Flat comfortable fabric and bleaching and dyeing process thereof

A flat and fabric technology, applied in the direction of fiber type, textile, yarn, etc., can solve the problems of poor air permeability and water absorption of fabrics, affecting wearing comfort, rough outer surface of fabrics, etc., achieve soft hand feeling, improve water absorption effect, texture Thin and tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

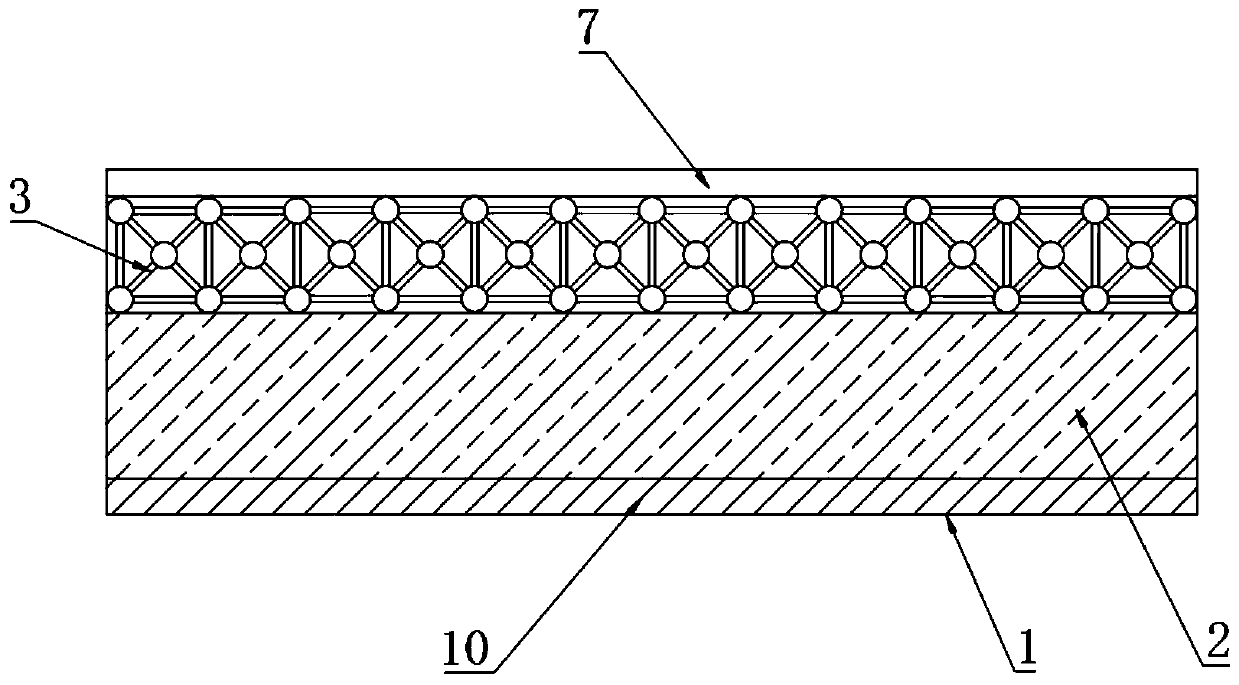

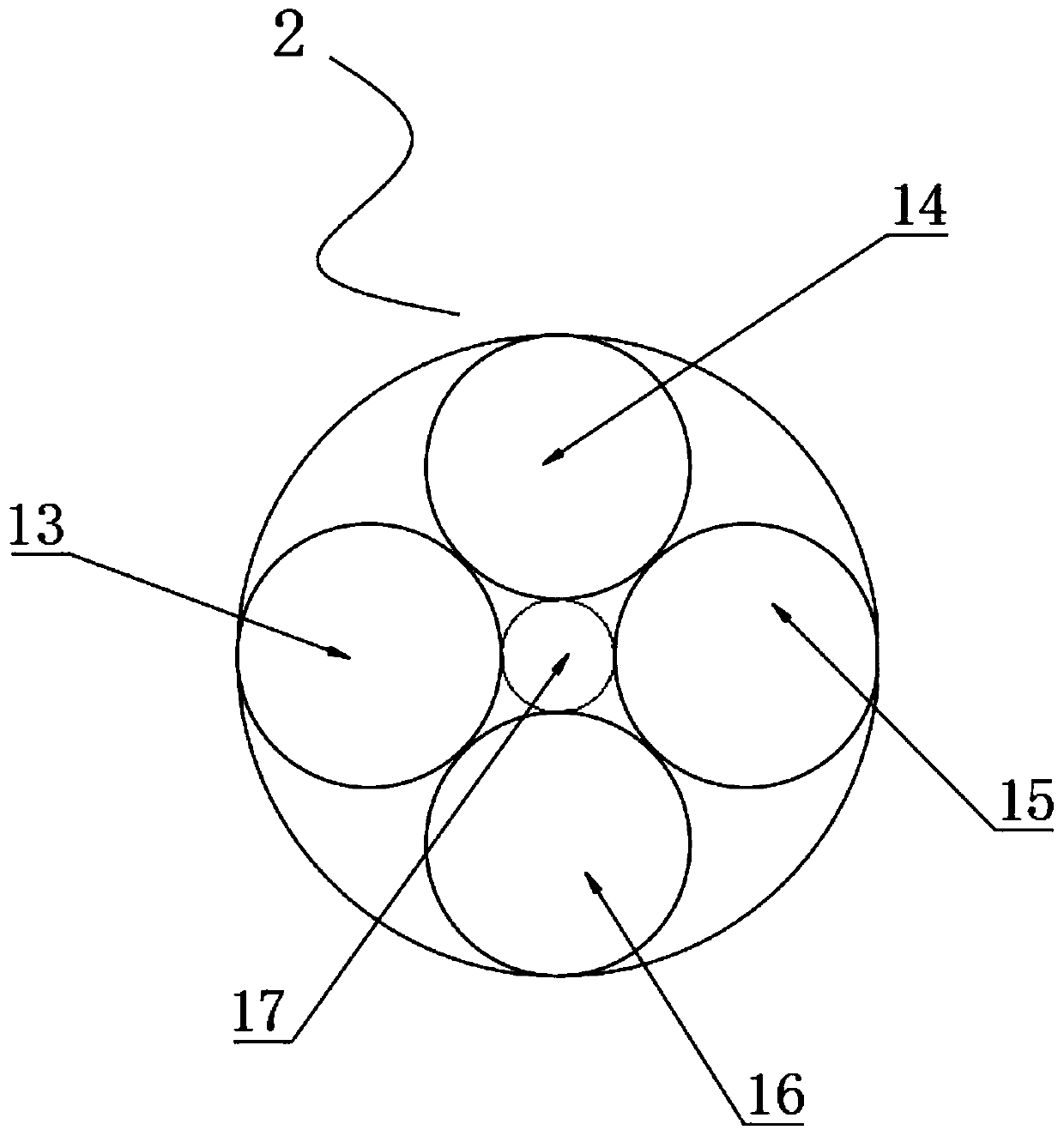

[0041] Such as Figure 1-6 As shown, the present invention provides a technical solution, a flat and comfortable fabric, comprising a fabric body 1, the fabric body 1 is fixedly connected with a substrate 2, and the substrate 2 includes cotton yarn 13, viscose yarn 14, cotton viscose yarn 15, Polyester cotton yarn 16 and air hole 17;

[0042] In order to improve the softness of the base body 2 and ensure the breathable effect of the base body 2, the base body 2 is spirally woven by cotton yarn 13, viscose yarn 14, cotton viscose yarn 15 and polyester-cotton yarn 16. Cotton yarn 13, viscose yarn 14. There are air holes 17 at the interlaced positions of the cotton viscose yarn 15 and the polyester-cotton yarn 16;

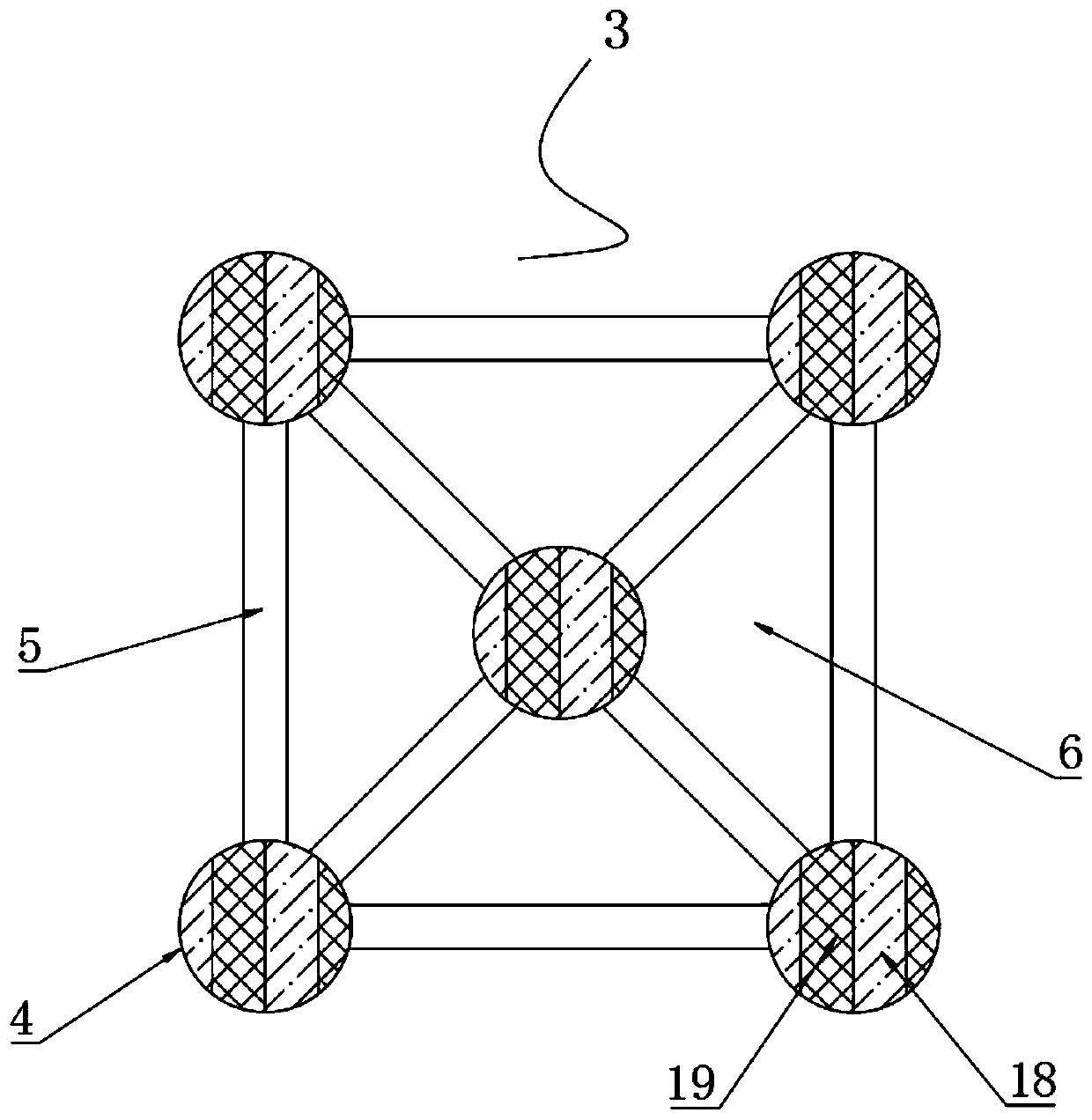

[0043] The top of the substrate 2 is fixedly connected with a breathable layer 3, and the inside of the breathable layer 3 is staggered and filled with water-absorbing balls 4, and every two water-absorbing balls 4 are fixedly connected with a connecting wire 5, and ...

Embodiment 2

[0048] Such as Figure 1-6As shown, the present invention provides a technical solution, a flat and comfortable fabric, comprising a fabric body 1, the fabric body 1 is fixedly connected with a substrate 2, and the substrate 2 includes cotton yarn 13, viscose yarn 14, cotton viscose yarn 15, Polyester cotton yarn 16 and air hole 17;

[0049] In order to improve the softness of the base body 2 and ensure the breathable effect of the base body 2, the base body 2 is spirally woven by cotton yarn 13, viscose yarn 14, cotton viscose yarn 15 and polyester-cotton yarn 16. Cotton yarn 13, viscose yarn 14. There are air holes 17 at the interlaced positions of the cotton viscose yarn 15 and the polyester-cotton yarn 16;

[0050] The top of the substrate 2 is fixedly connected with a breathable layer 3, and the inside of the breathable layer 3 is staggered and filled with water-absorbing balls 4, and every two water-absorbing balls 4 are fixedly connected with a connecting wire 5, and a...

Embodiment 3

[0055] Such as Figure 1-6 As shown, the present invention provides a technical solution, a flat and comfortable fabric, comprising a fabric body 1, the fabric body 1 is fixedly connected with a substrate 2, and the substrate 2 includes cotton yarn 13, viscose yarn 14, cotton viscose yarn 15, Polyester cotton yarn 16 and air hole 17;

[0056] In order to improve the softness of the base body 2 and ensure the breathable effect of the base body 2, the base body 2 is spirally woven by cotton yarn 13, viscose yarn 14, cotton viscose yarn 15 and polyester-cotton yarn 16. Cotton yarn 13, viscose yarn 14. There are air holes 17 at the interlaced positions of the cotton viscose yarn 15 and the polyester-cotton yarn 16;

[0057] The top of the substrate 2 is fixedly connected with a breathable layer 3, and the inside of the breathable layer 3 is staggered and filled with water-absorbing balls 4, and every two water-absorbing balls 4 are fixedly connected with a connecting wire 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com