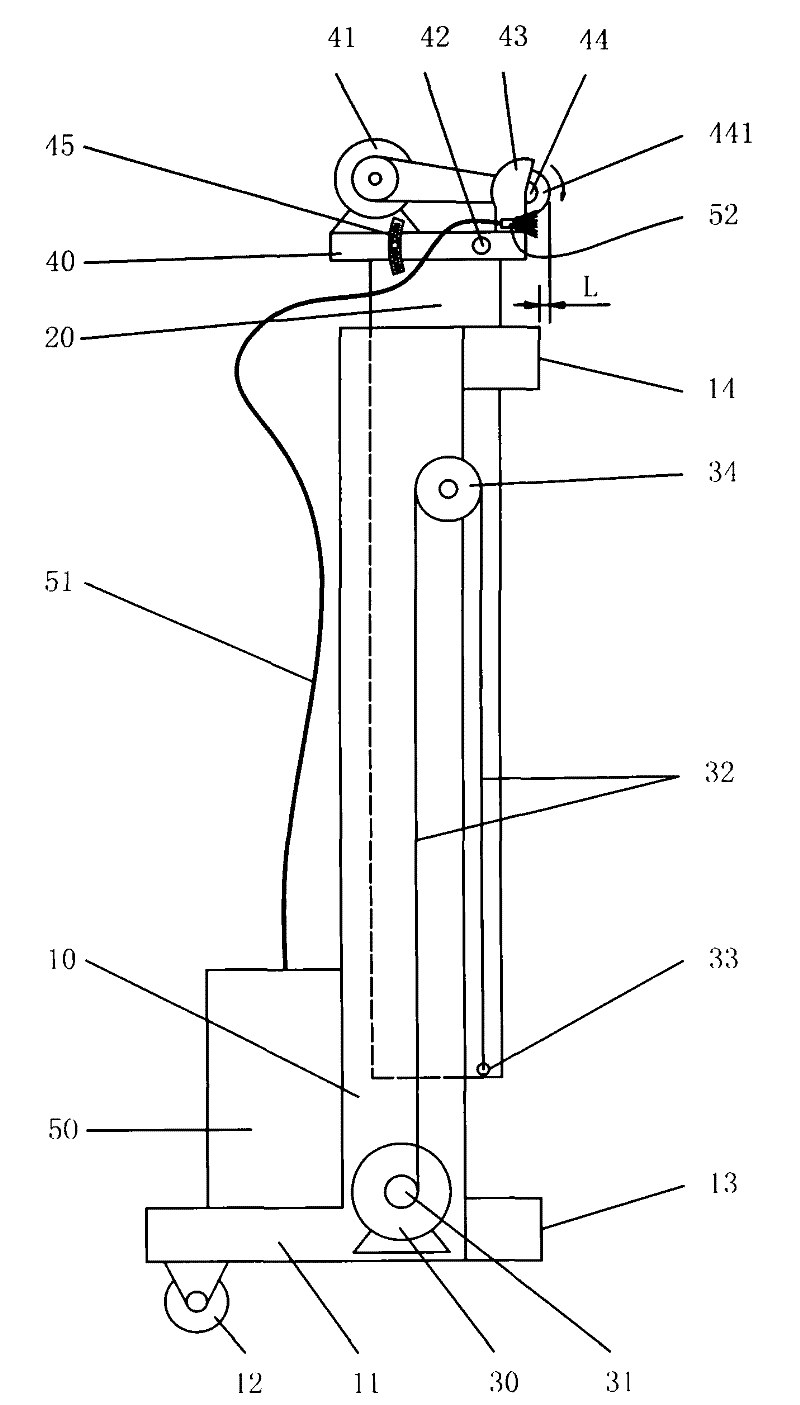

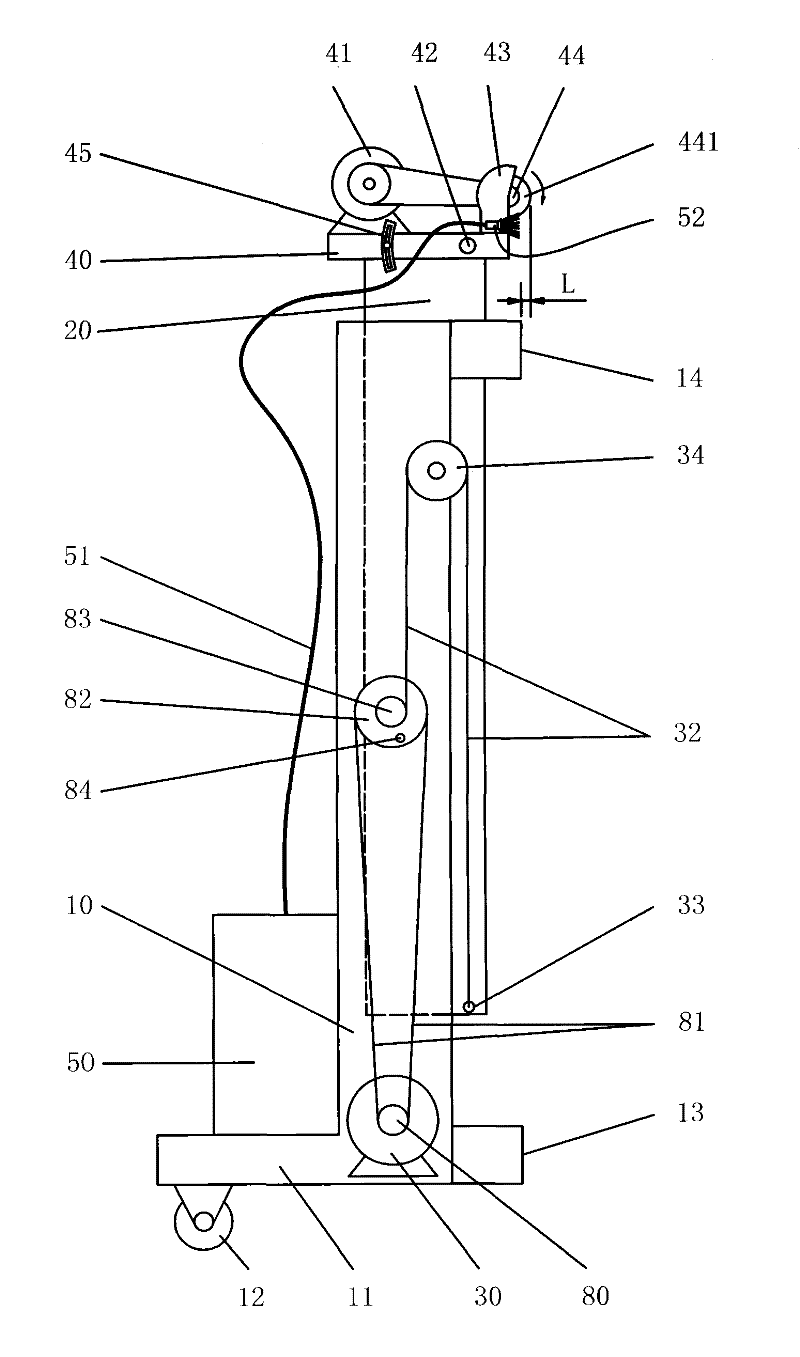

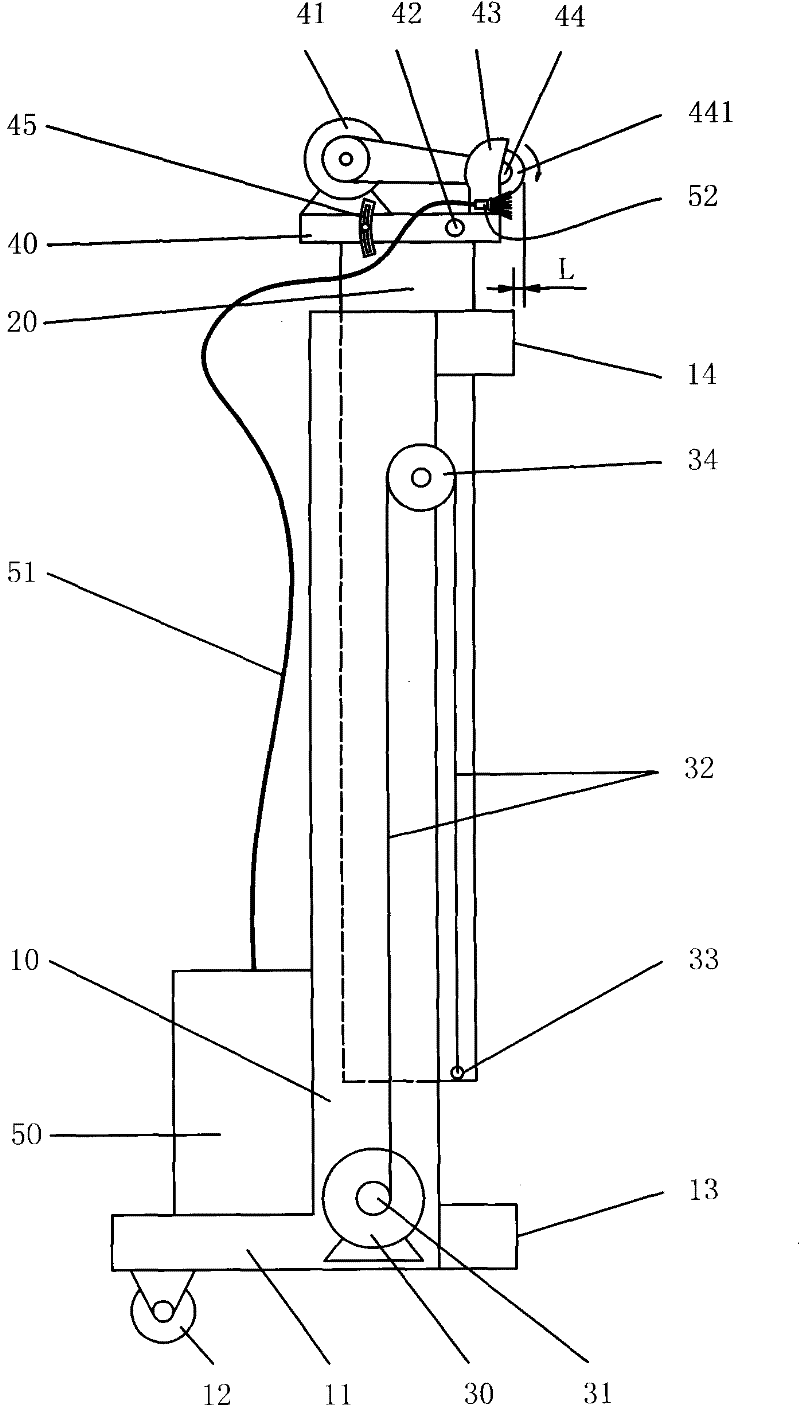

[0016] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-2 :

[0017] The telescopic dust-free wall slotting machine is provided with a slideway 10 and an atomizing dust removal mechanism 20 on the base 11. The slideway 10 is provided with a slide bar 20 moving along the slideway 10 and a slide bar lifting mechanism. The upper and lower parts of the side are respectively provided with limit blocks 13, 14, and the top of the slide bar 20 is hinged with a slotting working part. More than two circular saw blades 441 are installed on the 44, the rear portion of the circular saw blades 441 is provided with a safety cover 43, and the shower nozzle 52 connected with the atomizing dust removal mechanism 50 with the conduit 51 is arranged on the lower side of the safety cover 43, The atomization and dust removal mechanism 50 can use an electric sprayer or a high-pressure pump to increase the water pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com