Cleaning device with good cleaning effect for electronic hardware shell production

A technology of cleaning effect and cleaning device, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as poor cleaning effects, achieve improved cleaning effects, improve cleaning effects, and improve cleaning The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

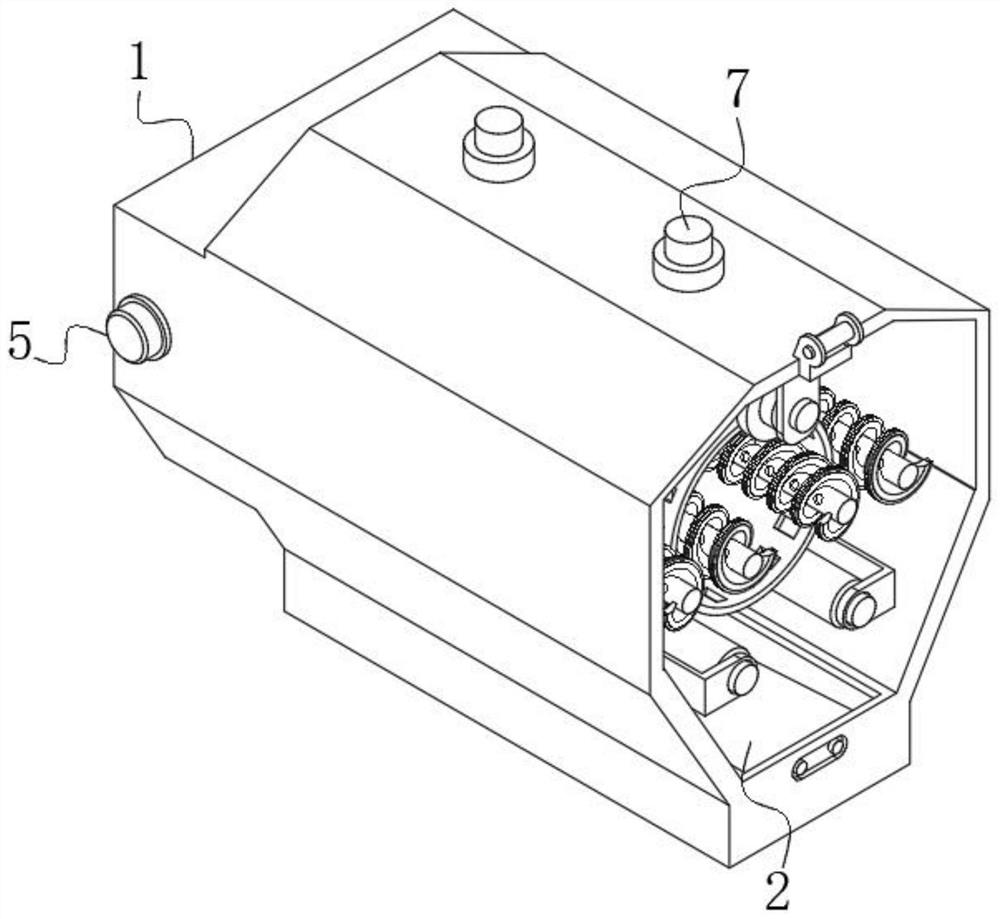

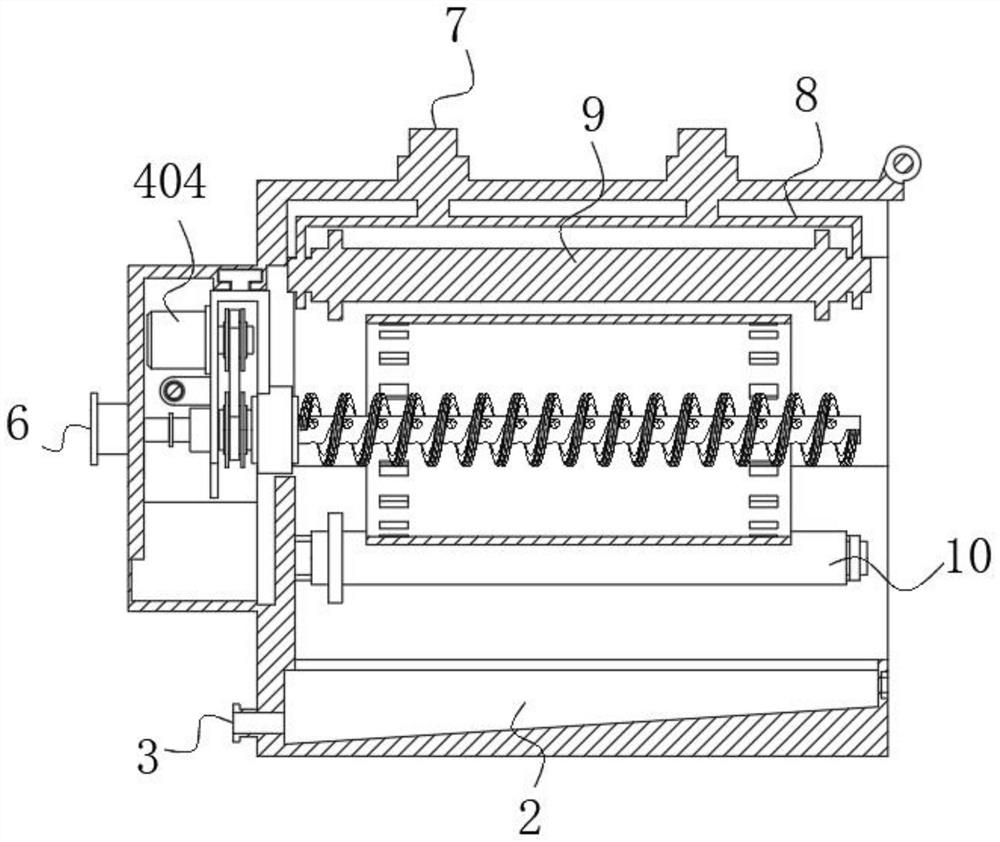

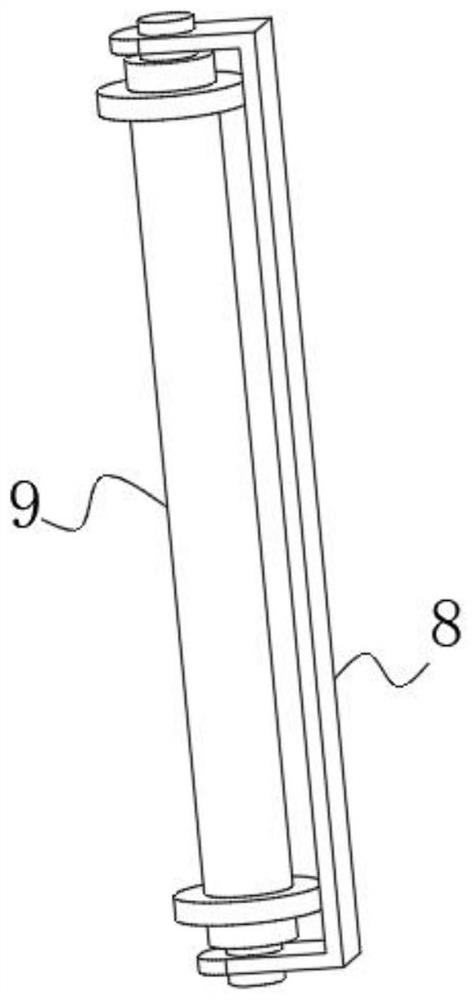

[0028] see Figure 1-7 , the present invention provides a technical solution: a cleaning device for the production of electronic hardware casings with good cleaning effect, including a casing 1, the end surface of the casing 1 is fixedly provided with a material inlet, and the end surface of the casing 1 is hinged with a material door, not shown in the figure It is shown that the surface of the material door is fixedly provided with a lock, the surface of the shell 1 is fixedly provided with a fastener matching the lock, the bottom of the shell 1 is fixedly provided with a waste water discharge chamber 2, and the interior of the waste water discharge chamber 2 is fixedly provided with a water guide slope , the back of the housing 1 is fixedly installed with a waste discharge pipe 3 communicating with the waste water discharge chamber 2. When in use, the waste discharge pipe 3 communicates with the external drainage pipe;

[0029] The top of the inner surface of the housing 1 i...

Embodiment 2

[0034] see Figure 1-7 , the present invention provides another technical solution: a cleaning device for the production of electronic hardware casings with good cleaning effect, comprising a casing 1, the end surface of the casing 1 is fixedly provided with a material inlet, and the end surface of the casing 1 is hinged with a material door, as shown in the figure Not shown in the figure, the surface of the material door is fixedly provided with a lock, the surface of the shell 1 is fixedly provided with a fastener matching the lock, the bottom of the shell 1 is fixedly provided with a waste water discharge chamber 2, and the interior of the waste water discharge chamber 2 is fixedly provided with a guide On the water slope, the back of the housing 1 is fixedly installed with a waste discharge pipe 3 connected to the waste water discharge chamber 2. When in use, the waste discharge pipe 3 communicates with the external drainage pipe;

[0035] The top of the inner surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com