Cleaning device for welded circuit board

A cleaning device and post-soldering technology, applied in the cleaning method of tools, cleaning/polishing of conductive patterns, removing smoke and dust, etc., can solve the problems of circuit board damage, affecting the health of workers, and the cleaning solvent cannot be volatilized and cleaned independently. , to achieve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

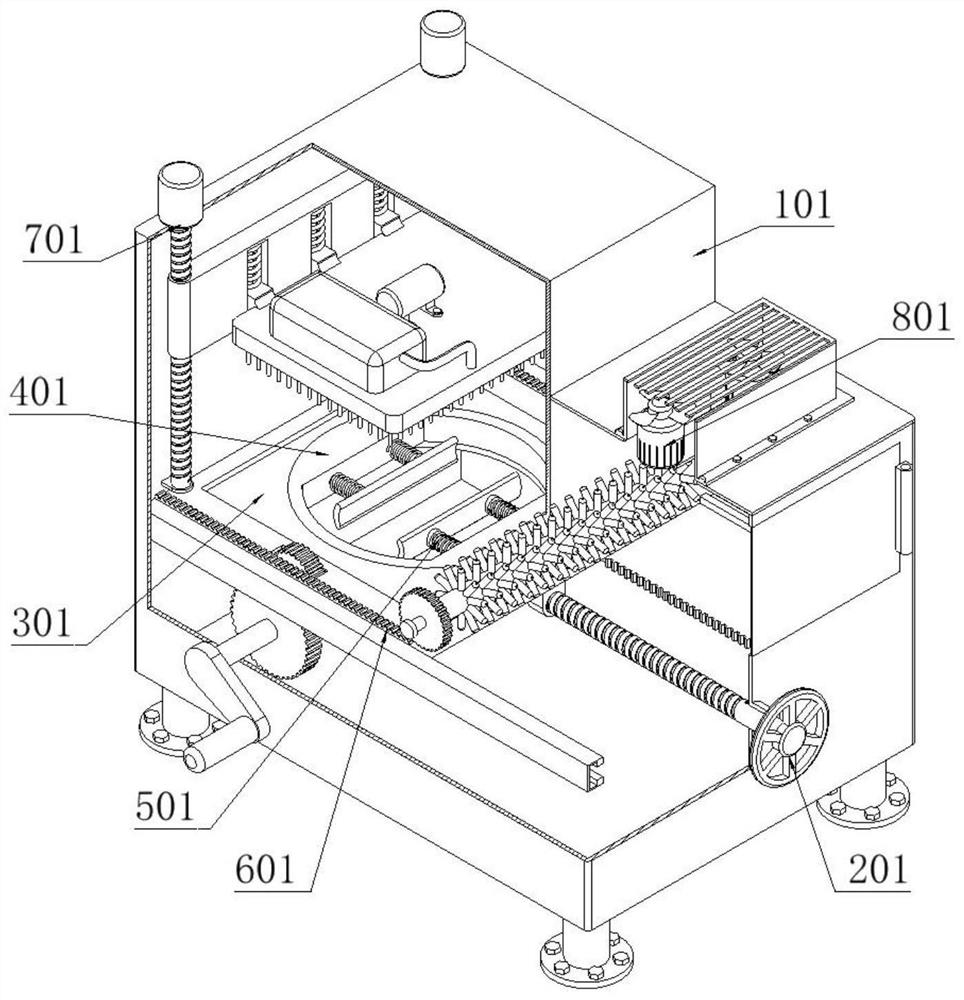

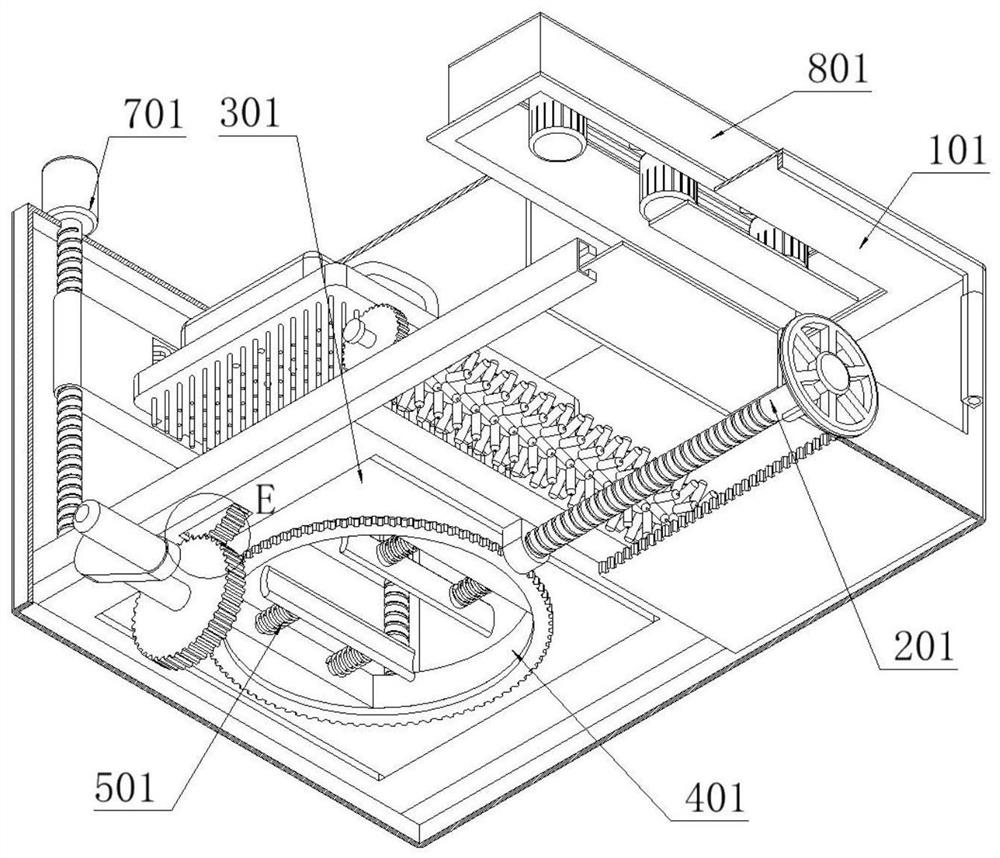

[0057] as attached figure 1 to attach Figure 15 Shown:

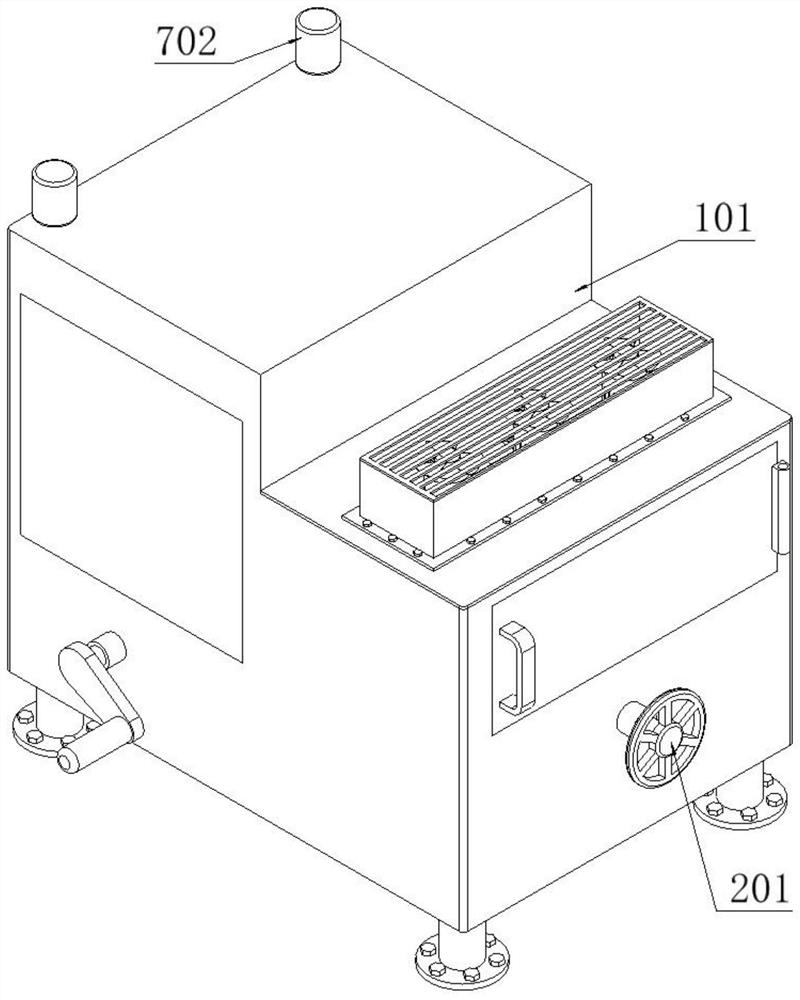

[0058] The present invention provides a cleaning device for circuit boards after welding, which includes a housing device 1;

[0059] The housing device 1, the housing device 1 is fixedly connected to the volatilization device 8 by bolts;

[0060] A supporting structure 2, the supporting structure 2 is slidably connected to the housing device 1;

[0061] Turning device 3, the turning device 3 is connected to the support structure 2 through the rotating shaft;

[0062] An adjustment device 4, the adjustment device 4 is connected to the turning device 3 through a rotating shaft;

[0063] The positioning device 5 is slidably connected to the adjusting device 4;

[0064] A dust removal structure 6, the dust removal structure 6 is connected to the housing device 1 through a rotating shaft;

[0065] The cleaning device 7 is fixedly connected to the housing device 1 .

[0066] as attached Figure 4 As shown, the housin...

Embodiment 2

[0096] On the basis of Embodiment 1, when the circuit board enters the device, the dust removal rack 601 drives the rotating dust removal sliver roller 602 to clean the circuit board of dust and static electricity while following the movement of the support bracket 202, and at the same time Wipe the solder joints; when the circuit board is soldered, each electronic component is often welded to the welding surface on the same side of the circuit board through the pins, so use the dust removal cotton sliver roller 602 to clean the pin welding surface, and no electronic components are needed. Clean the surface of the circuit board on the side to prevent loosening and desoldering of electronic components caused by the dust removal cotton sliver roller 602; During the movement, the rotating dust removal sliver roller 602 is driven to clean up the solvent residue on the circuit board. Since there are more electronic components welded on the circuit board surface on the electronic com...

Embodiment 3

[0102] On the basis of embodiment two, in order to accurately control the distance between the dust removal cotton sliver 6023 on the dust removal cotton sliver roller 602 and the surface of the circuit board, on the one hand, ensure that the dust removal cotton sliver 6023 can press the circuit board pin welding surface, and improve the surface cleaning effect; on the other hand, when the height of the electronic components on the circuit board is relatively large, increase the distance between the dust removal cotton sliver 6023 and the circuit board to ensure that the dust removal cotton sliver 6023 effectively cleans the residual solvent on the circuit board , can prevent the electronic components above the circuit board from being over-pressed, causing the electronic components to loosen and desolder, so the second magnetic block 6025 in the device is further improved.

[0103] The second magnetic attraction piece 6025 is an electromagnet, by controlling the size of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com