High-strength structure ceramic engraving machining device with double supporting and positioning mechanisms

A positioning mechanism and processing device technology, which is applied in ceramic forming machines, decorative arts, painting tools, etc., can solve the problems of not being able to gather debris, block the bottom section, and occupy both hands, so as to improve the efficiency of engraving operations and use flexibly Convenience and the effect of reducing work fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

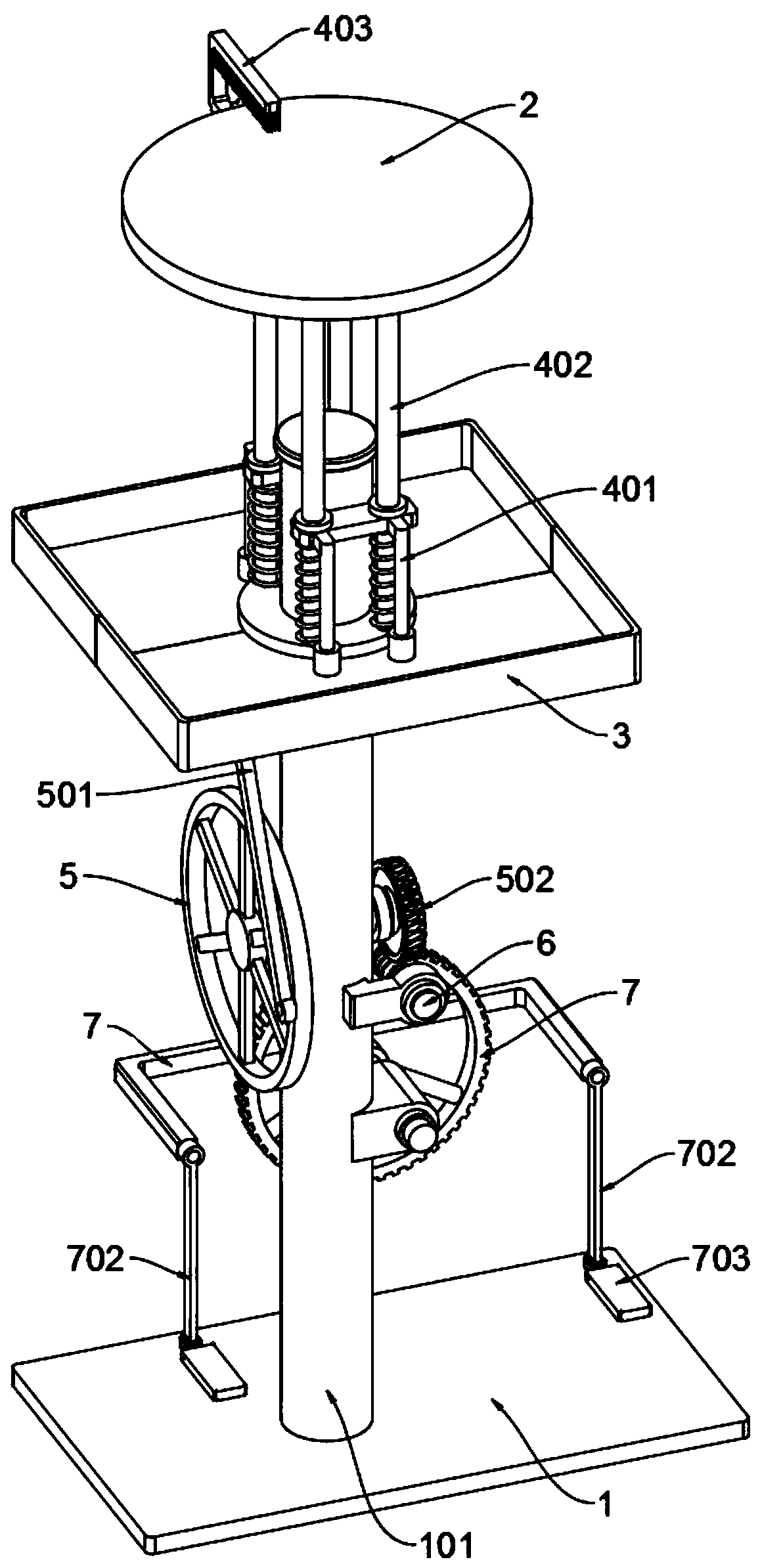

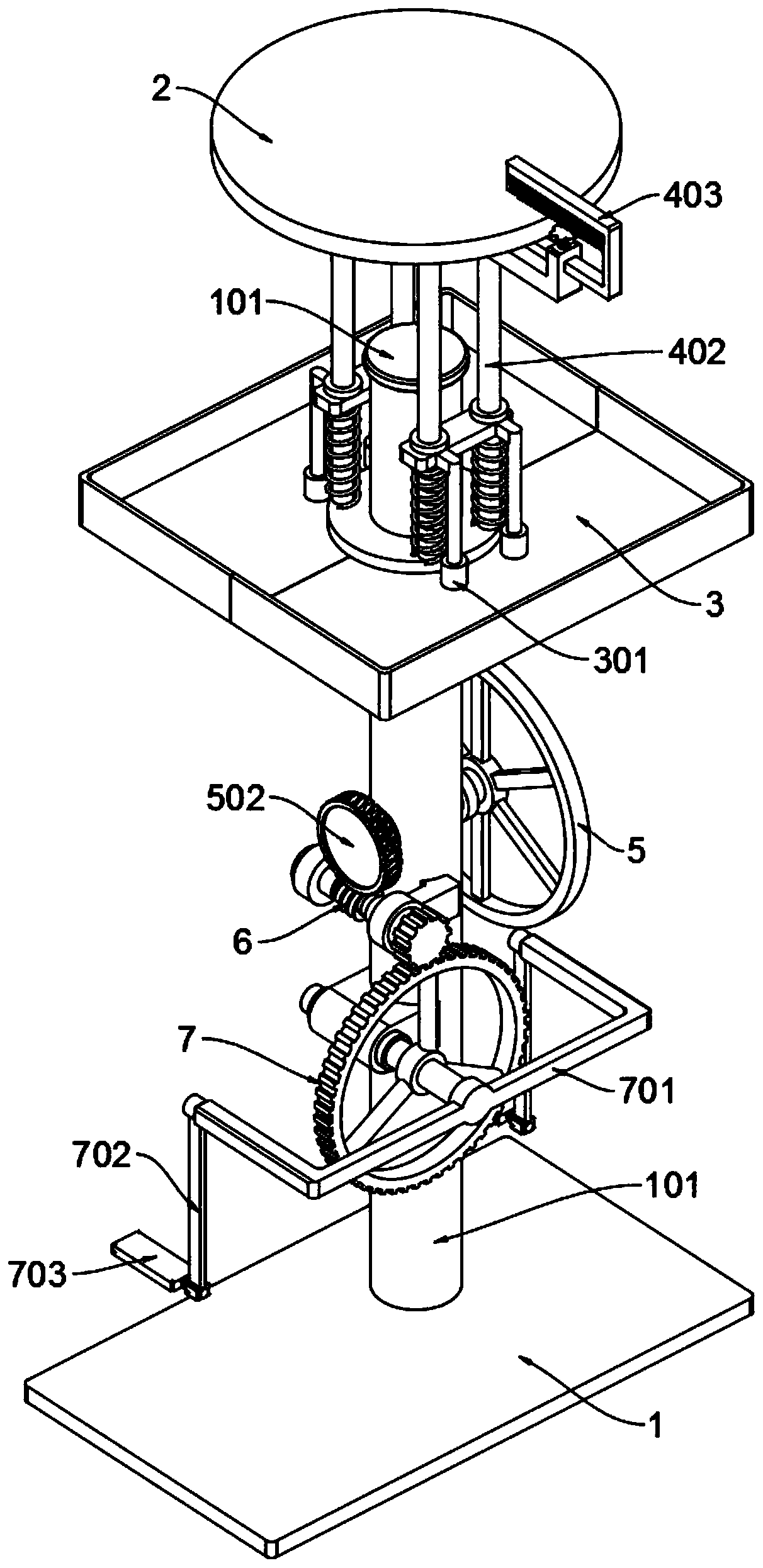

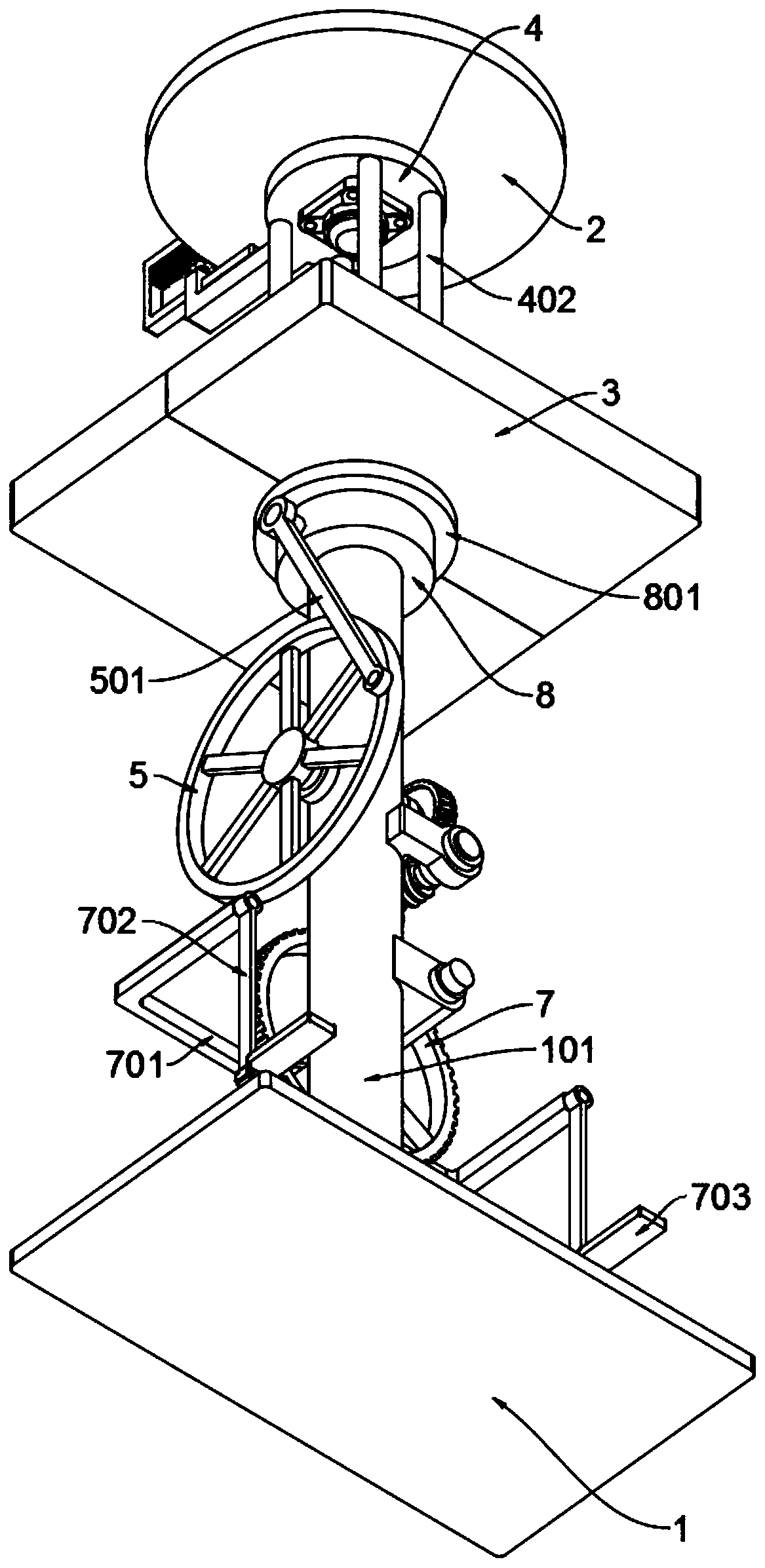

[0030] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a high-strength structural ceramic carving processing device equipped with a double support positioning mechanism, including a base 1, a slag receiving tray 3 and a circular sliding seat 8, the base 1 includes a main support column 101, the base 1 is vertically welded with a main support column 101 in the middle of the top, the upper half of the main support column 101 is slidably provided with a circular sliding seat 8, and the lower half of the main support column 101 is sequentially arranged from top to bottom The runner 5, the worm 6 and the runner 5 are arranged and inserted, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com