Patents

Literature

353results about "Hand artistic tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

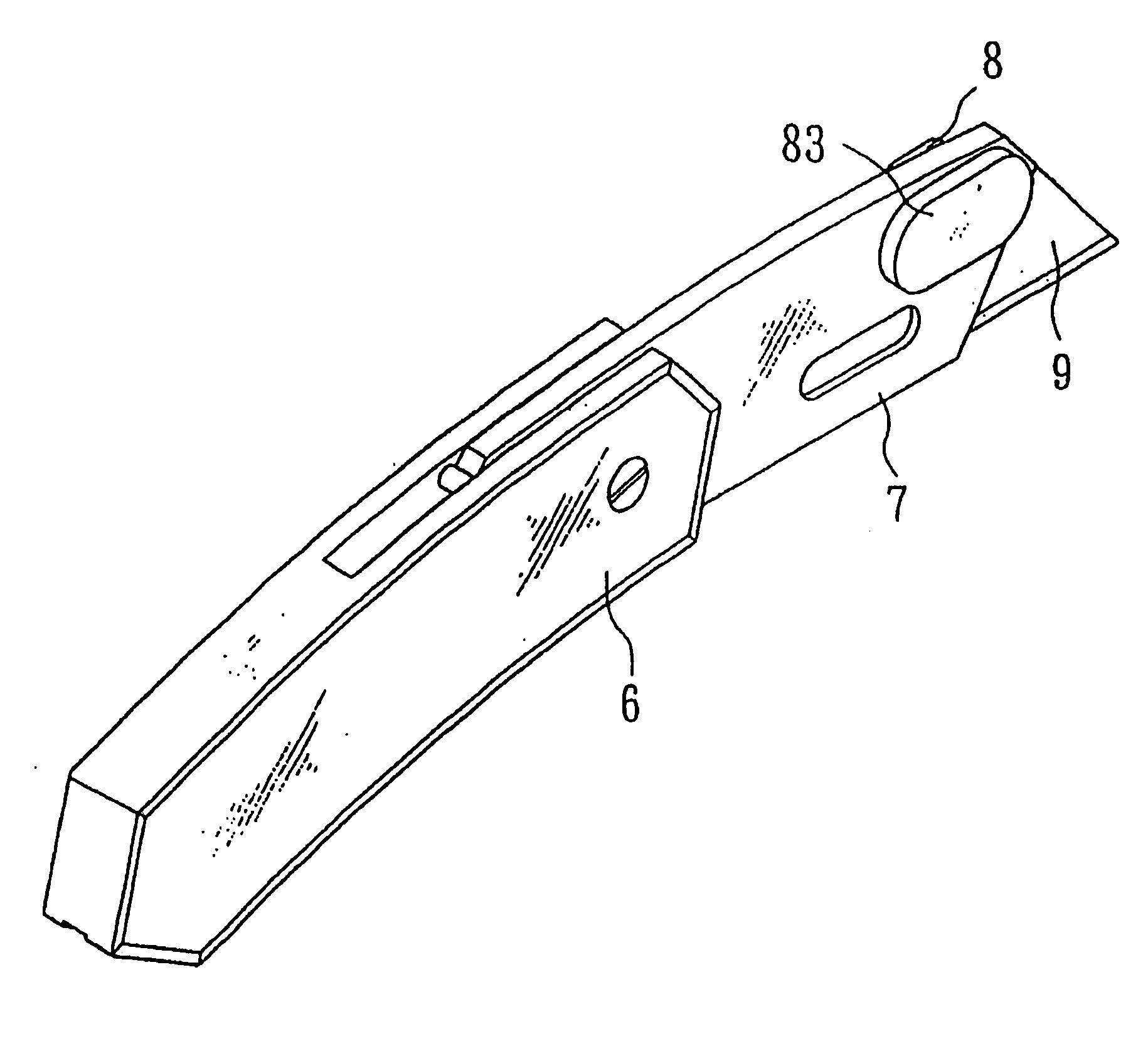

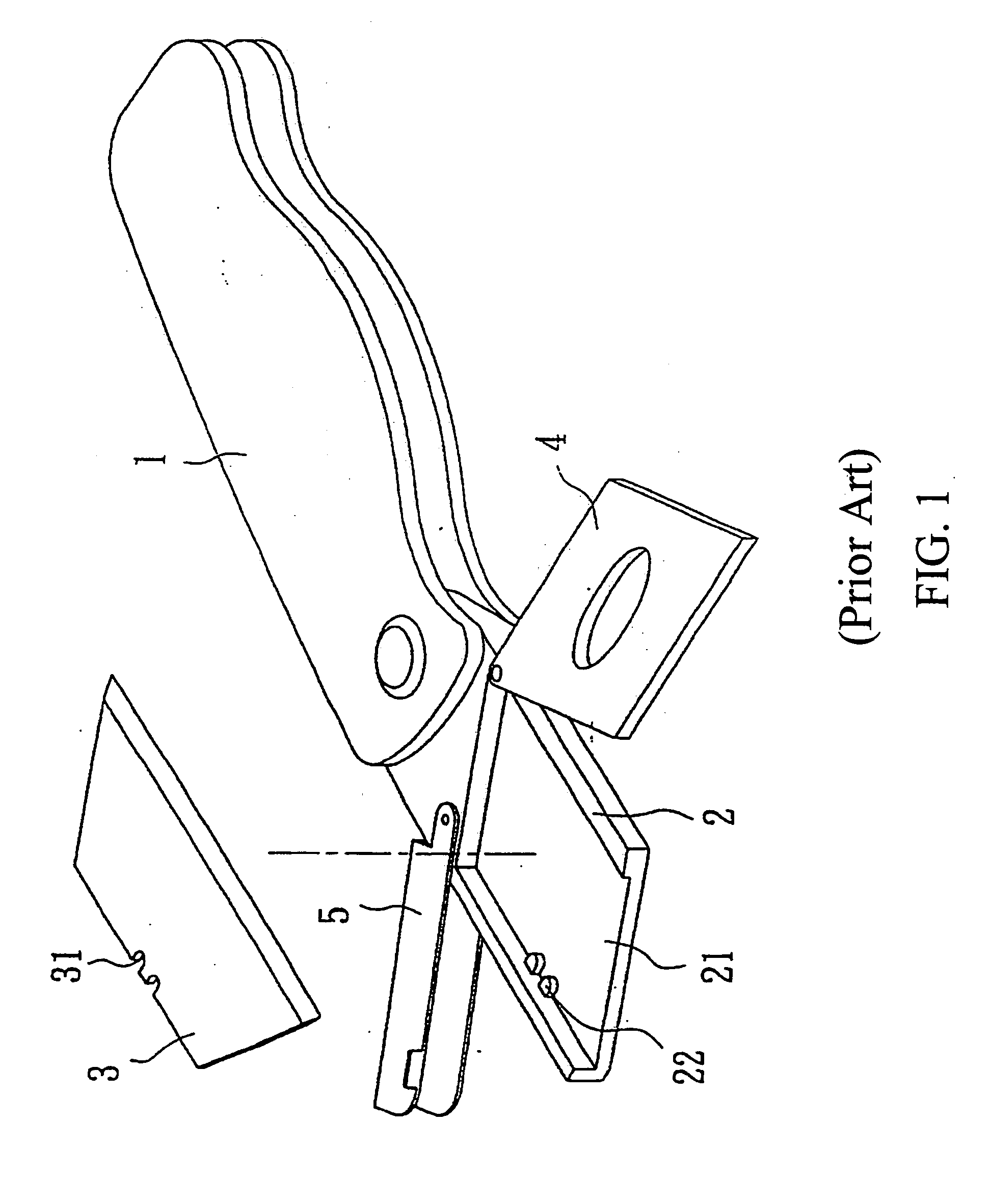

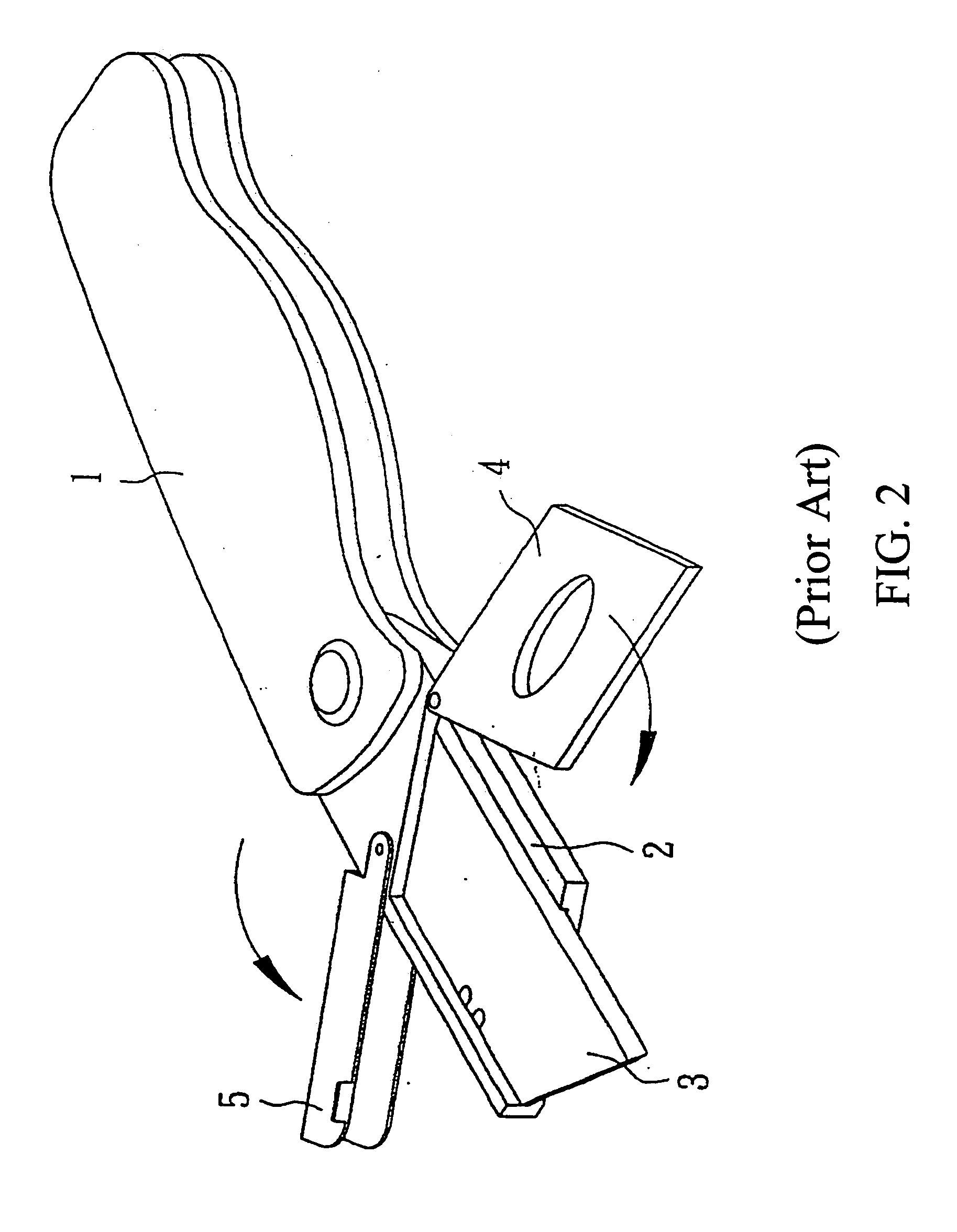

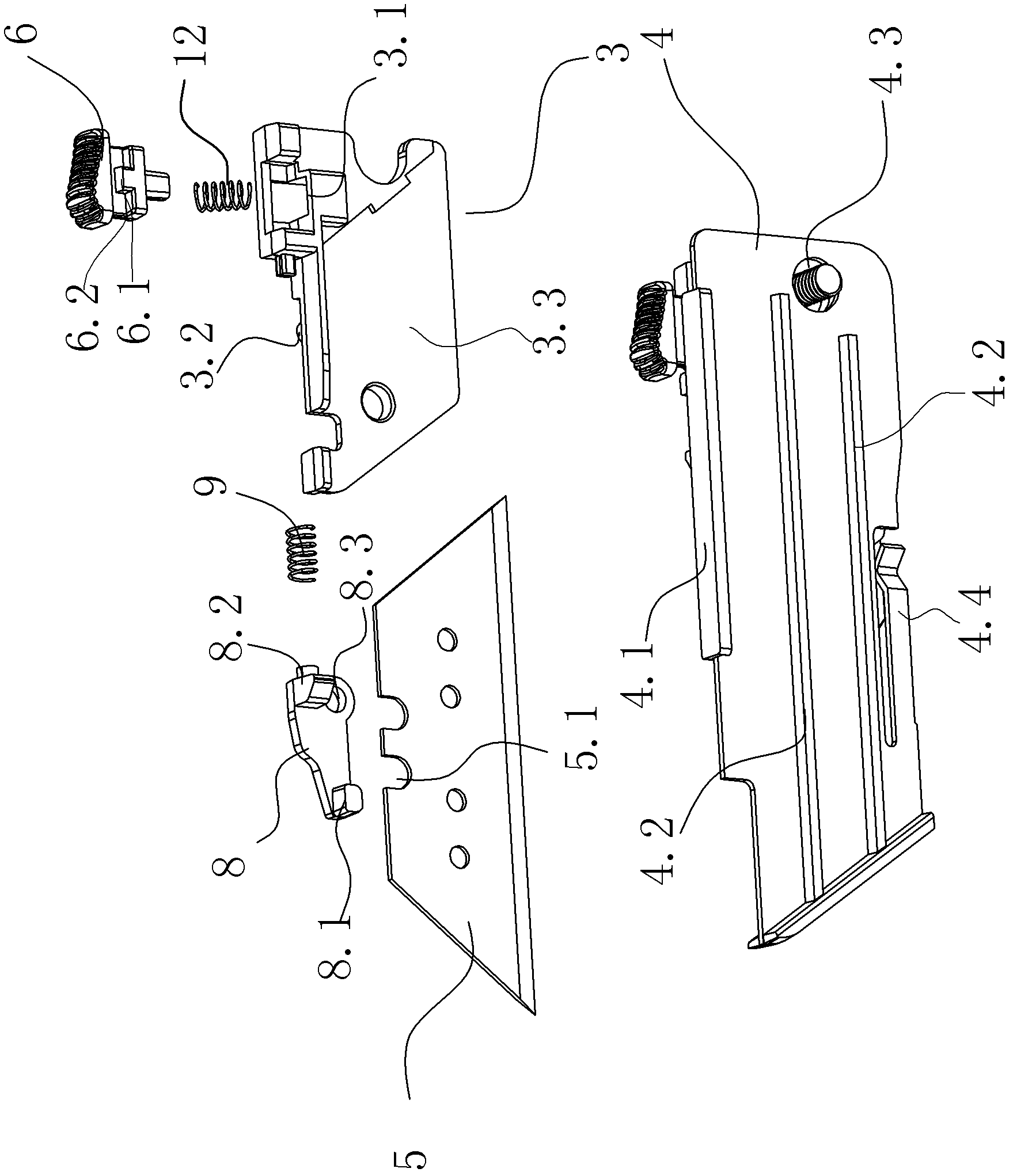

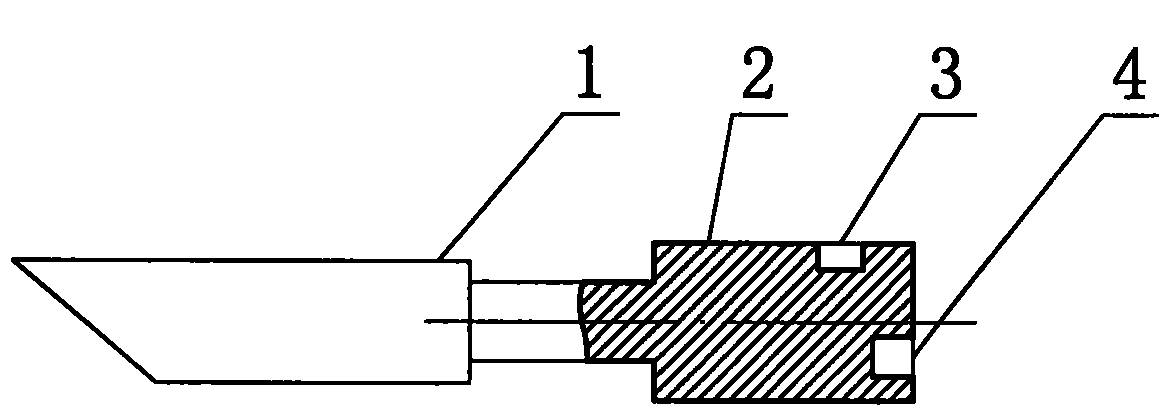

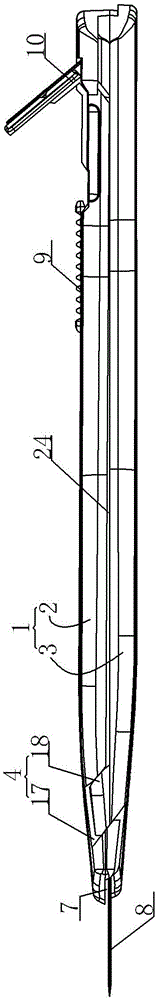

Knife having removable blade

InactiveUS20050278955A1Positive controlEasy to replaceHand artistic toolsThrusting weaponsPositive controlEngineering

A knife is provided having a blade that can be replaced easily without risk to the user, allowing the user to maintain positive control over the blade during replacement. In an exemplary embodiment, the knife includes a lock coupled to a blade holder. The lock extends through apertures of the blade holder to engage the blade. More particularly, the lock can move between an engaged position in which the lock engages a recess of the blade and a disengaged position in which the lock disengages the blade, allowing the blade to be removed. With the lock disengaged, a user can remove the blade while maintaining positive control over the blade.

Owner:TEST RITE PRODS

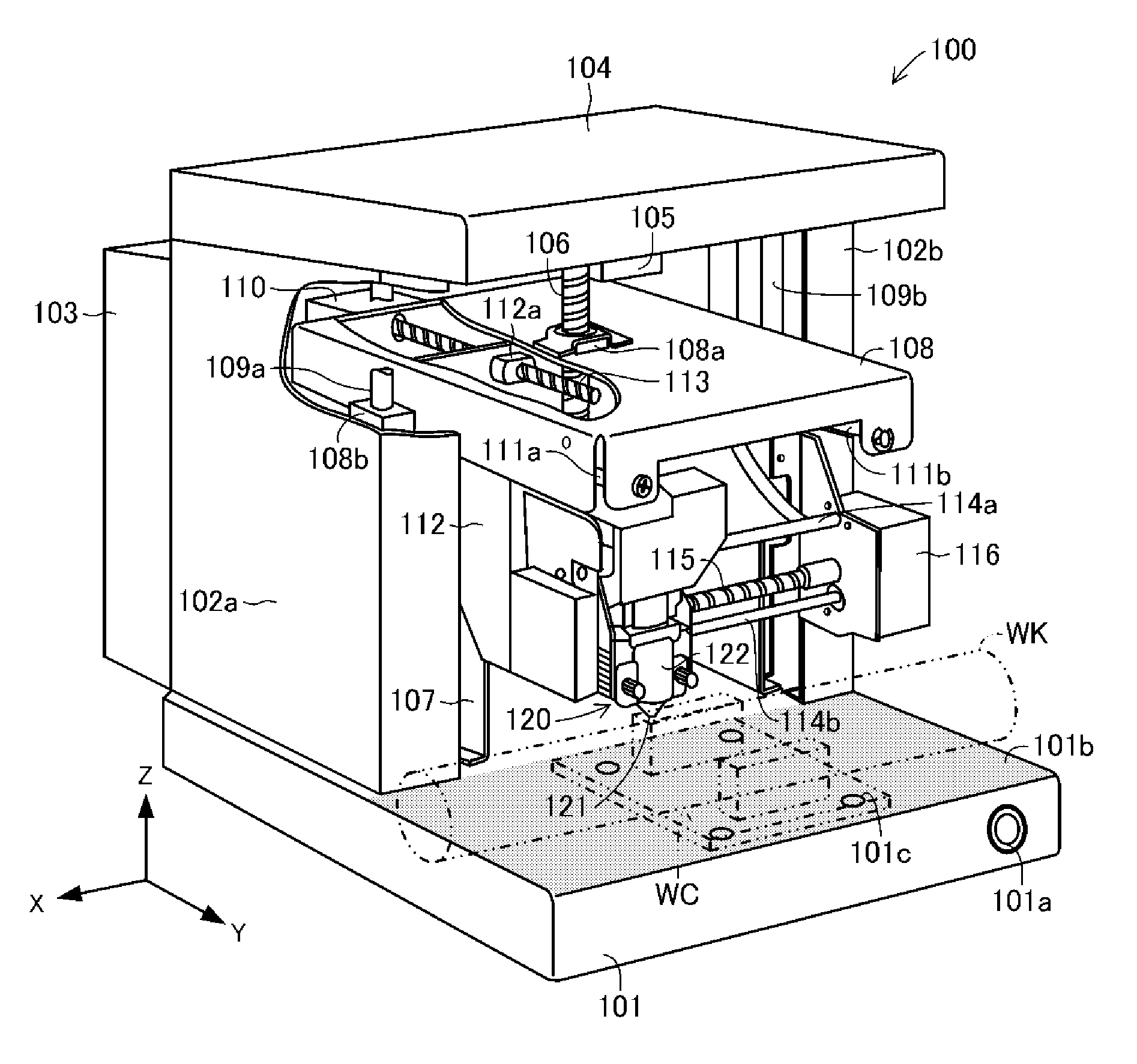

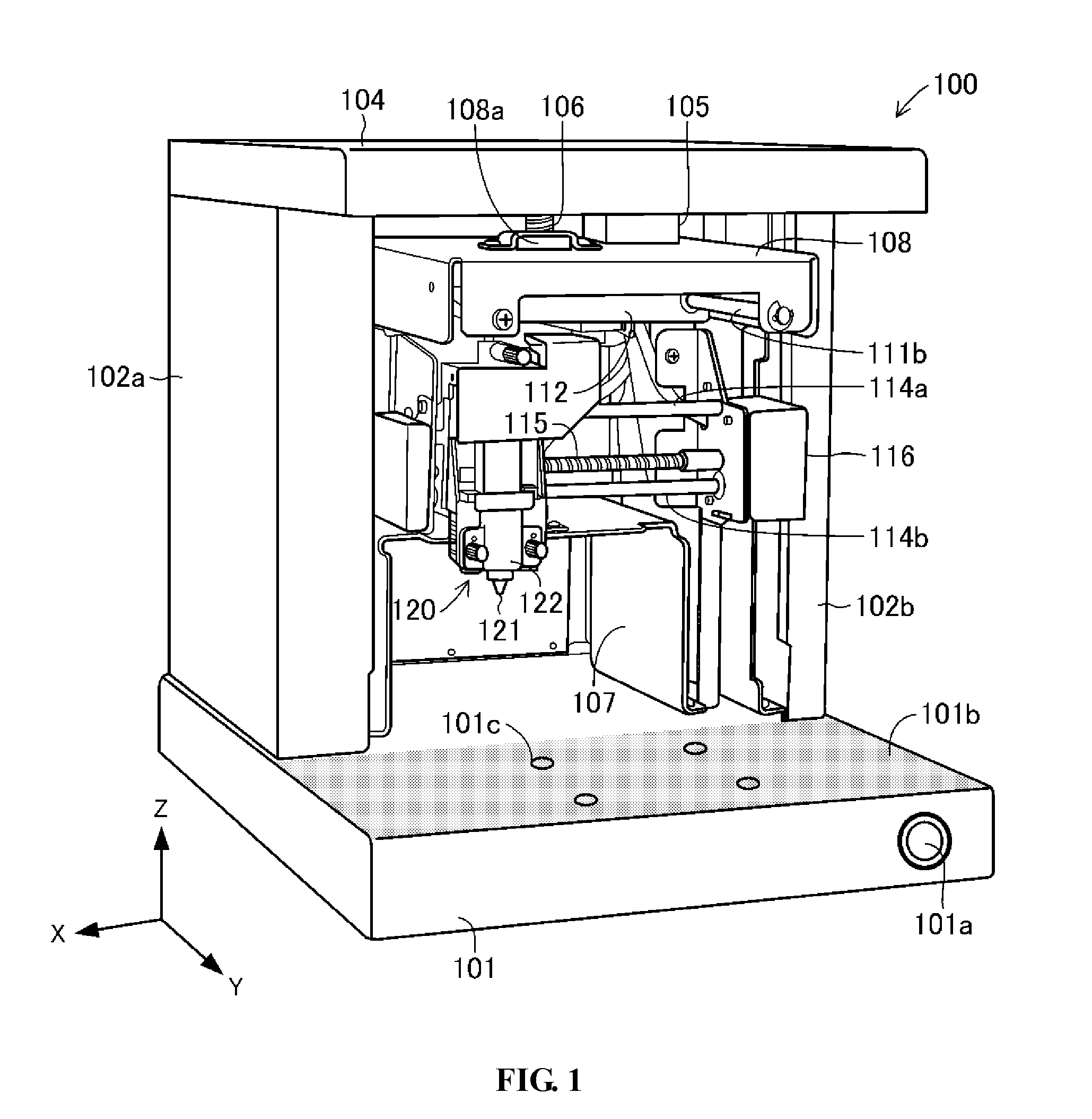

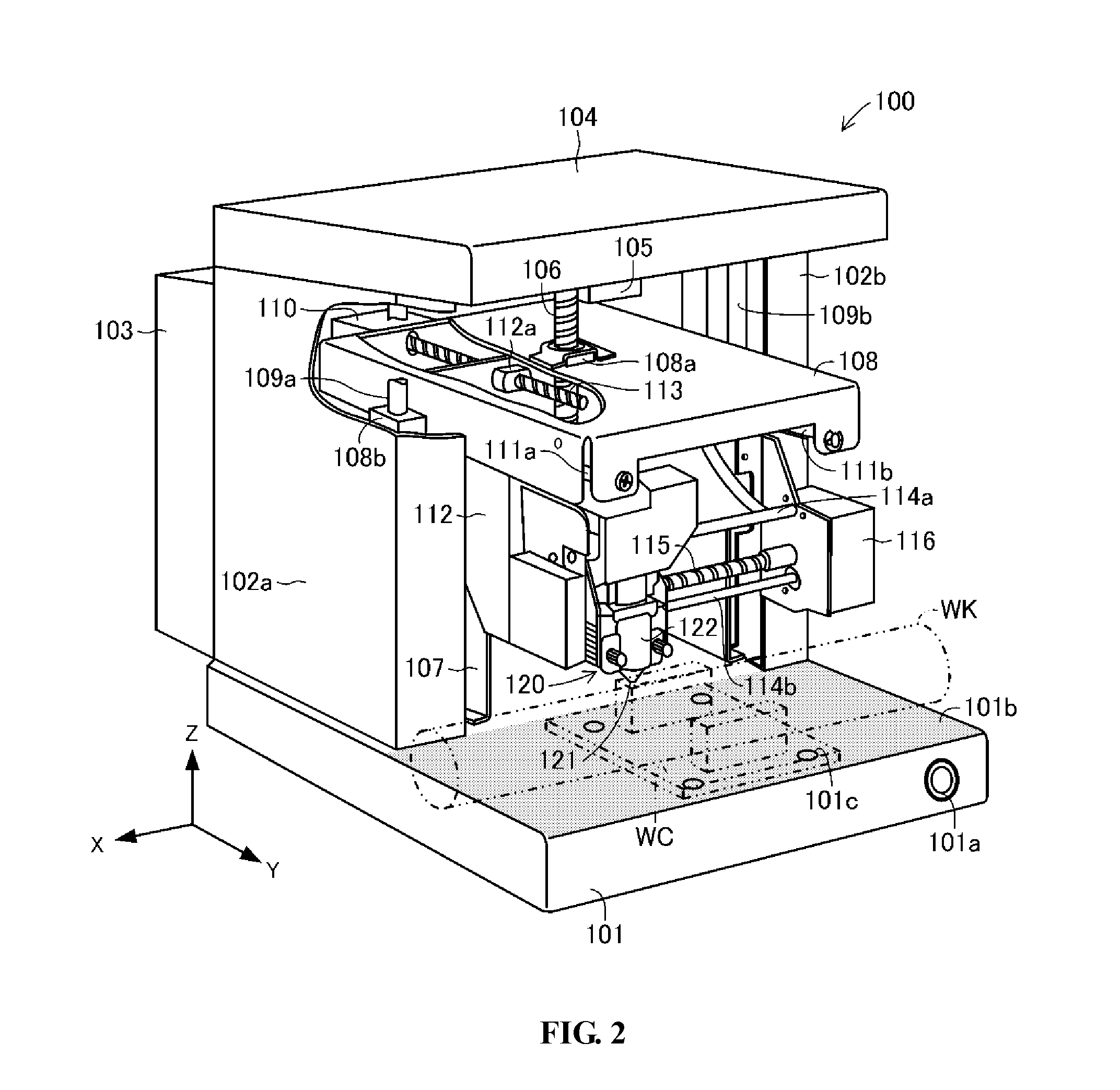

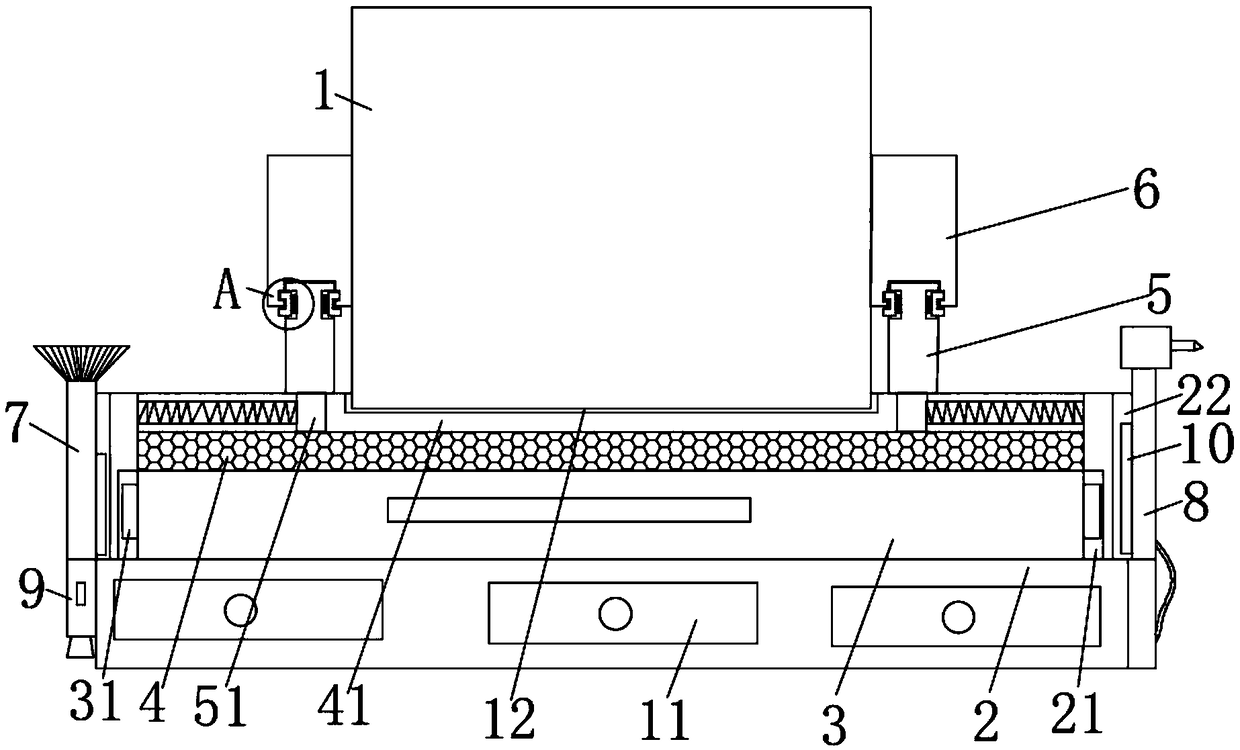

Stamping machine

ActiveUS20110168039A1Mechanical working/deformationHand artistic toolsEngineeringMechanical engineering

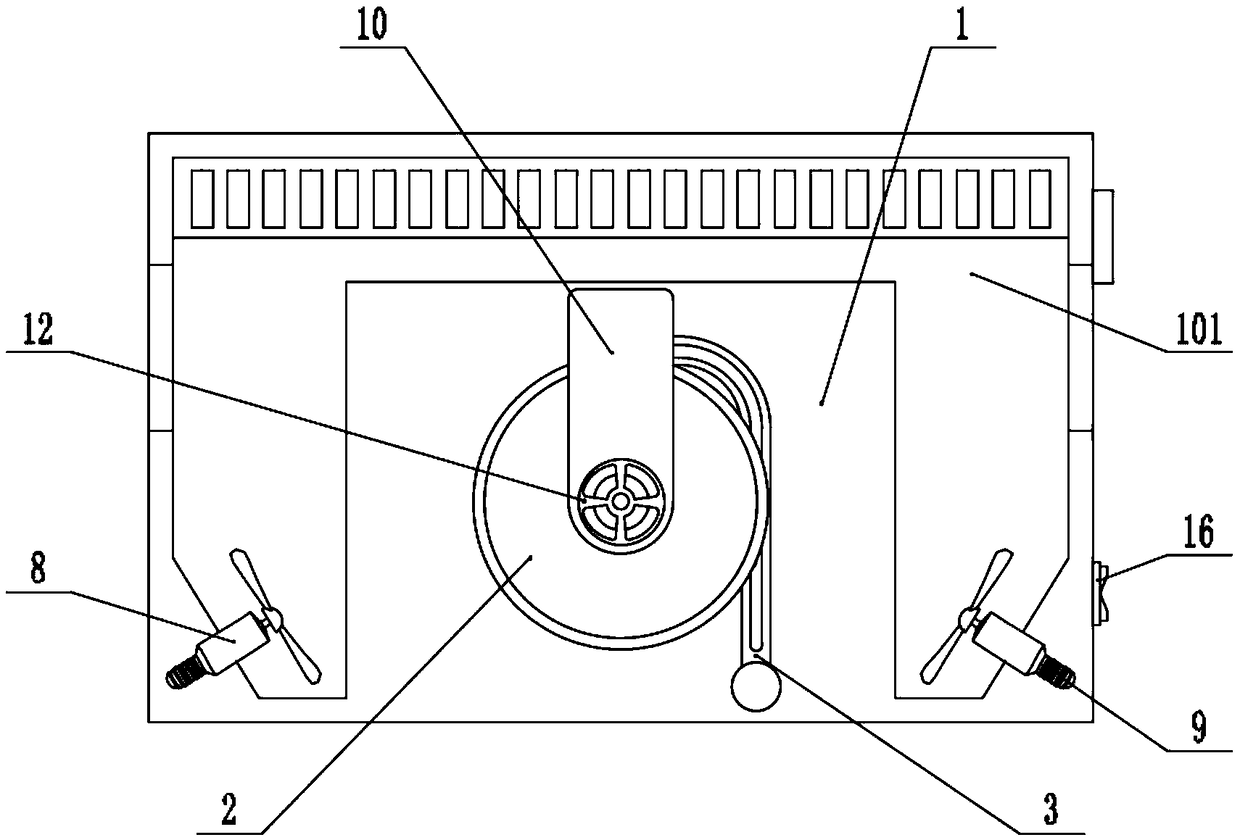

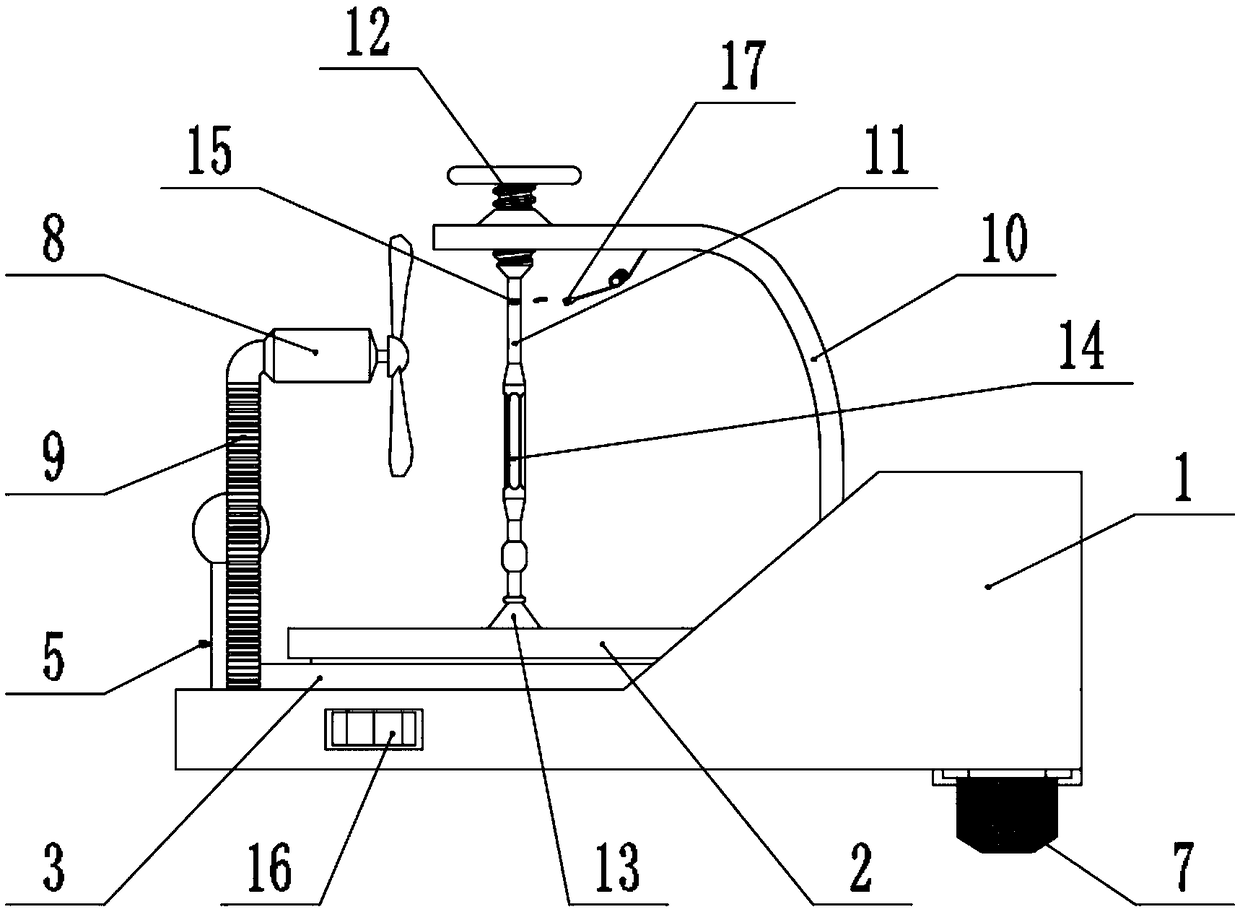

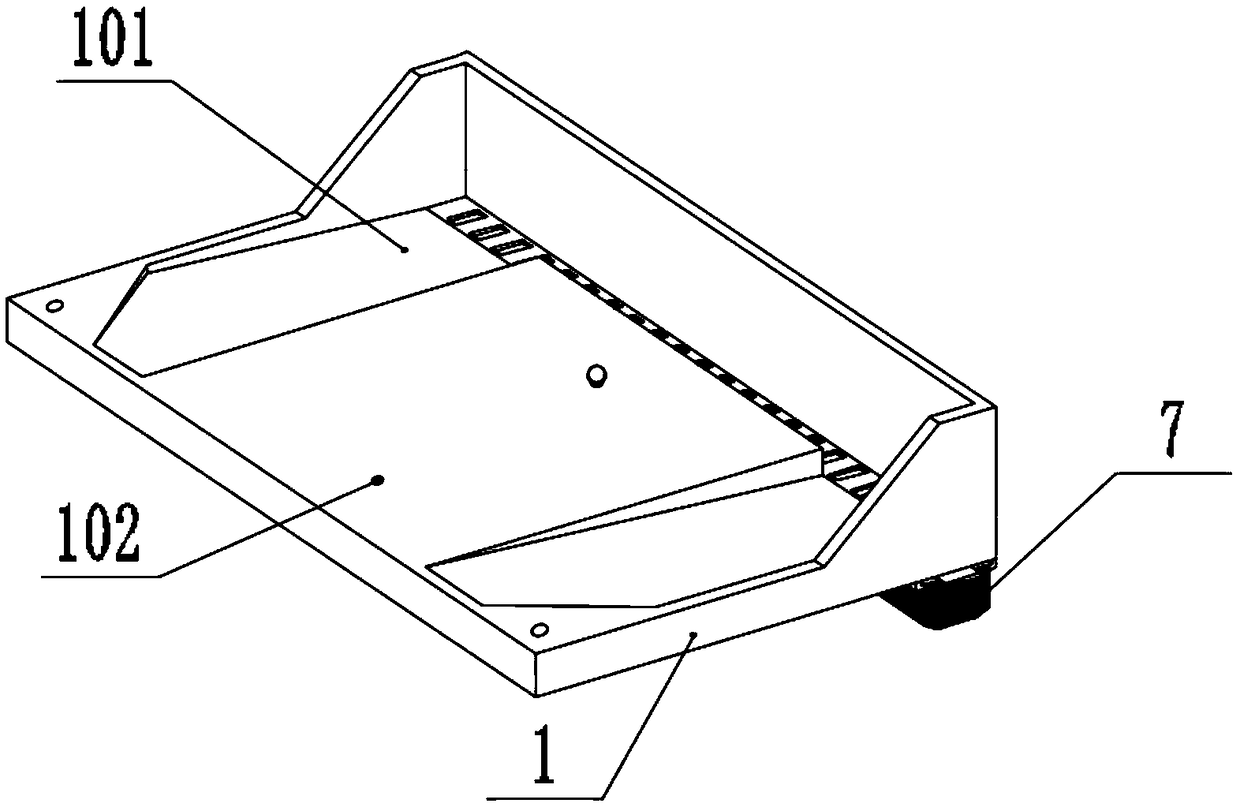

An engraving device that forms a desired image via a plurality of engraved marks in a surface of an object via a working tool is presented. The engraving device includes a base comprising a retainer configured to retain the object, a X-direction displacement means located above the base, configured to displace the working tool along a X-axis along the surface of the object, a Y-direction displacement means located above the base, configured to displace the working tool along a Y-axis perpendicular to the X-axis along the surface of the object, and a Z-direction displacement means located above the base, configured to displace the working tool along a Z-axis toward and away from the object.

Owner:ROLAND DG CORP

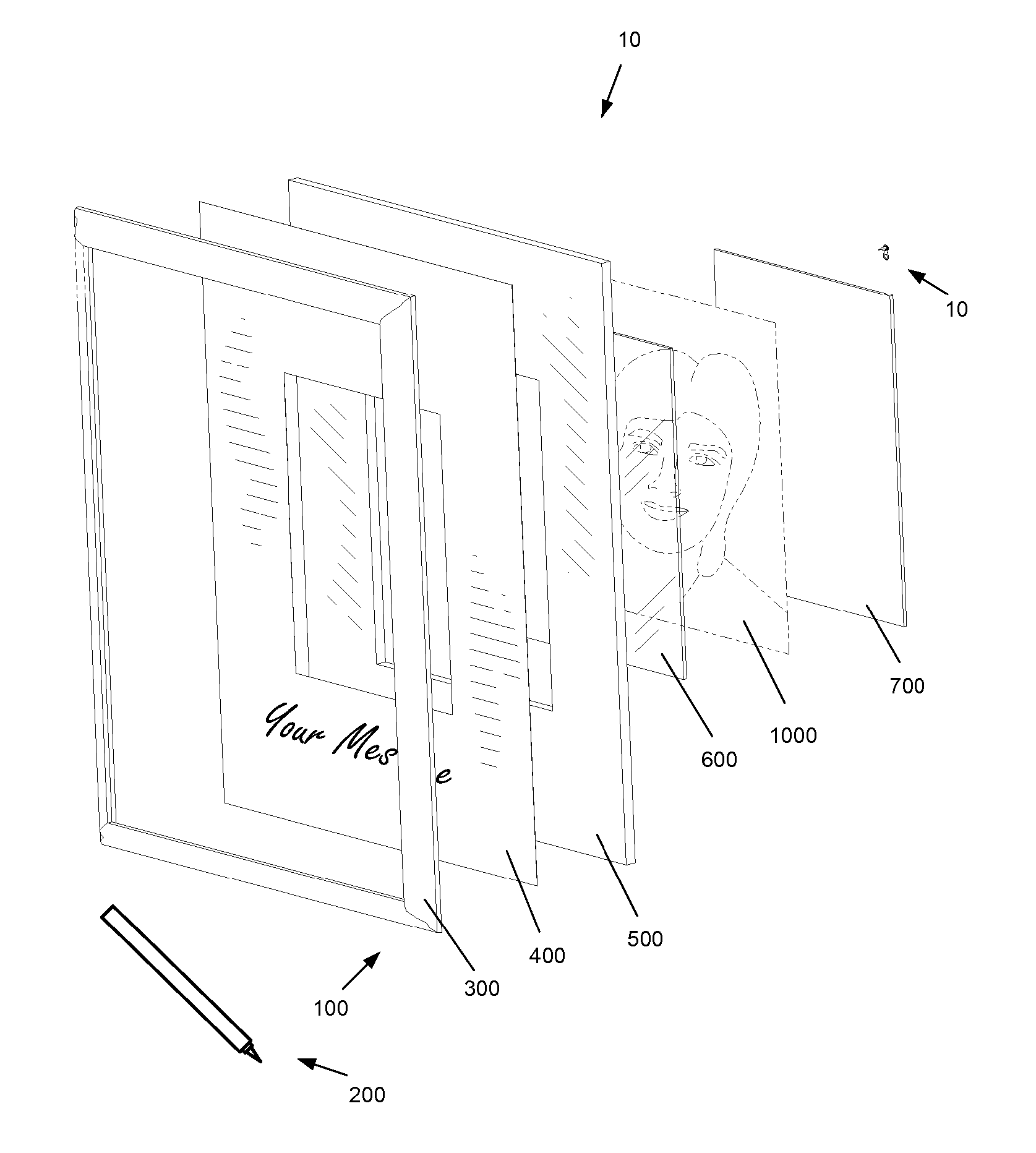

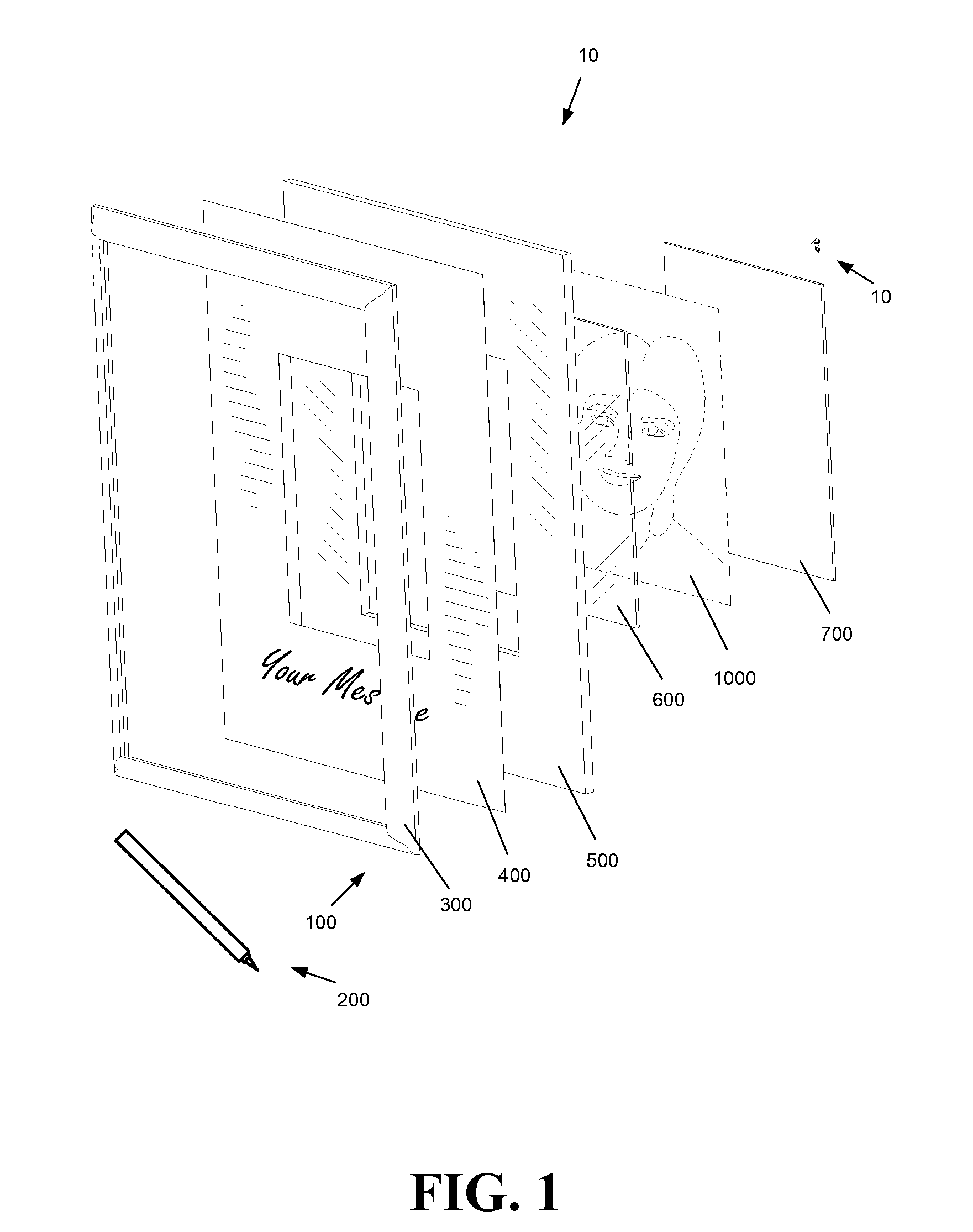

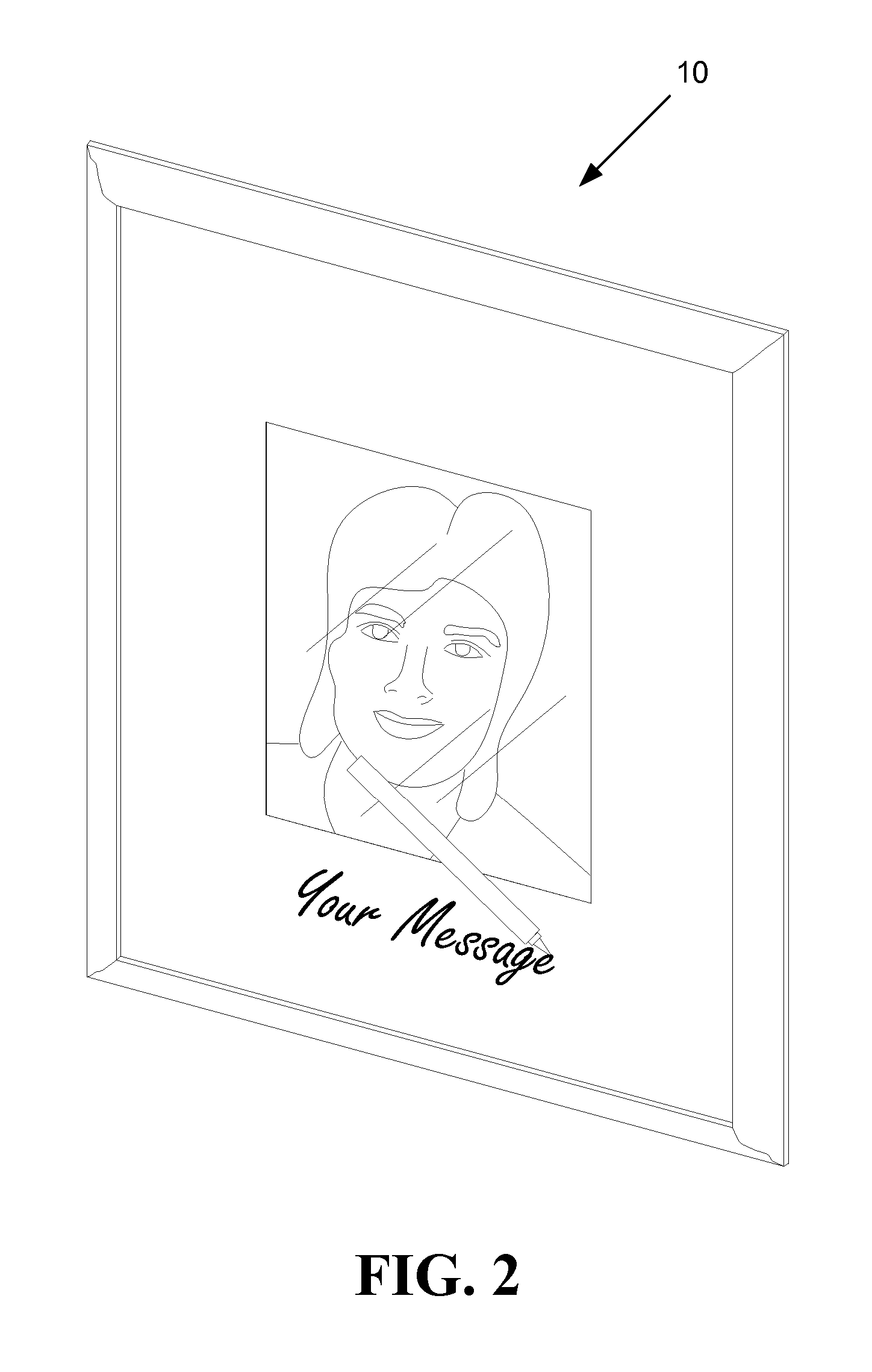

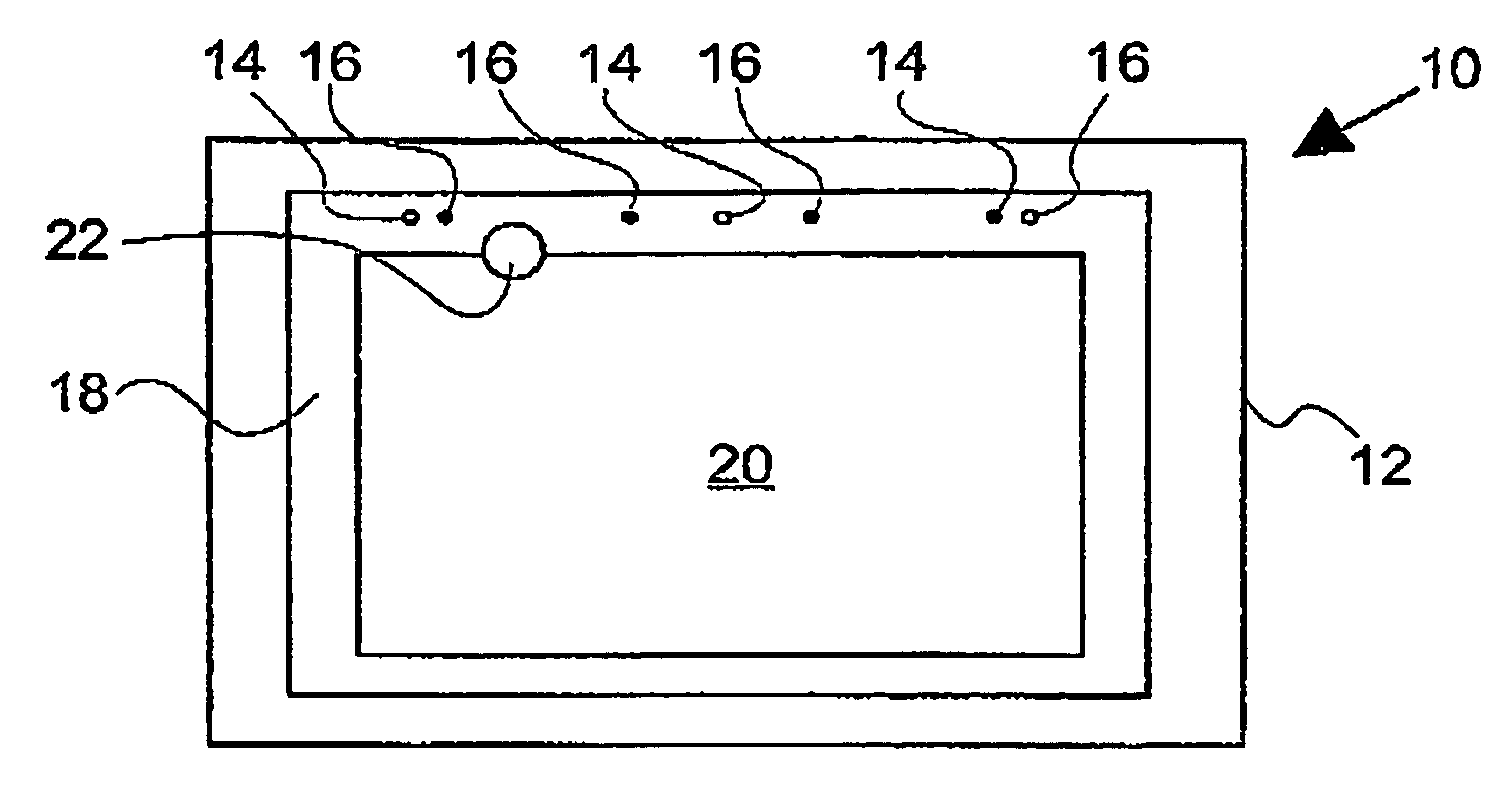

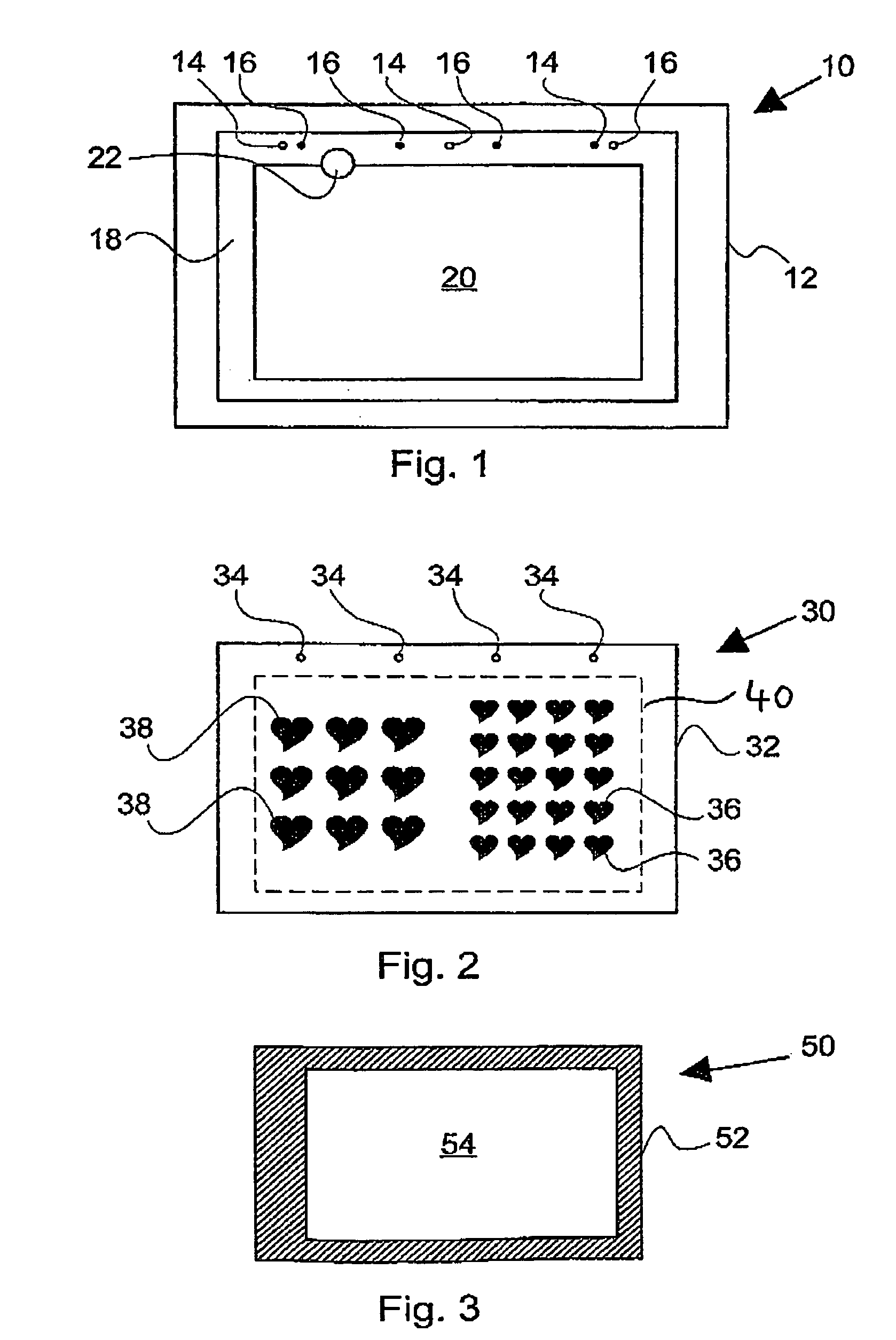

Memorabilia kit and system

InactiveUS20080000127A1Easy and efficient to manufactureDurable and reliable constructionHand artistic toolsPicture framesEngineeringDocumentation

A memorabilia kit and system directed to a more durable guest signature platform is disclosed. Elements include a memorabilia assembly, a signature engraving scribe, a polishing cloth and an instruction card. The memorabilia assembly is typically comprised of a frame, a metal signature mat board, a first backing material, a protective material, a second backing material, flex-tabs and hanging hardware. Additional elements of the memorabilia assembly may include a stock photo or document. Additional elements of the memorabilia kit may include an instruction card picture frame, an instruction card stand, a memorabilia assembly stand.

Owner:SHIMER GARY W

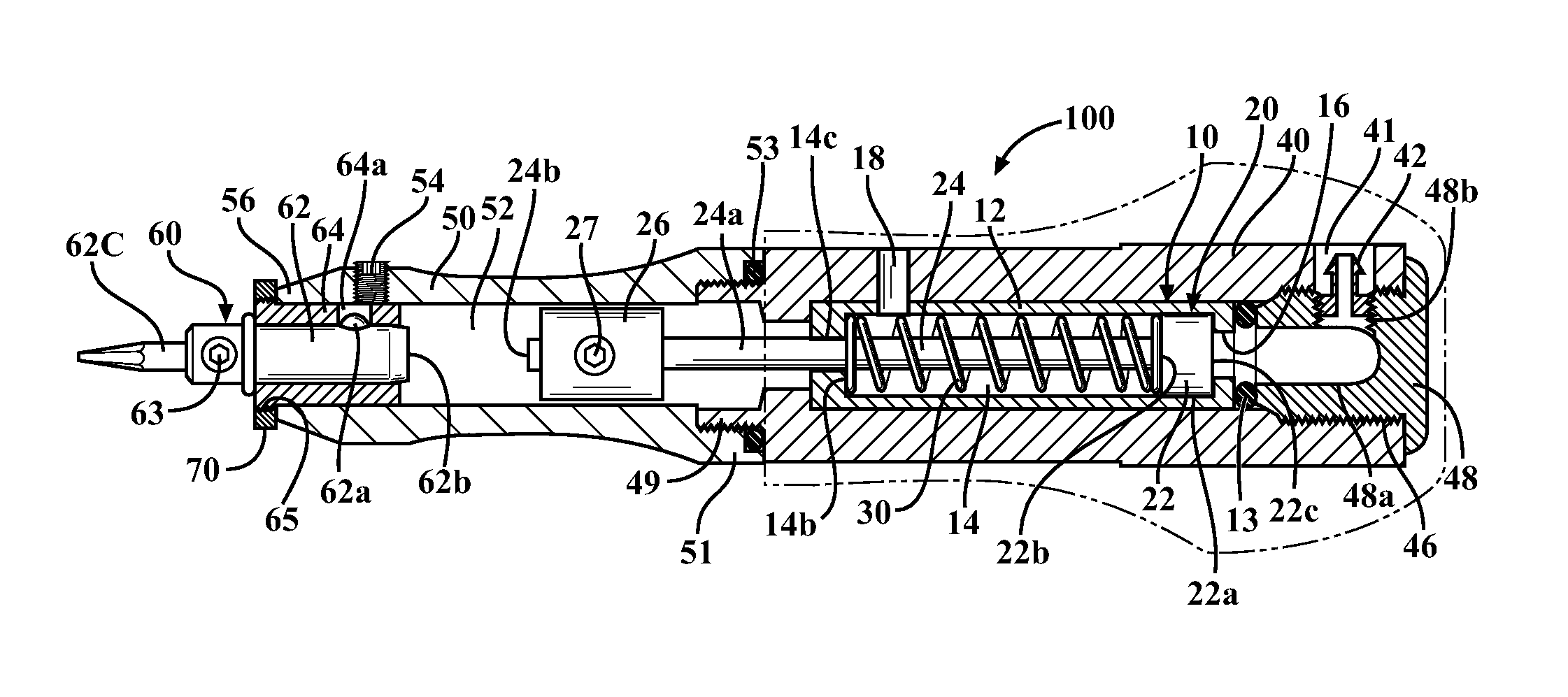

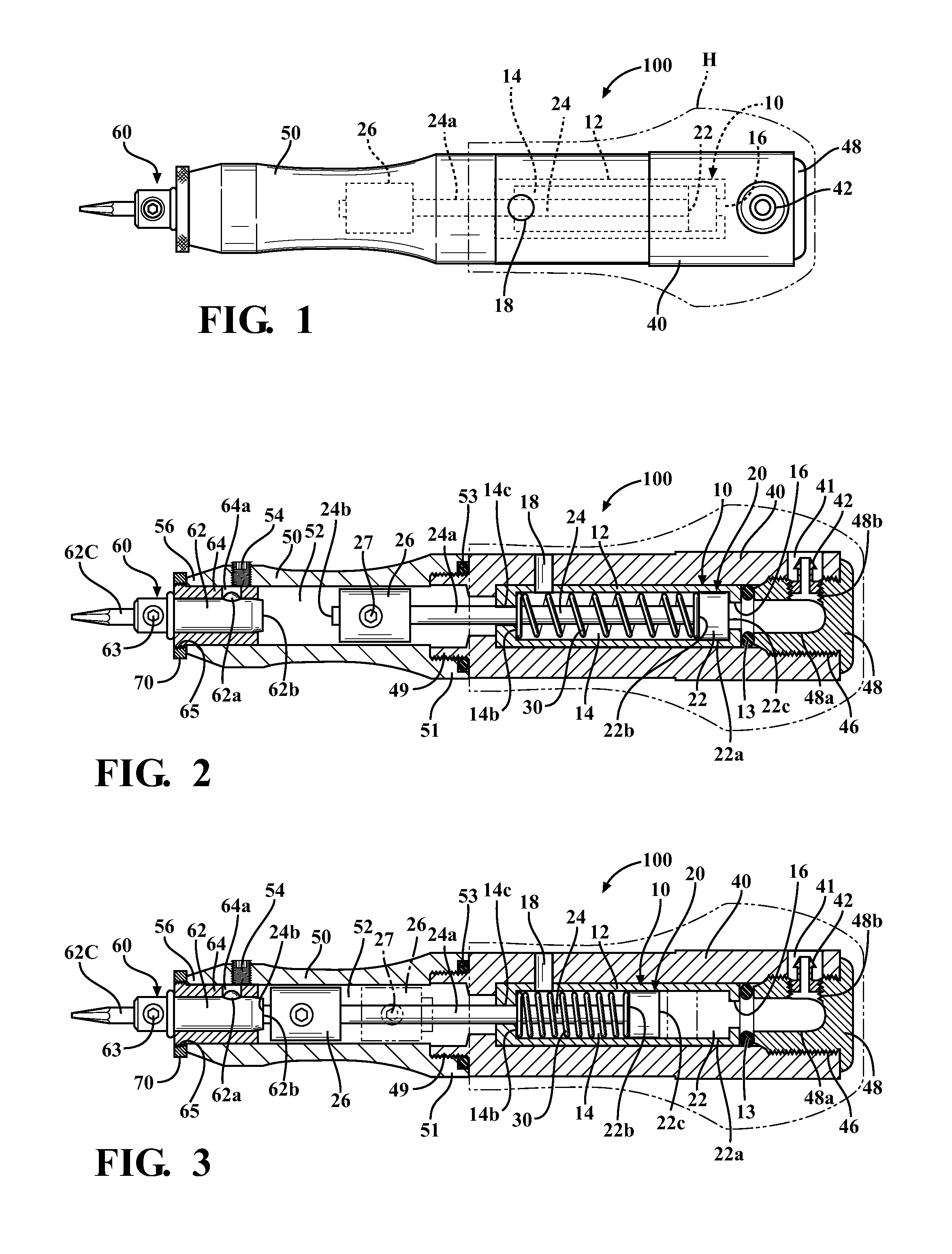

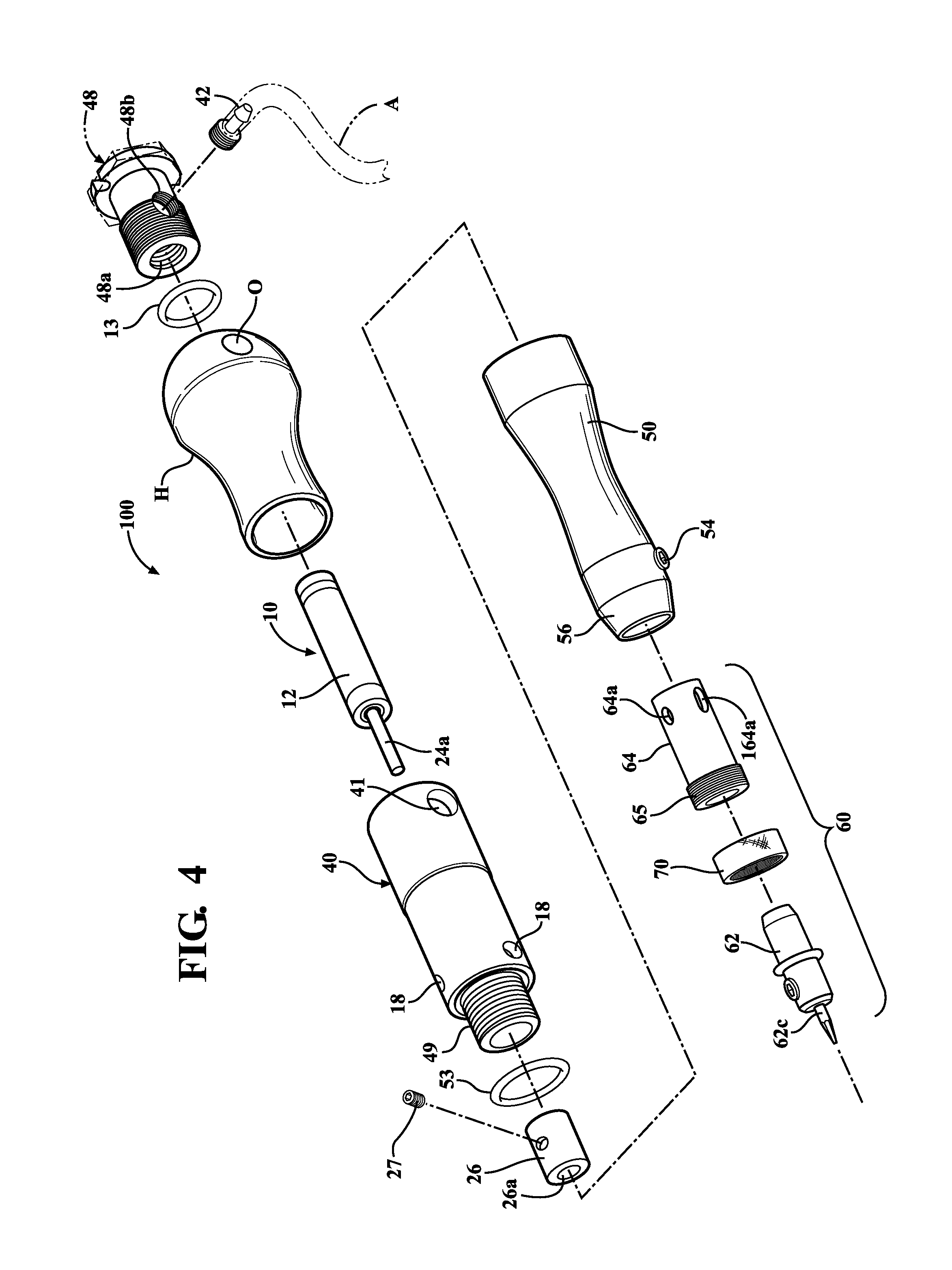

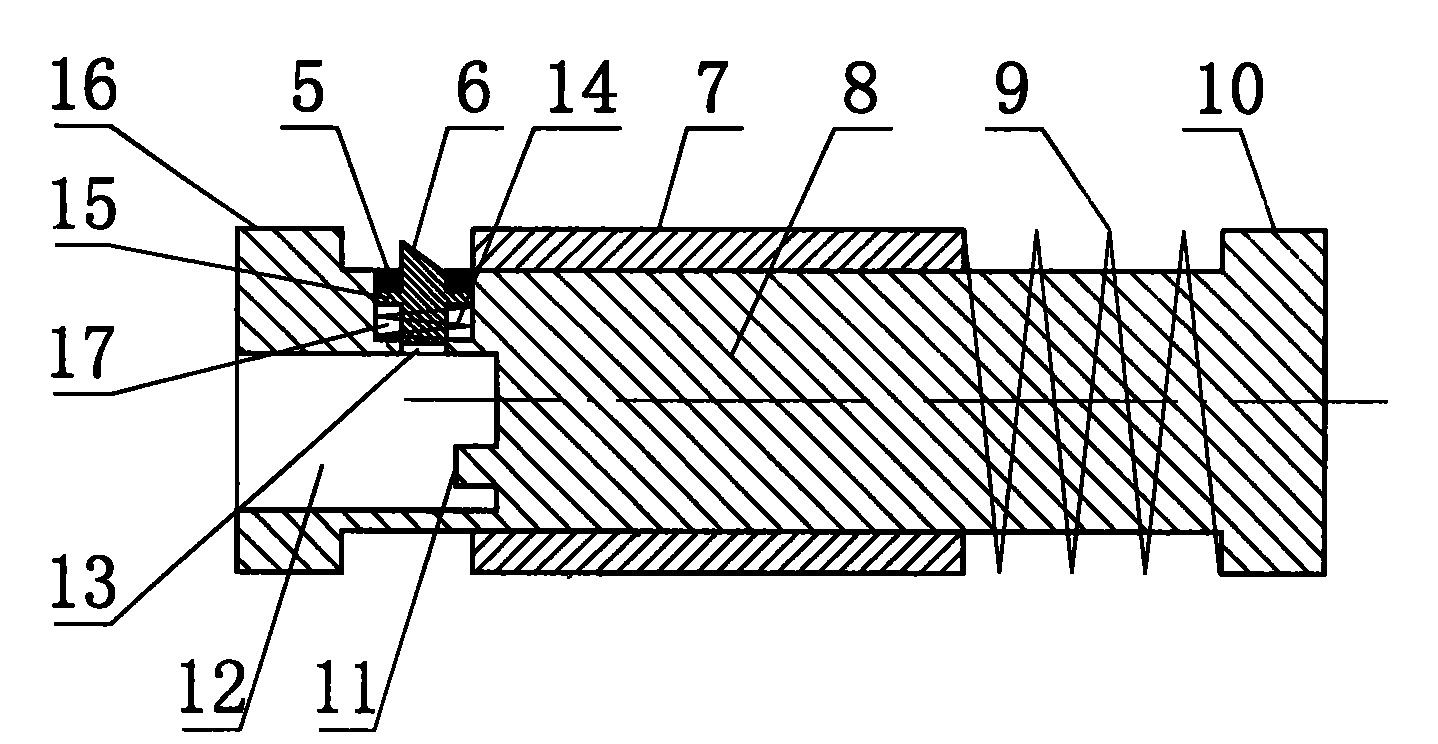

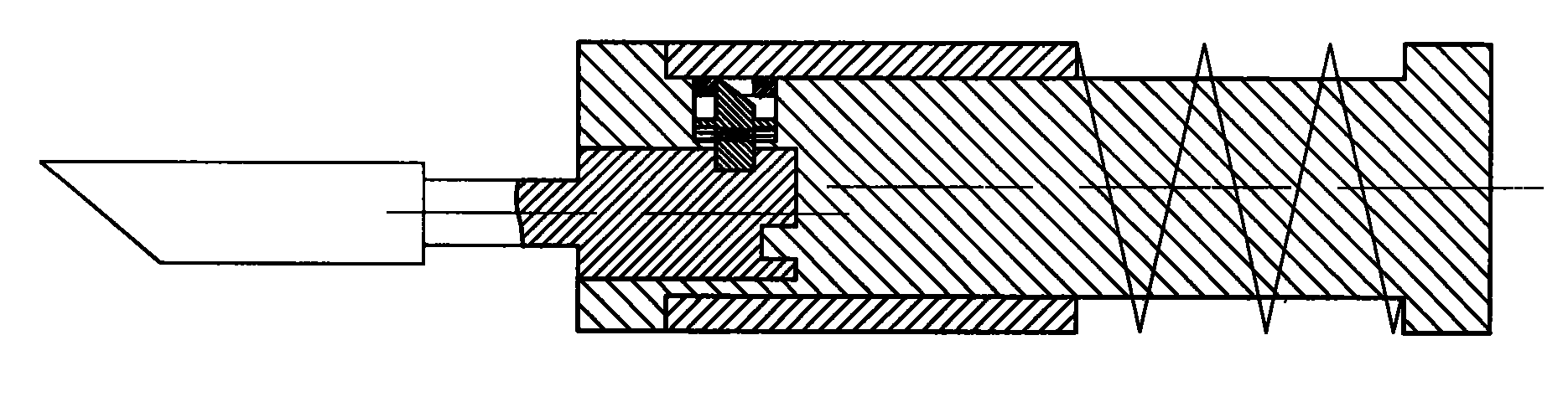

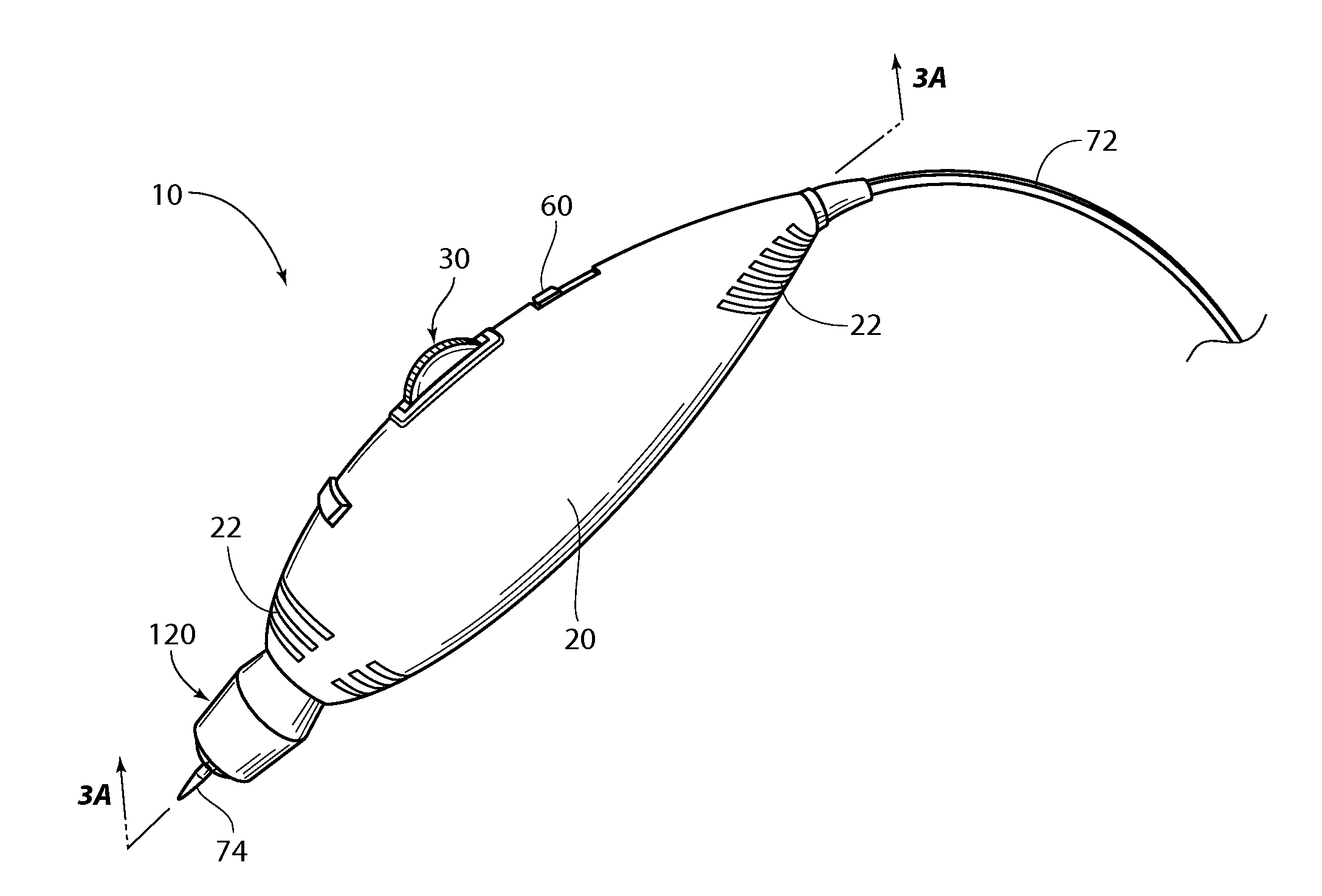

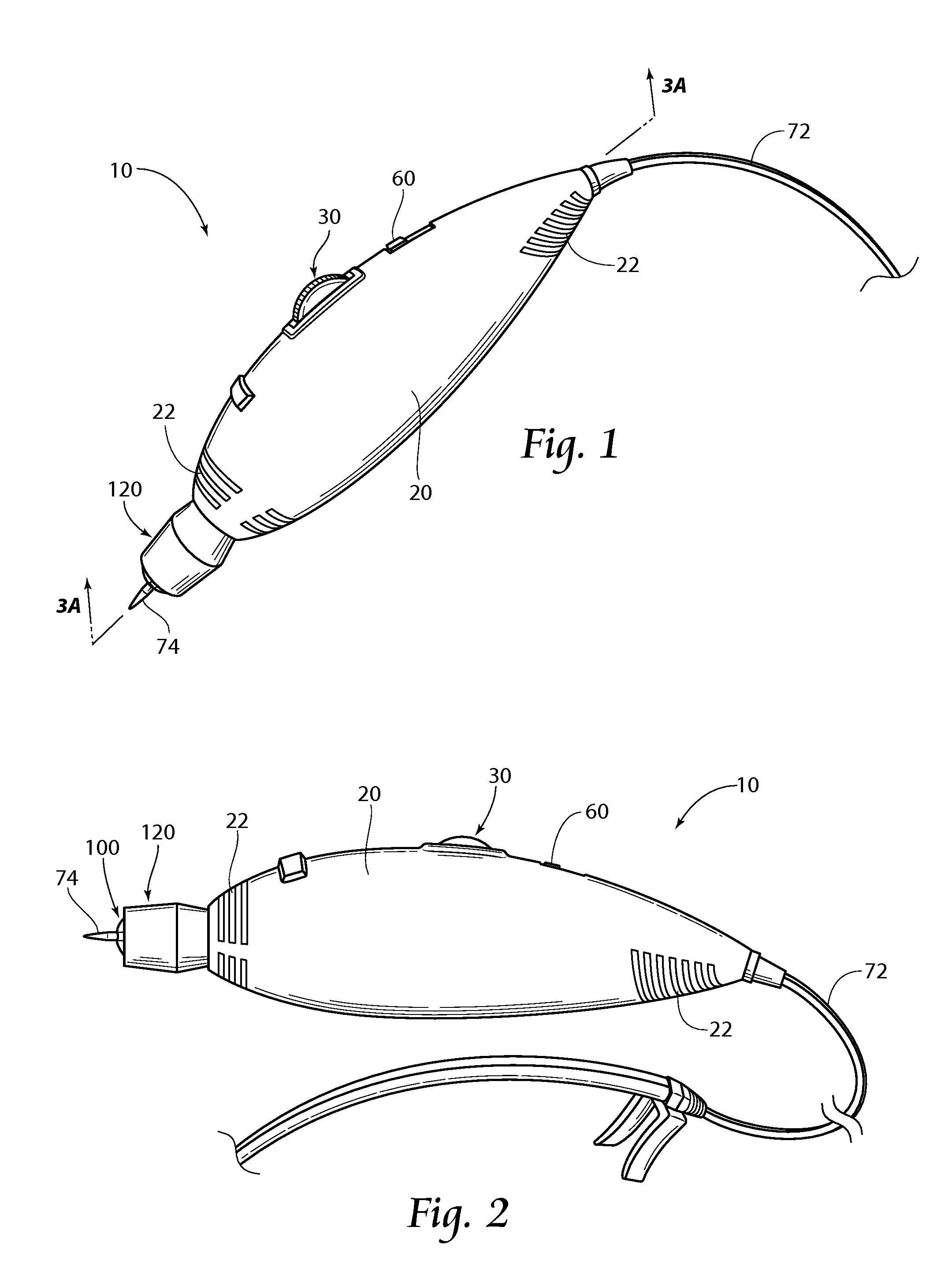

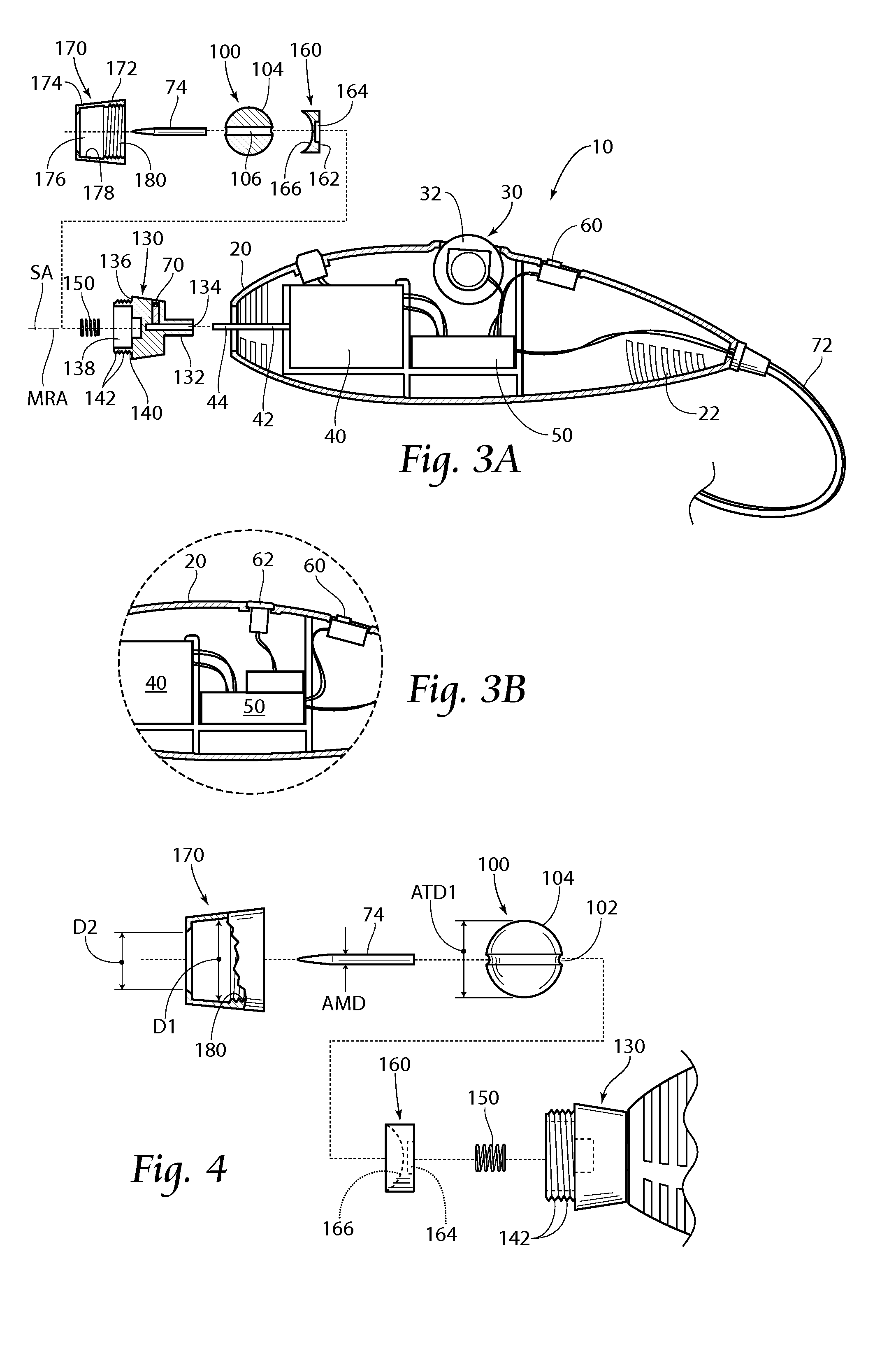

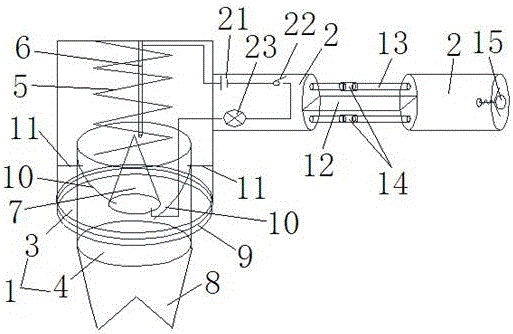

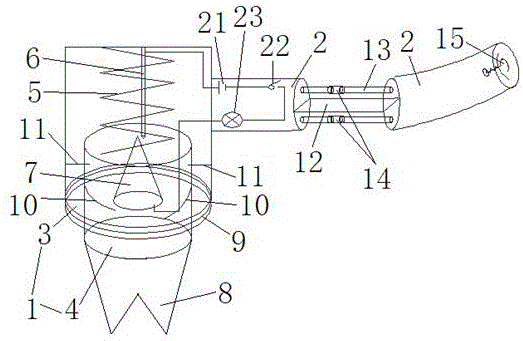

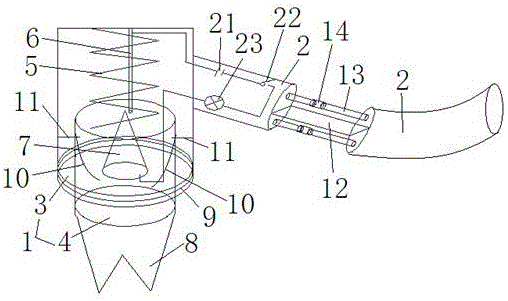

Pneumatic actuator for impact engraving tool

ActiveUS9079286B1Control moreReduce rateHand artistic toolsPortable percussive toolsReciprocating motionEngineering

A pneumatic actuator for use in pneumatic impact tools of the type used to engrave jewelry, and an impact tool adapted for the pneumatic actuator. The actuator includes a cylinder body with a pneumatic chamber housing a piston assembly reciprocating in response to pulses of pressurized air. The piston assembly includes a piston base and a striker pin in the pneumatic chamber, an outer end of the striker pin extending through and residing outside a forward end of the chamber. The outer end of the striker pin has an enlarged striker head of greater mass than the striker pin and / or the piston base in the chamber. A pneumatic impact tool is also disclosed, and includes a forward stylus section having a guide bore for the striker head and holding a graver assembly in spaced relationship to the striker head.

Owner:GRABOUTIL

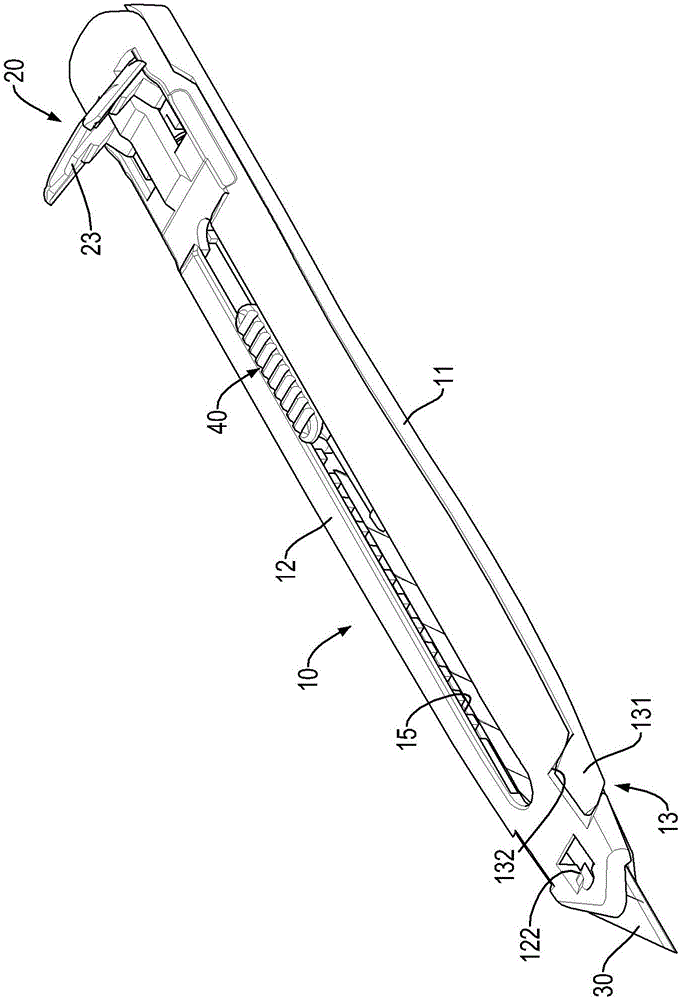

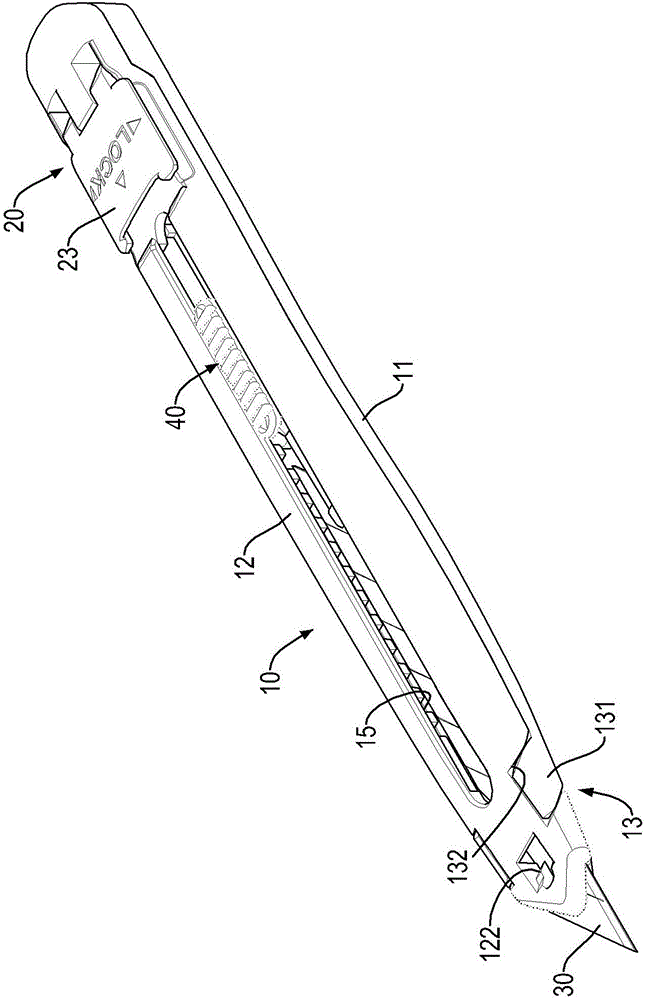

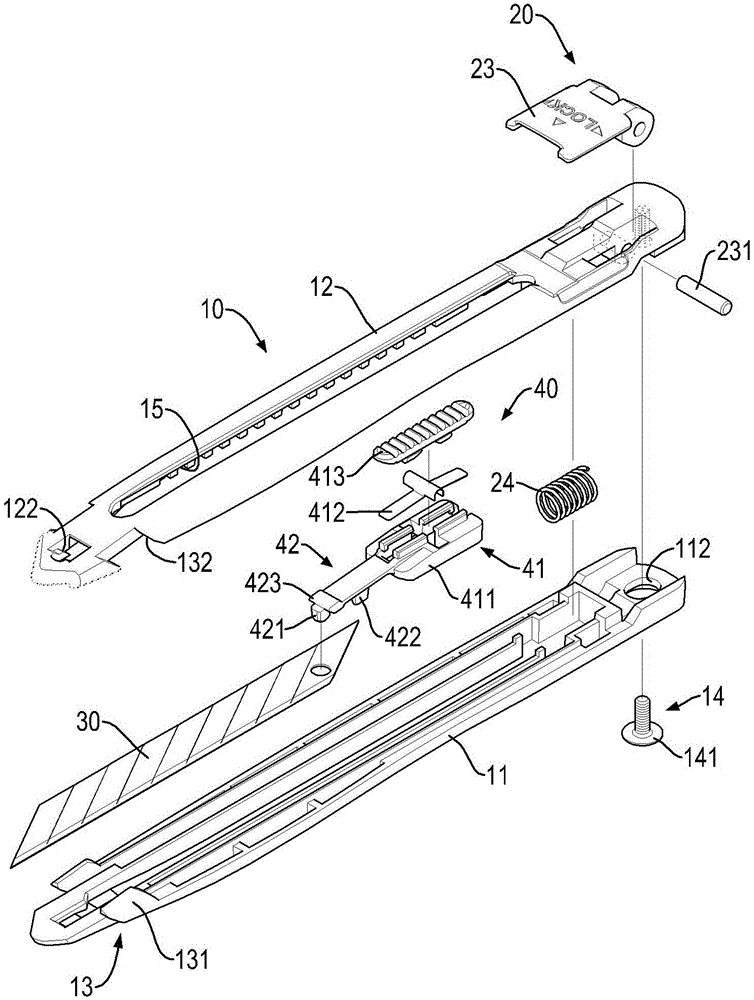

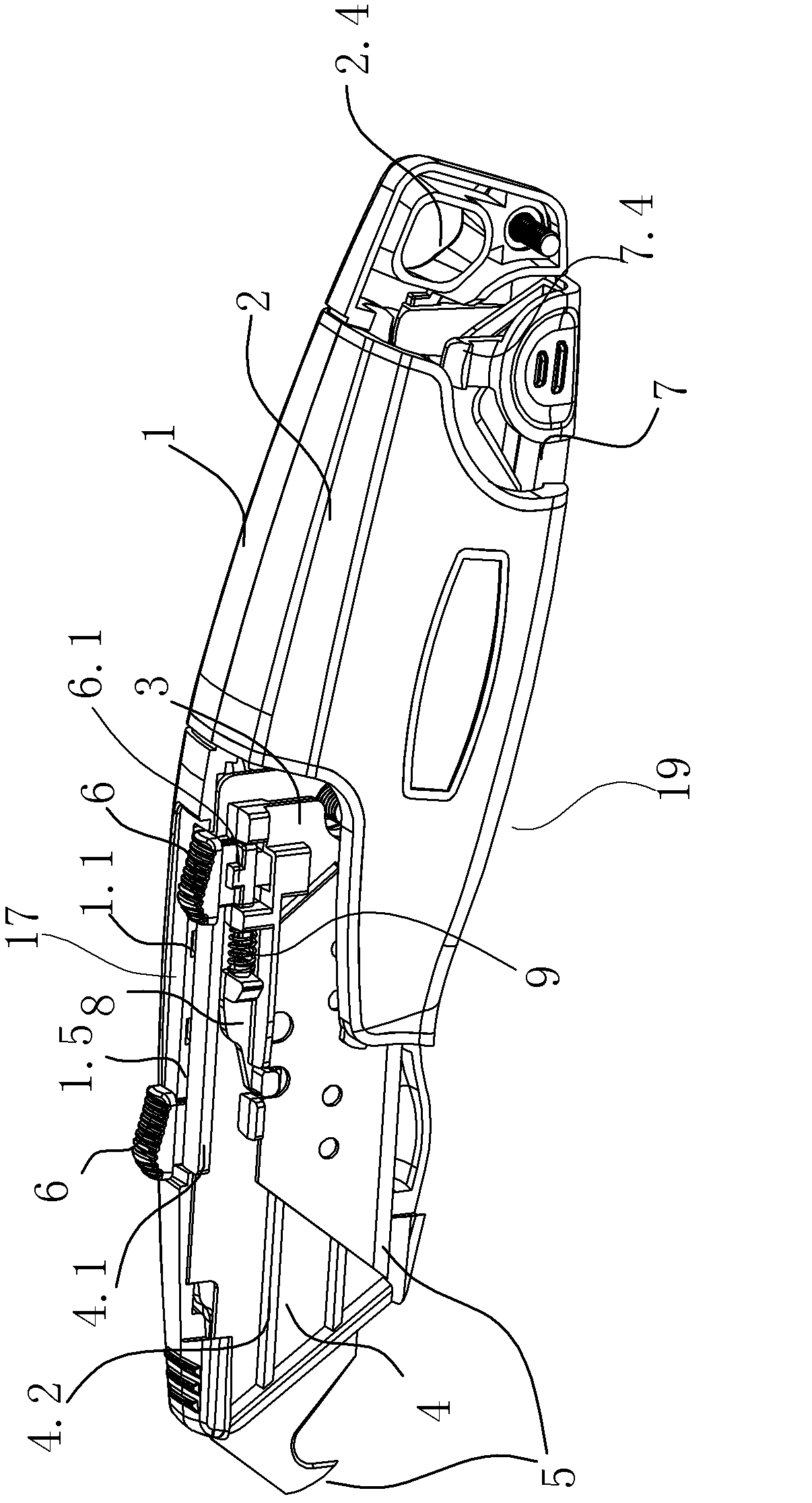

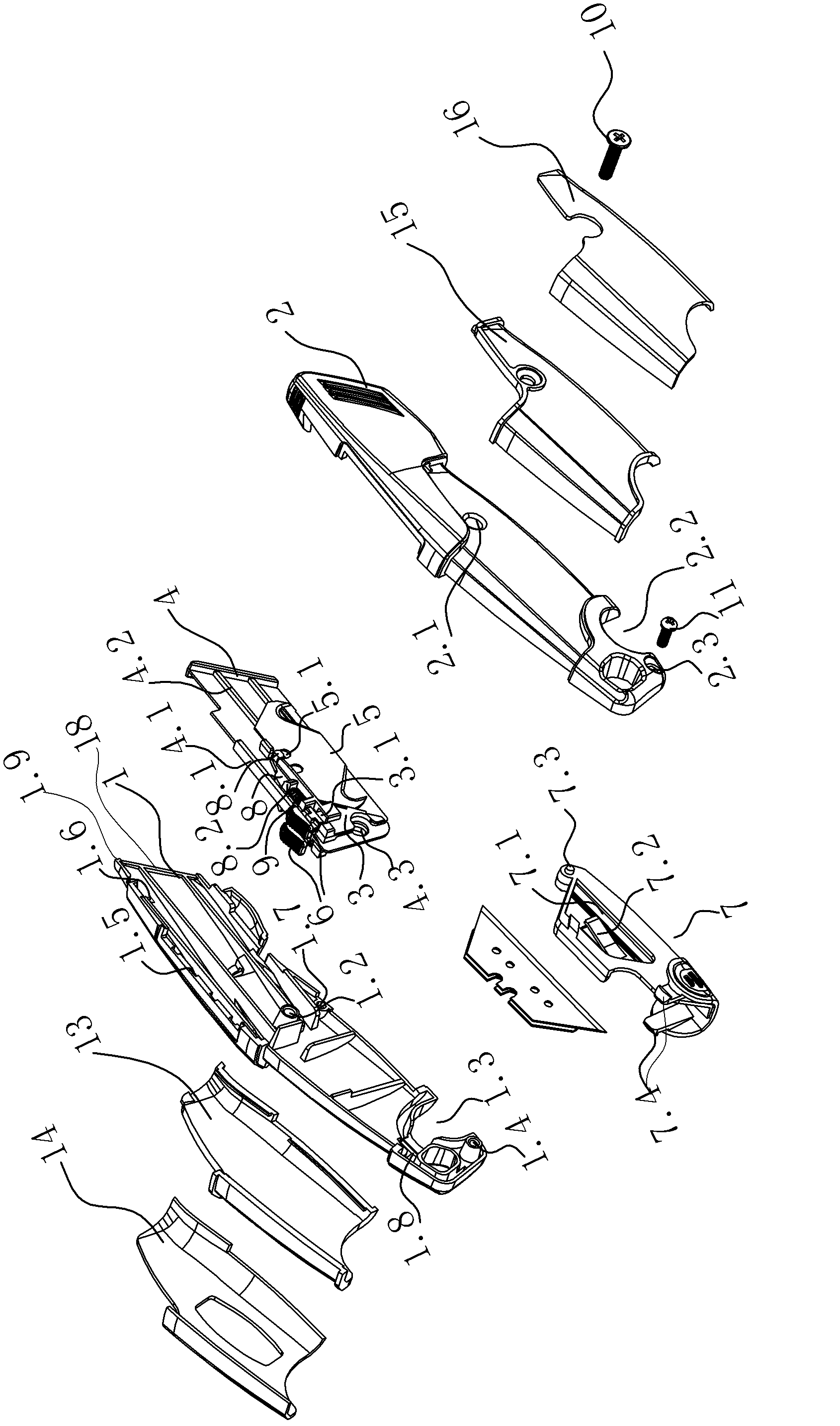

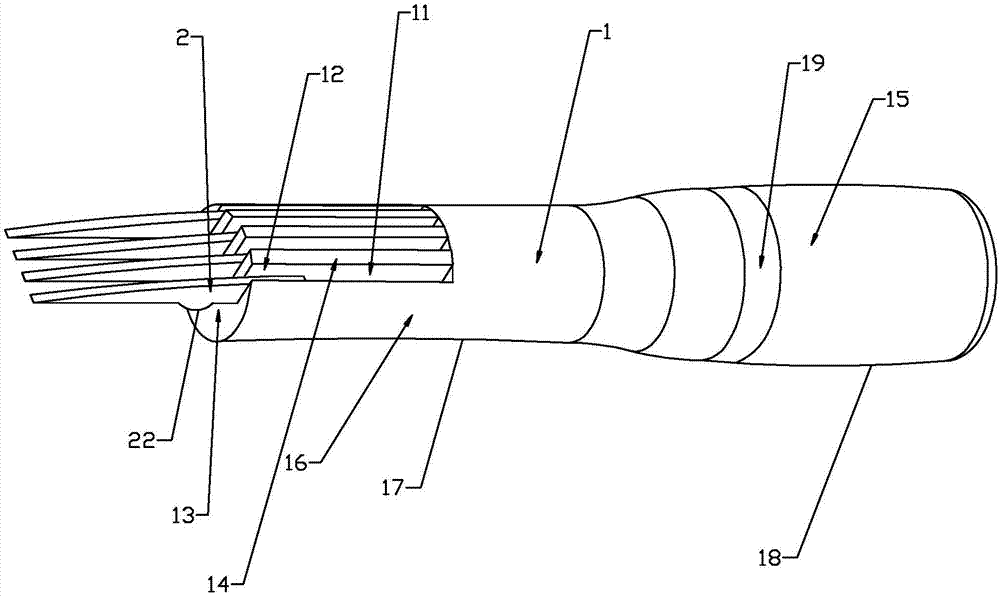

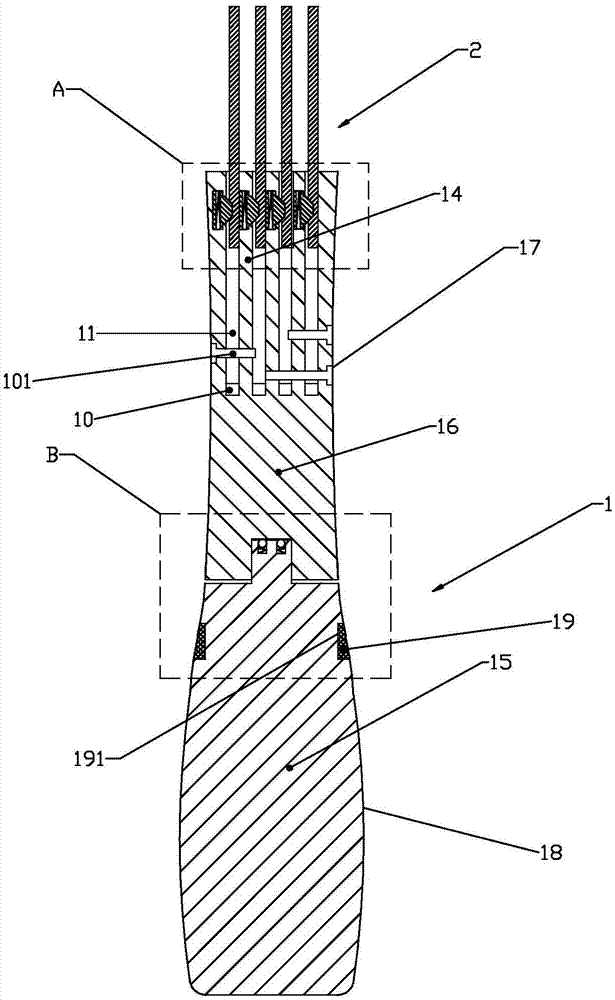

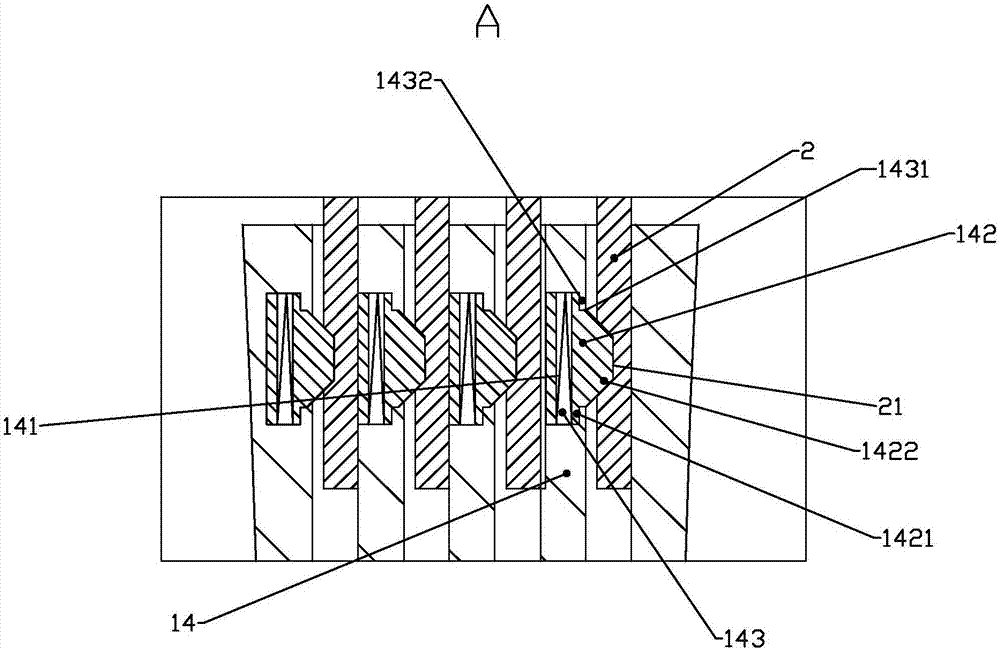

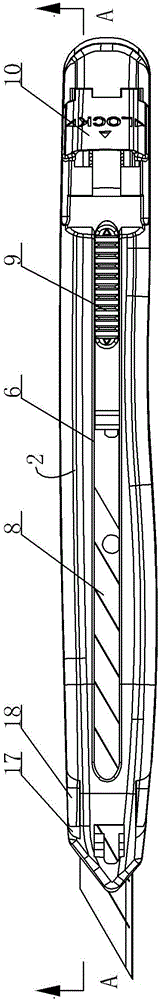

Art knife

The invention provides an art knife. The art knife has the advantage of convenient operation and comprises a knife body, a locking structure, an adjuster movably arranged in the knife body, and a blade connected to the adjuster. The knife body comprises a lower knife holder, an upper knife holder and a bevel limiting structure which makes the lower knife holder and the upper knife holder be abutted against each other obliquely. The lower knife holder and the upper knife holder can move oppositely. The locking structure is arranged one rear end of the knife body and comprises a datum point, a first driving face and a second driving face, and the first driving face or the second driving face is abutted against the upper knife holder or the lower knife holder. The distance from the datum point to the first driving face is a first distance. The distance from the datum point to the second driving face is a second distance. The first distance is larger than the second distance. When the first driving face or the second driving face is abutted against the upper knife holder or the lower knife holder, the upper knife holder and the lower knife holder move oppositely, the front ends of the upper knife holder and the lower knife holder are guided by the bevel limiting structure, and opposite movement is formed correspondingly.

Owner:顺德工业(江苏)有限公司

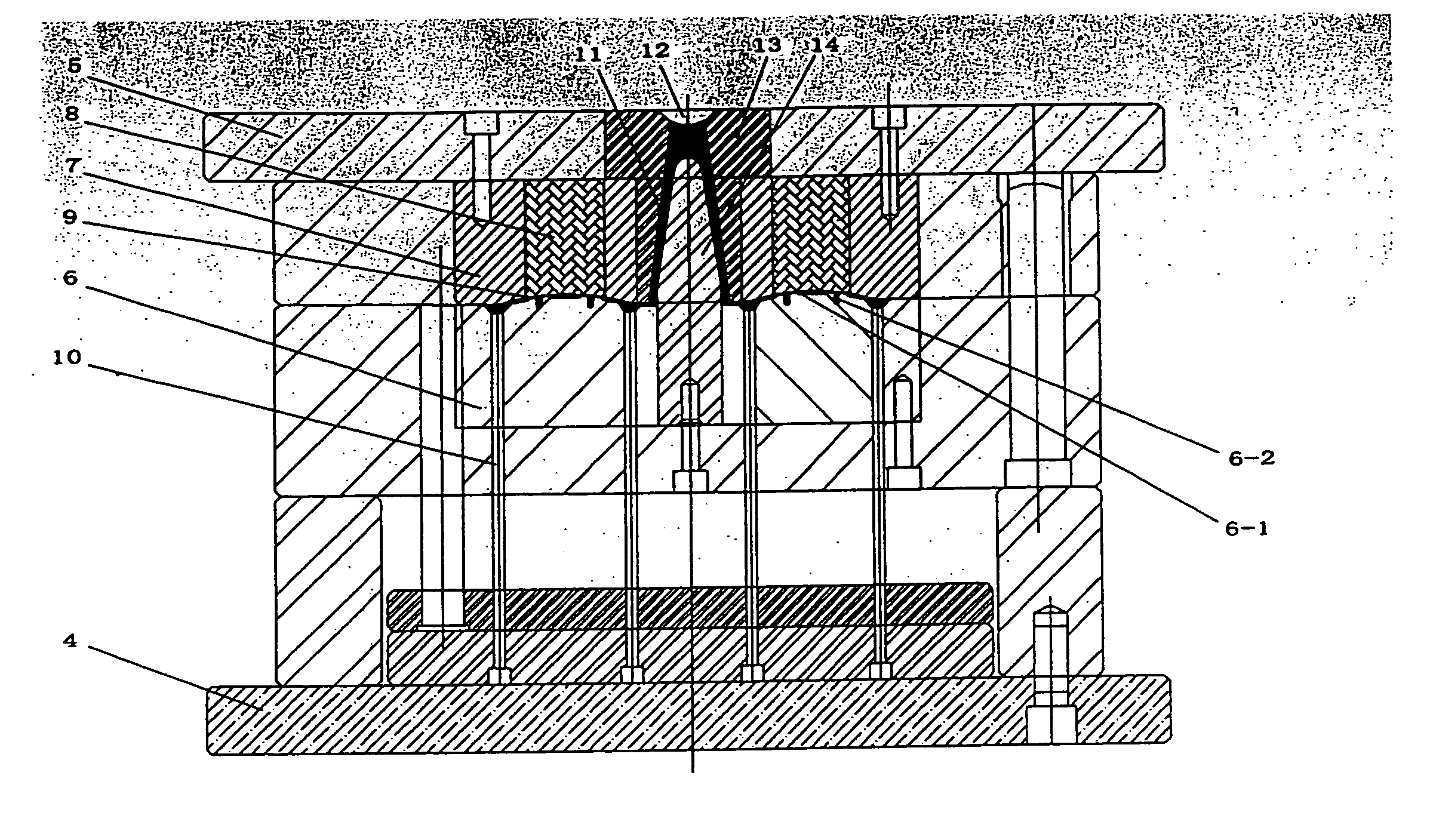

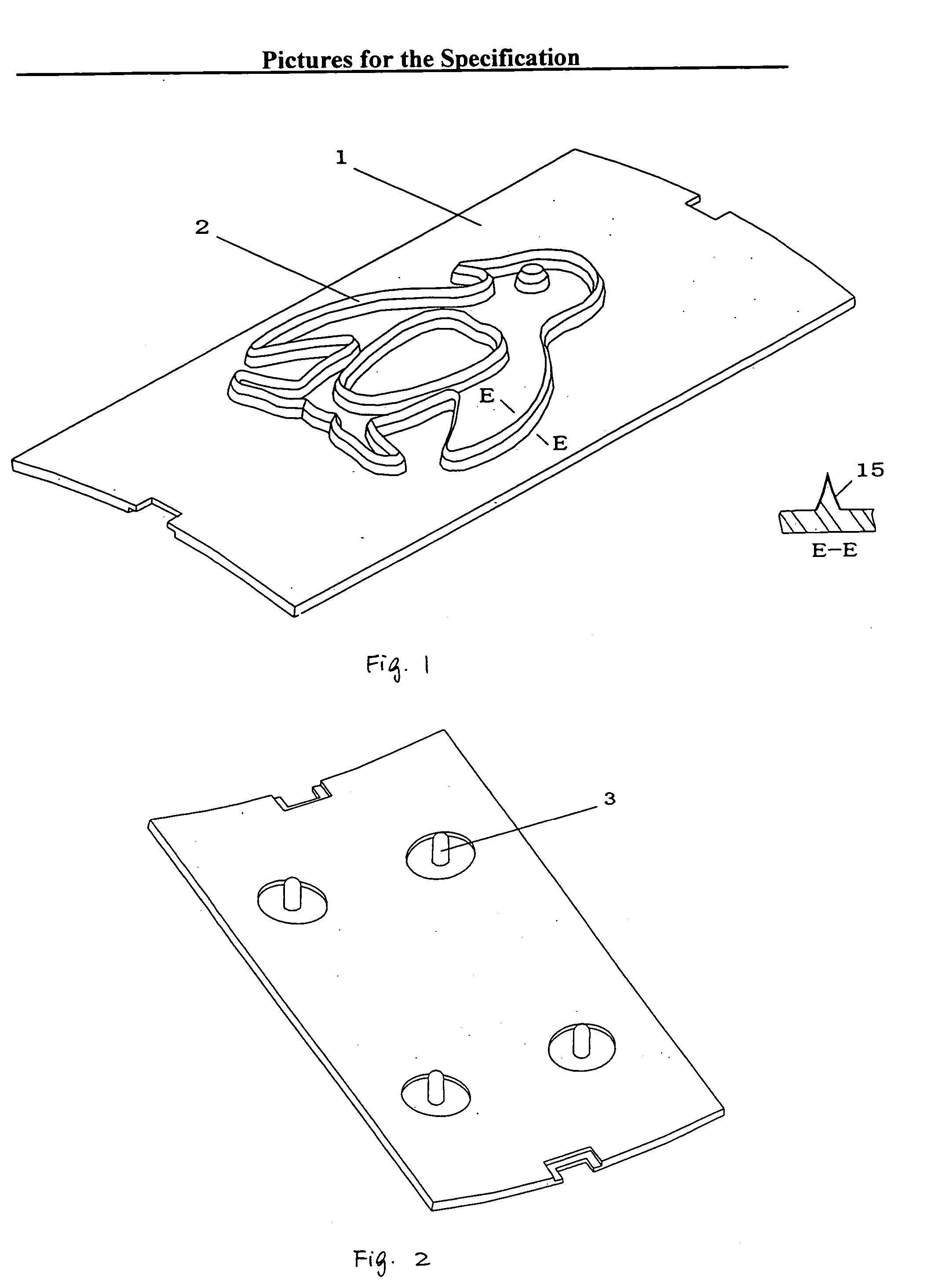

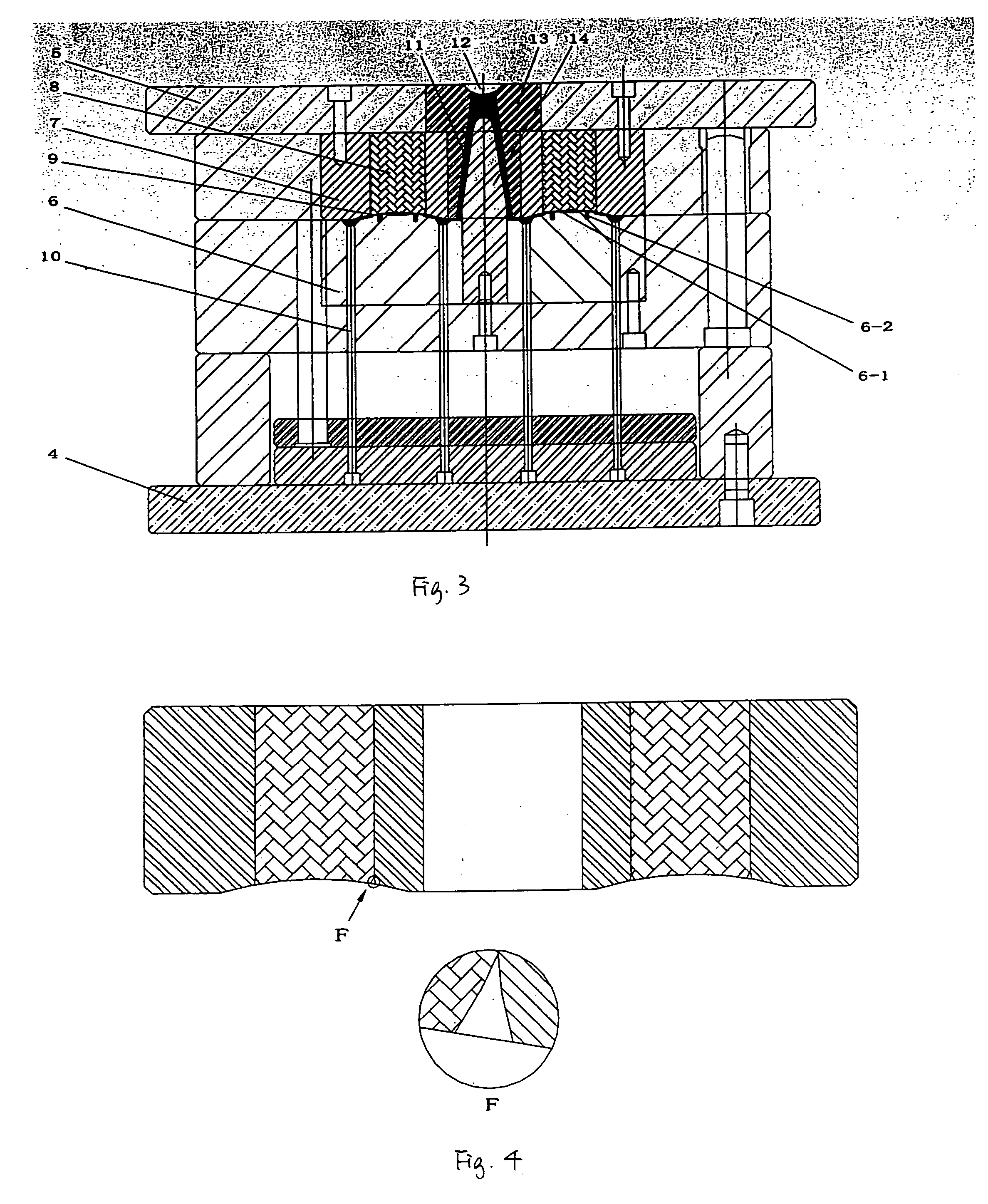

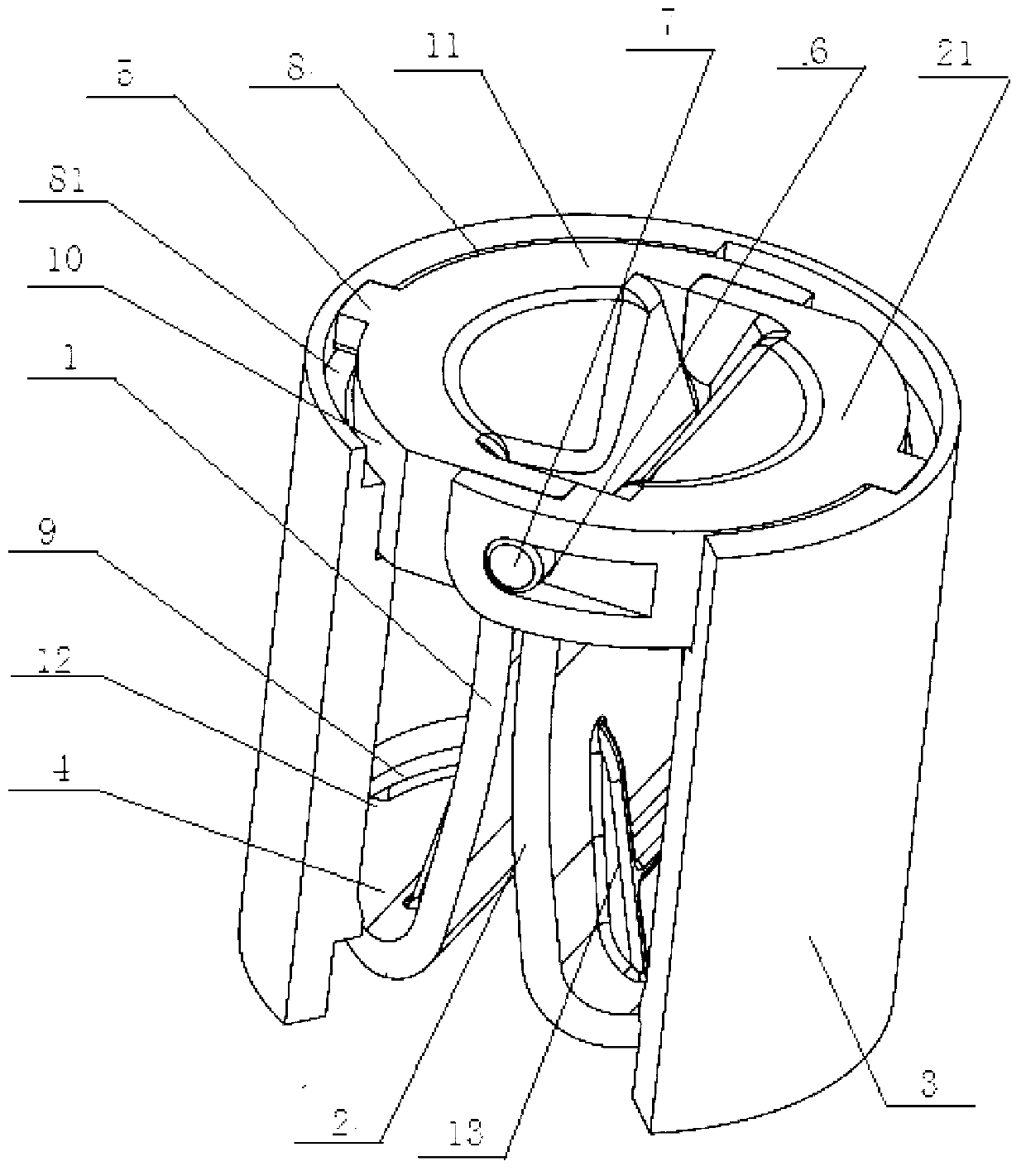

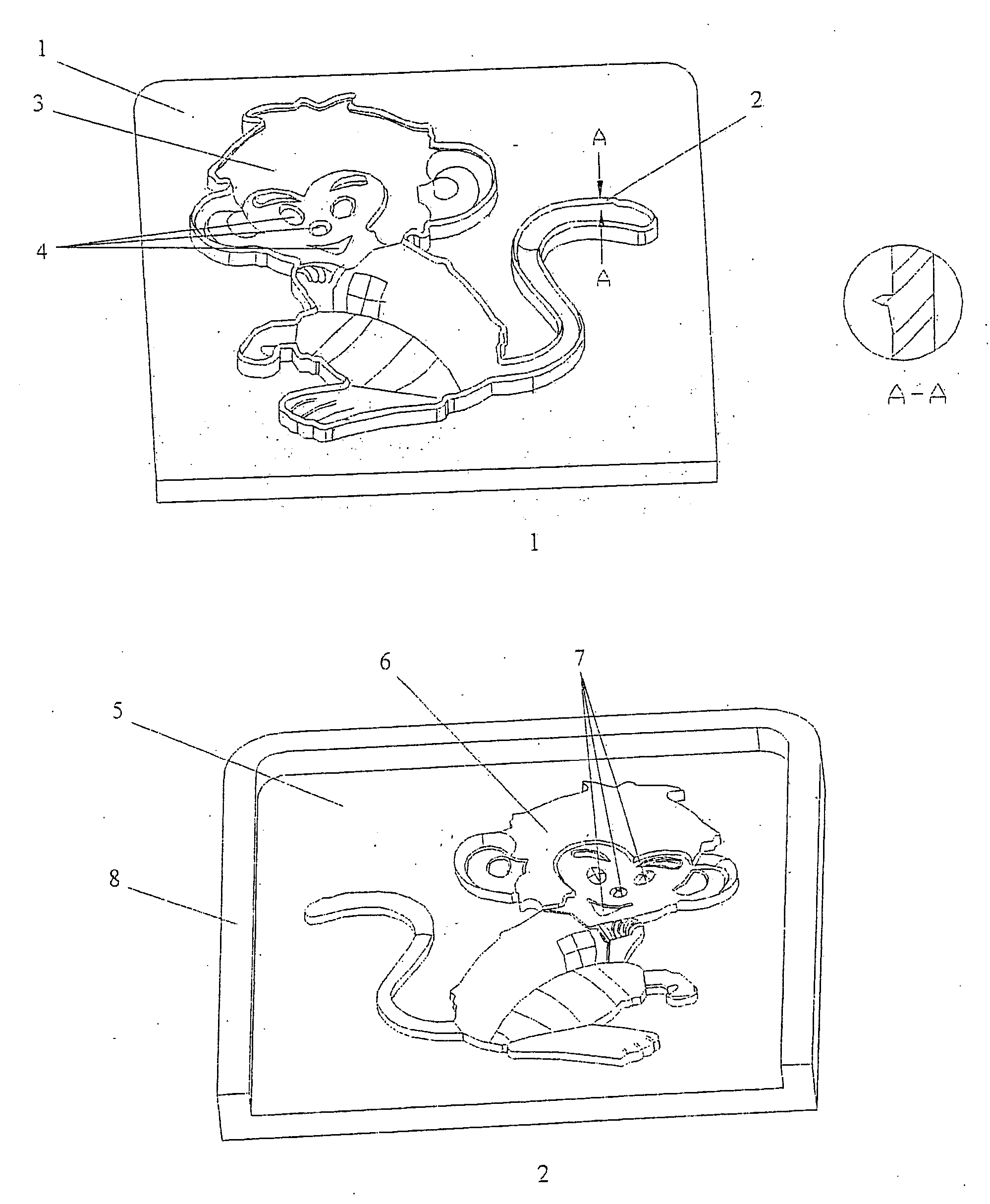

Pattern cutter, its processing methods and moulds

InactiveUS20060042419A1Easy constructionOperational securityHand artistic toolsCutting toolsDie castingEngineering

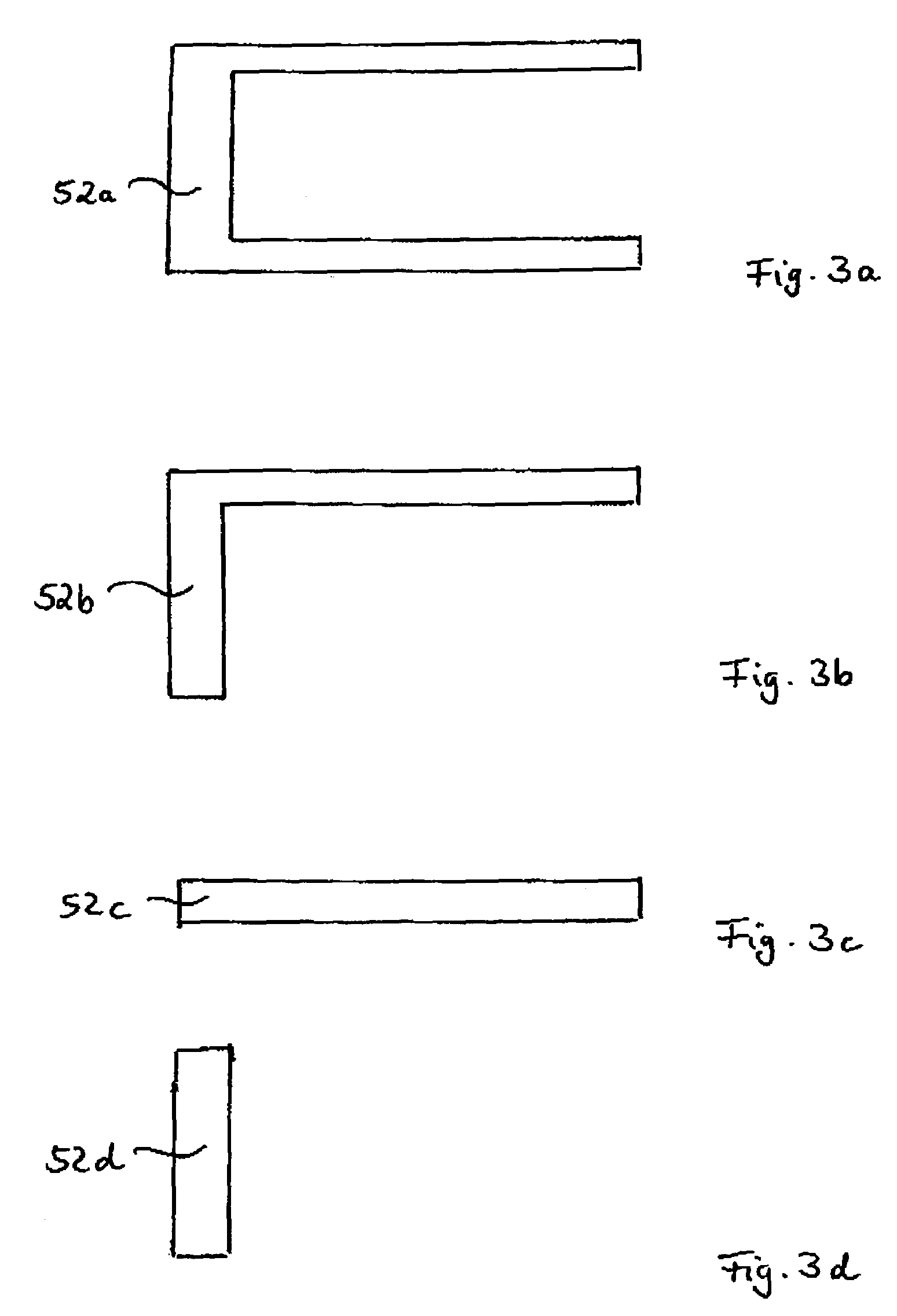

Disclosed here in the present invention is a pattern cutter, including a base and cutting blade. The cutting blade is located on the base. The blade forms the shape of pattern to be cut. The said base and cutting blade are of one-piece structure, which is machined to shape at one go through die-casting process. A method for processing such a pattern cutter, which directly utilizes mould to die cast the base and blade that are joined together. The said cutting blade forms the pattern shape that requires to be cut. A mould that is applied to the aforesaid processing method, inside the mould there is arranged a cavity for blade forming purpose. The said blade-forming cavity is of triangle or combination of triangle and rectangle or combination of triangle and trapezoid. The depth of blade-forming cavity is greater than or equal to 2.5 mm. The included angle at the sharp end of the blade-forming cavity is smaller than or equal to 60°. The present invention is characterized by simple and rational construction, easy to manufacture, low cost, high product accuracy and good consistency, with a wide range of adaptability and better market prospect.

Owner:DENG YEQING +1

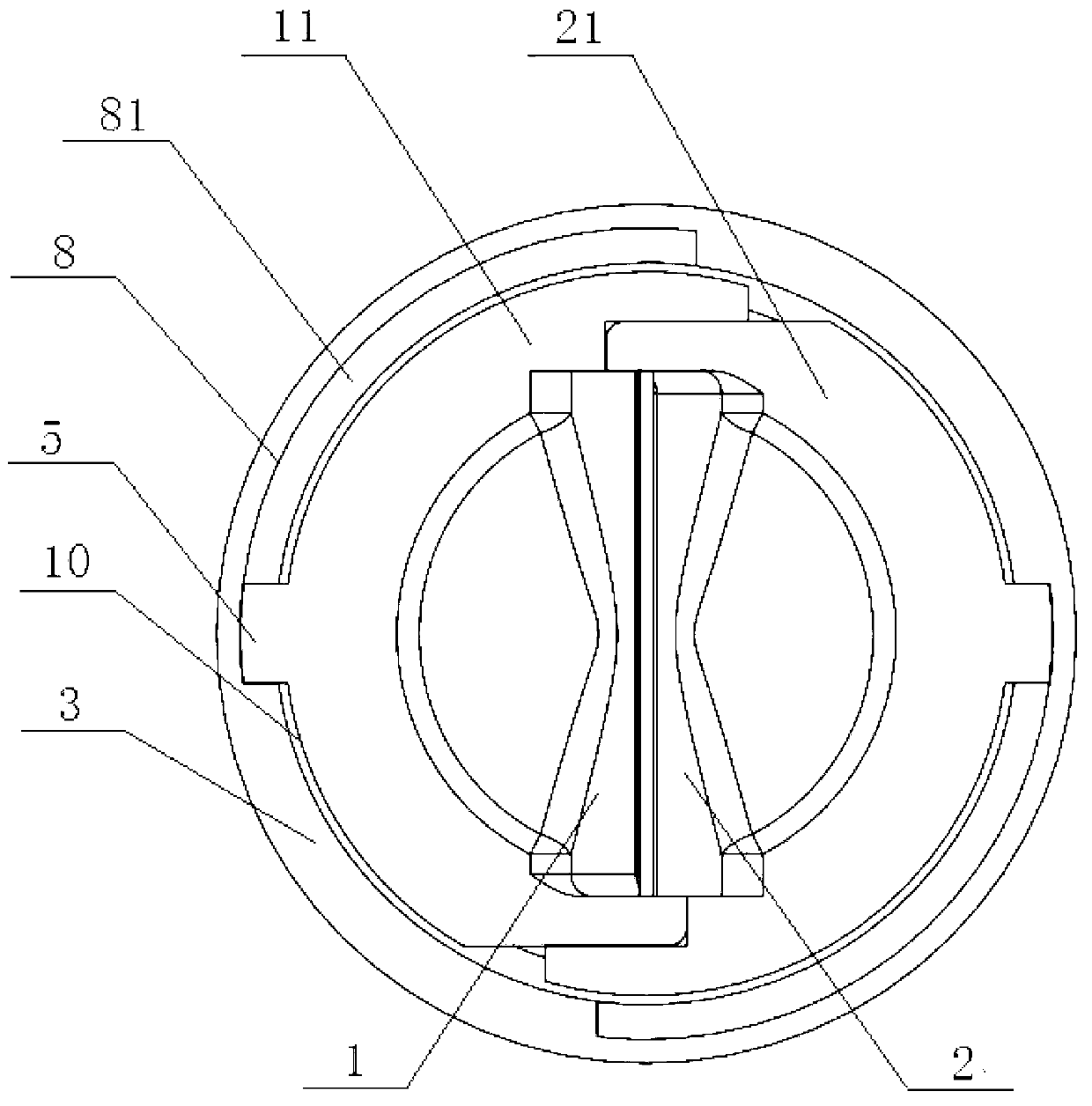

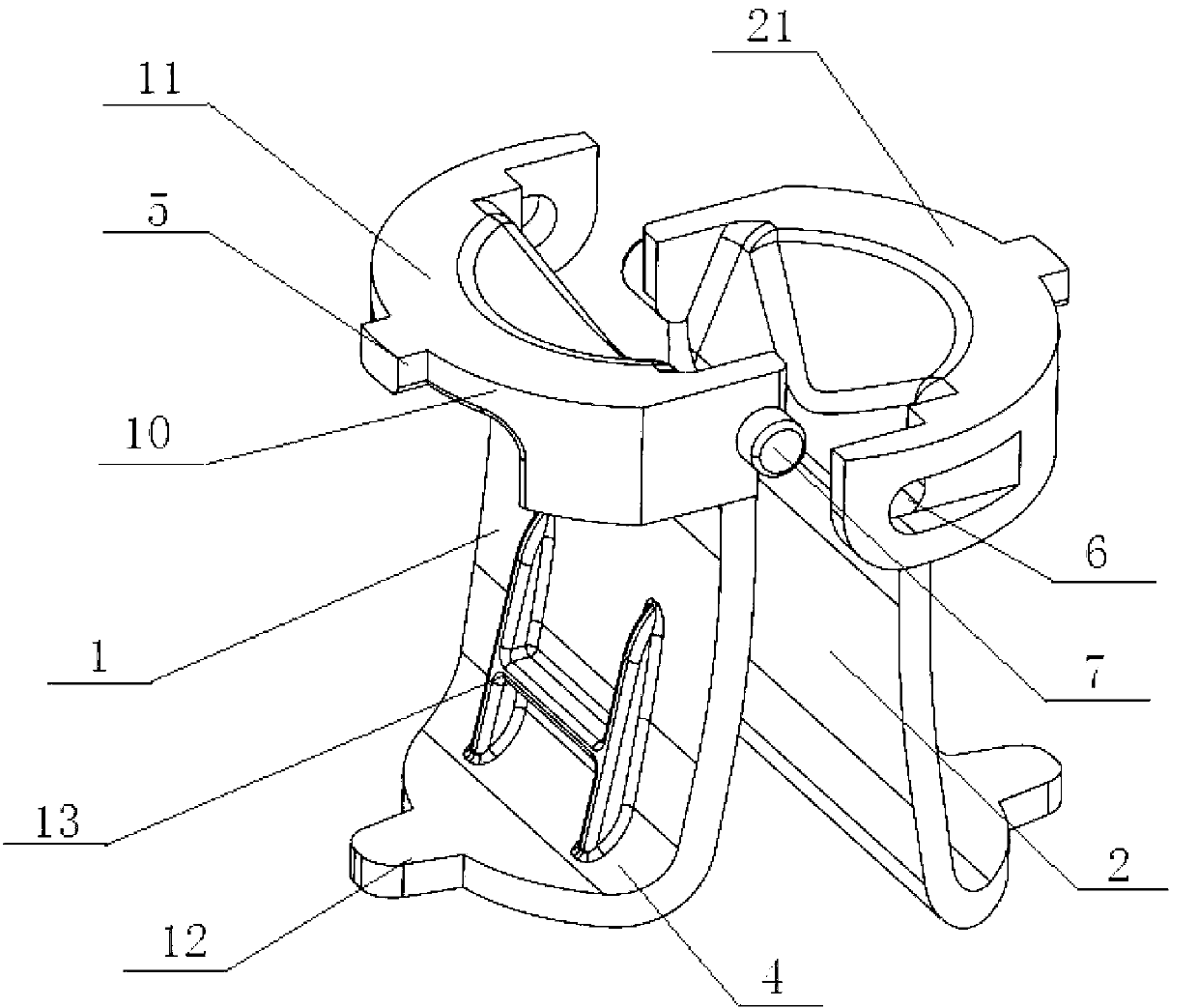

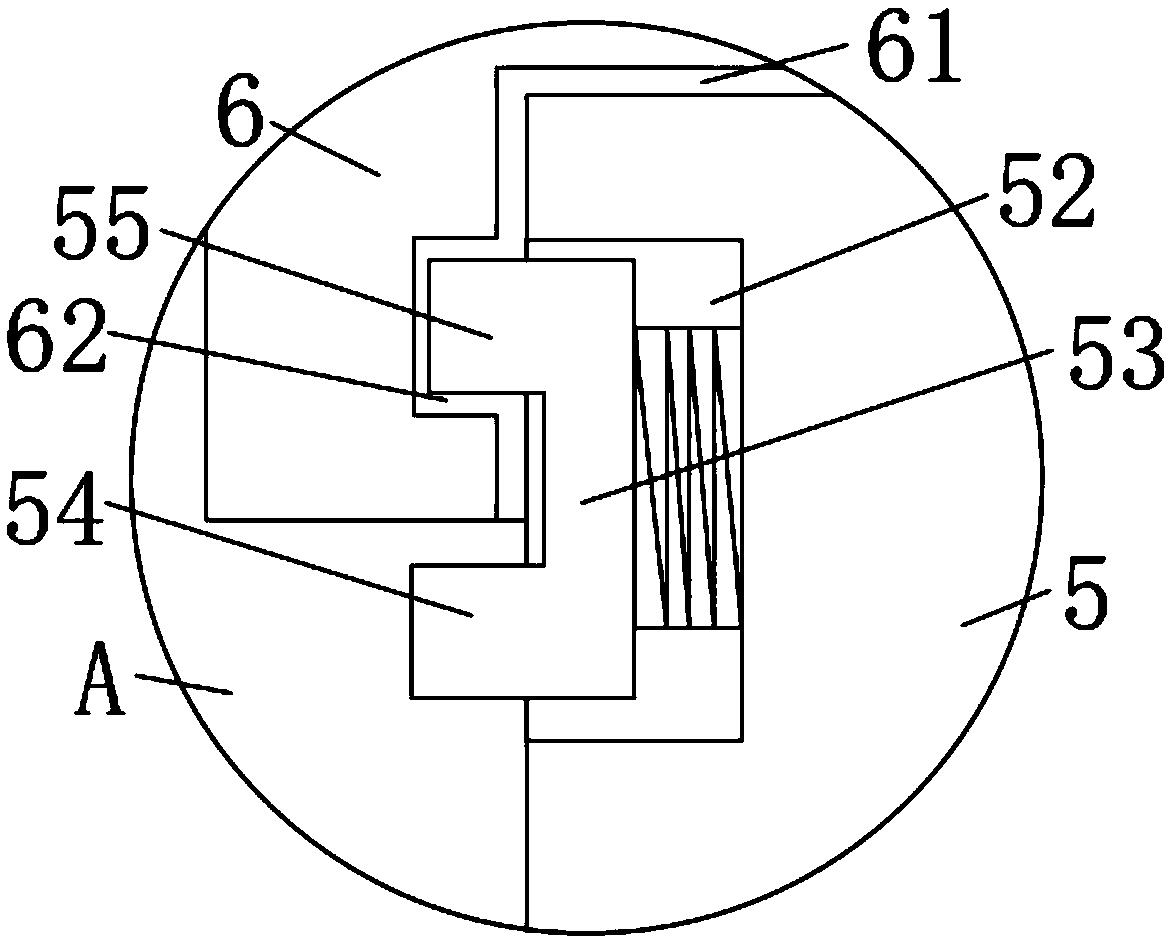

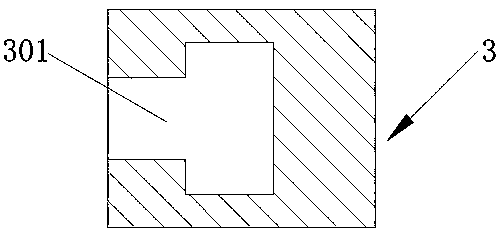

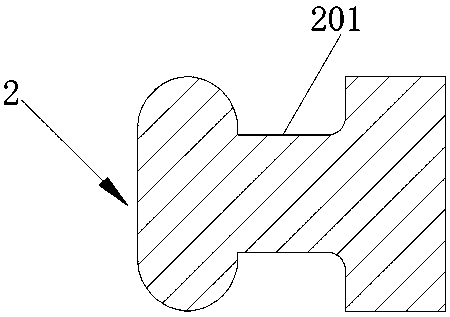

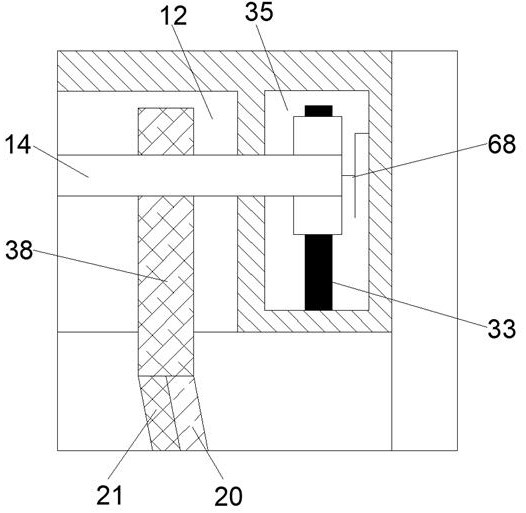

Rotary clamping mechanism and application method thereof

Owner:SHANGHAI QIMAI HARDWARE

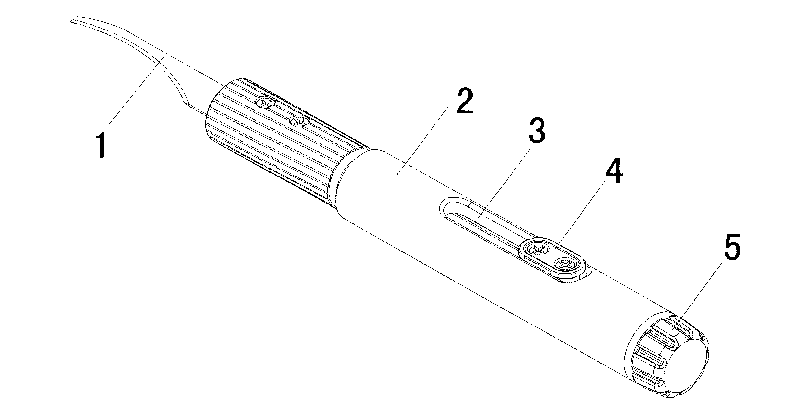

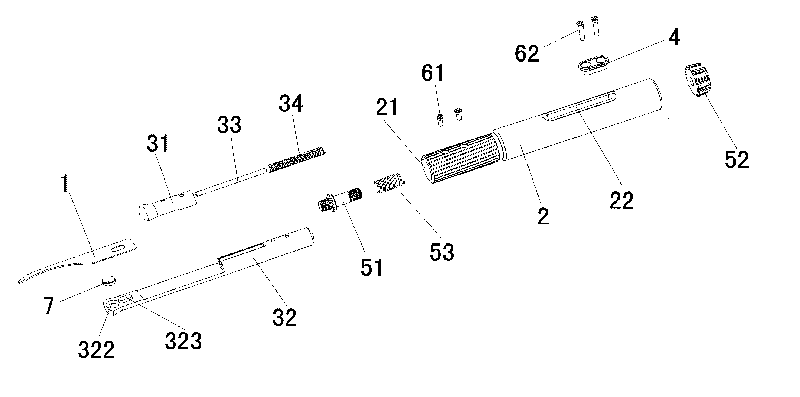

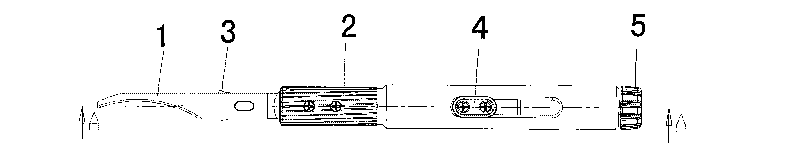

Carving knife

InactiveCN101734071AFor quick replacementQuick installationHand artistic toolsLocking mechanismKnife holder

The invention provides a carving knife. The carving knife comprises a blade and a knife holder and also comprises a cutter head component, a cutter head push key and a cutter head locking mechanism which are arranged on the knife holder, wherein the blade is arranged on the cutter head component, the cutter head push key is connected with the cutter head component to move the cutter head component frontward, and the cutter head locking mechanism is arranged on the tail of the knife holder and can be used to lock the retracted cutter head component. The blade of the carving knife of the invention can be changed and installed fast and safely; and the operation is safe and convenient.

Owner:SHANGHAI KUNJEK HANDTOOLS & HARDWARE

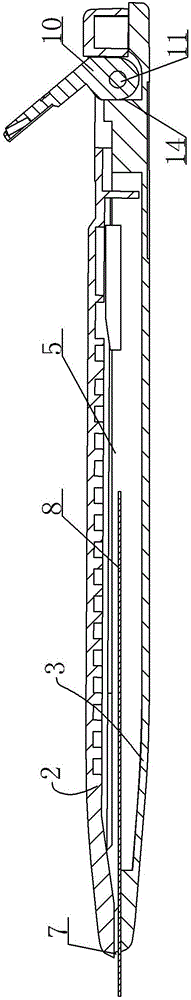

Art knife

ActiveCN103381606ATimely replacementEasy to useHand artistic toolsMetal working apparatusEngineeringKnife blades

The invention provides an art knife which comprises a housing and is characterized in that two groups of knife rests are arranged in parallel, the two groups of knife rests are arranged in the cavity in the front part of the housing through a knife rest gasket in a sliding manner respectively, different kinds of blades are arranged on each group of knife rest, a push button, which has a pop-up upward trend, is arranged at the upper end of the knife rest, a strip groove, which is corresponding to the upper edge of the knife rest gasket, is formed in the upper edge of the housing, two parallel push grooves, on which the two push buttons can slide, are formed between the strip groove and the upper edge of the knife rest gasket, and a clamp foot, which is matched with a tap position groove to conduct positioning, is arranged at the side part of the push button, so as to realize the stretch of the blades and the positioning of the tap position. The art knife has a beautiful appearance, is safe to use and convenient to operate, has the functions of an assistant blade and double blades, and can afford different kinds of blades as required, and realize quick blade exchange and tap position positioning.

Owner:ZHEJIANG XINGDA STATIONERY

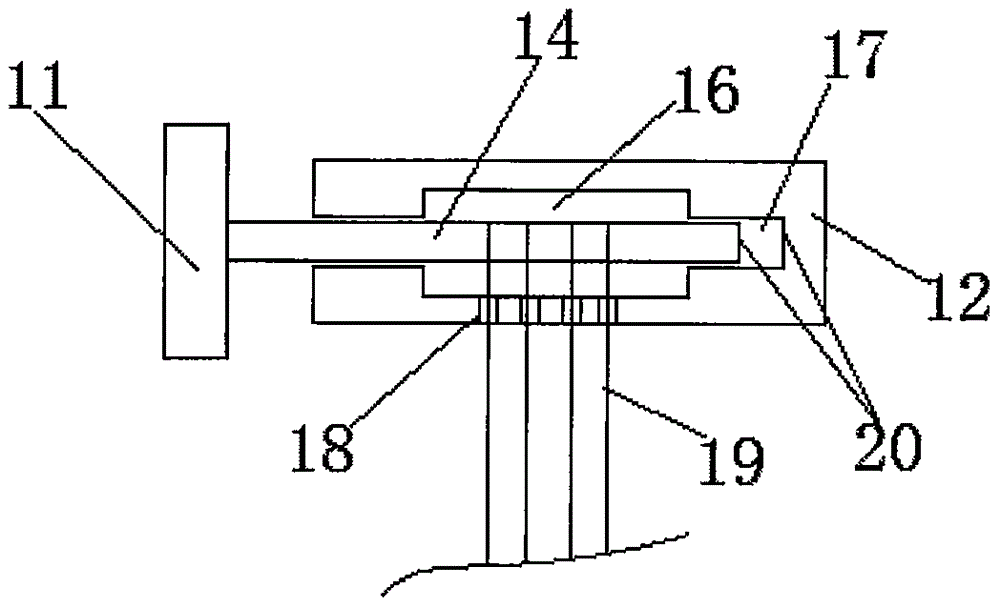

Sliding-sleeve multi-head nicking tool

The invention relates to an engraving tool, in particular to a sliding-sleeve multi-head nicking tool comprising a tool bit, a tool bit handle, a side hole, an end hole, a fixing ring, a lock rod, a sliding sleeve, a hand shank, a sliding sleeve spring, a solid spring plate, an eccentric column, a mounting hole, a locking hole, a lock rod spring, a lock rod sheet, a baffle ring and a lock hole cavity, wherein the cylindrical tool bit handle is arranged at the tail end of the tool bit and integrates with the tool bit, the side hole is arranged on the side wall of the tool bit, the end hole is arranged on the non-center position at the end head of the tool bit handle, the mounting hole is a longitudinal blind hole arranged on the end surface of one end of the hand shank, which is provided with the baffle ring, the lock hole cavity is a transverse blind hole arranged on the side wall of the hand shank, the axial leads of the mounting hole and the lock hole cavity are perpendicularly crossed, the lock rod is arranged in the lock hole cavity, the inclined plane end of the lock rod extends out of the center of the fixing ring, and the sliding sleeve is sleeved on the hand shank to form a movable fit with the hand shank.

Owner:NANTONG GUOSHENG PRECISION MACHINERY

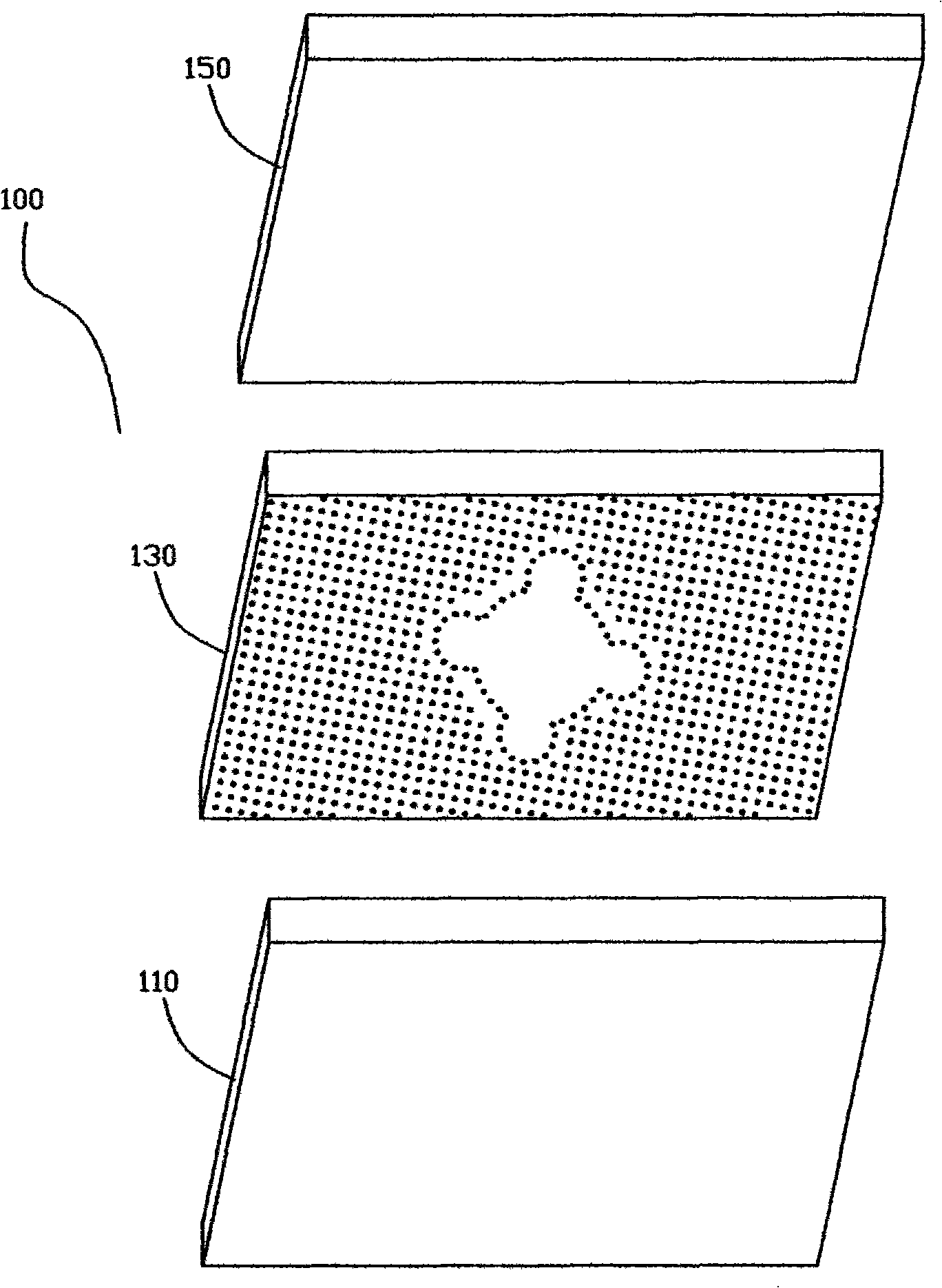

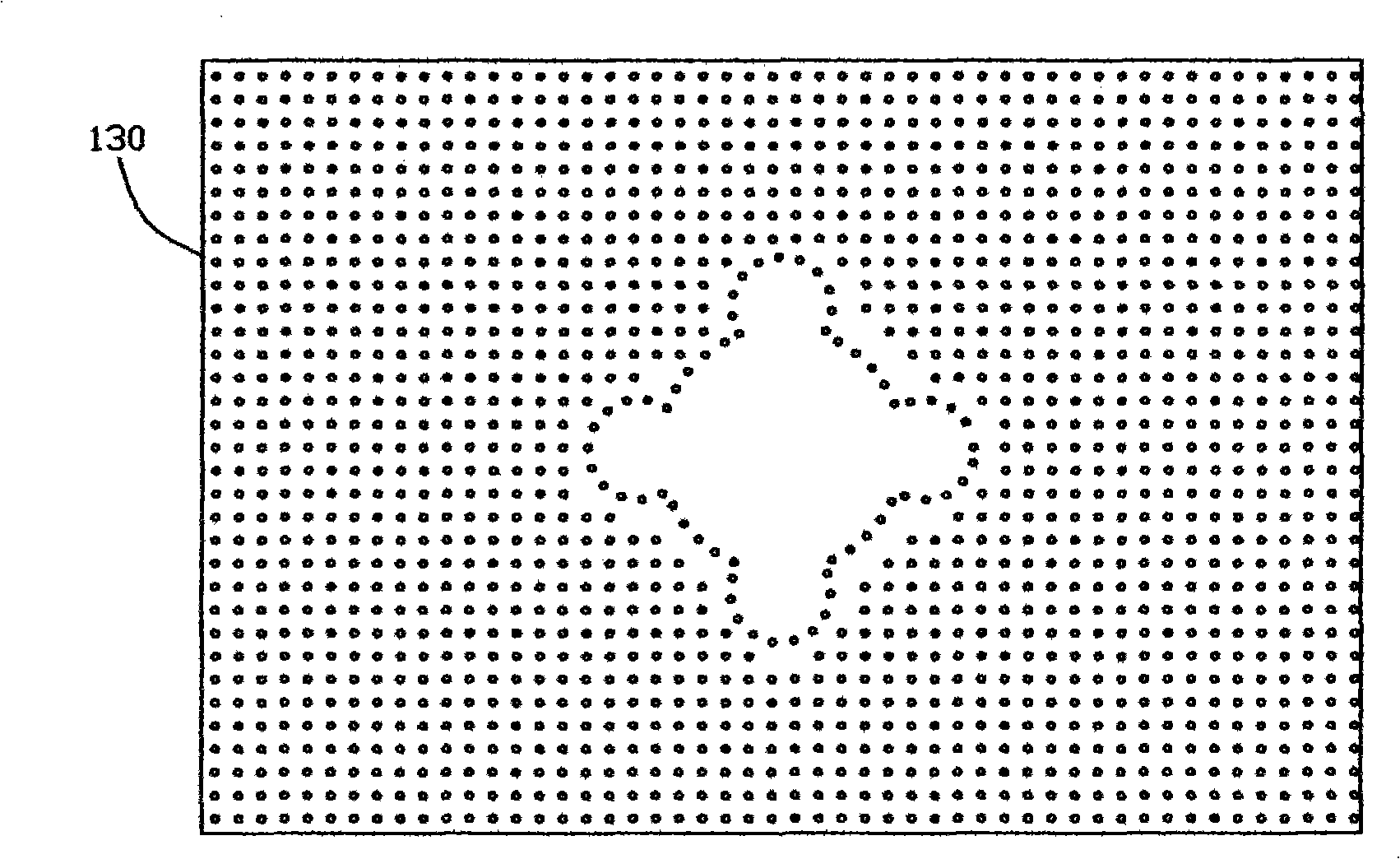

Device and method for applying patterns and/or labels to a substantially flat surface of an article

InactiveUS7121196B2Freedom of choiceLiquid surface applicatorsMechanical working/deformationEngineering

Owner:MELLIS HORST

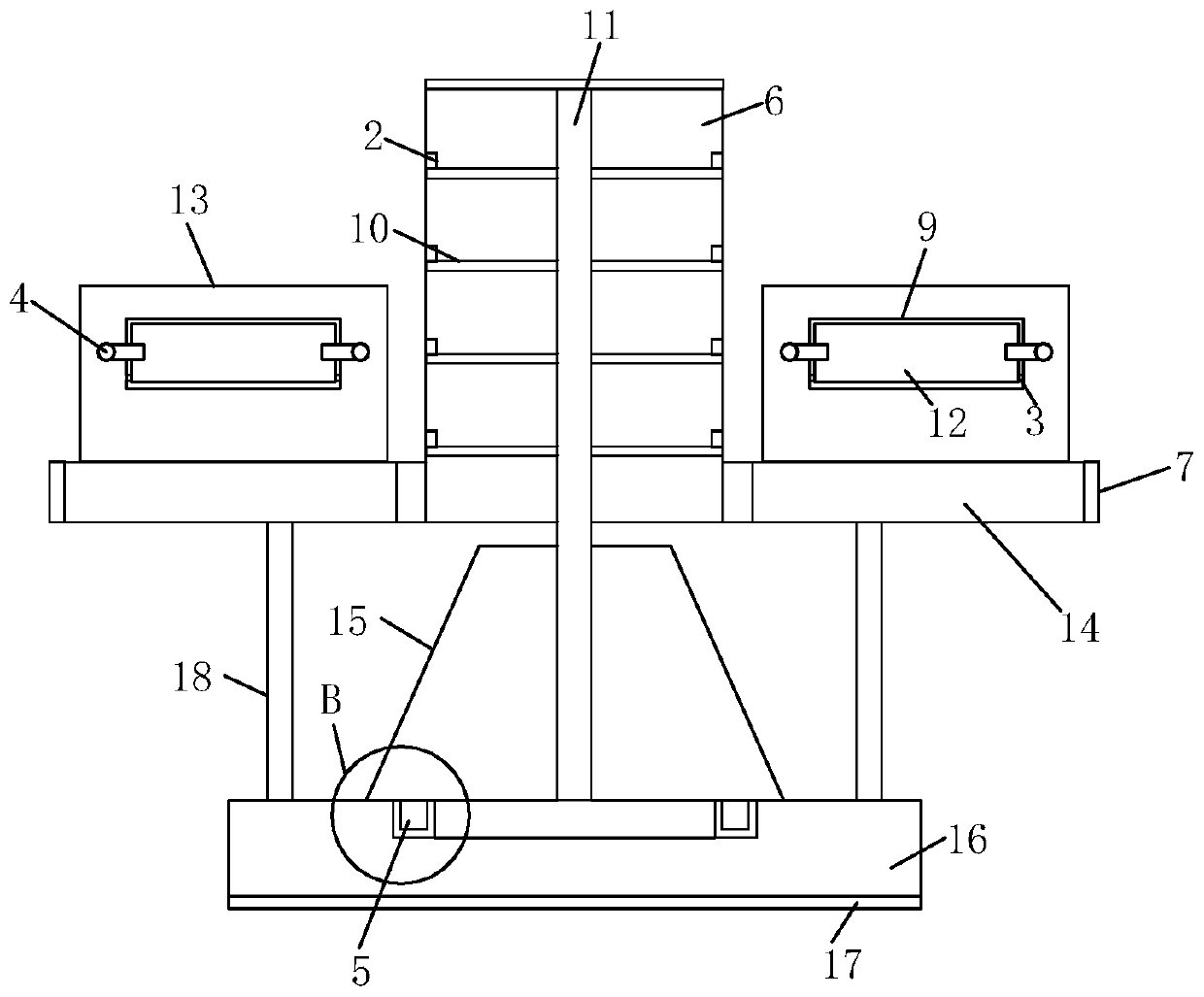

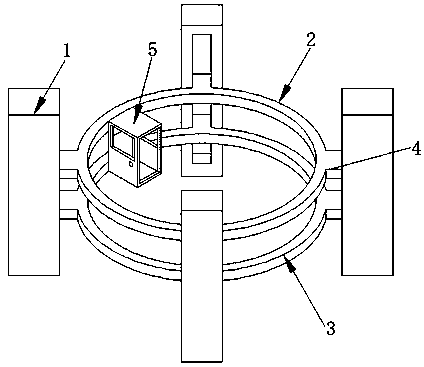

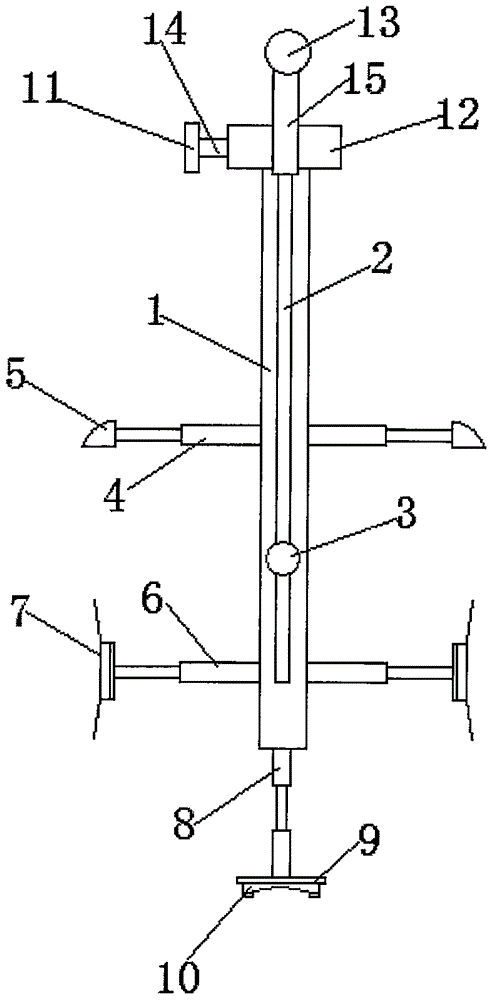

Multi-station working table for sculpture works

InactiveCN110053005AAvoid scratchesAvoid scratching the operatorHand artistic toolsWork benchesEngineeringSquare Shape

The invention relates to the technical field of working tables, in particular to a multi-station working table for sculpture works. The multi-station working table for the sculpture works comprises asupport table and a base, wherein four clapboards are vertically and uniformly arranged at the upper end of the support table; a sliding mechanism is arranged in the middle of the upper end of the base; the upper end of a rotary shaft penetrates through a circular hole and extends to the upper part of the support table; multiple support plates are arranged at the upper end of the outer side of therotary shaft in parallel; a square-shaped groove is formed in one side of each clapboard; rotating mechanisms are arranged at the lower ends of two sides of the inner parts of the square-shaped grooves; and fixing mechanisms are arranged on clapboards on two sides of the outer parts of the square-shaped grooves. The multi-station working table for the sculpture works provided by the invention canprovide a working site for multiple operating personnel, can be used for classifying and storing tools for sculpture, and is convenient to take the tools at the same time, so that the working efficiency is improved; and meanwhile, sharp cutters can be placed independently, so that the occurrence of the phenomenon that the operating personnel are scratched by the cutters is avoided.

Owner:温州亨嘉文化传媒有限公司

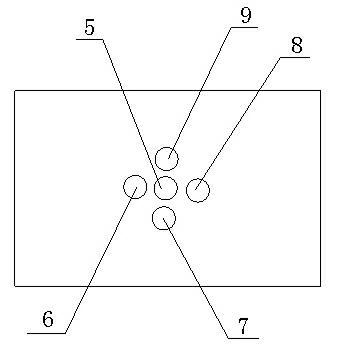

Ceramic sculpture platform

The invention discloses a ceramic sculpture platform, and relates to ceramic equipment. A rotating shaft (2) is arranged on the lower portion of a rotating table (1), the lower portion of the rotating shaft (2) is connected with a motor (3) with the lower portion provided with a base (4), a casing pipe (5) is connected to the rotating shaft (2) in a sleeved mode, the outer side of the casing pipe (5) is welded with a support (6), one side of an installing plate (7) is fixed on the casing pipe (5), a lamp holder (8) is installed on the installing plate (7), the lower end of a cardan joint (9) is fixed on the lamp holder (8), and the upper end of the cardan joint (9) is provided with a lighting lamp (10). The ceramic sculpture platform is novel in structure, the motor is utilized for driving the rotating table to rotate, and a lighting device is arranged on one side of the ceramic sculpture platform, so that sculpturing is convenient, and practicality is high.

Owner:陈仲礼

Engraving fixing device for ceramic processing

ActiveCN108909329AConvenient post-engraving workAvoid scatterLighting applicationsMechanical apparatusEngravingWorking environment

The invention provides an engraving fixing device for ceramic processing. The engraving fixing device comprises a power source switch and a miniature power source plug, wherein the top part of an engraving table is provided with a material leaking groove; the bottom part of the material leaking groove is of a hollow structure; the front end of the end surface of the top part of the engraving tableis provided with a circular positioning groove, and the bottom part of an inserting bolt is glidingly connected with the interior of the positioning groove; the top part of a rotary disc is of a circular plate-shaped structure, and the rotary disc is positioned at the end surface of the top part of the engraving table; a rotary handle is of an L-shaped strip structure, and the bottom part of therotary handle is glidingly connected with the end surface of the top part of the engraving table; a rubber gasket is attached to the inside sawtooth-shaped structure of the rotary handle. The engraving fixing device has the advantages that when an operator engraves a bottled magnetic blank, the crushed residue of porcelain clay from the engraving is blown away from the surface of the magnetic blank, the exterior of the magnetic blank is cleaner, and the operator can conveniently perform the engraving operation lately; by arranging the material leaking groove and a net cage, the previous blowncrushed residue of porcelain clay away from the surface of the magnetic blank can be collected, so as to avoid the pollution to working environment due to scattering of the crushed residue of the porcelain clay.

Owner:陈春燕

Technique for producing slice with pin-holing forming design and production tool

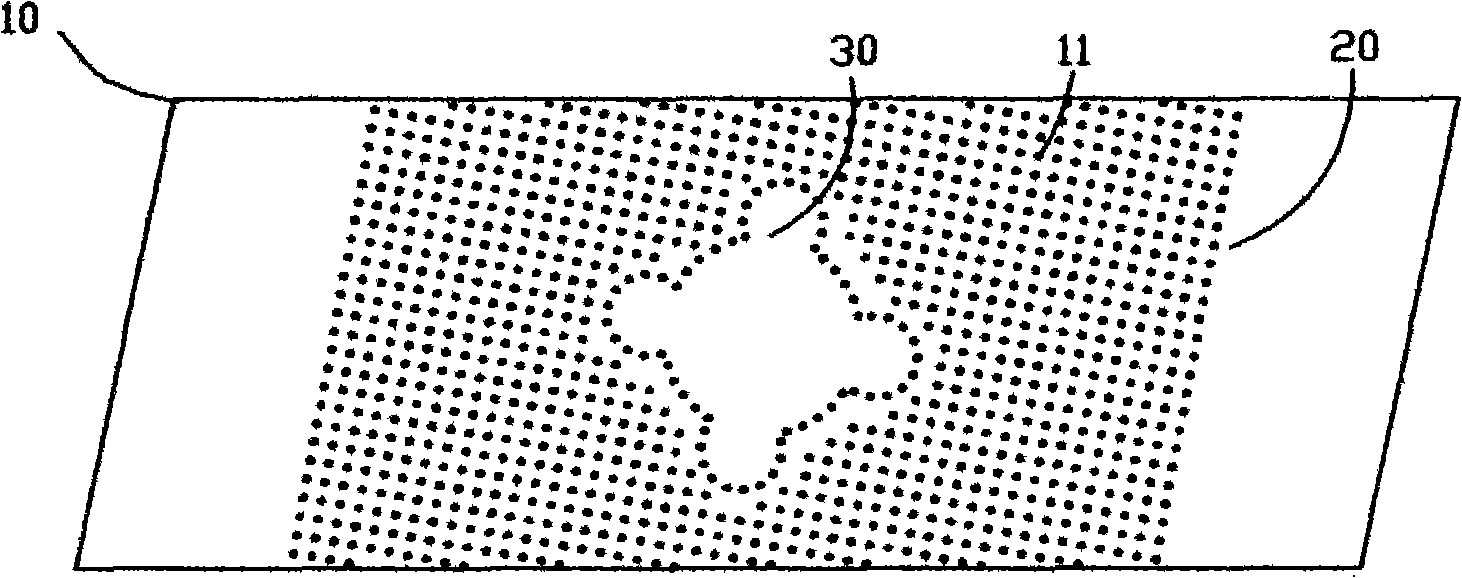

InactiveCN101244672ARealize the manufacturing processHigh efficiency of production processHand artistic toolsDecorative surface effectsLanternBiomedical engineering

Owner:蒋怡婷

Carving and fixing device for wood product machining

ActiveCN108544397AEasy to adjustMeet the clamping and fixing needsHand artistic toolsWork holdersArchitectural engineeringWood product

The invention discloses a carving and fixing device for wood product machining. The device comprises a movable turntable; a circular clamping groove and an annular chute are formed in the upper end ofthe movable turntable; multiple self-adaption clamping rods are uniformly distributed in the circular clamping groove; the self-adaption clamping rods consist of fixed sleeves, movable rods and springs; the bottom surfaces of inner cavities of the fixed sleeves are fixedly connected with the lower ends of the movable rods through springs; multiple slide blocks are slidingly connected into the annular chute; support plates are fixed at the upper ends of the slide blocks; two electric extension rods are fixed on the inner side of the support plate; a connecting base is arranged at the middle part of the lower end of the movable turntable; a support column is rotationally connected to the lower end of the connecting base; and a base is fixed at the lower end of the support column. The deviceis reasonable in structural design, and is provided with the movable turntable, the support column and the base for conveniently adjusting the carving angle of wood product workpieces; and the self-adaption clamping rods can provide side support to the wood product workpieces, and cooperate with the electric extension rods to meet the clamping and fixing demands of the wood product workpieces with various shapes.

Owner:安徽忠盛新型装饰材料有限公司

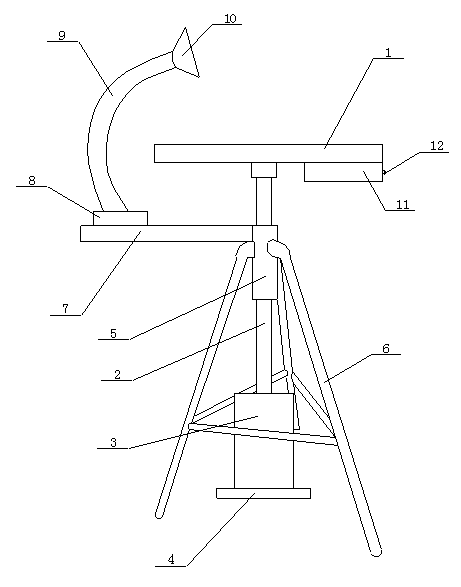

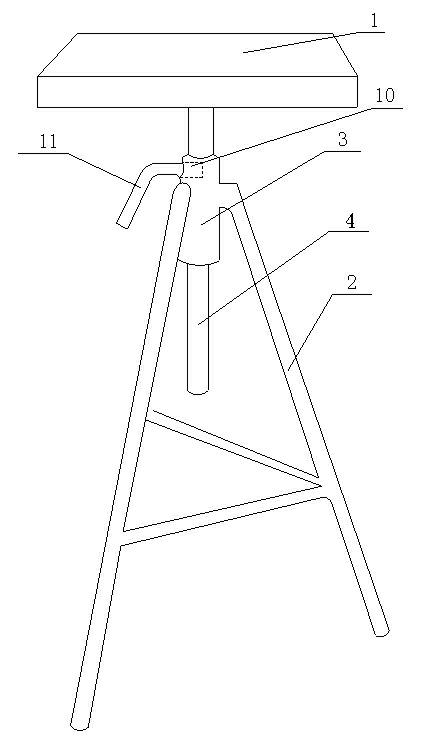

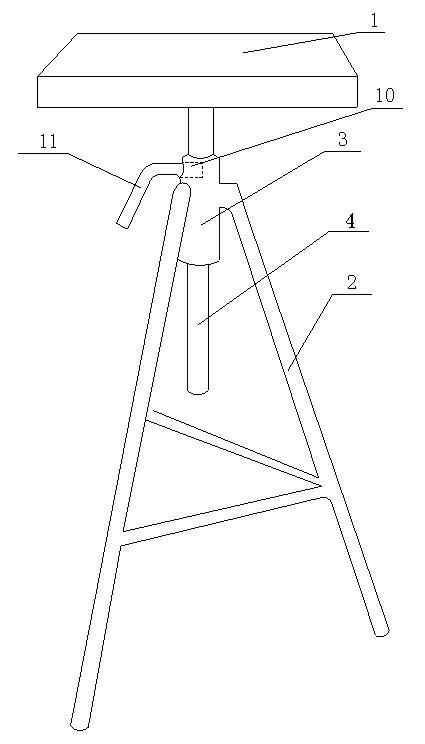

Ceramic art sculpture process table

The invention discloses a ceramic art sculpture process table which comprises a working tabletop and a triangular support, wherein a nut is fixedly arranged at the top end of the triangular support, a lead screw is inserted into the nut, a plurality of inner holes matched with the lead screw are arranged on the bottom surface of the working tabletop, the lower end of the lead screw penetrates the nut and is vertical to the ground, the upper end of the lead screw penetrates the nut and is in contact with the inner holes on the bottom surface of the working tabletop, a screw hole is formed on the side surface of the nut, and a handle is screwed into the screw hole. The ceramic art sculpture process table has the advantages of simple structure, capability of realizing lifting, positioning in different angles and convenience in ceramic art sculpture.

Owner:姜建华

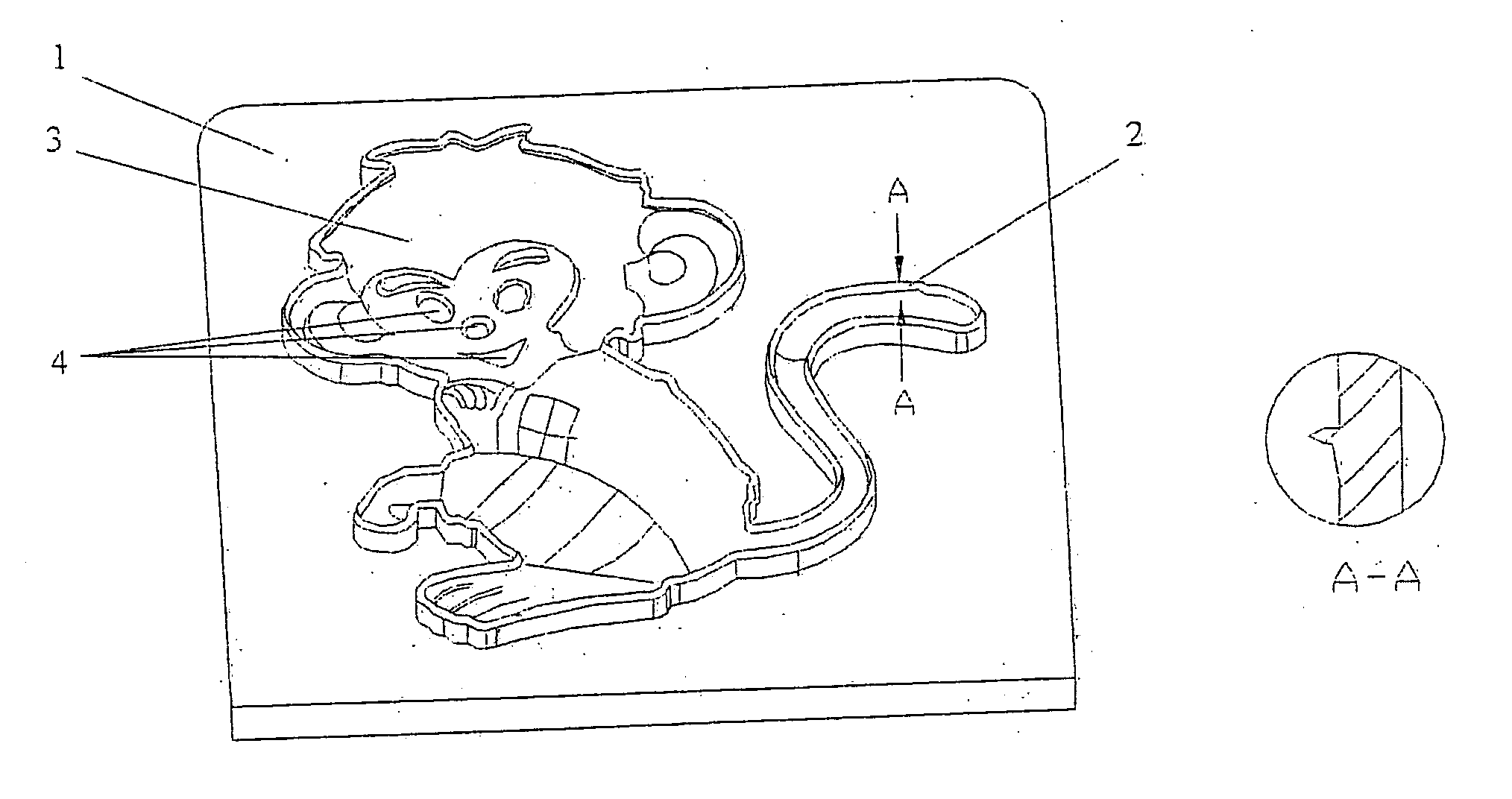

Image cutter for producing stereo relief image

InactiveUS20060179995A1Decorative resultBetter-visualized effectHand artistic toolsSpecial ornamental structuresComputer graphics (images)3d image

Owner:ANGEVINE FAYE +1

Fixing device for bamboo artware machining

The invention discloses a fixing device for bamboo artware machining and relates to the technical field of the bamboo artware machining. The fixing device for the bamboo artware machining comprises afixing device body; the fixing device body comprises a fixing table, a residue collecting box, a net rack, supporting rods and a fixing clamp; the residue collecting box is movably installed at the middle part of the upper end of the fixing table; the lower end of the net rack is fixedly connected with the upper end of the residue collecting box; and the lower ends of the supporting rods are movably connected with one side of the upper end of the net rack. With the adoption of the fixing device for the bamboo artware machining, the fixing clamp can be dismounted from the supporting rods, so that fixing clamps in different sizes are replaced so as to fixing and machining raw materials in different sizes; and one ends of second sliding blocks are fixedly connected with the inner side wall ofa second sliding groove through compression springs, so that the raw materials required to be machined can be fixed more tightly by the fixing clamps, falling broken residues in the machining processof bamboo artware can directly fall into the residue collecting box through the net rack, and cleaning after the machining is facilitated.

Owner:安吉盛康竹制工艺厂

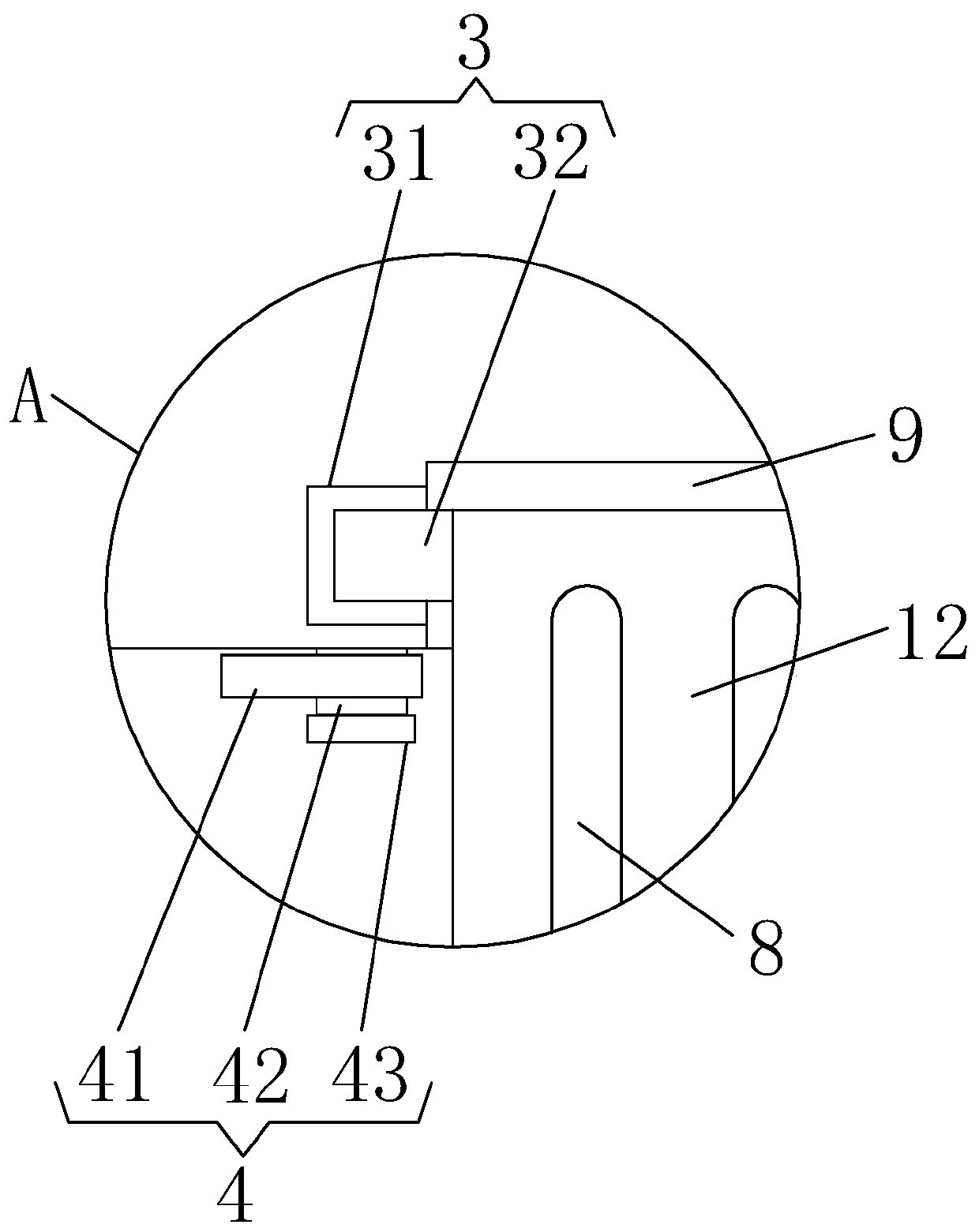

High-strength structure ceramic engraving machining device with double supporting and positioning mechanisms

ActiveCN111331714AAvoid cleaning hassleEffect engravingHand artistic toolsAuxillary shaping apparatusLeft halfButt joint

The invention discloses a high-strength structure ceramic engraving machining device with double supporting and positioning mechanisms, and relates to the technical field of manual ceramic machining tools. The problem that most of existing machining devices cannot intensively contain slag generated by engraving, so that the slag is scattered and falls off to pollute the ground, and cleaning is inconvenient. The high-strength structure ceramic engraving machining device with the double supporting and positioning mechanisms comprises a base, a slag receiving disc and a round sliding seat, wherein a main supporting column is vertically welded to the middle of the top end of the base, the round sliding seat is arranged on the upper half section of the main supporting column in a sleeving and sliding mode, a rotating wheel and a worm are sequentially arranged on the lower half section of the main supporting column from top to bottom in a rotating and inserted mode, the rotating wheel facesthe left side and is directly arranged on the main supporting column in a penetrating mode, and the worm is located on the right side of the main supporting column. According to the device, a left half-cutting box and a right half-cutting box can be inserted and fixed to the circular sliding base through two inserting frames, and the two half-cutting boxes are in butt joint with each other and positioned to form the complete slag receiving disc.

Owner:嘉兴德基机械设计有限公司

Colored relief shaping cutter

ActiveCN107009800ALighten the burden of carryingReduce use costHand artistic toolsEngineeringUtilization rate

The invention relates to a colored relief shaping cutter. The colored relief shaping cutter comprises a rod body, and blades arranged at the end parts of the rod body; multiple detachable blades rotationally matched with the rod body are arranged on the rod body in the width direction in sequence; storage tanks for placing and hiding the blades are arranged on the rod body corresponding to all the blades; and the rod body is produced by a metal material. The colored relief shaping cutter adjusts the blade number and freely dismounts each blade according to the use demands, reduces the carrying burden of handicraftsmen, reduces the use cost, increases and reduces the number of the detachable blades, adjusts blade gaps, increases the tool use rate and utilization rate, has no need to manufacture a colored relief, manufactures various blades with different widths and numbers to satisfy the shaping demands of plant models, and is used in a module combination manner.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Controllable solidifying type technologic clay sculpture material

The invention relates to a controllable and cured type technique clay sculpture material, which adopts epoxy resin, PVC paste resin, talc powder and light calcium carbonate as raw materials. The raw materials are mixed evenly and then stirred into putty shape composition 1; curing agent, the PVC paste resin and the talc powder are mixed evenly and stirred into semi-transparent paste, in which the light calcium carbonate is added, thus obtaining composition 2. The two compositions are mixed evenly in accordance with a certain ratio, thus obtaining the controllable and cured type technique clay sculpture material. The invention is characterized in that: the invention not only has the plasticity (being moulded into different shapes randomly) of the traditional technique clay sculpture material (clay), but also has long storing time; besides, the cured time can be controlled (a plurality of hours or a plurality of days) under low temperature (below 0 DEG C); the invention is characterized by constructability, innocuity, adjustable hardness of products and extremely high impact resistance (being uneasy to be broken), etc. The invention is the technique clay sculpture material with excellent comprehensive property.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

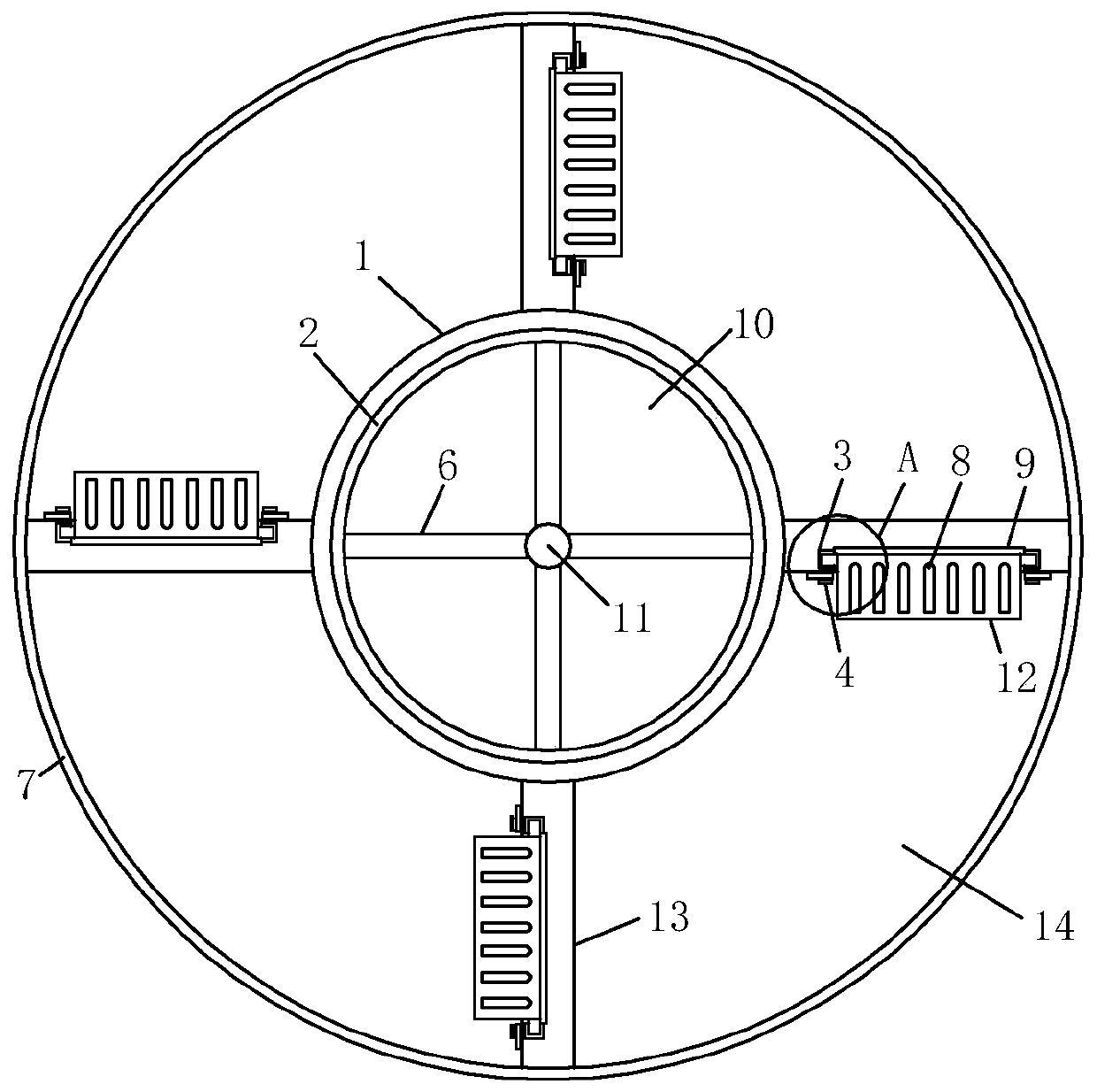

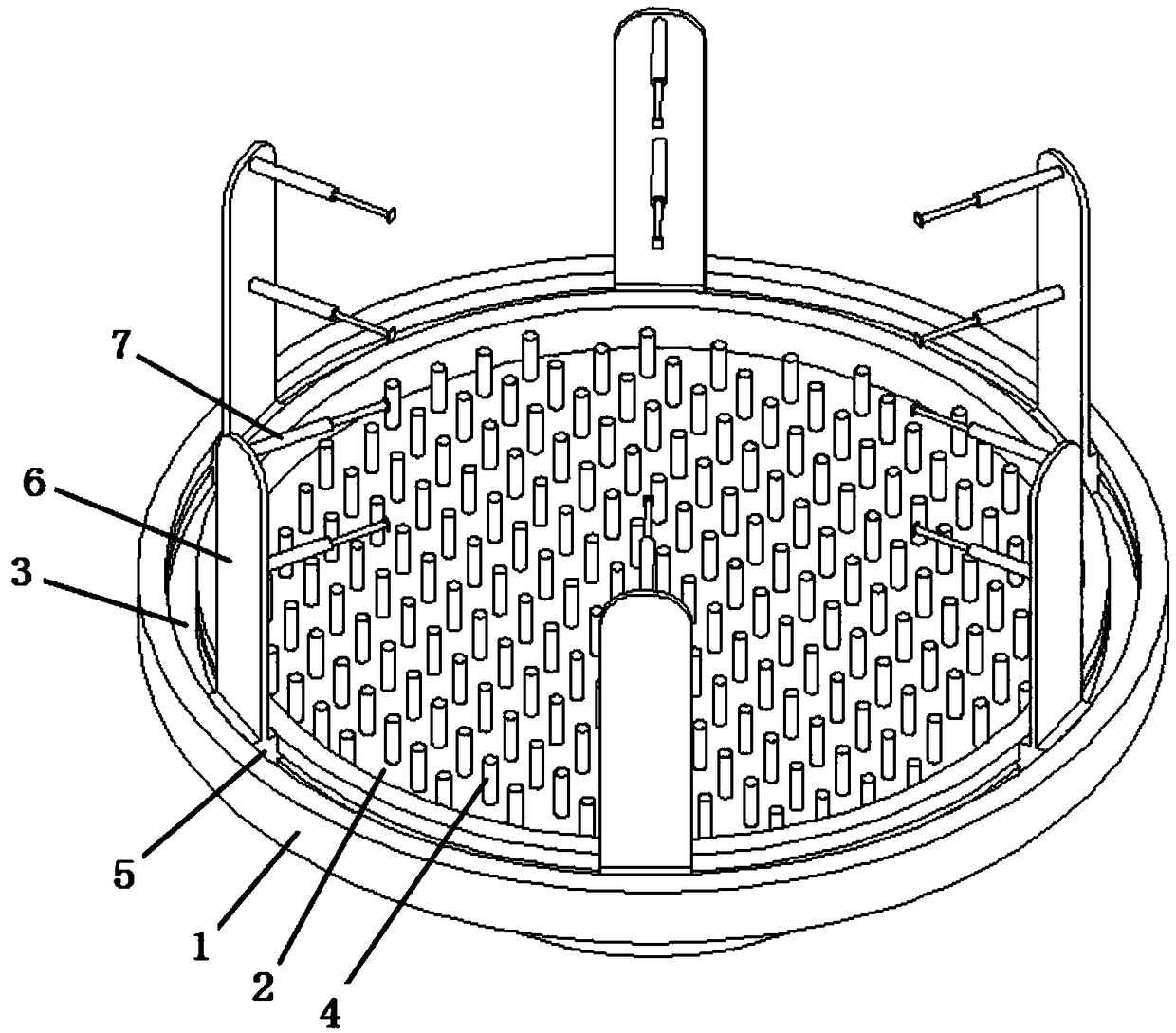

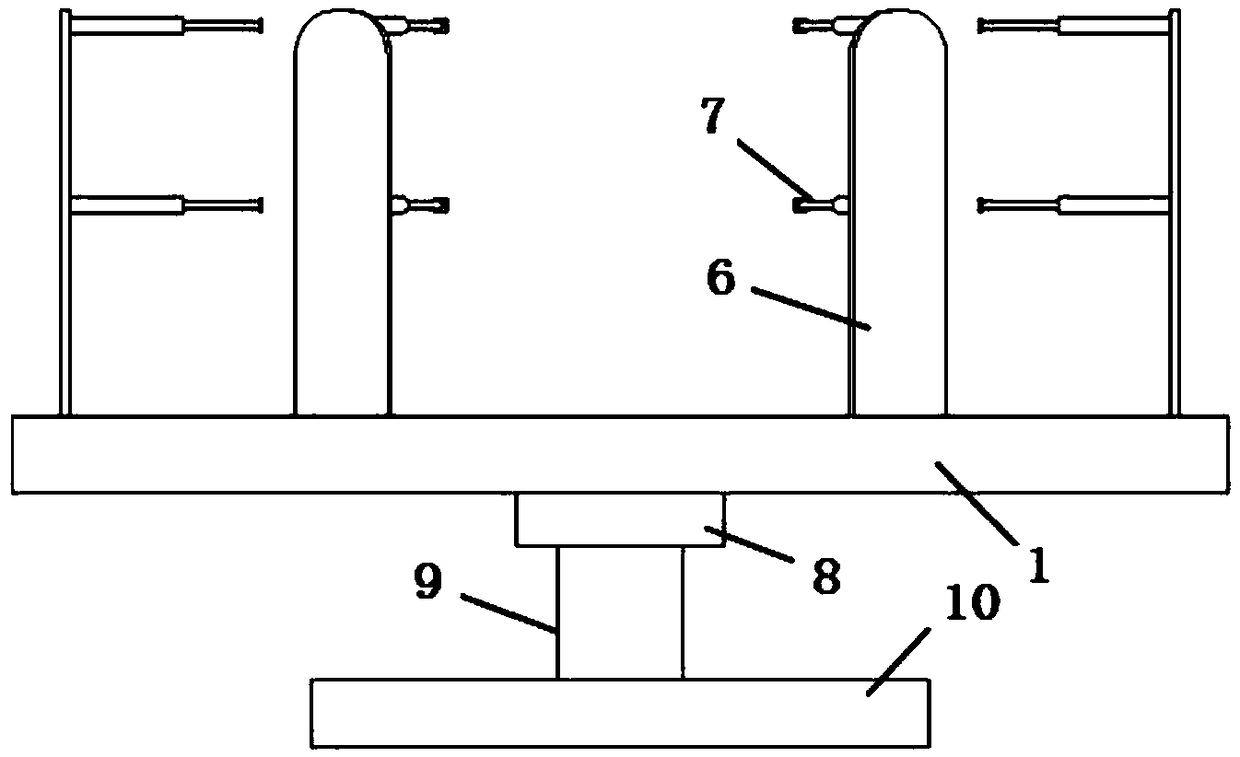

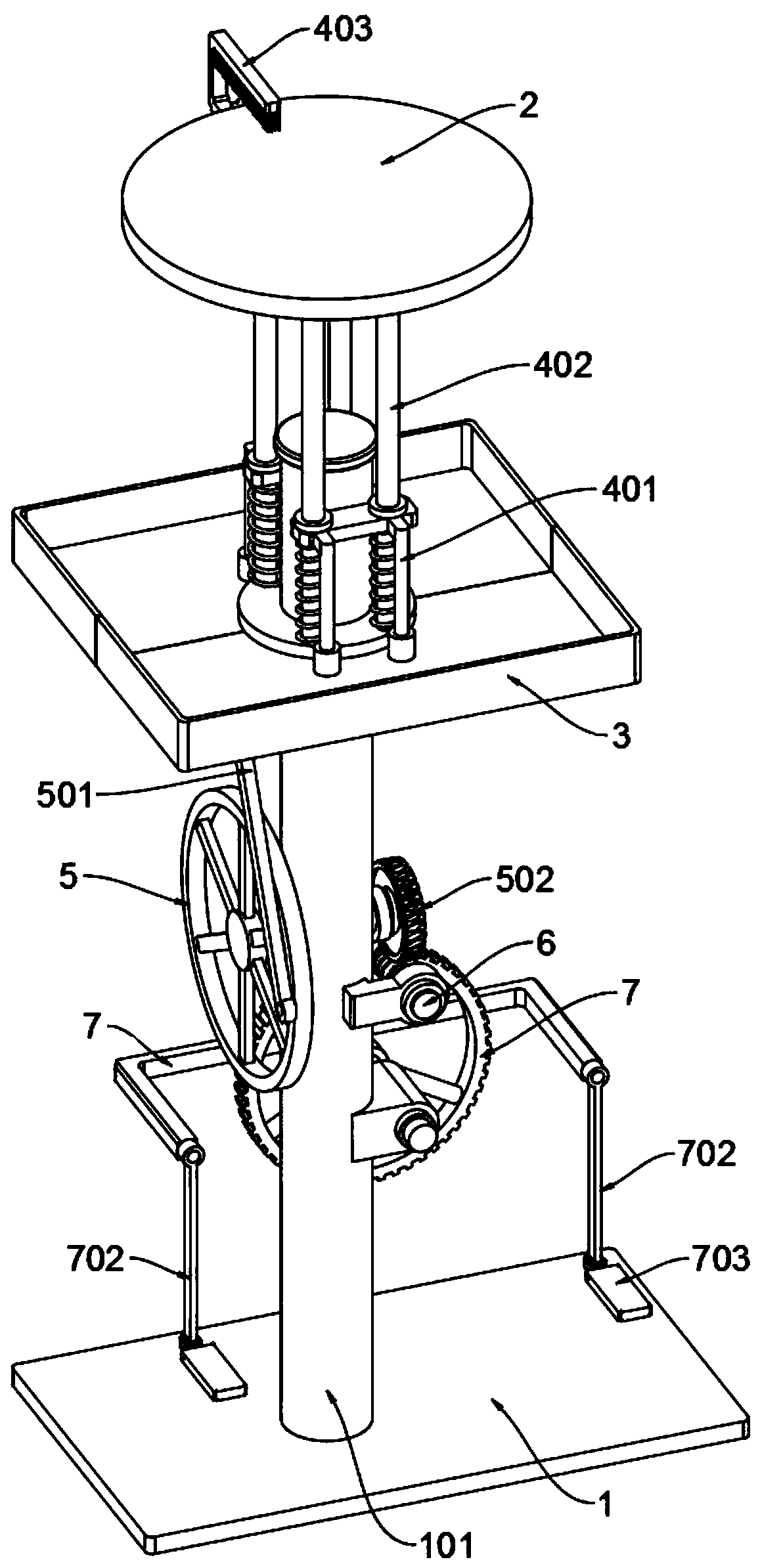

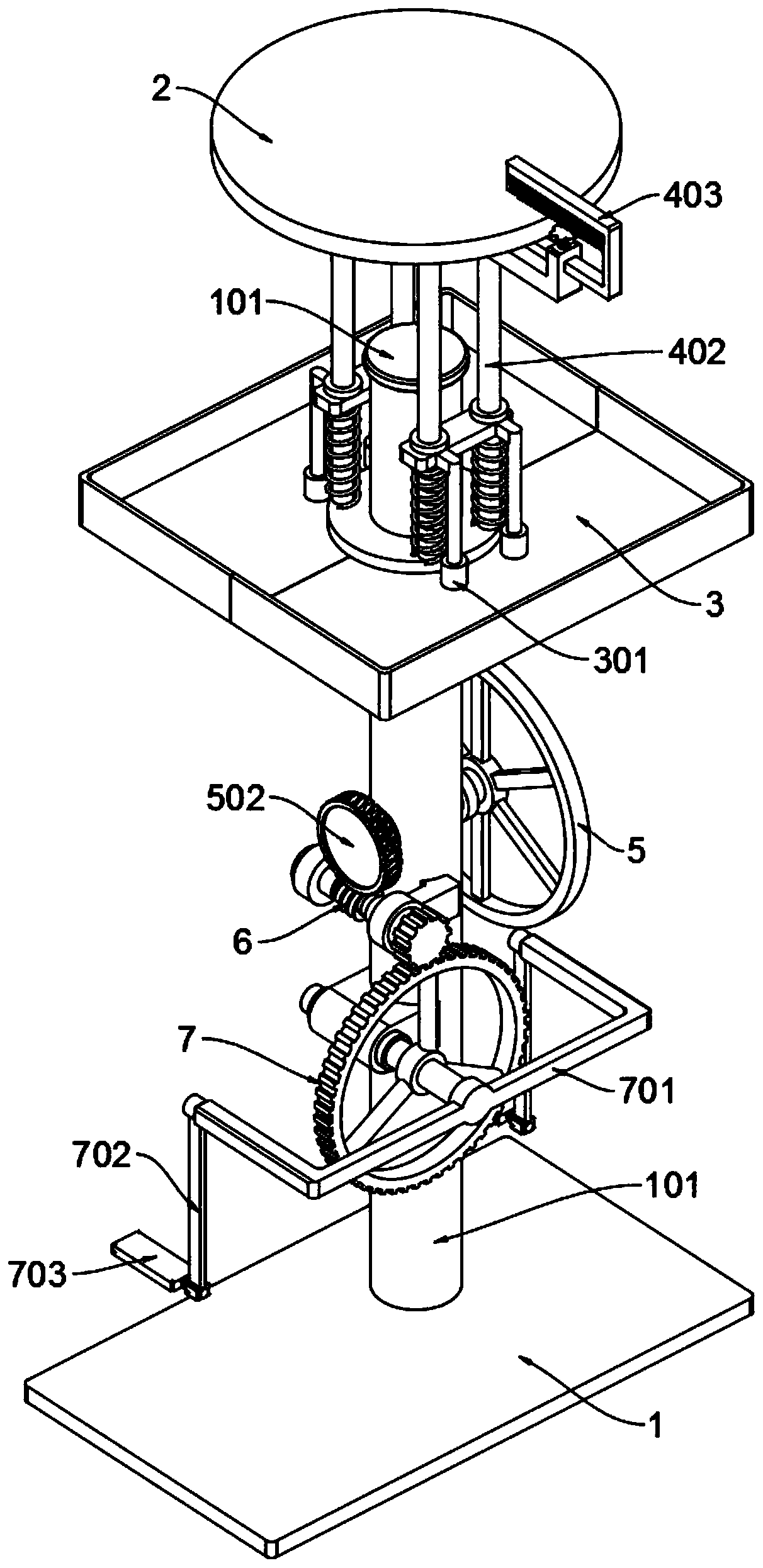

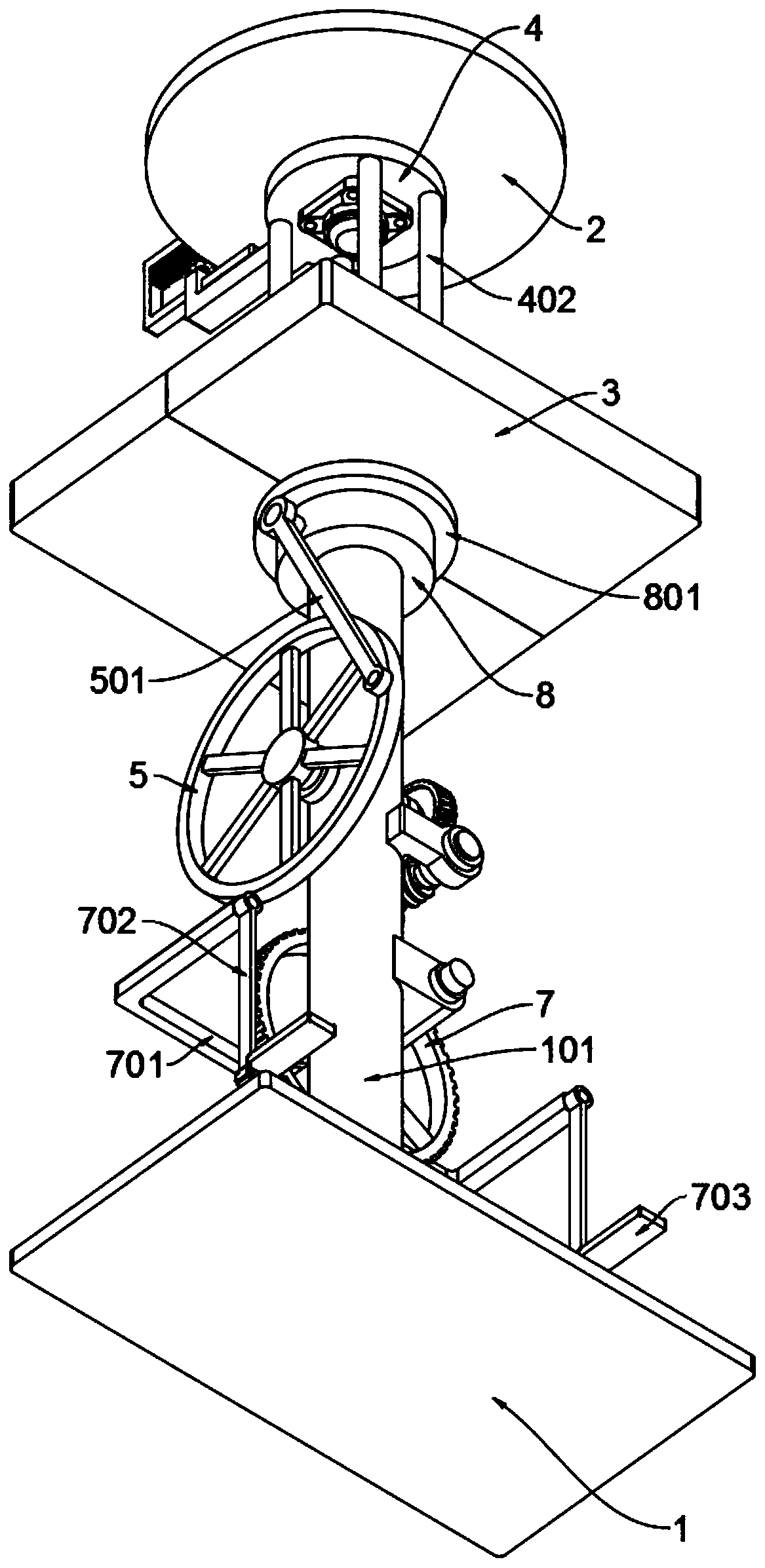

Multi-station worktable for large sculpture artware

ActiveCN108621669AReasonable structureEasy to organizeHand artistic toolsOrnamental structuresEngineeringAnnular array

The invention discloses a multi-station worktable for large sculpture artware. The multi-station worktable comprises a lifting platform, a first annular rail, a second annular rail, a working bin anda PLC; the first annular rail is a circular rail, and is provided with four sets of rectangular plate structured cooperating plates at the outer end; the four sets of cooperating plates are arranged out of the first annular rail in an annular array manner with the axis of the first annular rail as circle center; the four sets of cooperating plates and the first annular rail are integrally molded;the second annular rail is a circular rail, and is provided with four sets of cooperating plates at the outer end; the four sets of cooperating plates are arranged out of the second annular rail in anannular array manner with the axis of the second annular rail as circle center; the four sets of cooperating plates and the second annular rail are integrally molded; and the first annular rail and the second annular rail are consistent in diameter and axis. The multi-station worktable for the large sculpture artware is reasonable in structure and easy to use, has multiple working directions under the effect of the PLC, and deserves wide application.

Owner:聊城市天工景观艺术有限公司

Art Medium Surface Treatment Tool

An art medium applicator includes a rotating shaft and an art medium coupled thereto for causing the medium to travel through an application path for transfer to a substrate. The applicator includes a coupling assembly, and may include an applicator tip including a cavity into which the art medium is inserted and supported. An art medium modifier includes a rotating shaft and an art medium modifier coupled thereto for causing the modifier to travel through an application path for modification of an art medium previously applied to a substrate.

Owner:BUSSIE JACOB G

Art knife structure capable of clamping blade

PendingCN106217416AEasy to fixNo shakingHand artistic toolsMetal working apparatusEngineeringMechanical engineering

The invention provides an art knife structure capable of clamping a blade. The blade can be clamped so as not to shake during a use process, so that the accurate cutting is realized, the blade can be firmly fixed, and the stability in using the blade is improved. The art knife structure capable of clamping the blade comprises a knife body comprising a first knife body and a second knife body, the blade, an adjuster, a locking block and a spring; the first knife body is located relatively above the second knife body; the front end of the first knife body and the front part of the second knife body are mutually fastened to form a slope limiting structure capable of relatively sliding; the blade is located in a blade guiding slot; the adjuster is used for clamping the blade; the locking block is fixedly arranged on the rear part of the first knife body through a rotary shaft; a spring installation cavity is reserved between front positions, of the locking block, on which the first knife body and the second knife body are located; the front end of the spring is arranged on the first knife body in an ejecting way; and the rear end of the spring is arranged on the second knife body in an ejecting way.

Owner:顺德工业(江苏)有限公司

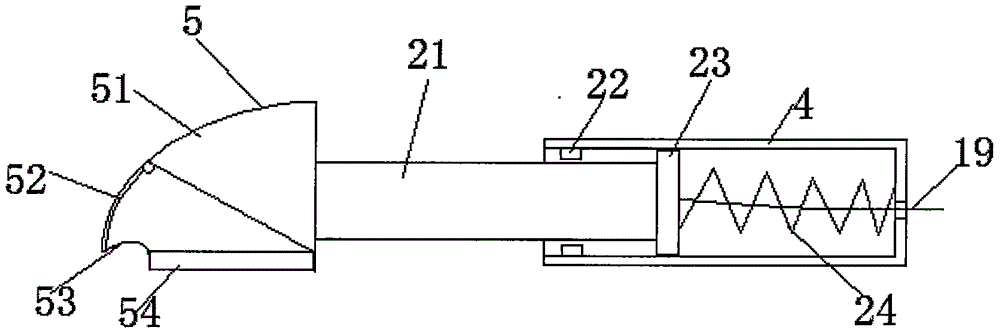

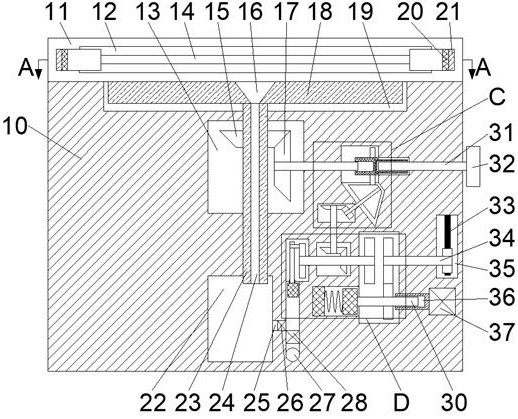

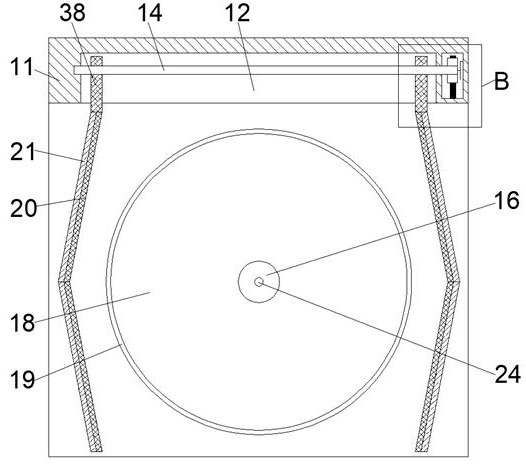

Disordered aesthetics creation hammer

The invention discloses a disordered aesthetics creation hammer. A hammer sleeve comprises an open end and a closed end, one end of an elastic hammer is sleeved with the hammer sleeve, a hammering surface is arranged at the other end of the elastic hammer, a spring is arranged between the inner bottom surface of the closed end of the hammer sleeve and one end, sleeved with the hammer sleeve, of the elastic hammer, a staggered rod is arranged on the inner bottom surface of the closed end of the hammer sleeve, a staggered cone is arranged at one end, sleeved with the hammer sleeve, of the elastic hammer, two positioning grooves are formed in the outer wall of the elastic hammer, upper sections of the positioning grooves are vertical, lower sections of the positioning grooves are inclined, one end of each positioning rod is inserted in the positioning groove, the other end of each positioning rod is fixed on the hammer sleeve, the staggered cone and the staggered rod constitute a slide rheostat, one end of the staggered cone is connected with an indication lamp, a switch, a power supply and the staggered rod sequentially, the switch, the power supply and the indication lamp are arranged on a handle, an elastic piece and fixing rods are arranged at a middle section of the handle, middles of the fixing rods are disconnected, lantern rings are arranged in the middles of the fixing rods, and the tail end of the handle warps upwards. The hammer is particularly applicable to three-dimensional art works such as clay sculptures and the like, is used for knocking out irregular pits on soft art materials, and is beneficial to presentation of disordered aesthetics.

Owner:兰陵财金产业发展有限公司

Fixing device for glass bottle carving

InactiveCN106739735ADoes not affect engraving workConcentrate on engraving workHand artistic toolsOther artistic work equipmentsEngineeringBottle

The invention discloses a fixing device for glass bottle carving. The fixing device comprises a fixed cylinder; a hollow fixed rod is vertically arranged on the side surface of the fixed cylinder; a pair of first support frames and a pair of second support frames are symmetrically arranged on the side surfaces of the fixed rod; the first support frames and the second support frames both can extend; clamping blocks are mounted at the end parts of the first support frames; support discs are mounted at the end parts of the second support frames; a chute is axially formed in the fixed rod; and an illuminating lamp is assembled in the chute. The fixing device fixes a glass bottle by an internal support mode, dose not influence the carving work at all, has no need of use a hand of a carver to keep the glass bottle stable, enables the carver to be more concentrated on the carving work, is simple in structure and convenient to use, can fix and adjust the fixing position, angle and the like according to actual demands of the carver, and provides an ideal auxiliary tool for glass bottle carving.

Owner:拾六盏(上海)网络科技有限公司

Auxiliary positioning and machining device applicable to ceramic products in different specifications

InactiveCN112060298ATo achieve the purpose of automatic centeringAchieve fixationHand artistic toolsGrinding drivesEngineeringBevel gear

The invention relates to the related field of ceramic machining or equipment, and discloses an auxiliary positioning and machining device applicable to ceramic products in different specifications. The auxiliary positioning and machining device comprises a main body box; a rotary disc cavity with an upward opening is formed in the main body box; a positioning box located on the back side of the rotary disc cavity is fixedly connected to the tail end of the back side of the upper end surface of the main body box; a positioning cavity with a forward opening is formed in the positioning box; a conveying belt cavity extending downwards into the main body box is formed on the right side of the positioning cavity; a large bevel gear cavity is formed on the lower side of the rotary disc cavity; and an air cavity is formed on the lower side of the large bevel gear cavity. By the aid of positioning sliding blocks and touch switches on the two sides of the device, the purpose of automatic centering of circular ceramic products is achieved, so that the machining efficiency is improved, meanwhile, the positioning precision is improved, and the later-period machining quality of the ceramic products is guaranteed; in addition, the certain adsorption force is generated by an adsorption cavity for the ceramic products through an air exhaust piston in the device, so that the ceramic products inthe different specifications and sizes are fixed, and the applicability of the device is improved.

Owner:FOSHAN XIANNA CRAFTS CO LTD

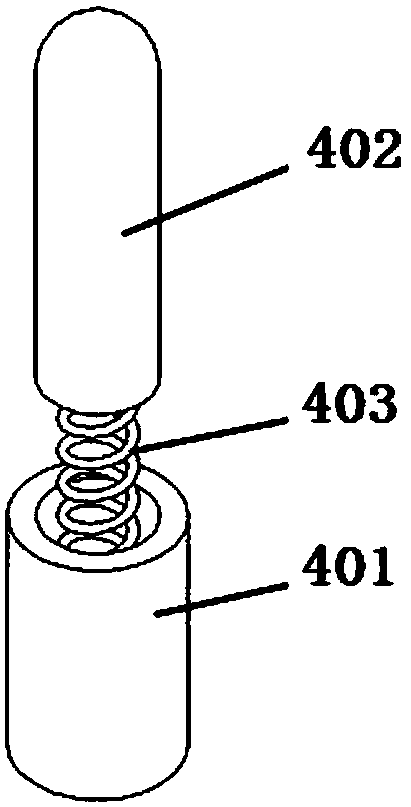

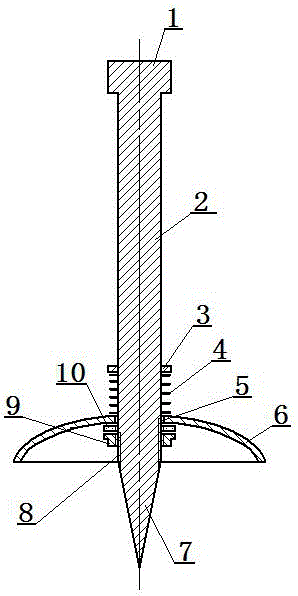

Steel chisel beneficial for labor protection

InactiveCN106363822AAvoid hittingExtended service lifeHand artistic toolsWorking accessoriesStone wallChisel

The invention discloses a steel chisel beneficial for labor protection. The steel chisel includes a cylindrical striking part, a cylindrical pin body part and a pyramid shape drill head. The main characteristics of the steel chisel are as follows: the outer diameter end of the bottom part of the cylindrical pin body part is provided with an integrated form of c-ring; a compression spring is covered on the outer diameter end of the cylindrical pin body part below the c-ring; a hollow ball mask body is adjustably covered on the outer diameter end of the cylindrical pin body part below the compression spring; the cylindrical pin body part below the compression spring is provided with an external screw thread that is matched and connected with a flange nut; the compression spring is in a free style condition; a rubber gasket is covered on the outer diameter end of the cylindrical pin body part between the flange nut and the ball mask body; the outer diameter of the ball mask body is set at 10-15 cm; the material of the ball mask body is transparent organic glass. The steel chisel can avoid to the greatest extent the carved broken stones falling down to hit on the face of a worker. The steel chisel is especially suitable for carving characters and patterns on stone walls.

Owner:罗道仟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com