Patents

Literature

105results about How to "Avoid cleaning hassle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

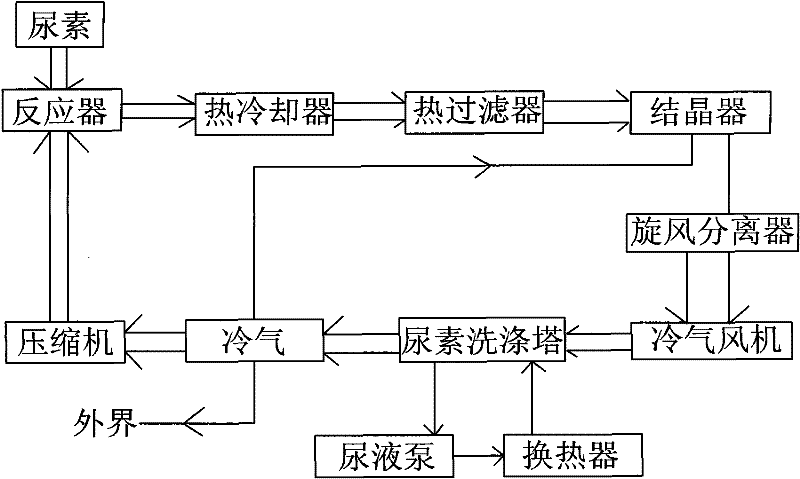

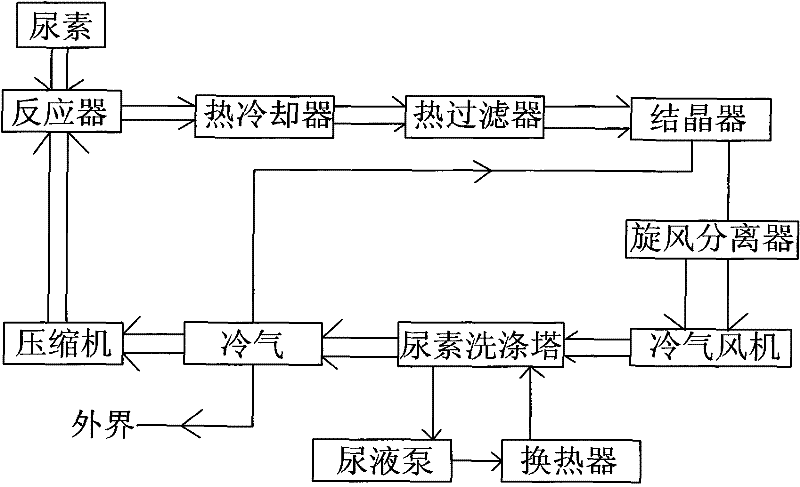

Energy-saving process for producing melamine

InactiveCN102452992APrevent spoilagePrevent melting point riseOrganic chemistryChemical industryComing outCatalytic function

The invention relates to an energy-saving process for producing melamine, comprising the following steps: using urea as the raw material, and producing melamine, ammonia and carbon dioxide in a reactor under the catalytic function of a catalyst at 350-420 degrees centigrade and a pressure of 0-1.5 MPa through reaction, wherein material gas from the reactor enters a hot-gas cooler, and the cooled hot technological gas enters a filter to be filtered, and the filtered technological gas containing melamine enters a crystallizer, and the melamine after crystallization enters a cyclone separator, and the separated solid triamine is sent to a storage bin to be packaged, and the gas coming out from the cyclone separator enters a heat exchanger; cooling the gas containing ammonia and carbon dioxide at about 200-220 degrees centigrade by water to about 30-145 degrees centigrade, and purifying the technological gas in an urine liquid washing tower; separating urine liquid fog drops carried in the purified gas by a separator, wherein the gas after separation is divided into three ways: one way gas is compressed into the reactor by the compressing machine, and one way gas enters the crystallizer by a cool air fan through pressure boosting to be used as cool air, and one way is a tail gas exhaust system for other purposes. The process disclosed by the invention has characteristics of compact equipment, simple technology, less energy consumption, cost saving and so on.

Owner:郗运柱

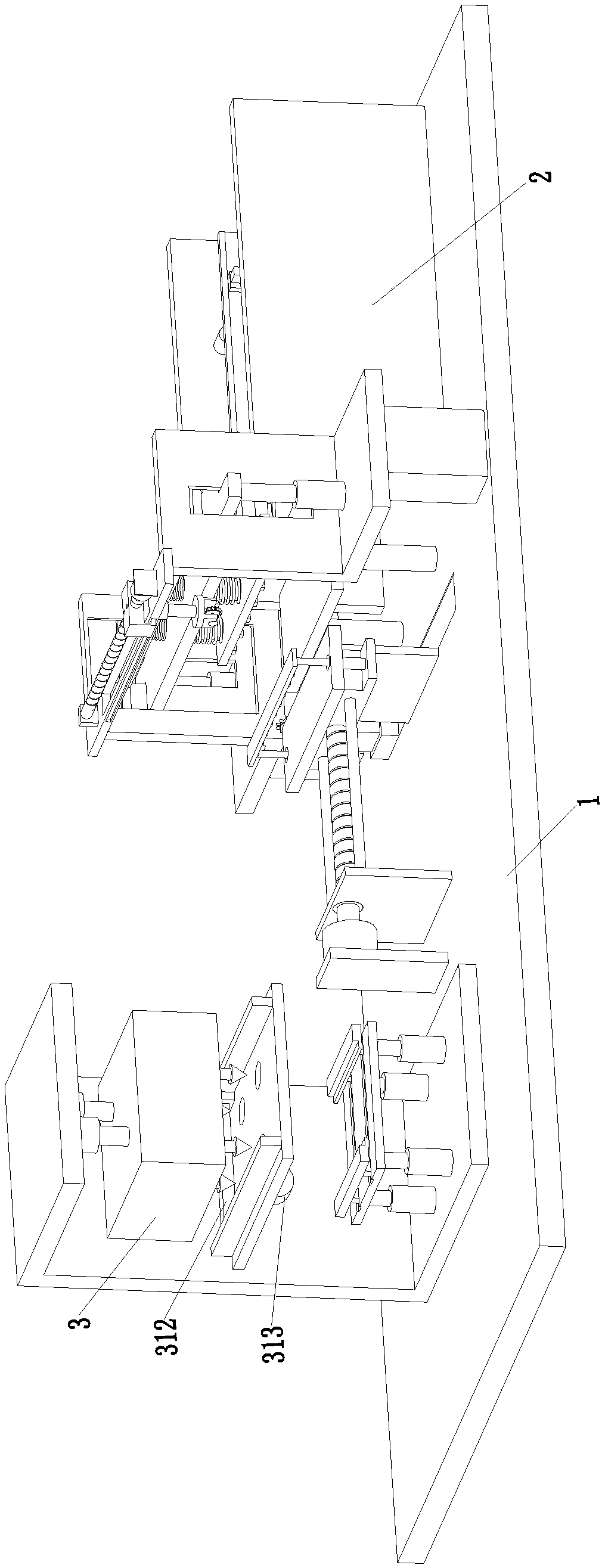

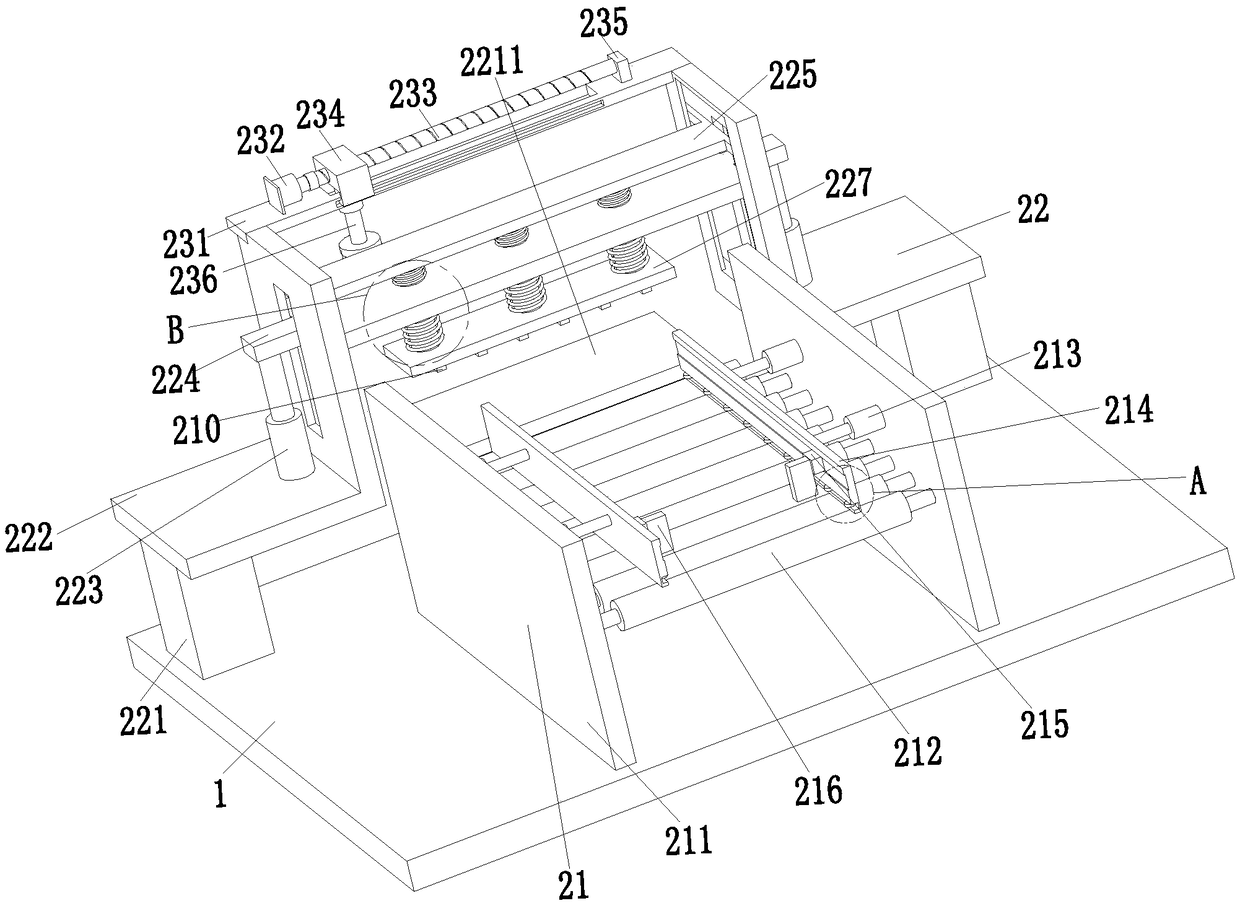

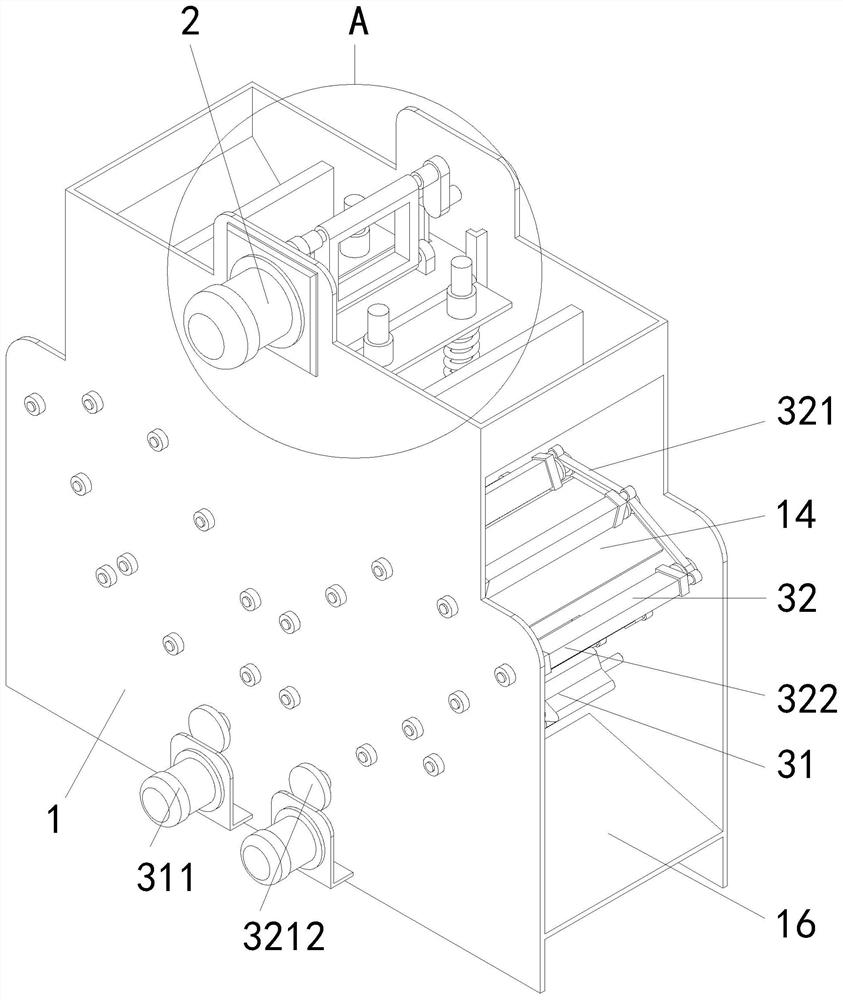

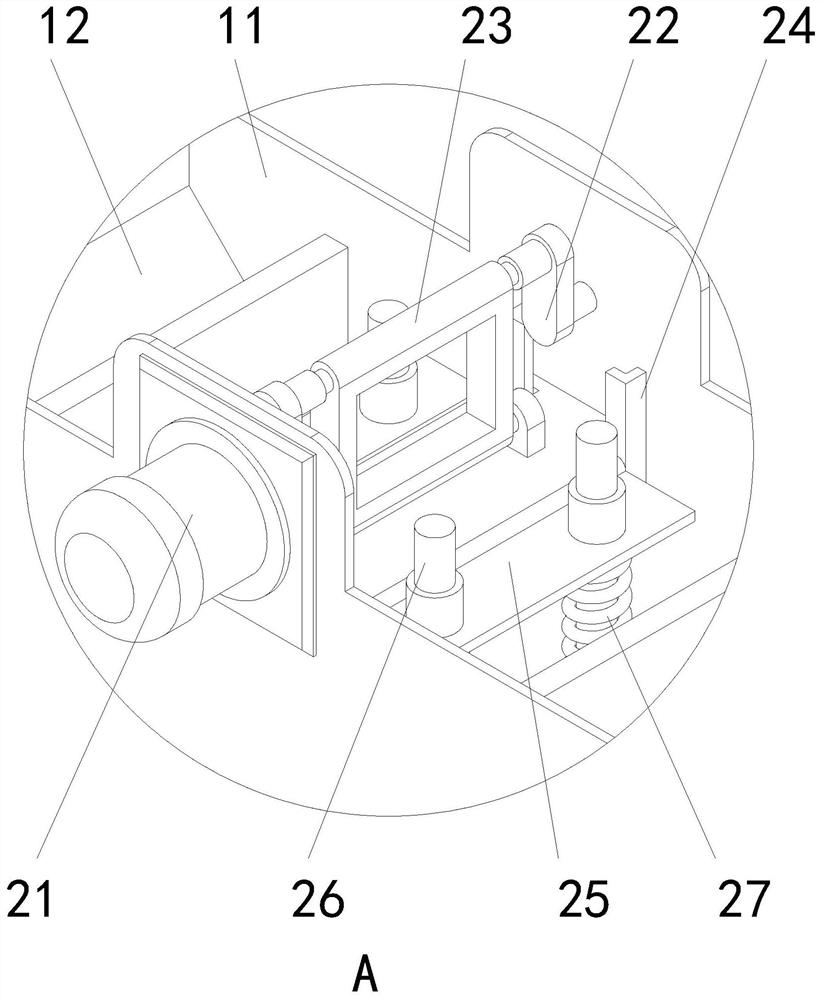

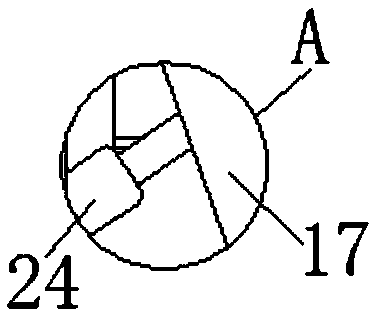

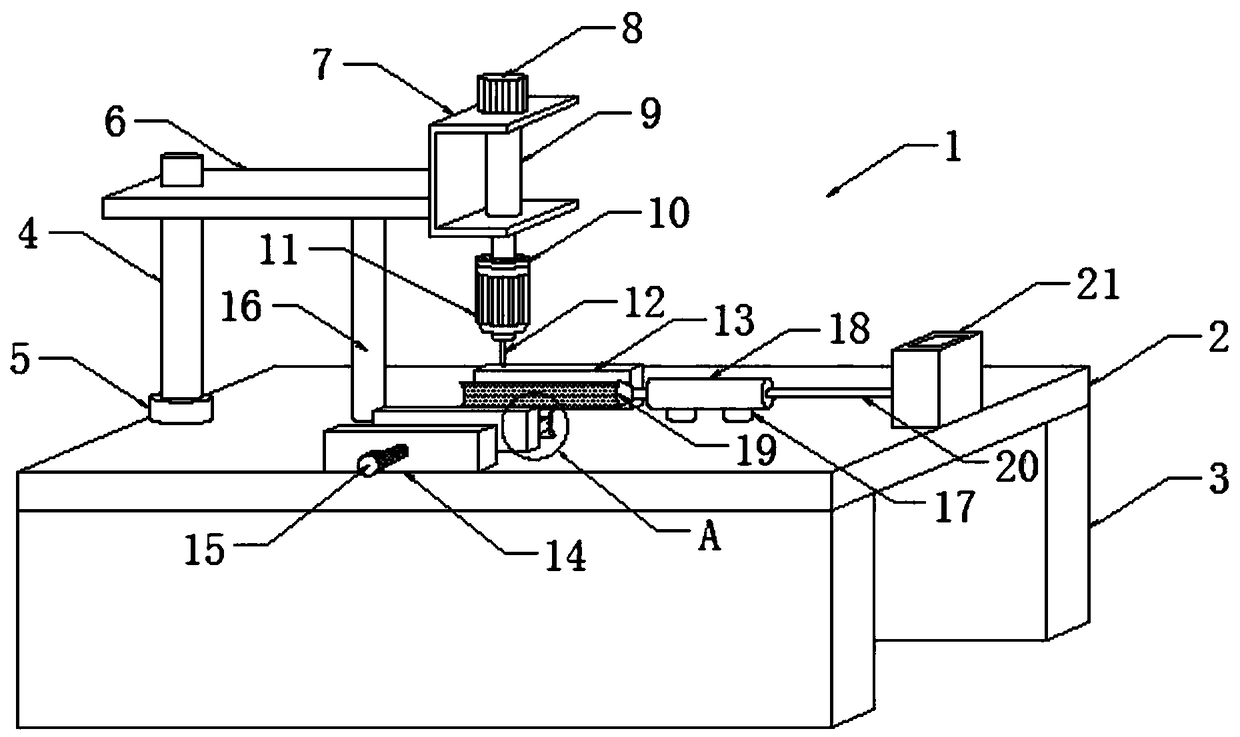

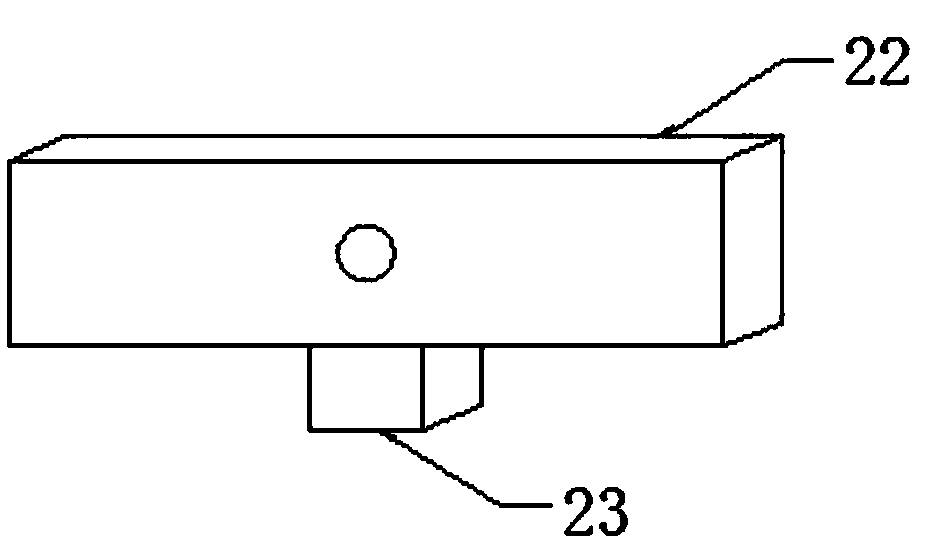

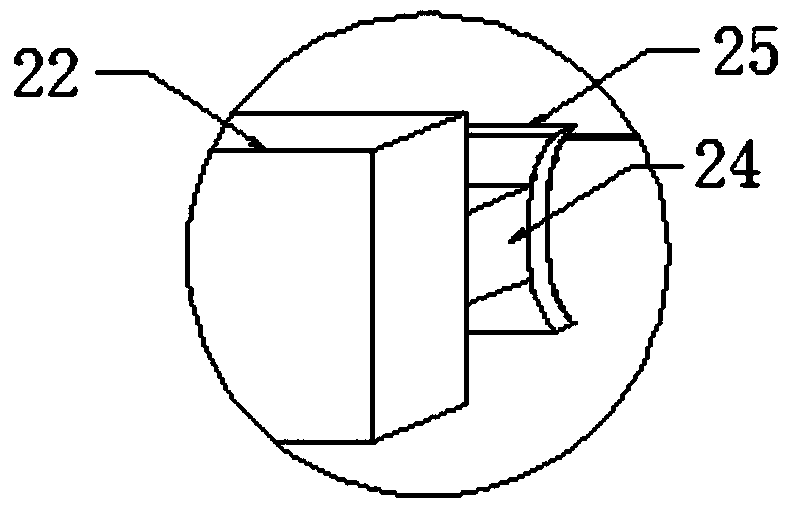

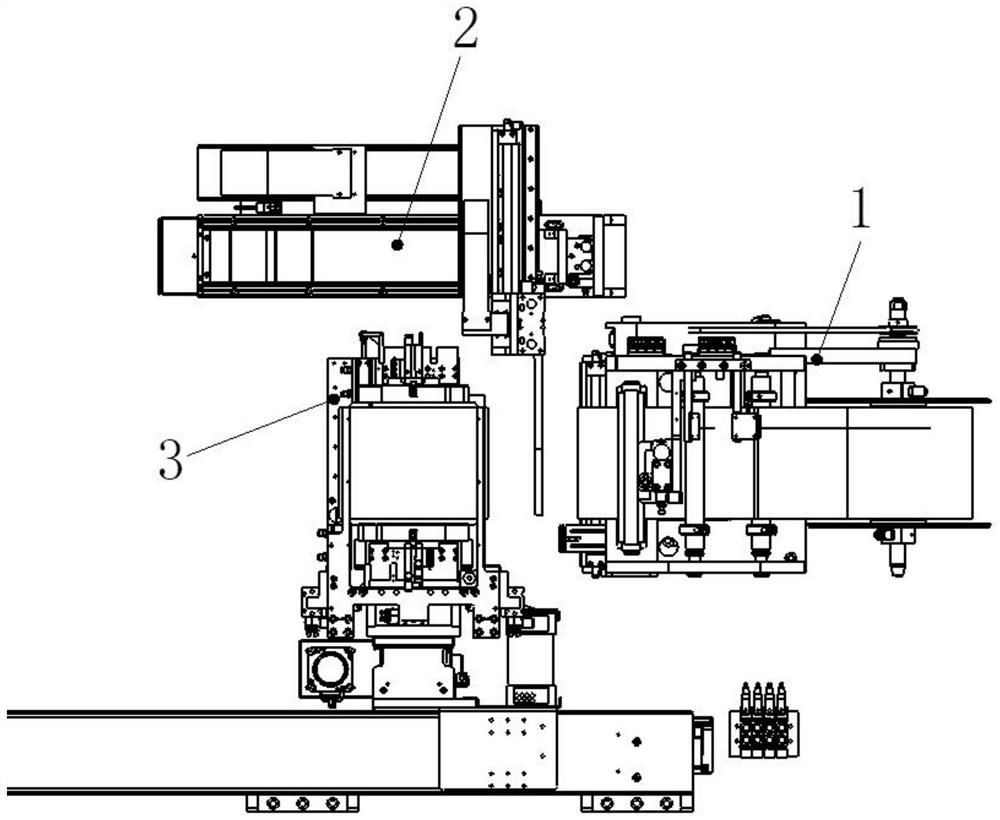

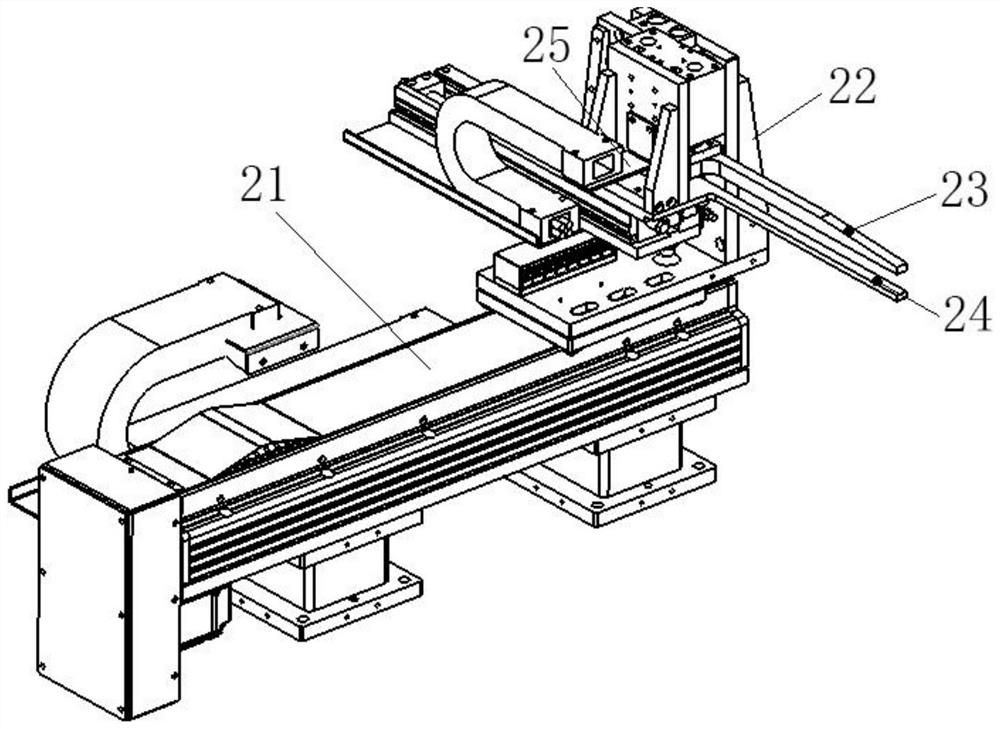

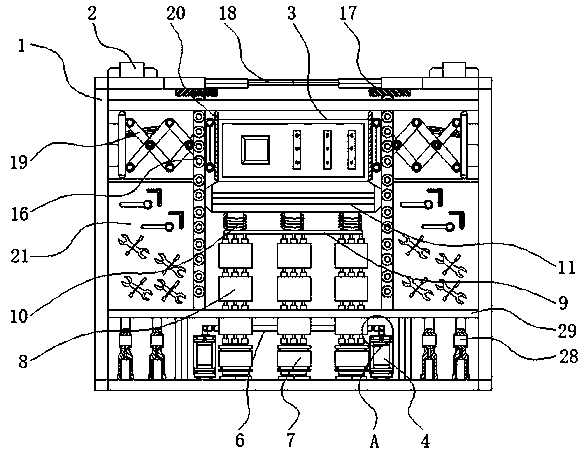

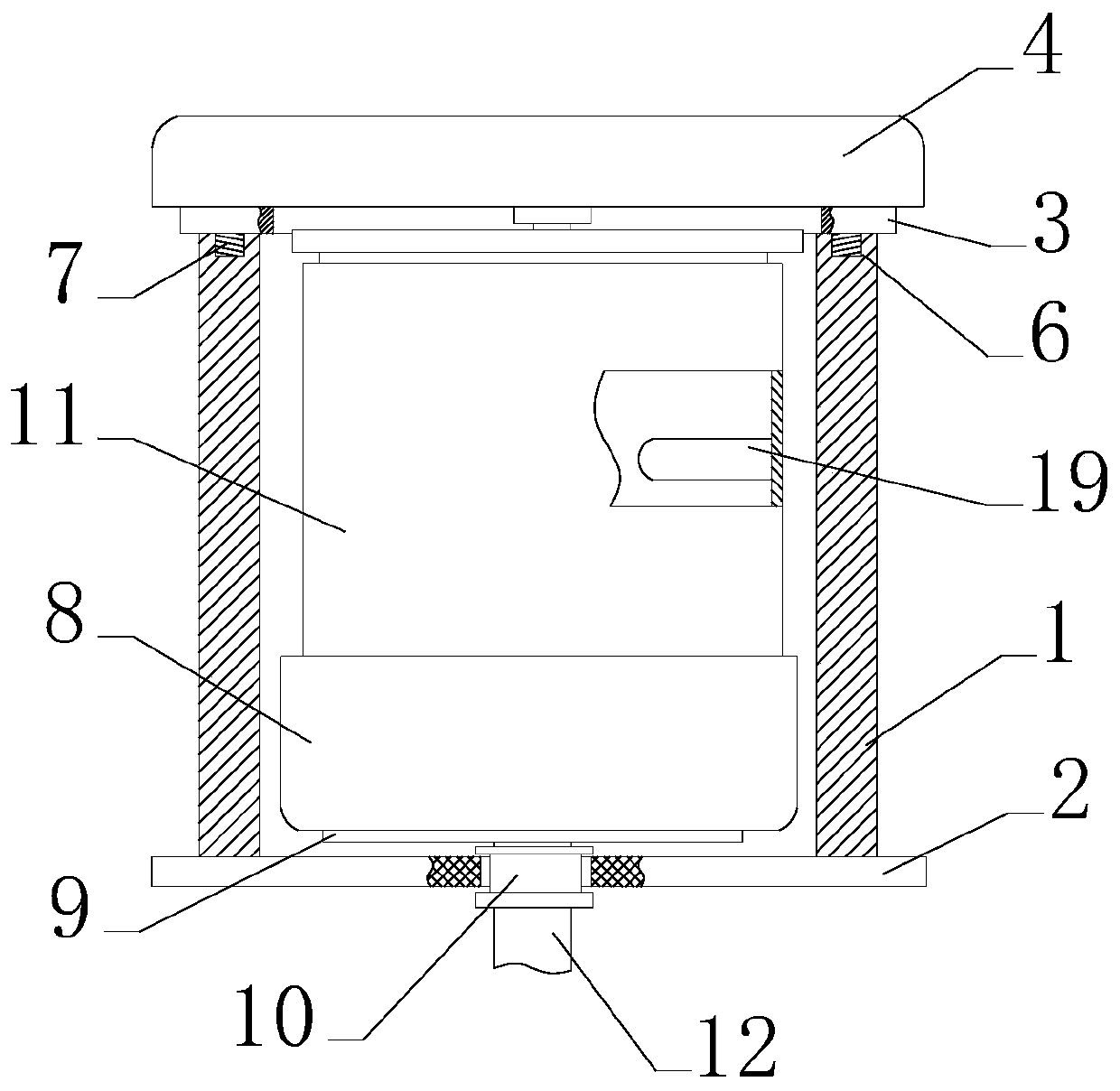

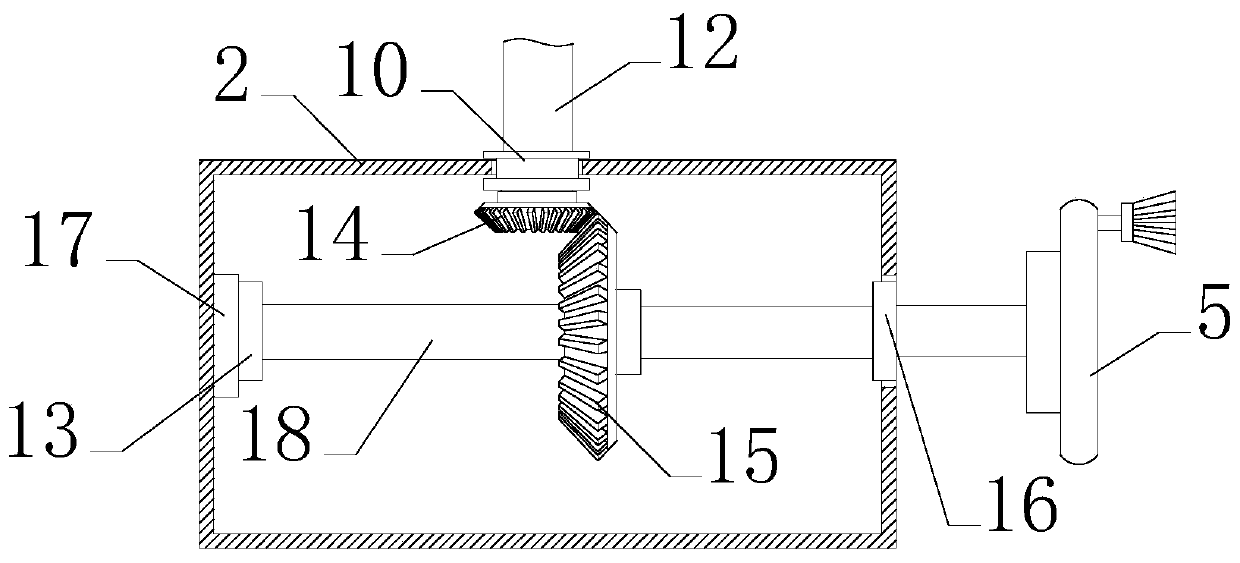

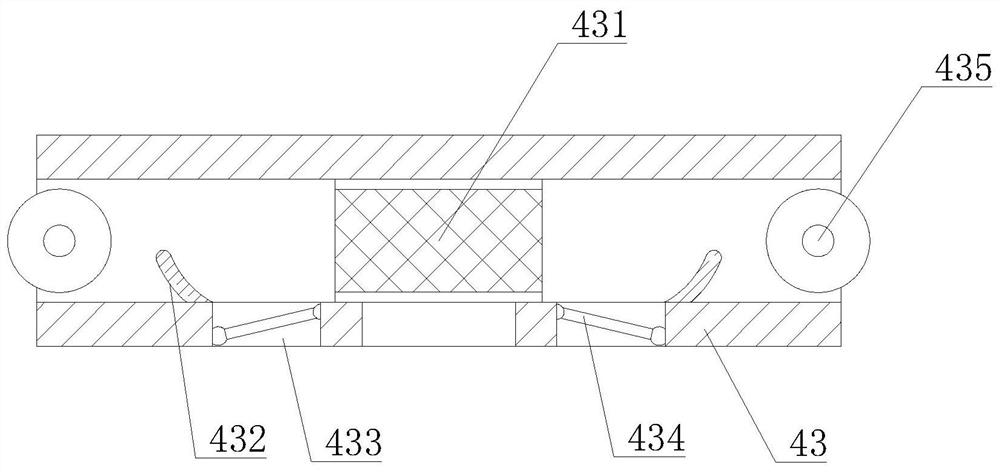

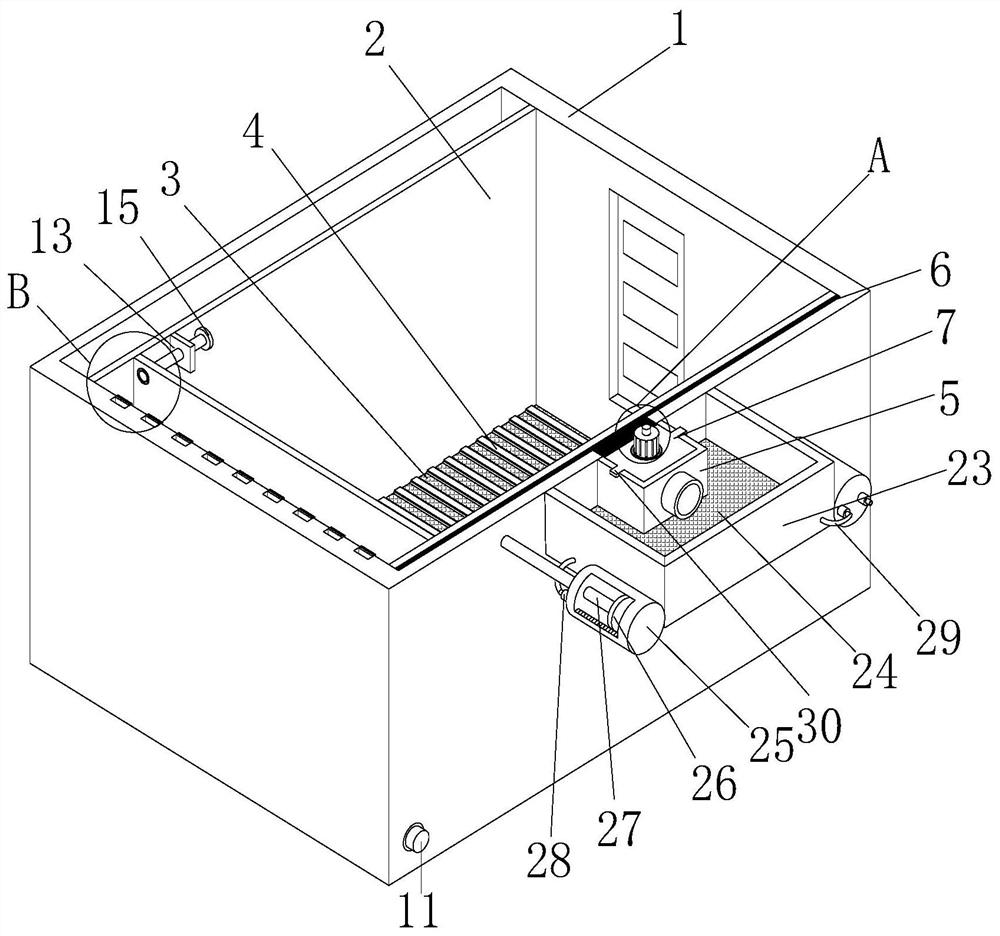

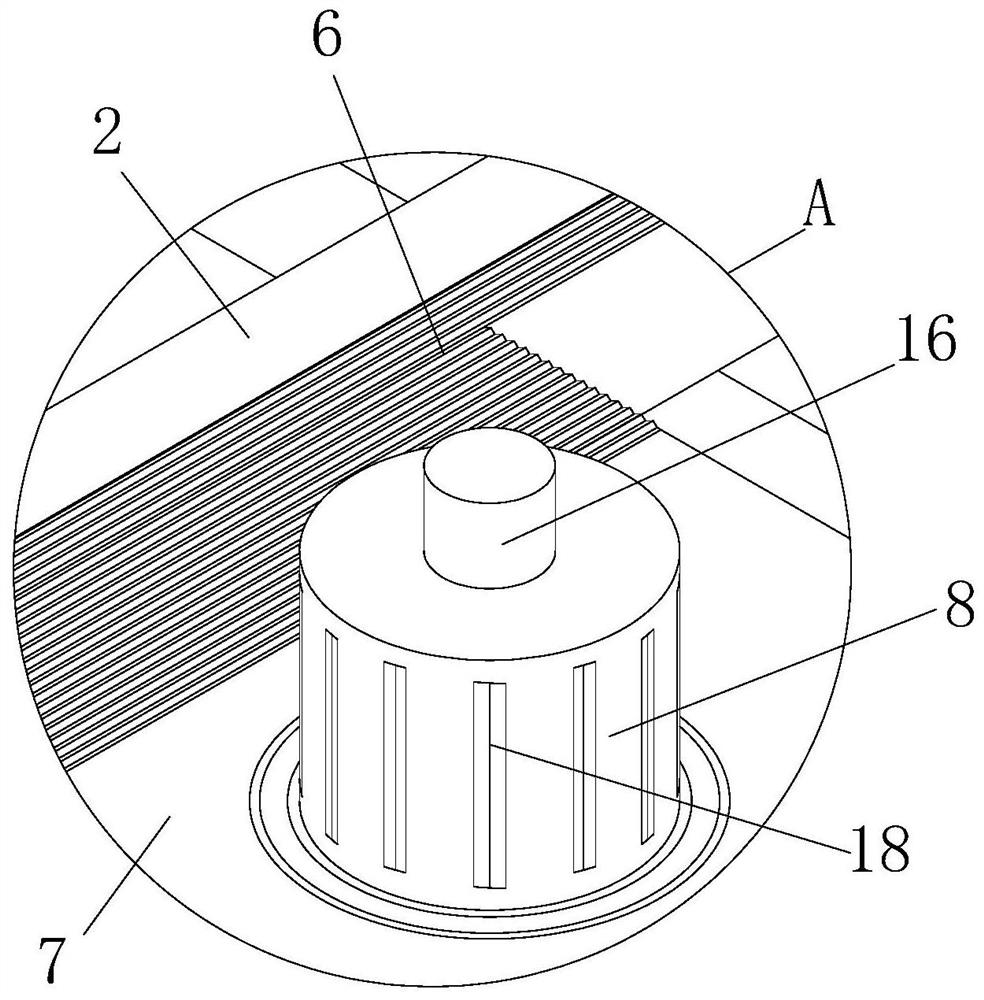

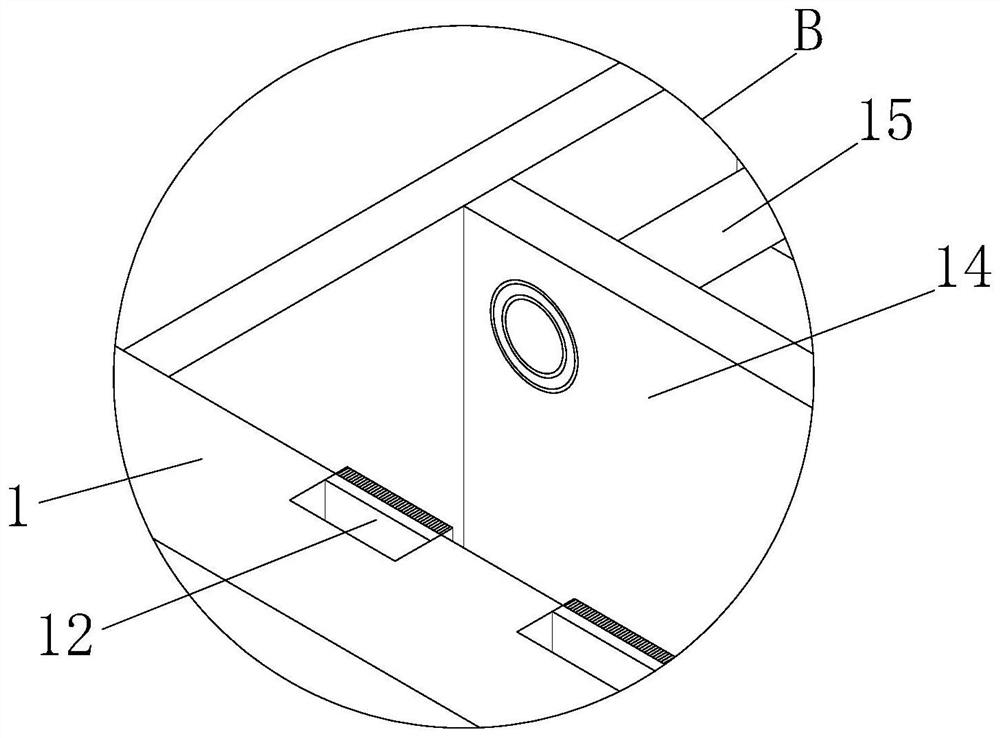

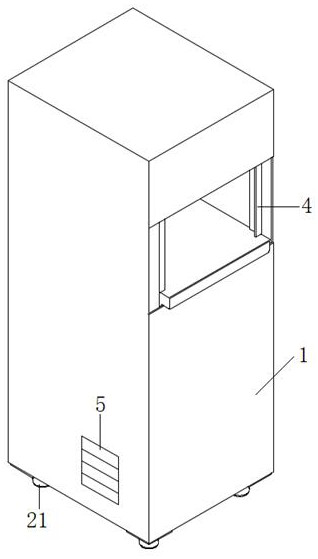

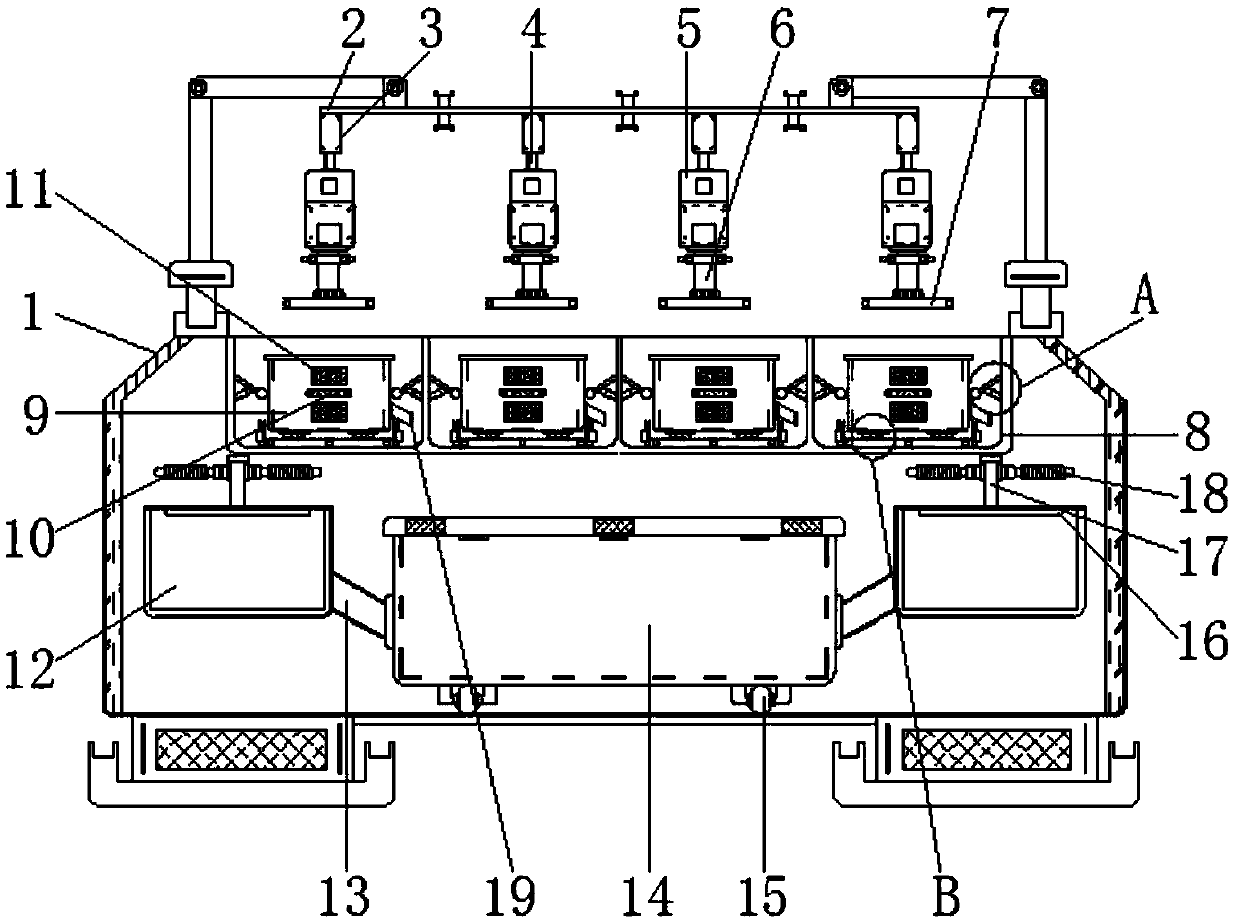

Automatic aluminum base plate cutting and drilling equipment and automatic aluminum base plate machining method

ActiveCN108994618ARealize automatic cleaningRealize automatic cutting of aluminum substrateOther manufacturing equipments/toolsMetal working apparatusInstabilityMechanical equipment

The invention relates to automatic aluminum base plate cutting and drilling equipment and an automatic aluminum base plate machining method. The automatic aluminum base plate cutting and drilling equipment comprises a bottom plate, a plate shearing device and a drilling device. The upper end of the bottom plate is sequentially provided with the plate shearing device and the drilling device from left to right. The automatic aluminum base plate cutting and drilling equipment and the automatic aluminum base plate machining method can solve the problems that according to existing equipment, an aluminum base plate is likely to twist and deform due to too large single-side stress during aluminum base plate cutting, and meanwhile, in the cutting process, the aluminum base plate is prone to cutting damage due to instability of the equipment; in the conveying process, mechanical equipment often damages the surface of the aluminum base plate, the phenomenon of surface scratching is caused; in the drilling process, the situation of waste scattering in the ordinary equipment drilling process is caused, and meanwhile manual cleaning is troublesome; and ordinary drilling equipment is single in work condition and cannot only drill one hole at a time, and the hearing of workers is often damaged due to too large noise in the drilling process. The functions of automatic aluminum base plate cutting and simultaneous multi-hole drilling can be achieved.

Owner:江门市利诺达电路科技有限公司

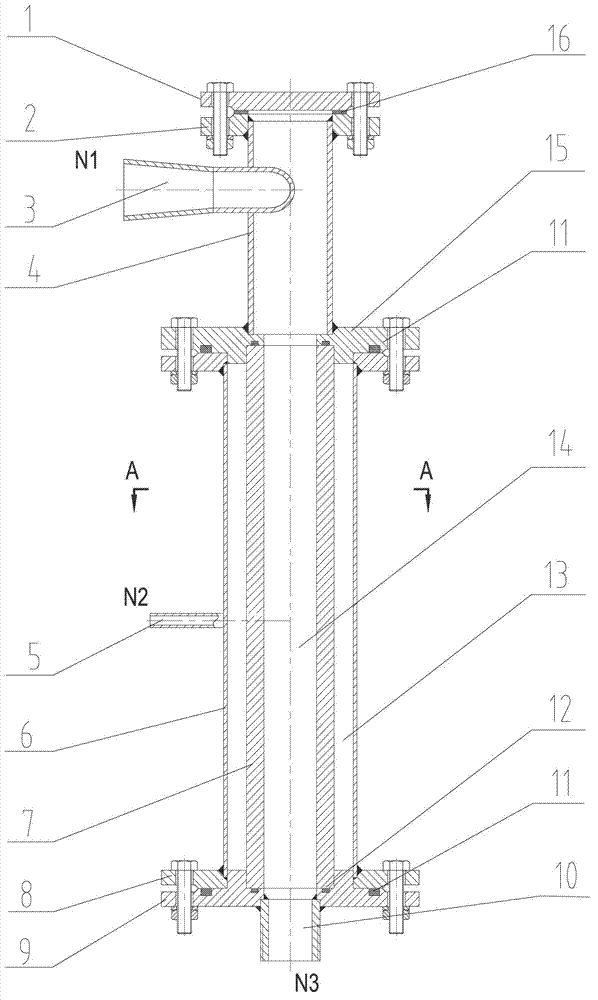

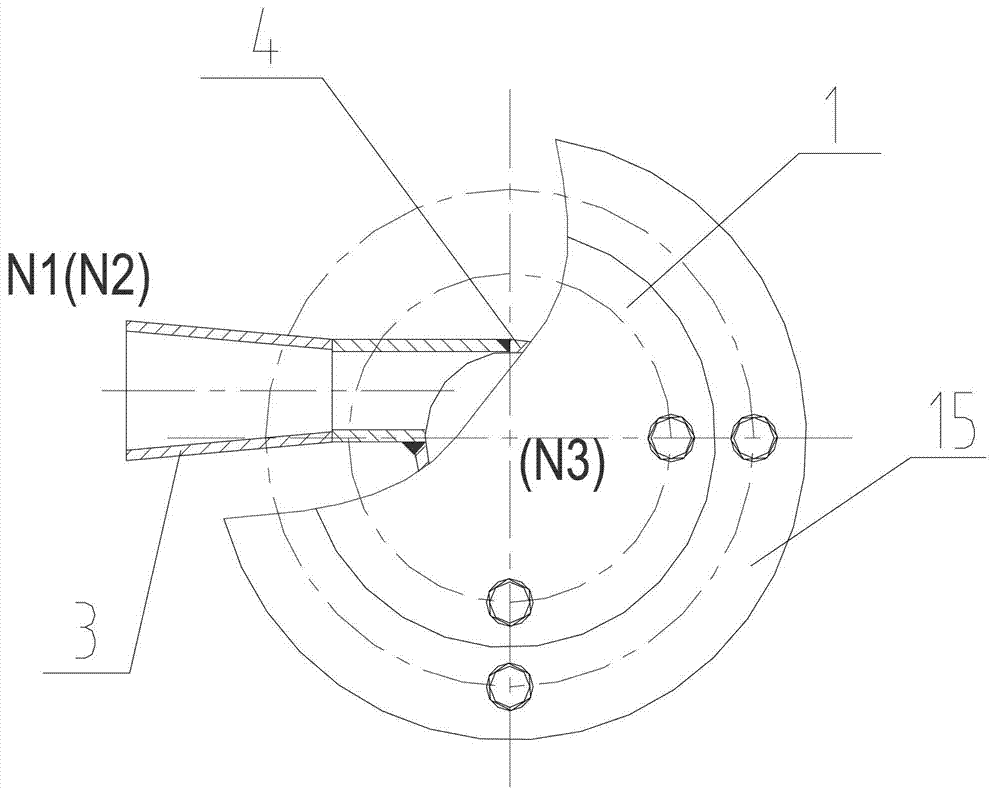

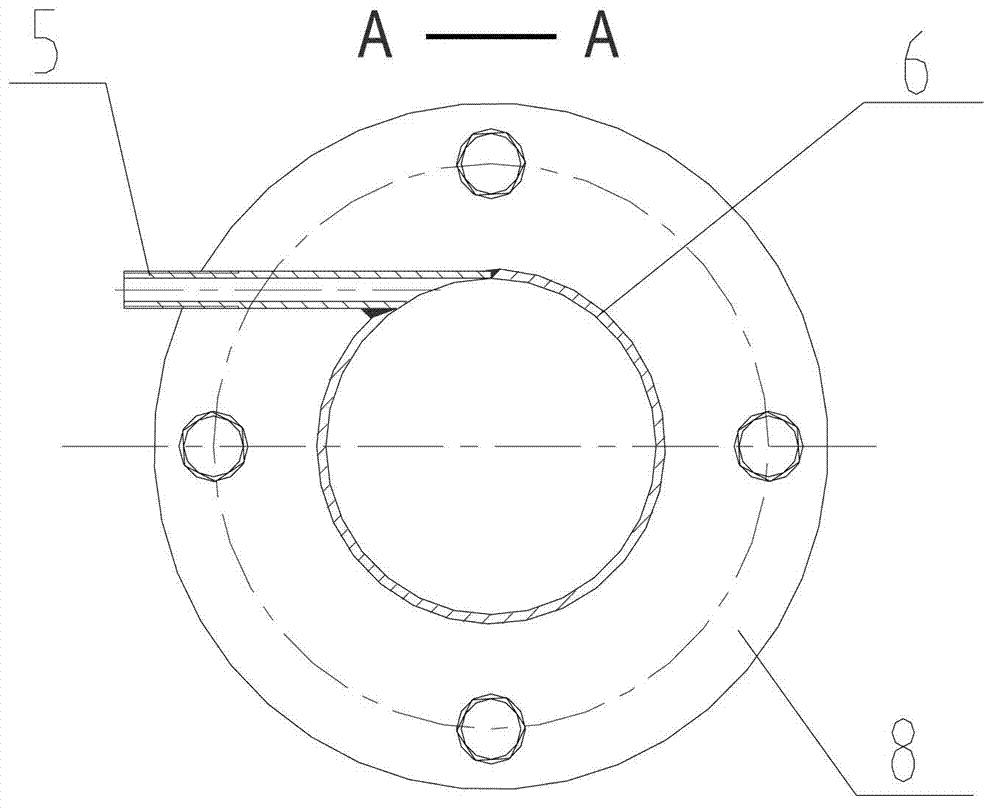

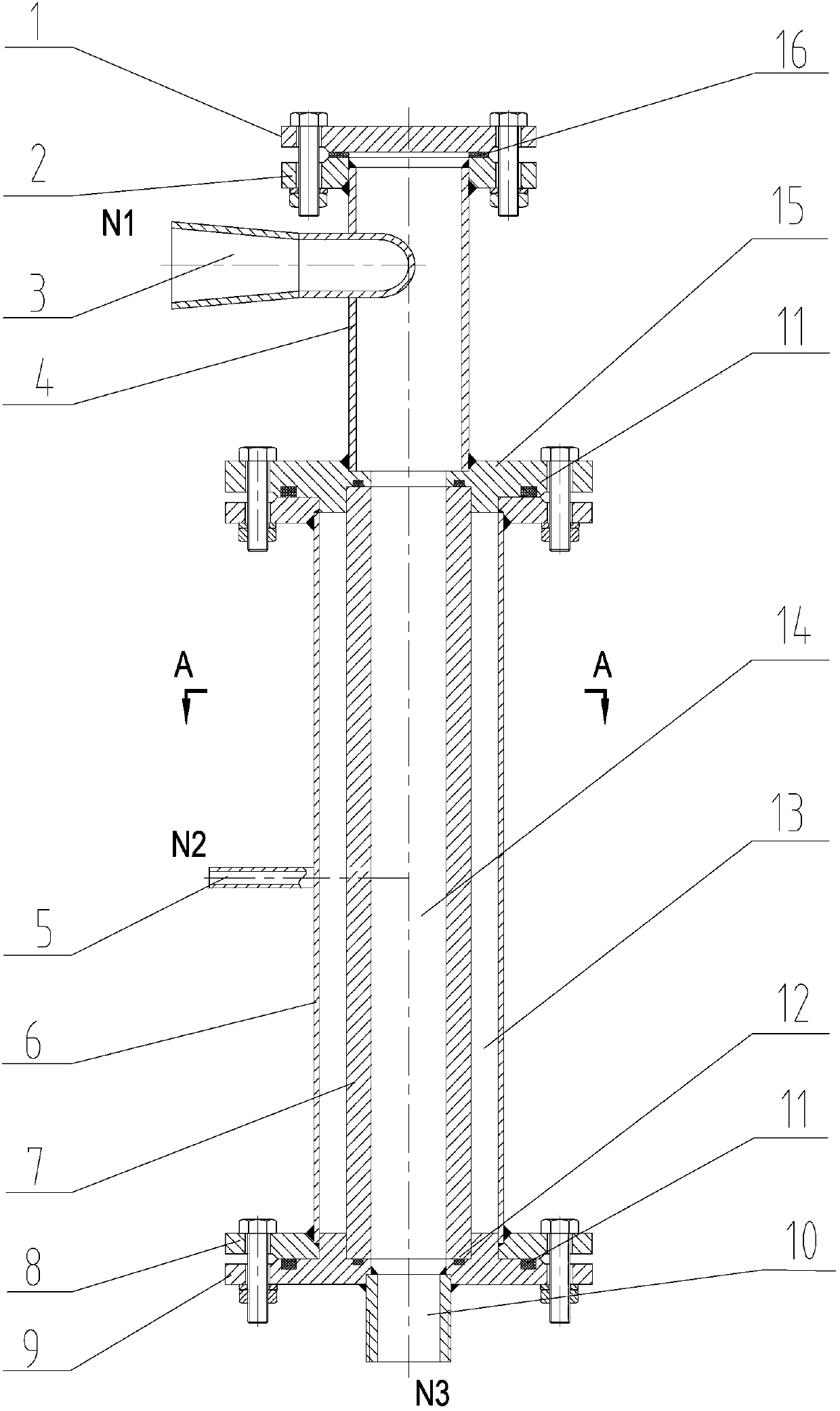

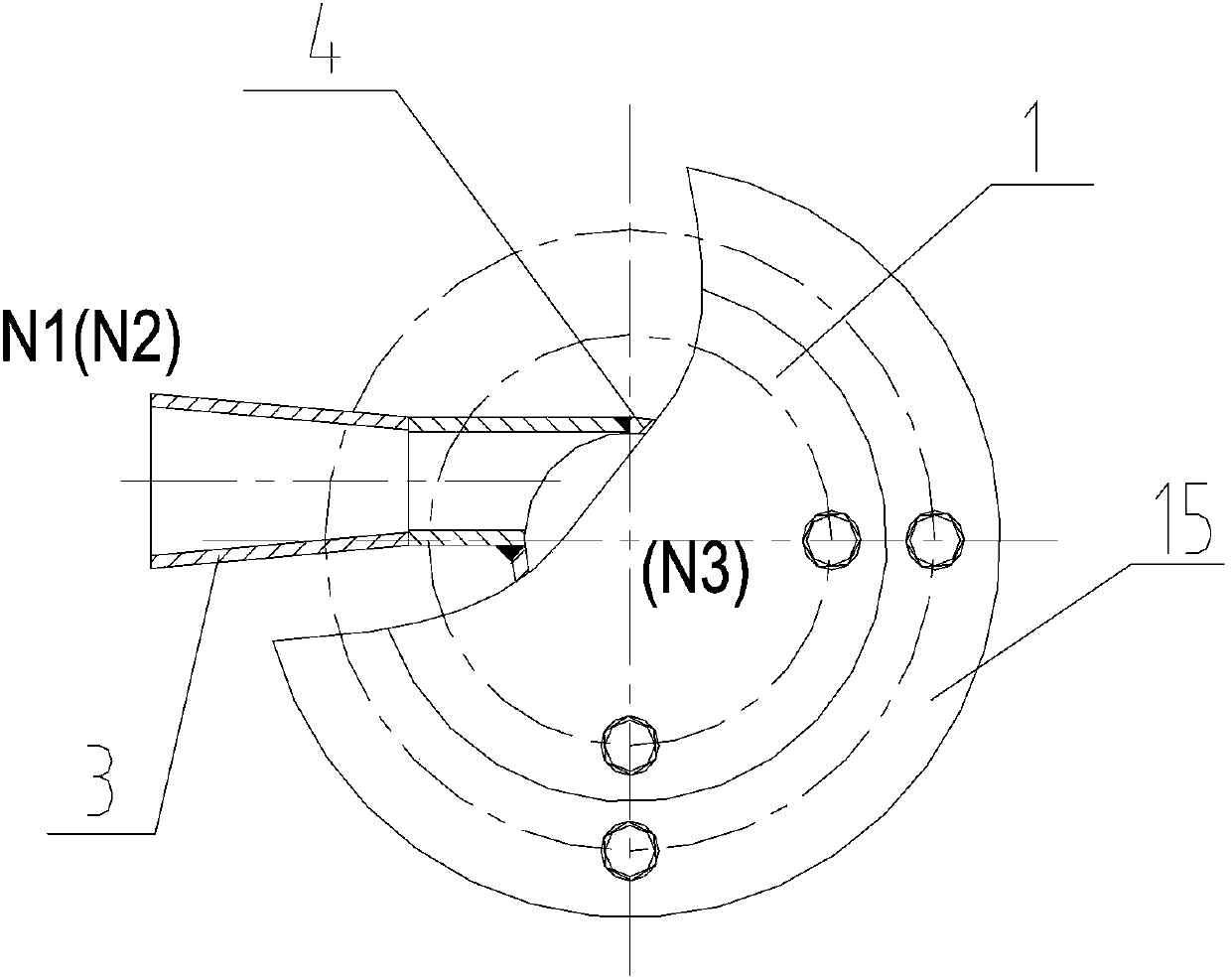

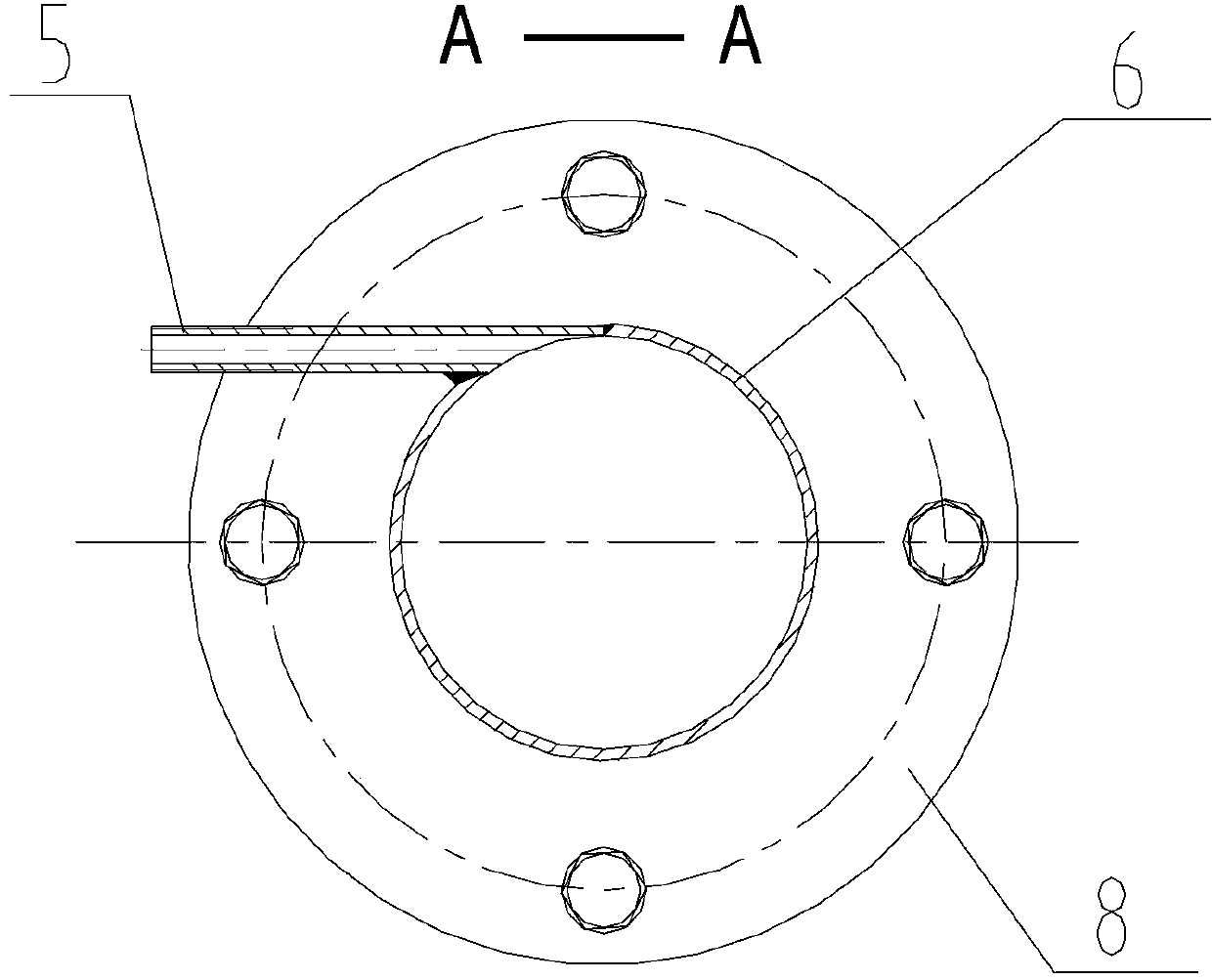

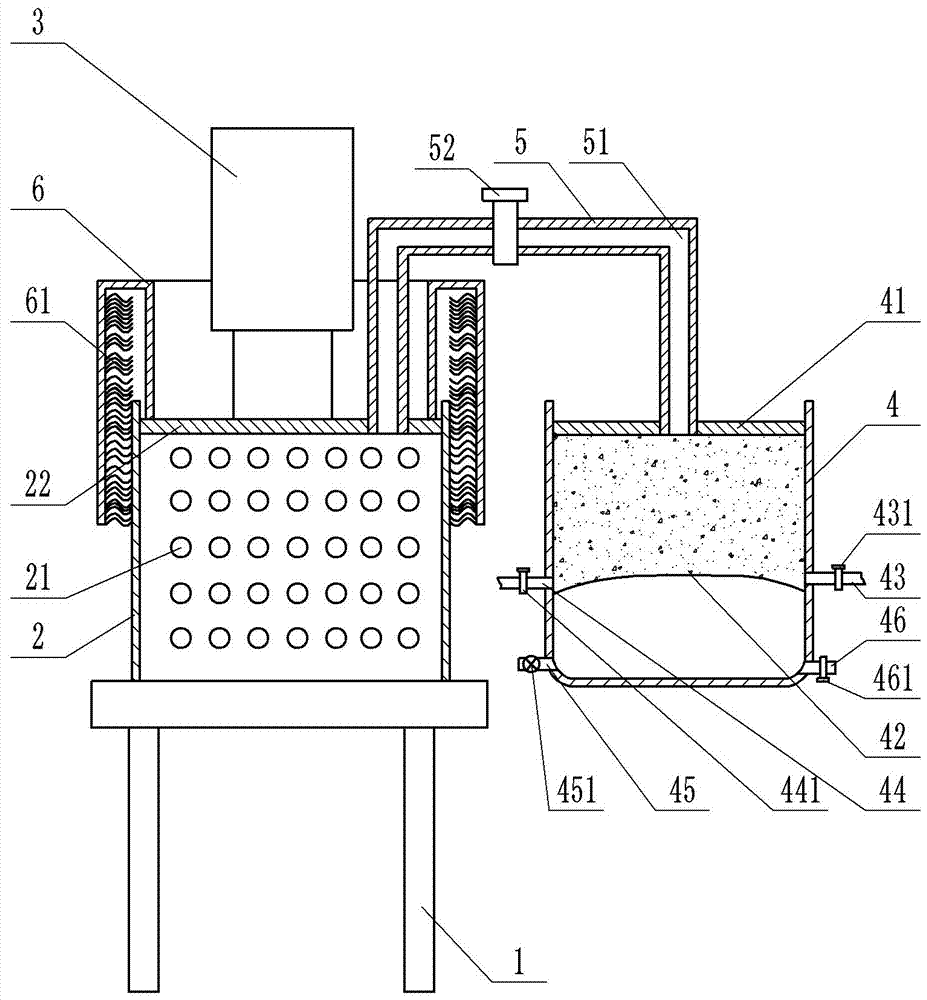

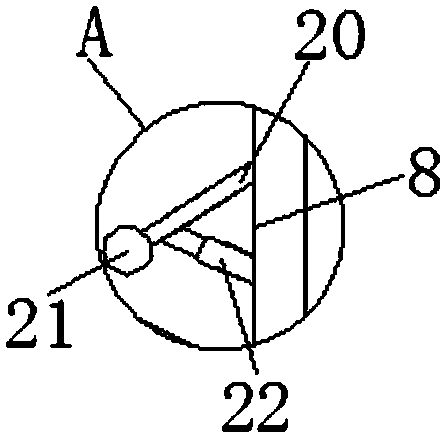

Micro-bubble generator for air floatation treatment of sewage

ActiveCN103193288AEffective generationUniform sizeWater/sewage treatment by flotationForeign matterMicro bubble

The invention discloses a micro-bubble generator for air floatation treatment of sewage. The micro-bubble generator comprises a water cavity pipe and a micropore pipe; one end of the water cavity pipe is connected with the micropore pipe, and the other end of the water cavity pipe is a closed end; the side wall of the water cavity pipe is provided with an inlet water pipe; an air cavity pipe is sleeved outside the micropore pipe, and a closed air cavity is formed between the air cavity pipe and the micropore pipe; the side wall of the air cavity pipe is provided with an inlet air pipe; and an opening end of the micropore pipe is connected with an outlet pipe. When the micro-bubble generator is in use, the treatment water and the treatment air respectively enter the water cavity pipe and the air cavity pipe of the micro-bubble generator through the inlet water pipe and the inlet air pipe, micro bubbles can be formed by cutting the air through the micropore pipe and continuous scouring and shearing the air through the treatment water flow, and the formed micro bubbles are carried by the water flow to be discharged through the outlet pipe. Due to the adoption of the micro-bubble generator, sufficient micro bubbles with a uniform size can be effectively generated, and the requirement of the air floatation purification process can be completely met; and the trouble for clearing the foreign matters in the treatment water blocking the micropore pipe can be avoided, the micro-bubble generator can be operated stably for a long time, no rotating part exists, and simplicity in use, installation, maintenance and repairing can be realized.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Efficient glass edge grinding device with protection function

InactiveCN109500687AWith protective functionGrinding stabilityEdge grinding machinesGrinding drivesSlagEngineering

The invention relates to the technical field of glass processing, and discloses an efficient glass edge grinding device with a protection function. The efficient glass edge grinding device comprises aworking table, wherein a cross column is fixedly arranged at the top of the working table, the top of the cross column is fixedly provided with a slag groove, the top of the cross column is fixedly connected with a machine case, a first motor is fixedly installed inside the machine case, and an output shaft of the first motor is fixedly connected with a rotating shaft. The efficient glass edge grinding device with the protection function effectively improves the stability of glass clamping, the glass can be adjusted according to the glass with different thicknesses, the application range is widened, the grinding of the glass is finer, so that the grinding quality of the glass is improved, the grinding efficiency is greatly improved, the safety performance of the grinding device can be improved, so that the self protection performance is improved, and accidental damage to workers caused by unstable potential safety hazards is avoided.

Owner:ANHUI HUAYAO GLASS

Method for preparing plant extract additive for cosmetics

ActiveCN112315852AFilter in timeTimely cleaning and dredgingCosmetic preparationsToilet preparationsProcess engineeringWaste management

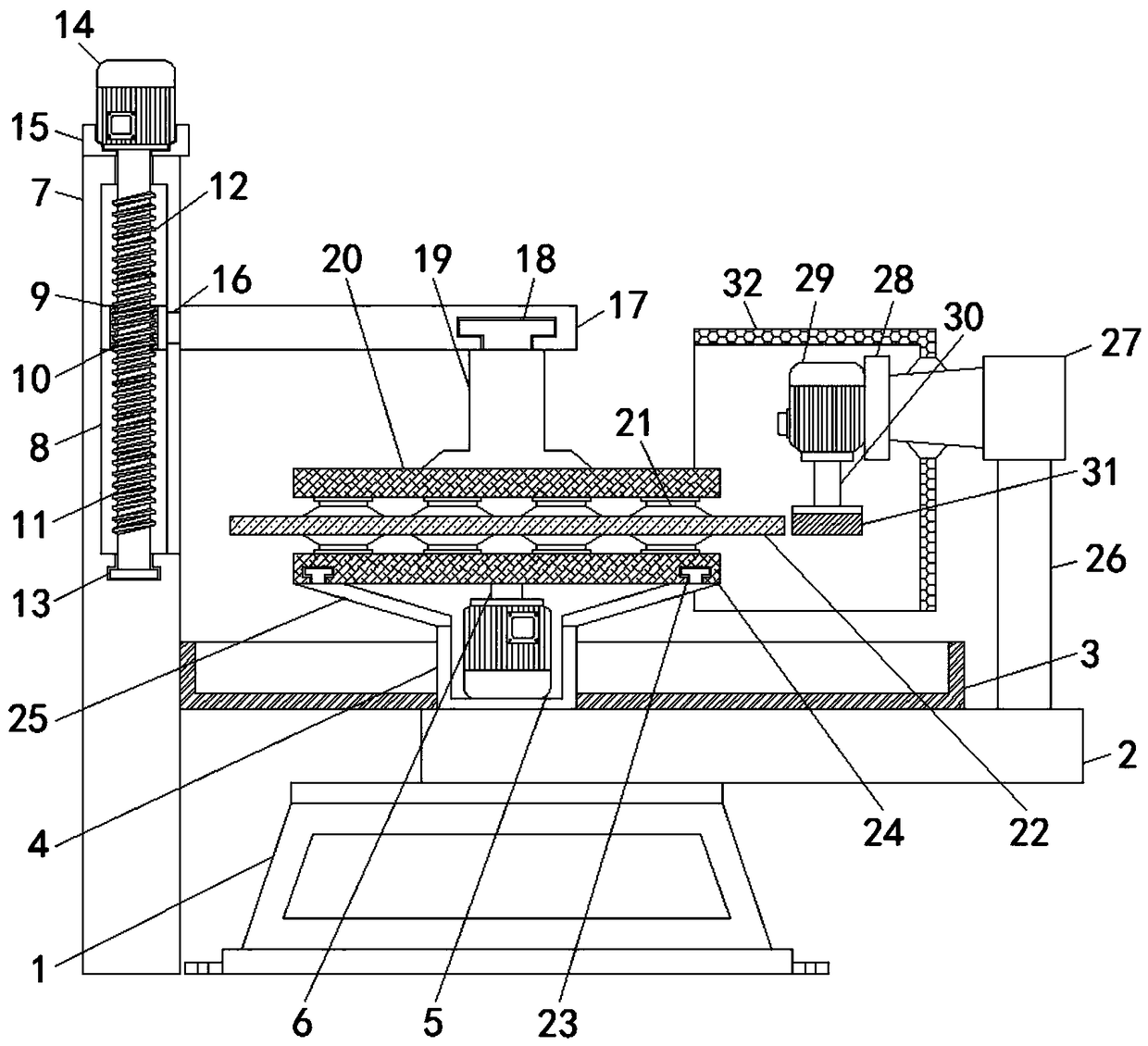

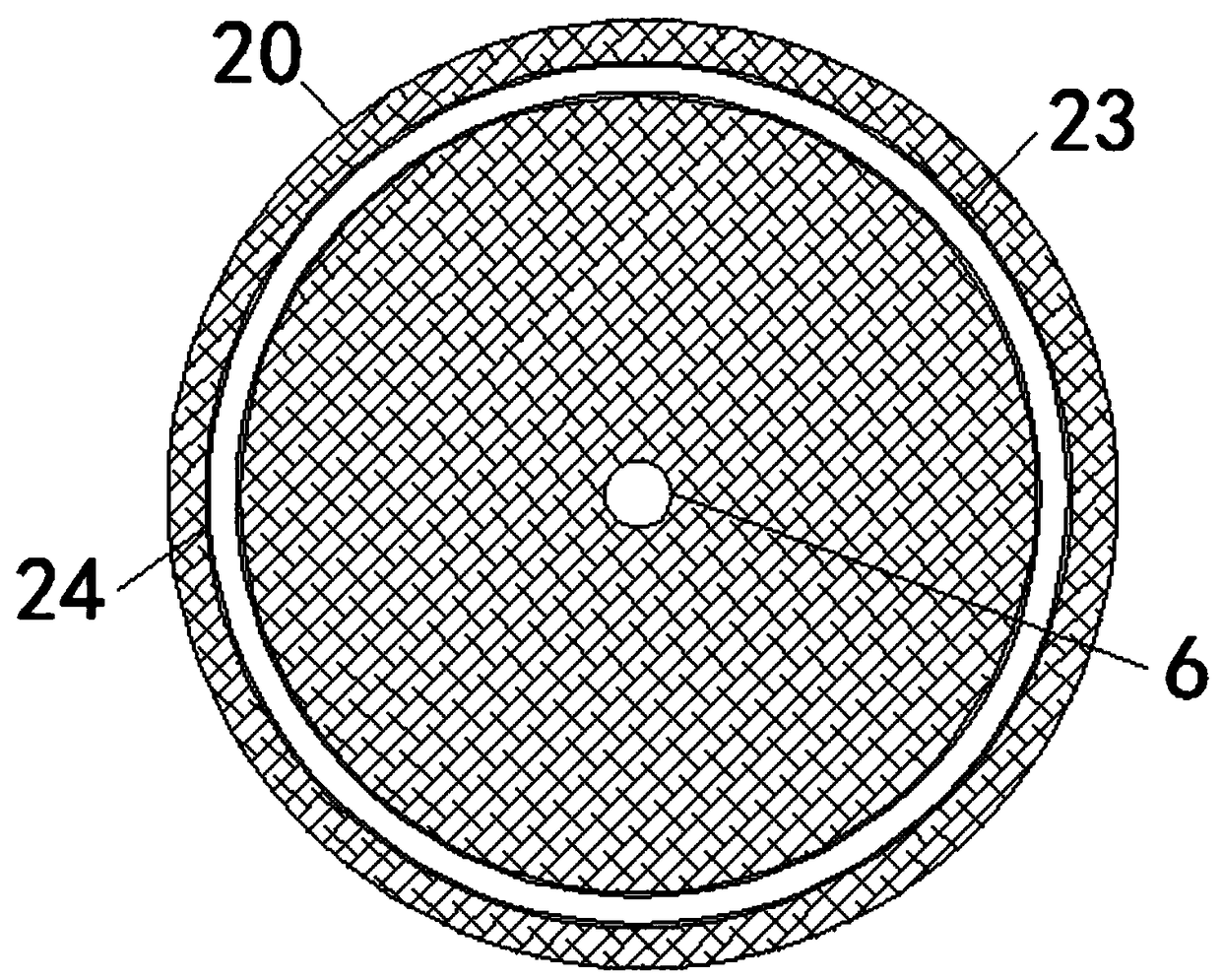

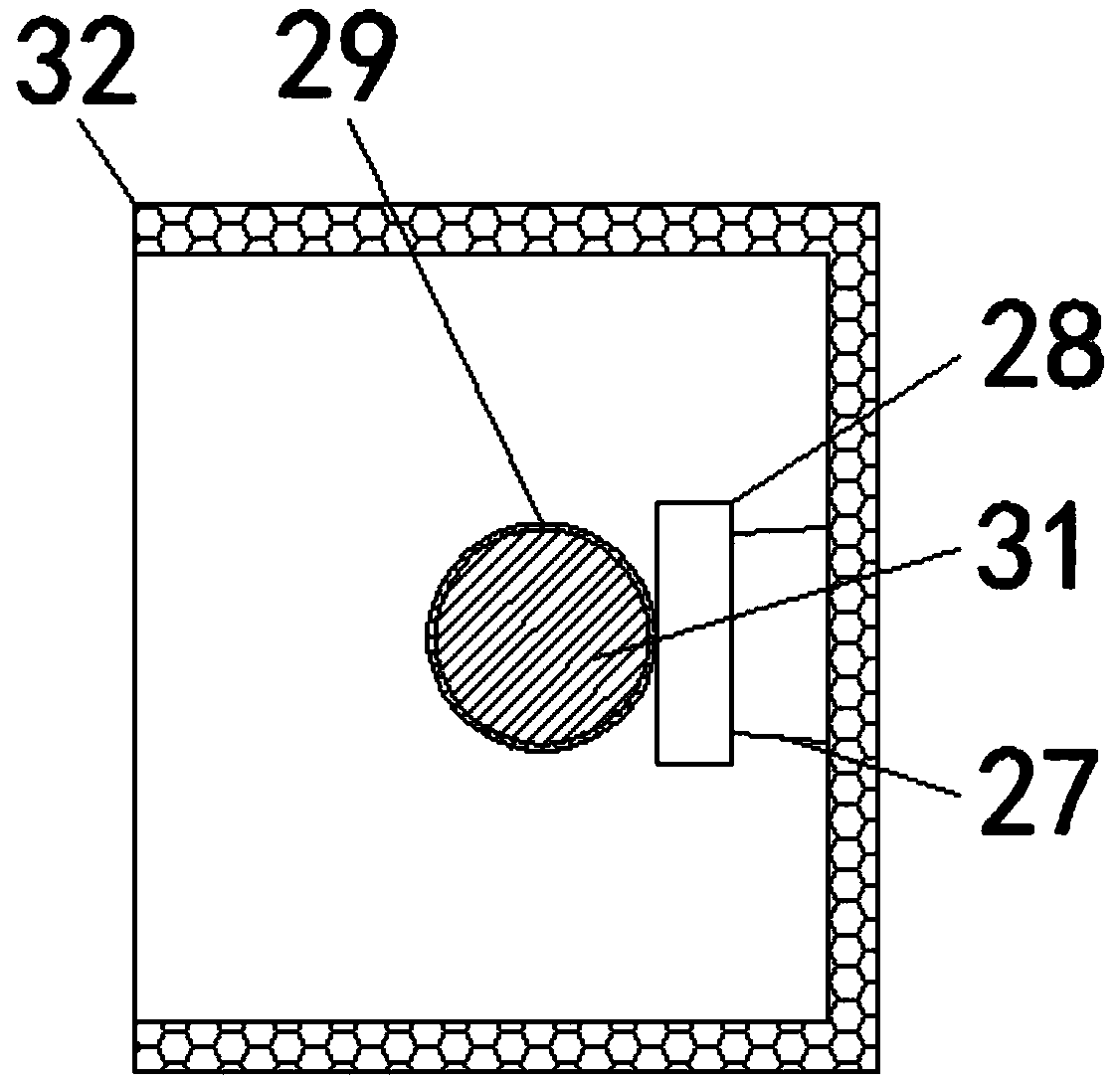

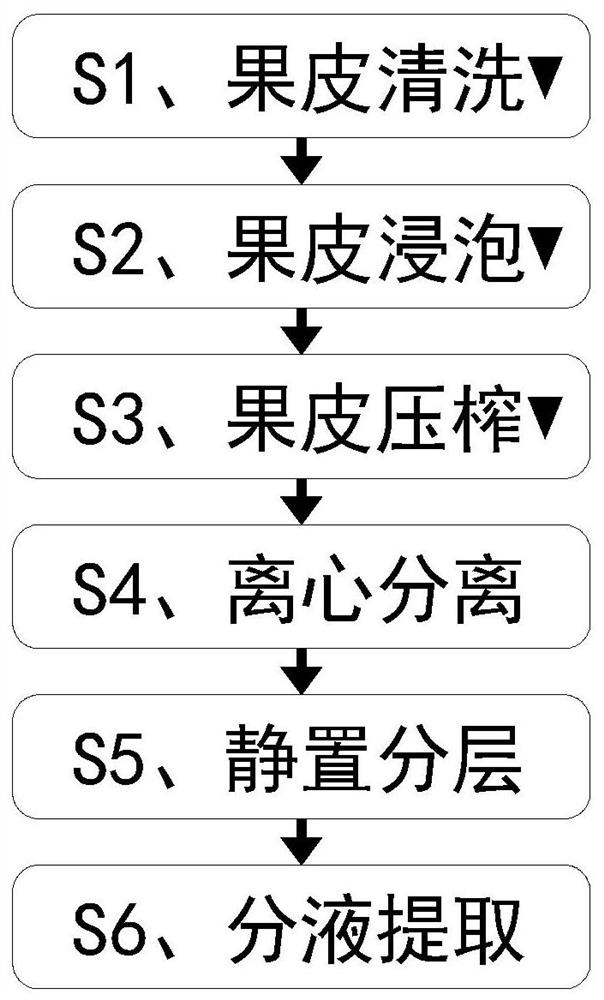

The invention relates to a method for preparing a plant extract additive for cosmetics and particularly relates to a device for preparing the plant extract additive for the cosmetics. The device comprises a rack, a squeezing mechanism for squeezing lemon peels and a waste discharging mechanism for discharging squeezed waste of the lemon peels, wherein the squeezing mechanism comprises a squeezingmotor, a crankshaft, a linkage frame, a guide rail, a lifting plate, a guide column, a compression spring and a squeezing hammer for being in squeezing contact with the lemon peels, and the waste discharging mechanism comprises a shaking cleaning mechanism and a waste conveying mechanism. The device involved with the method provided by the invention can be used for completing squeezing seepage ofessential oil of the lemon peels in a higher efficiency manner, meanwhile, can automatically discharge lemon peel waste and meanwhile can filter squeezed juice promptly.

Owner:广州宝仪生物科技有限公司

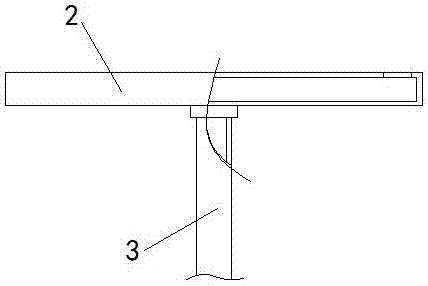

Automatic environment-friendly blackboard eraser

ActiveCN108099458AAdd practical functionsImprove sexual functionBoard cleaning devicesHydraulic cylinderEngineering

The invention relates to an automatic environment-friendly blackboard eraser. The automatic environment-friendly blackboard eraser comprises a base, a second hydraulic cylinder, a drawing tank, a first handle and a lower support rod. A cushion block is fixed to the bottom of the base. A supporting column is arranged at the upper end of the base. A first hydraulic cylinder is arranged on the supporting column. The upper end of the first hydraulic cylinder is connected with a first connecting rod. The second hydraulic cylinder is arranged at the left end of the first connecting rod. The left endof the second hydraulic cylinder is connected with a first blackboard eraser body through a second connecting rod. The bottom end of the first blackboard eraser body is fixedly provided with a dust collection plate. A first pipeline is arranged below the dust collection plate. An air pump is mounted on the first pipeline. The bottom of the first pipeline is connected with a second pipeline. The drawing tank is arranged below the second pipeline. The automatic environment-friendly blackboard eraser has the beneficial effects that the first blackboard eraser body is driven by the first hydraulic cylinder to move up and down so as to automatically erase characters up and down on a blackboard.

Owner:ZHEJIANG BEIWANG TOYS

Drilling device used for production of high valves

InactiveCN108655461APrevent looseningGuaranteed to workPositioning apparatusMaintainance and safety accessoriesEngineeringPiston rod

The invention discloses a drilling device used for production of high valves. The drilling device comprises a device body; the device body comprises a worktable; supporting plates are fixedly arrangedon two sides of the bottom of the worktable; a bearing column is arranged on one end of the top of the worktable; the bearing column is fixedly connected with the worktable through a bearing block; atop plate is fixedly arranged on the top end of the bearing column; a U-shaped plate is fixedly arranged on one end of the top plate; an air cylinder is arranged on the top of the U-shaped plate; a piston rod is connected to the output end of the air cylinder; the device is provided with a fixing block, a dust collector barrel body, a dust collector suction head, a pipeline and a dust storage box; during work, a dust collector can be started for work, so that dust and other impurities generated during working of workpieces can be sucked into the dust collector; trouble for cleaning after workis avoided; continuous work of the device is better facilitated; and use is more convenient.

Owner:蒋国良

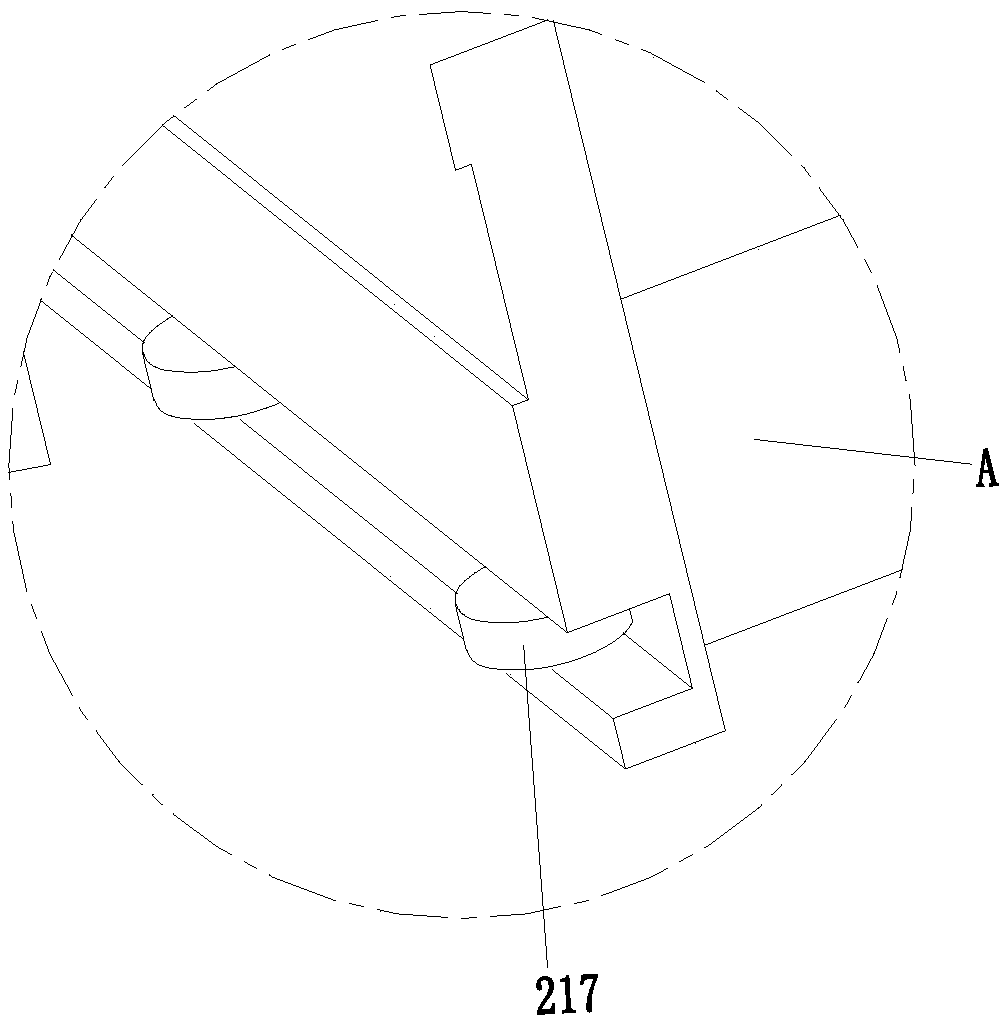

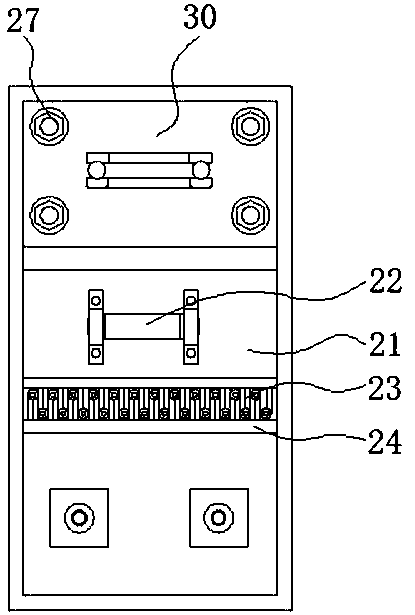

Micro bubble generation method and micro bubble generator

PendingCN110354705AHigh speedAvoid resistanceRotary stirring mixersTransportation and packagingPorosityMicro bubble

The invention belongs to the technical field of water treatment and relates to a micro bubble generation method and a micro bubble generator. The micro bubble generator comprises a microporous device,a hollow pipe, a rotating joint, a motor, a power output shaft, a driving shaft and an air pump, wherein the motor is connected with the microporous device through the power output shaft and the driving shaft in sequence and drives the microporous device to rotate around the axial direction of the driving device; the air pump is communicated with the microporous device through the rotating jointand the hollow pipe in sequence and inputs gases into the microporous device; the surface of the microporous device is provided with micropores of which the porosity is not lower than 28 percent; thesize of the micropores is 0.01 to 2 mu m; the gases entering the microporous device overflow from the micropores on the surface of the microporous device to form bubbles with particle size of 5 to 100mu m. The invention provides the micro bubble generation method and the micro bubble generator, which have the advantages of low energy consumption, simple structure and capability of stably producing a large amount of high-density micro bubbles with uniform particle size in liquid phase for a long term.

Owner:湖南亿纳环保科技有限公司

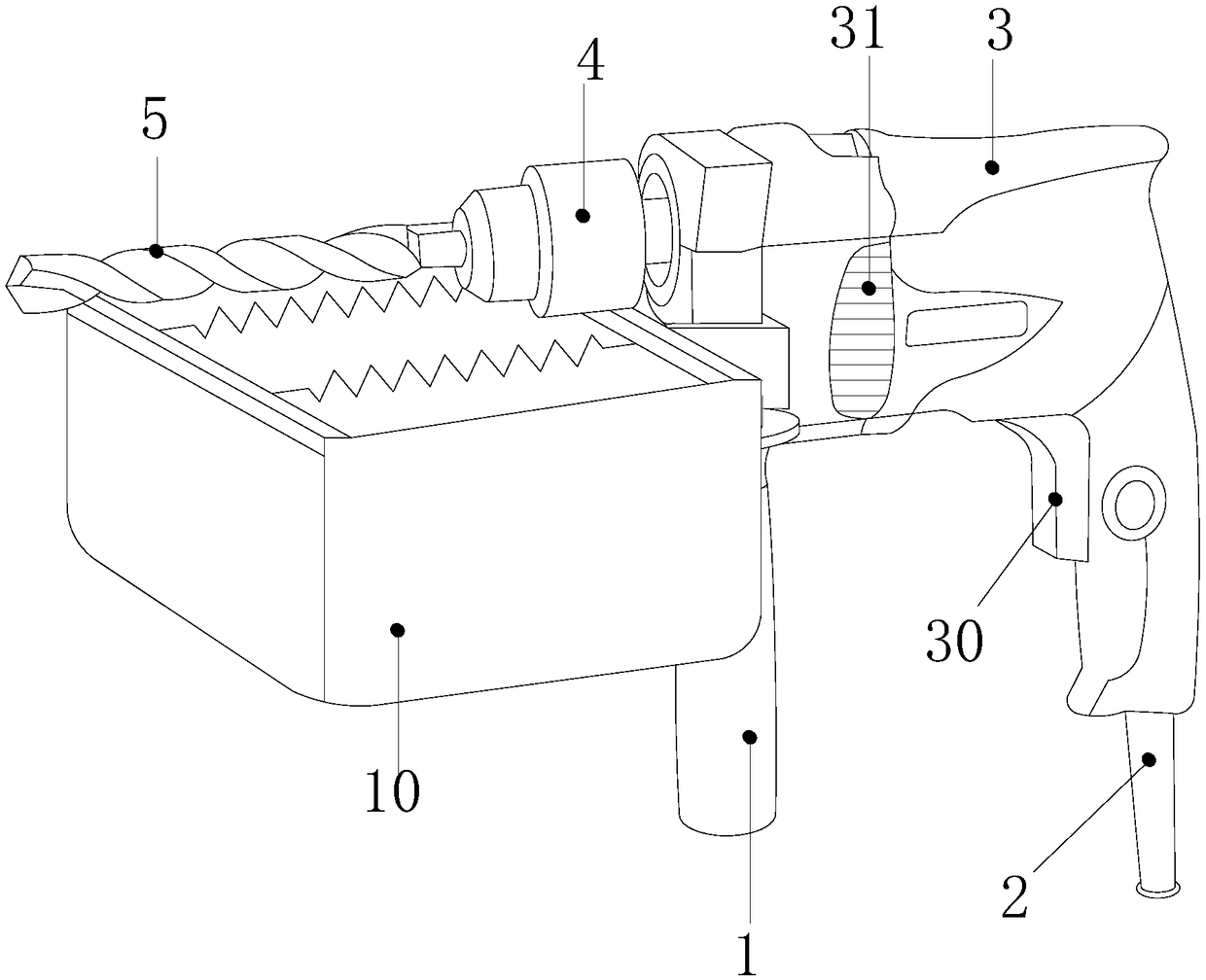

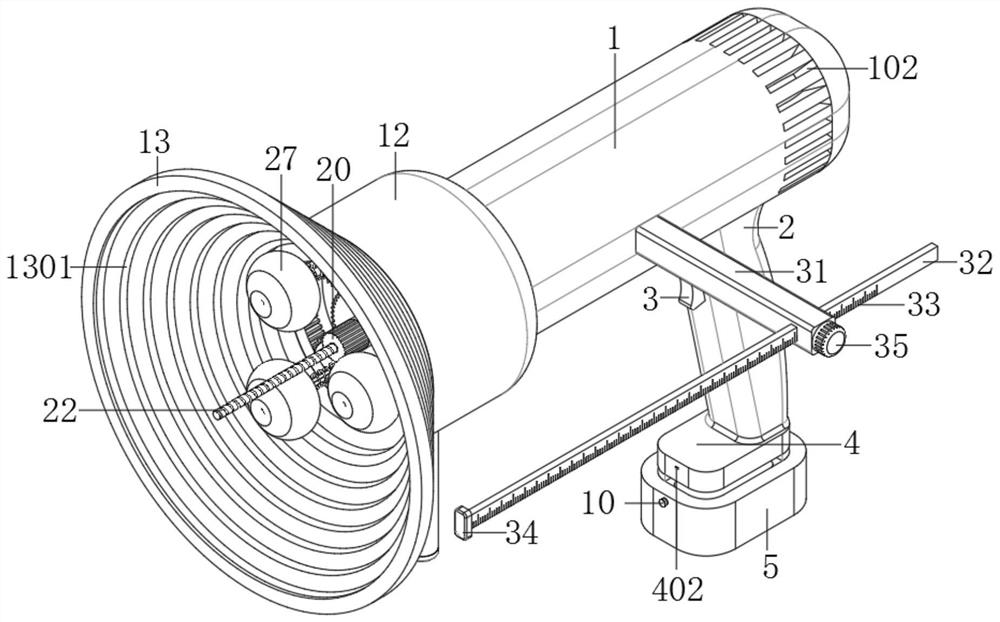

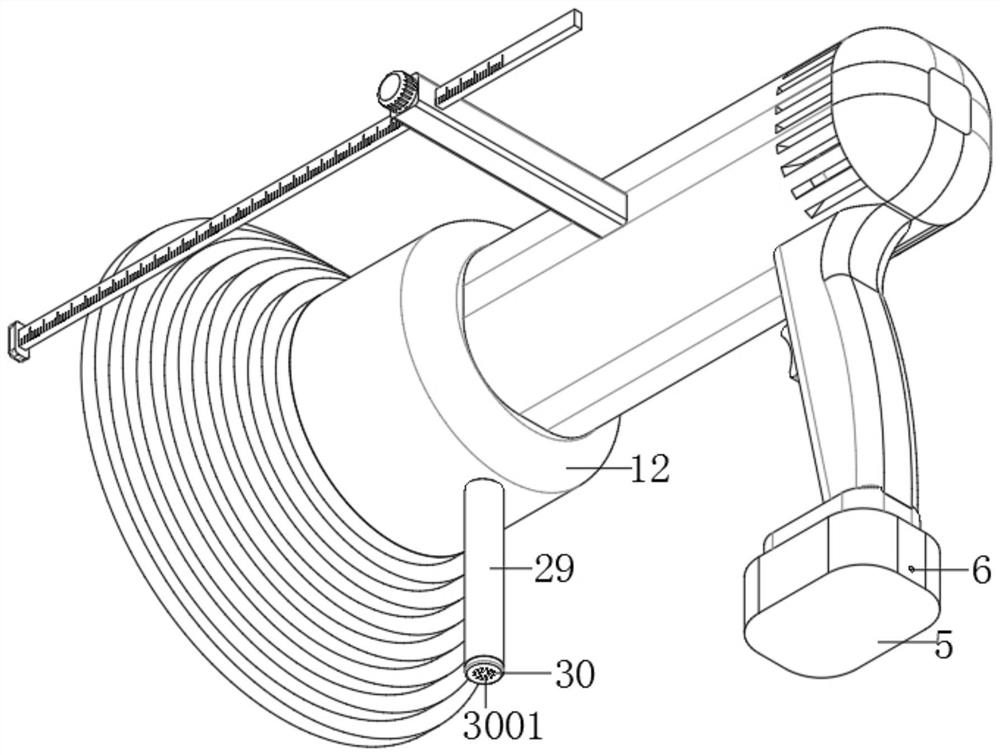

Mobile robot type drilling device for drilling of ceilings and walls

ActiveCN108772586AConvenient for centralized processingAvoid cleaning hassleWorking accessoriesWork benchesHand heldPetroleum engineering

The invention discloses a mobile robot type drilling device for drilling of ceilings and walls. The mobile robot type drilling device structurally comprises a hand-held fixing rod, a circuit connecting wire, a drilling main body, a connection rotating shaft and a drill bit. The hand-held fixing rod is connected below the front side of the drilling main body, and the circuit connecting wire is connected below the drilling main body and tightly connected with the inside of the drilling main body. The connection rotating shaft is connected to the left side above the drilling main body in an embedded mode, the connection rotating shaft and the drilling main body are connected in a fastening mode through buckles, the drill bit is inserted into the middle of the connection rotating shaft, and the drill bit is connected with the connection rotating shaft through buckles in a locking mode. The hand-held fixing rod is provided with a dust collecting clamping support, and the dust collecting clamping support is arranged below the drill bit and connected with the hand-held fixing rod in a locking mode. Falling dust and debris are collected inside a dust collecting hanging groove during usingby the arrangement of the mobile robot type drilling device provided with the dust collecting clamping support, so that centralized processing is facilitated, and the trouble of cleaning is avoided; and the drilling device can be freely disassembled after being used, the installation is more stable, falling off is not prone to occurring, and the use is more convenient.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

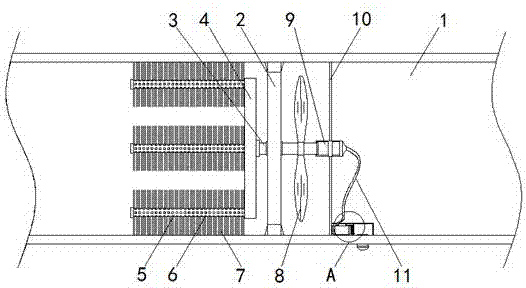

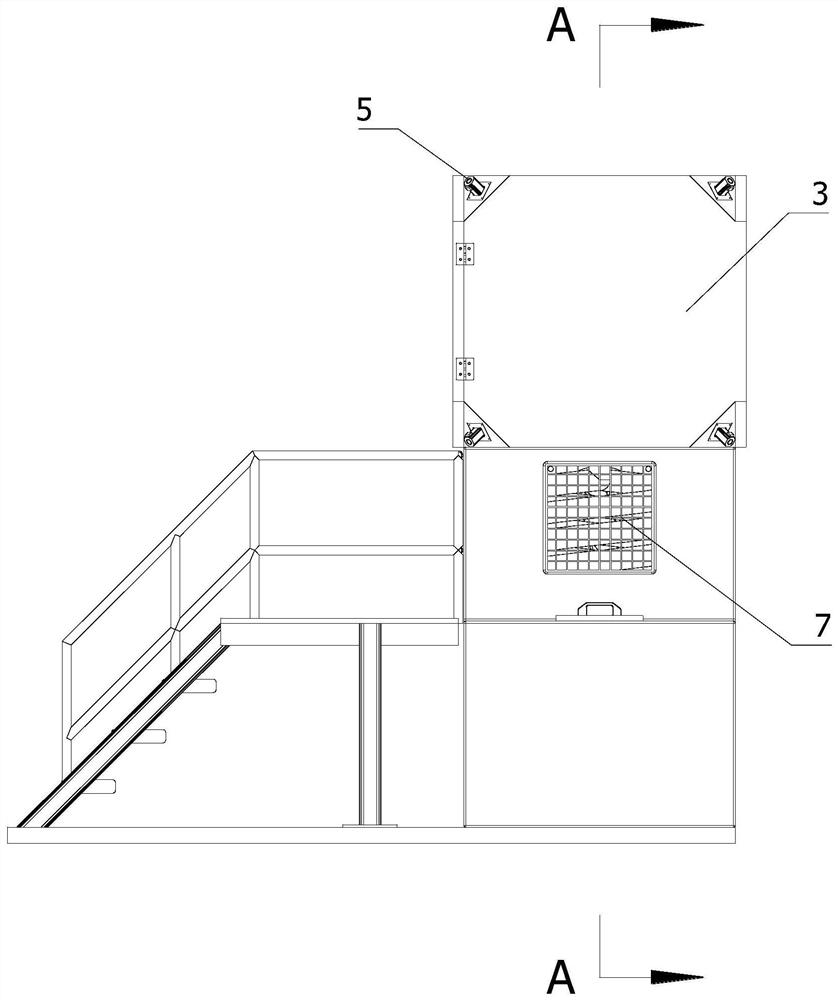

Environment-friendly ventilator convenient to wash all-roundly

PendingCN107060867AEasy to clean in all directionsEasy to cleanHollow article cleaningTunnel/mines ventillationStructural engineeringMechanical engineering

The invention relates to the technical field of ventilators, and discloses an environment-friendly ventilator convenient to wash all-roundly. The environment-friendly ventilator comprises a ventilator body, a support piece is fixedly mounted in the ventilator body, a hollow connection piece is mounted in the middle of the support piece in an inserted mode, and a hollow strutting piece communicating with the connection piece is fixedly mounted at one end of the connection piece; a hollow brush rod communicating with the strutting piece is fixedly mounted on the outer edge of the strutting piece, spray holes are formed in the surface of the brush rod, and brush hair mutually tangent with the inner wall of the ventilator body is fixedly mounted on the surface of the brush rod. According to the environment-friendly ventilator convenient to wash all-roundly, vortex blades can rotate independently under driving of wind power, and then drives the brush rod to rotate to achieve the purpose of enabling the brush hair to clean the inner wall of the ventilator body. The environment-friendly ventilator can completely clean the ventilator body, and is convenient to use.

Owner:阜宁县鑫虎机械有限公司

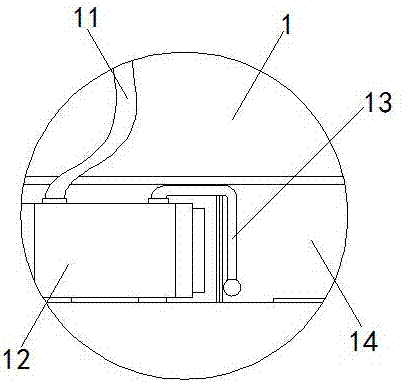

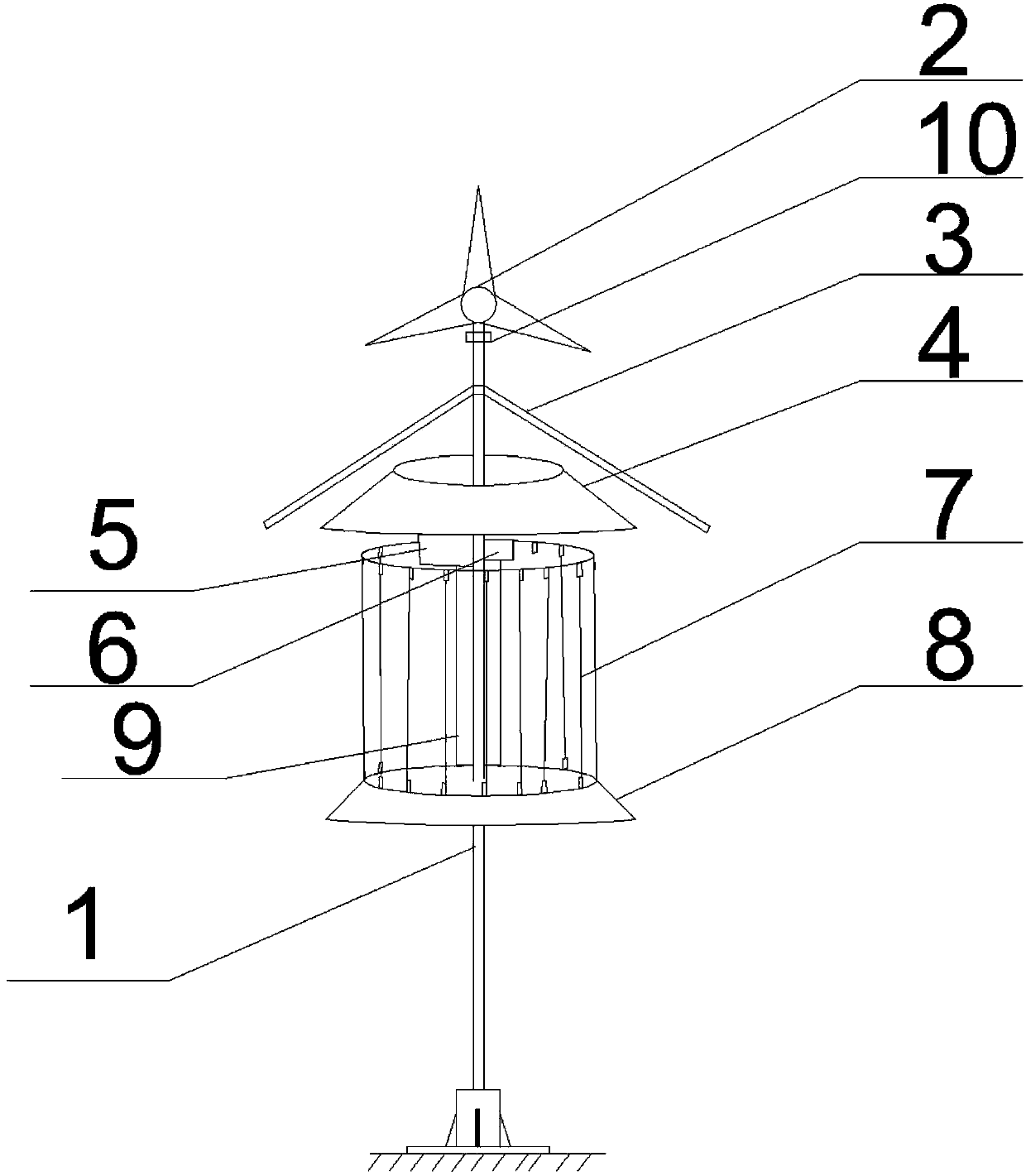

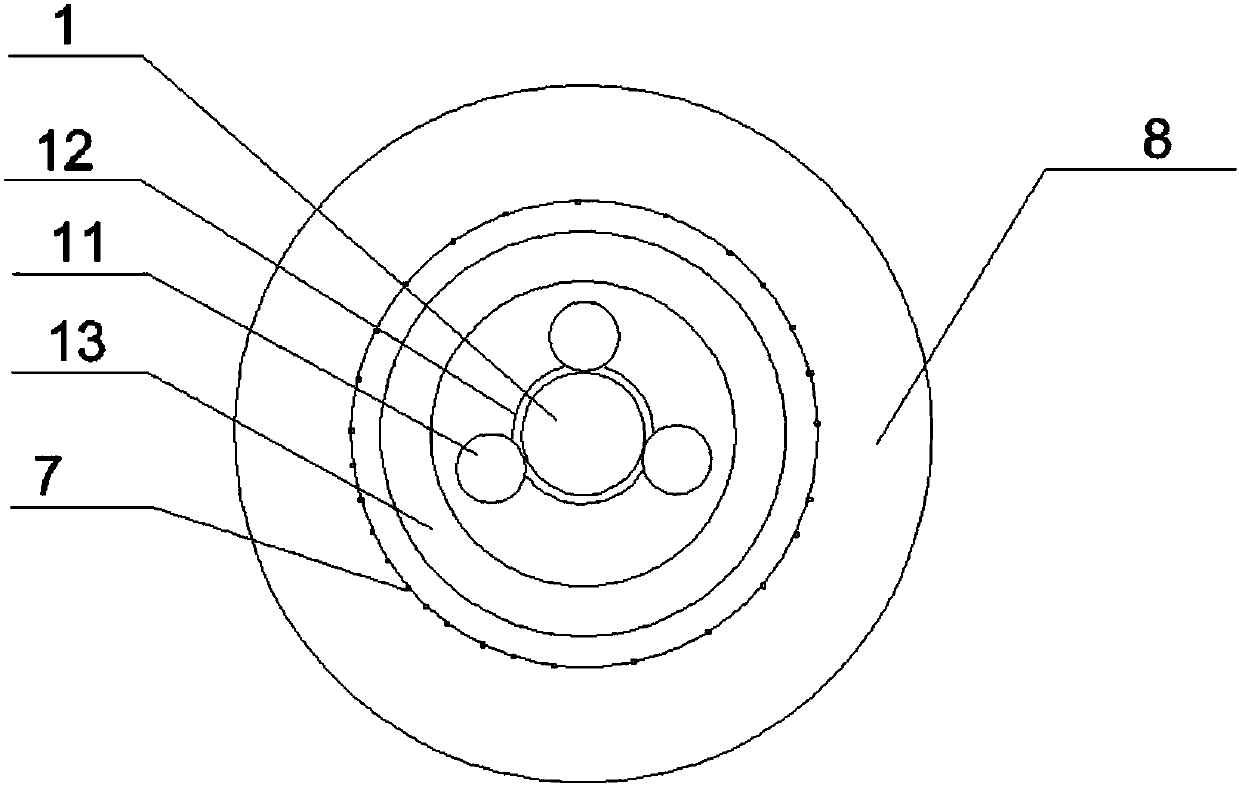

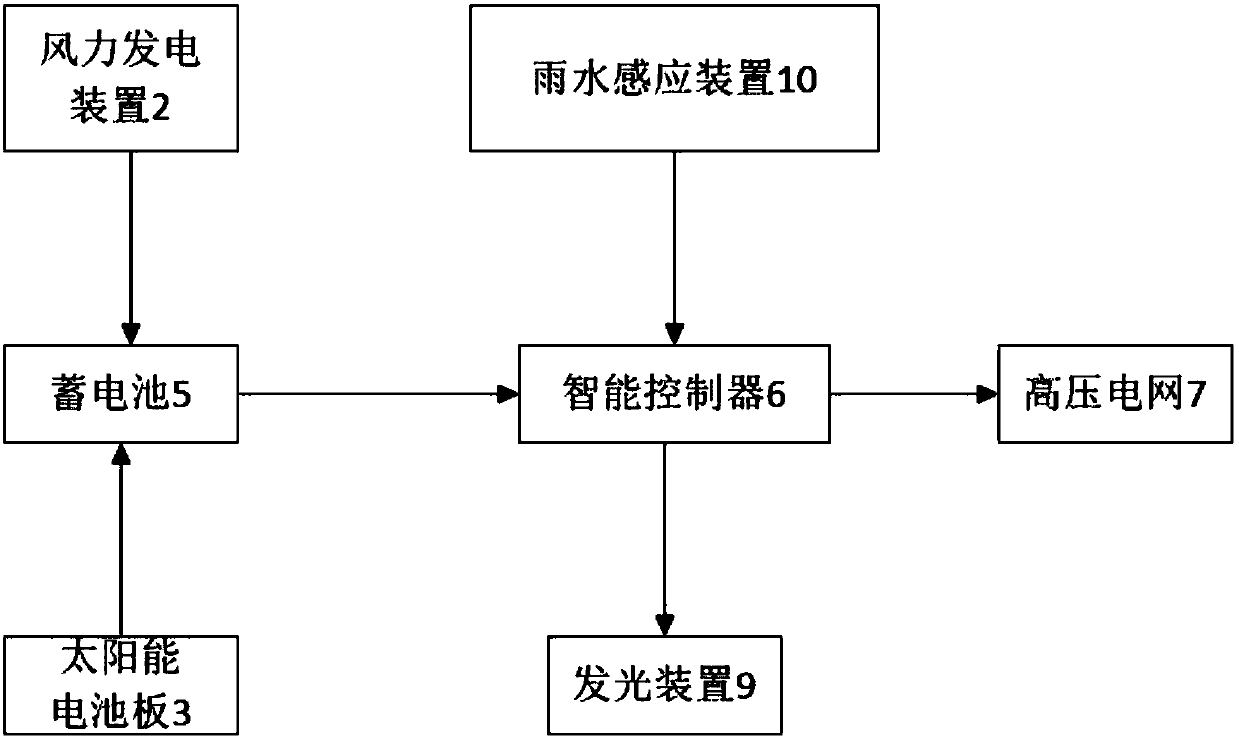

Energy-saving crop pest trapping and killing device

InactiveCN107711757AEffective attractionEffectively attracts pestsPV power plantsPhotovoltaic energy generationTrappingDecoy

The invention discloses an energy-saving crop pest trapping and killing device and belongs to the technical field of agricultural devices. The energy-saving crop pest trapping and killing device is used to solve the problems that an existing pest trapping and killing technology is not environmentally friendly, single in function and low in efficiency. The energy-saving crop pest trapping and killing device includes a vertical rod. A wind power generation device, a solar cell panel, a canopy, a storage battery, a light-emitting device and a supporting plate are sequentially arranged on the vertical rod from top to bottom. The light-emitting device is sleeved with a high voltage power grid, the storage battery is connected with an intelligent controller, the intelligent controller is connected with the light-emitting device and the high voltage power grid, the supporting plate is provided with a bait agent groove, and the light-emitting device is provided with yellow fluorescent paper. According to the energy-saving crop pest trapping and killing device, a power supply is provided through the wind power generation device and the solar cell panel, self-propelled power generation is performed in multiple modes, the energy-saving crop pest trapping and killing device is environmentally friendly and saves energy, pests are trapped and killed in a mode of combining light and baits, and the energy-saving crop pest trapping and killing device is multiple in functions and improves trapping and killing efficiency.

Owner:弘毅天承知识产权股份有限公司

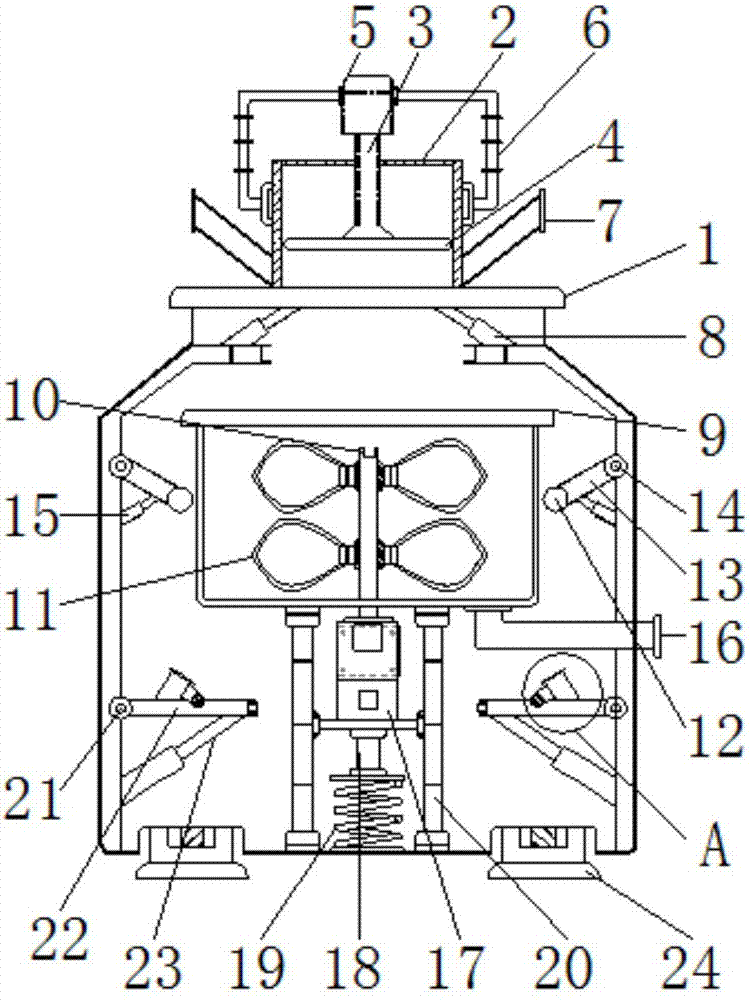

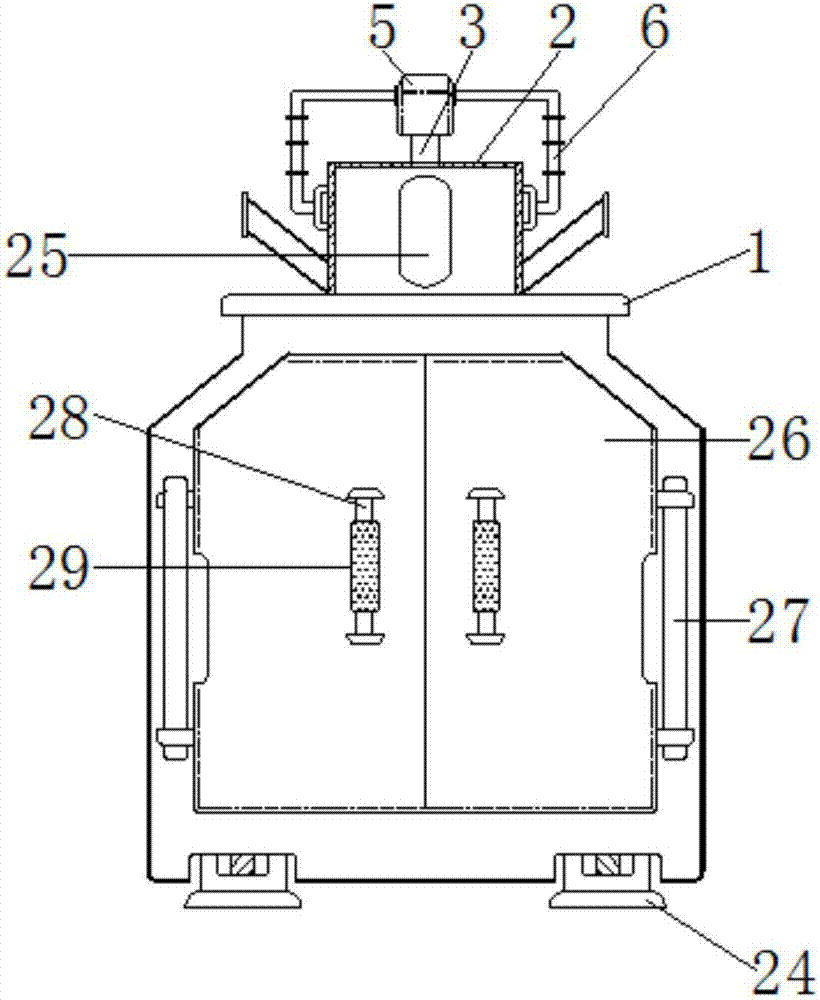

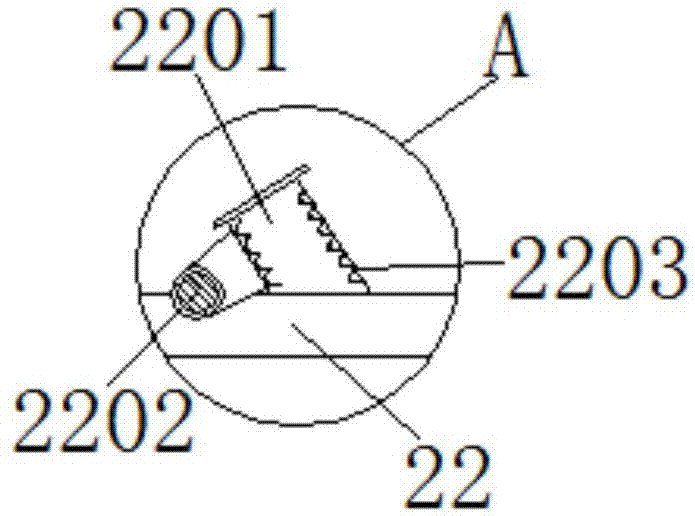

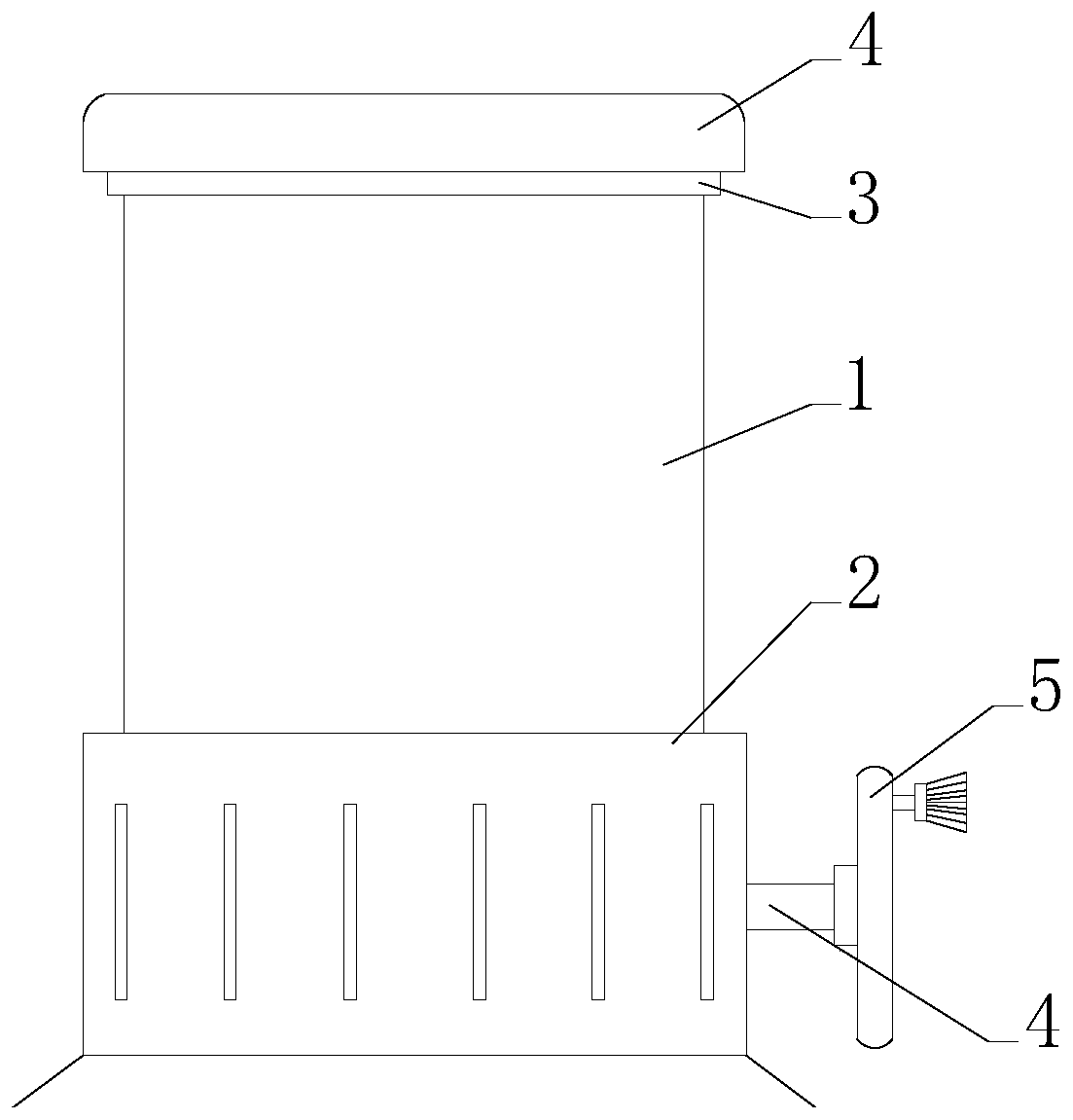

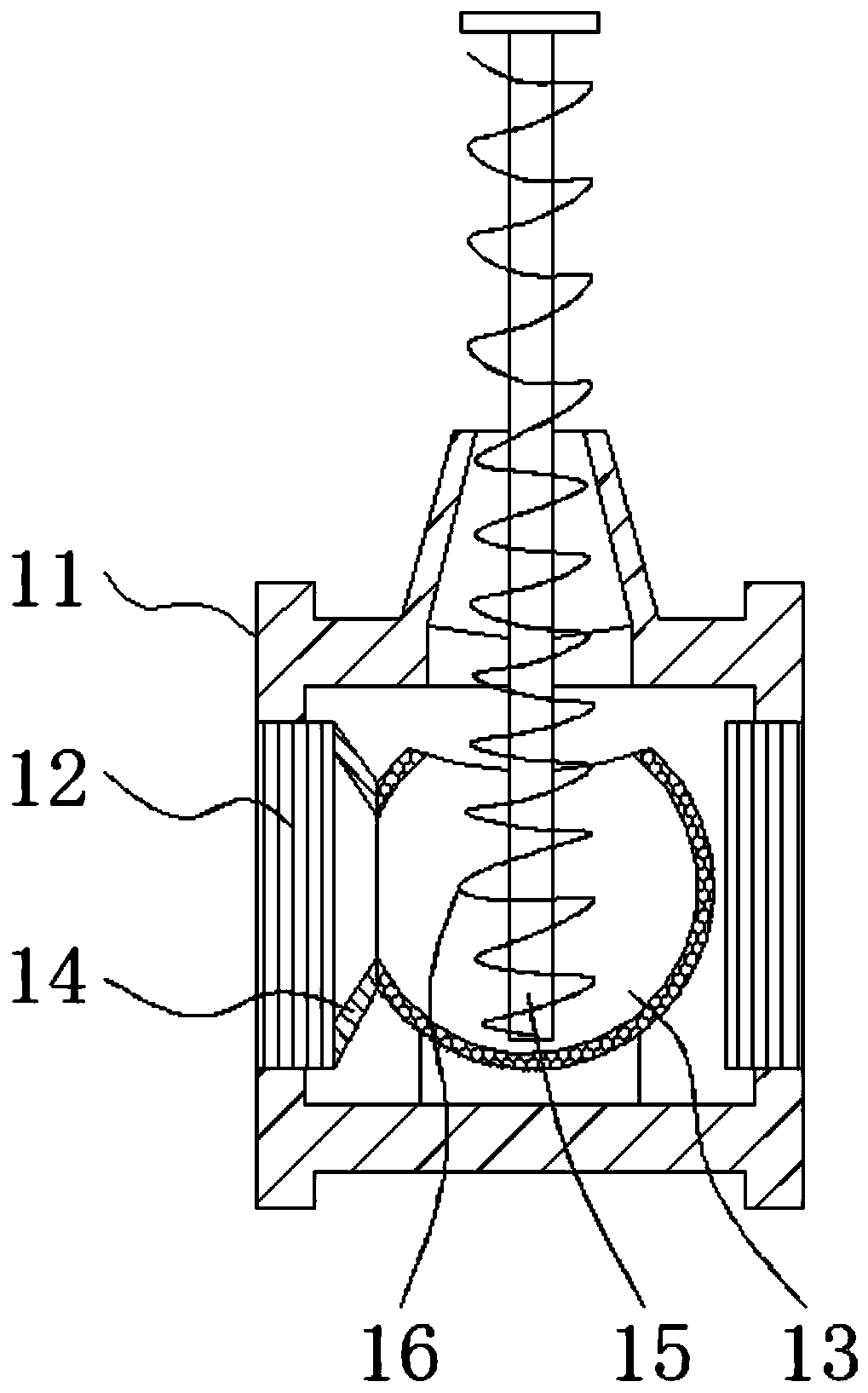

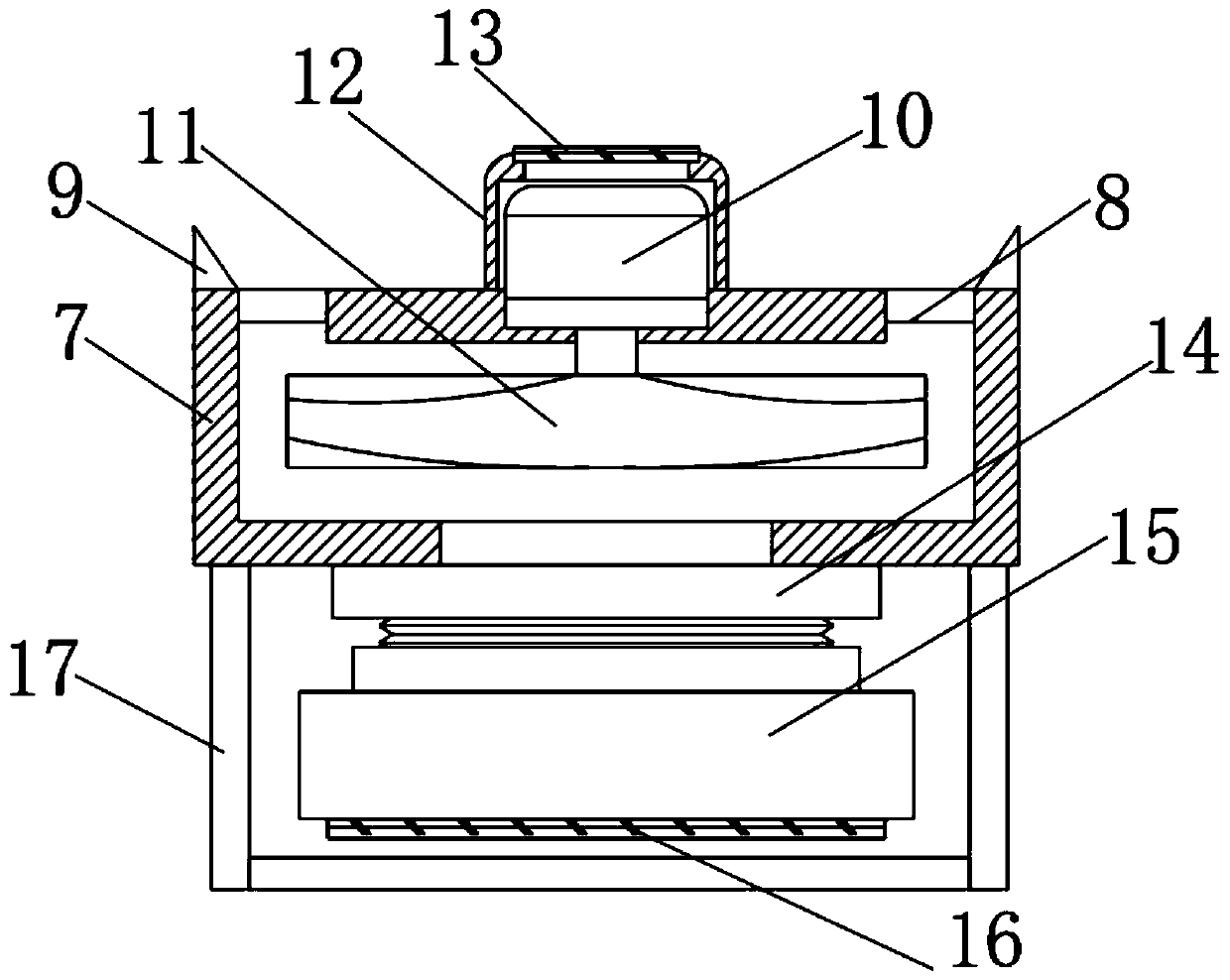

Compacting and drying integrated device for straw

InactiveCN107976015AImprove drying efficiencyStir wellDrying solid materials without heatDrying gas arrangementsHydraulic cylinderElectric machinery

The invention relates to a compacting and drying integrated device for straw. The compacting and drying integrated device comprises a device body, first hydraulic telescopic rods, knocking balls, a discharging pipe, a motor and bottom foots; a compaction chamber is arranged on the upper part of the device body, a compaction rod penetrate through the compaction chamber, a compaction plate is fixedat the bottom end of the compaction rod, and a hydraulic cylinder is arranged on the upper part of the compaction rod; a drying box is arranged on the position, at the inner side, between the knockingballs, knocking rods are fixed on the outer sides of the knocking balls, the upper ends of the knocking rods are connected with second rotating shafts, and the bottom ends of the knocking rods are connected with second hydraulic telescopic columns; and the discharging pipe is connected to the right side of the bottom part of the drying box. The compacting and drying integrated device of the strawhas the beneficial effects that the compaction plate is arranged, the compaction plate is driven by the hydraulic cylinder so that the straw can be compacted, and therefore water in the straw can beextruded, and part of the water contained in the straw can be conveniently removed.

Owner:吴达君

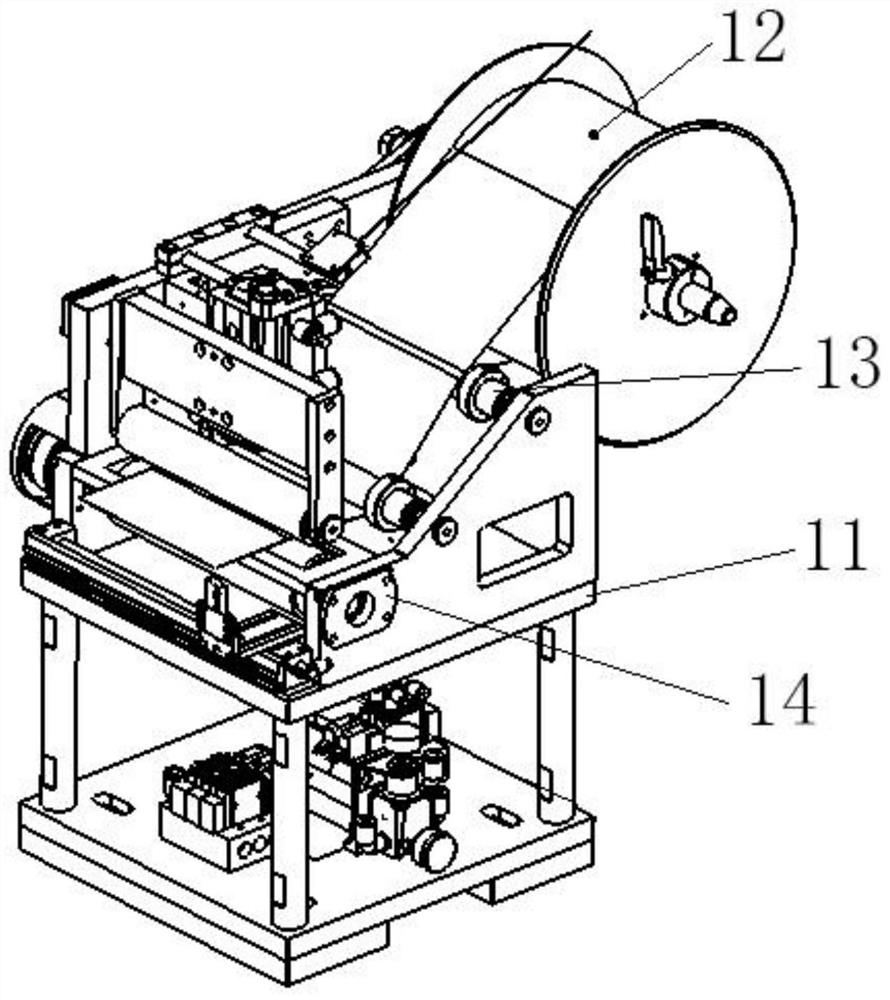

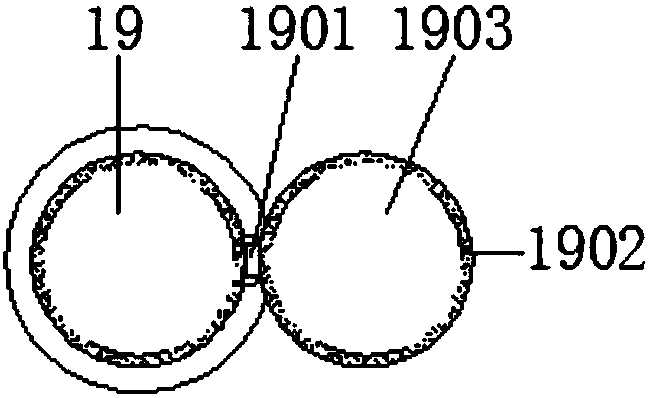

Film-coated precise ink-jet structure

ActiveCN112718304AAvoid cleaning hassleImprove production and processing efficiencySpraying apparatusFilm-outPrinting ink

The invention discloses a film-coated precise ink-jet structure which comprises a film supply mechanism, a film drawing mechanism, a film stretching mechanism, a film locking mechanism and an ink jet mechanism which are sequentially arranged. The film supply mechanism is used for storing and outputting a coating film. The film drawing mechanism is used for drawing the coating film out of the film supply mechanism to the film stretching mechanism. The film stretching mechanism is used for stretching and straightening the coating film drawn out by the film drawing mechanism. The film locking mechanism is used for pressing the coating film onto a product. The ink jet mechanism is used for spraying ink onto the film-coated product. Through cooperation of the film supply mechanism, the film drawing mechanism and the film stretching mechanism, a lens is covered with the coating film, the center area, namely a non-spraying area, of the lens is blocked, the coating film is reinforced and locked on the lens through the film locking device, and the printing ink is evenly sprayed to the lens through the ink jet device. In the spraying process, the non-spraying area is protected against being covered by the printing ink by the coating film. After spraying is finished, only the coating film needs to be torn, so that the trouble of cleaning the lens is avoided, and the lens production and processing efficiency is improved.

Owner:SHENZHEN TENSUN IND EQUIP

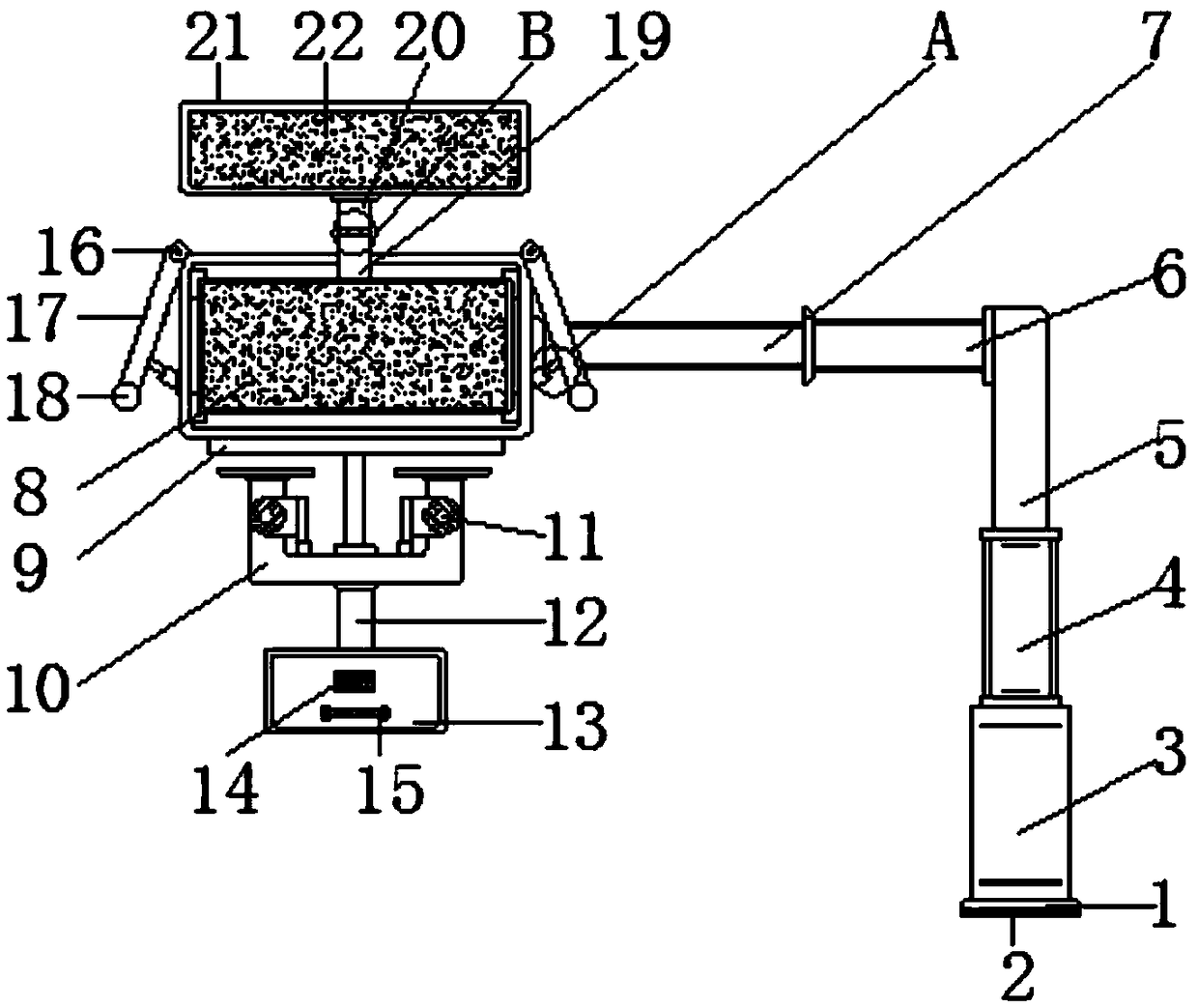

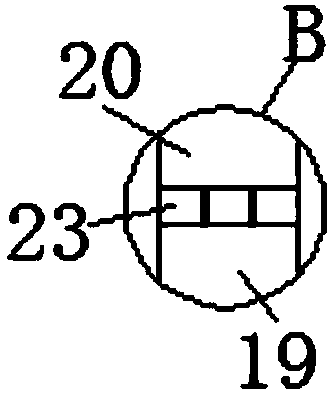

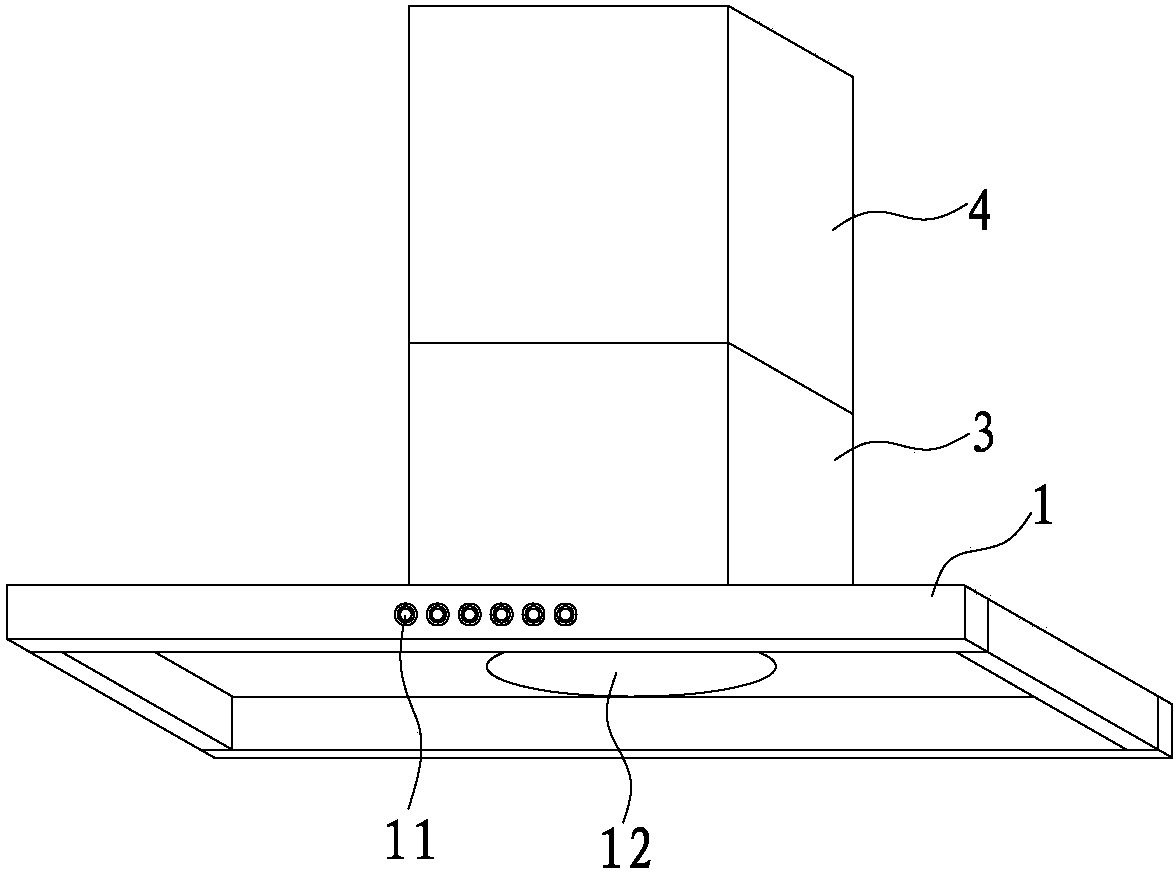

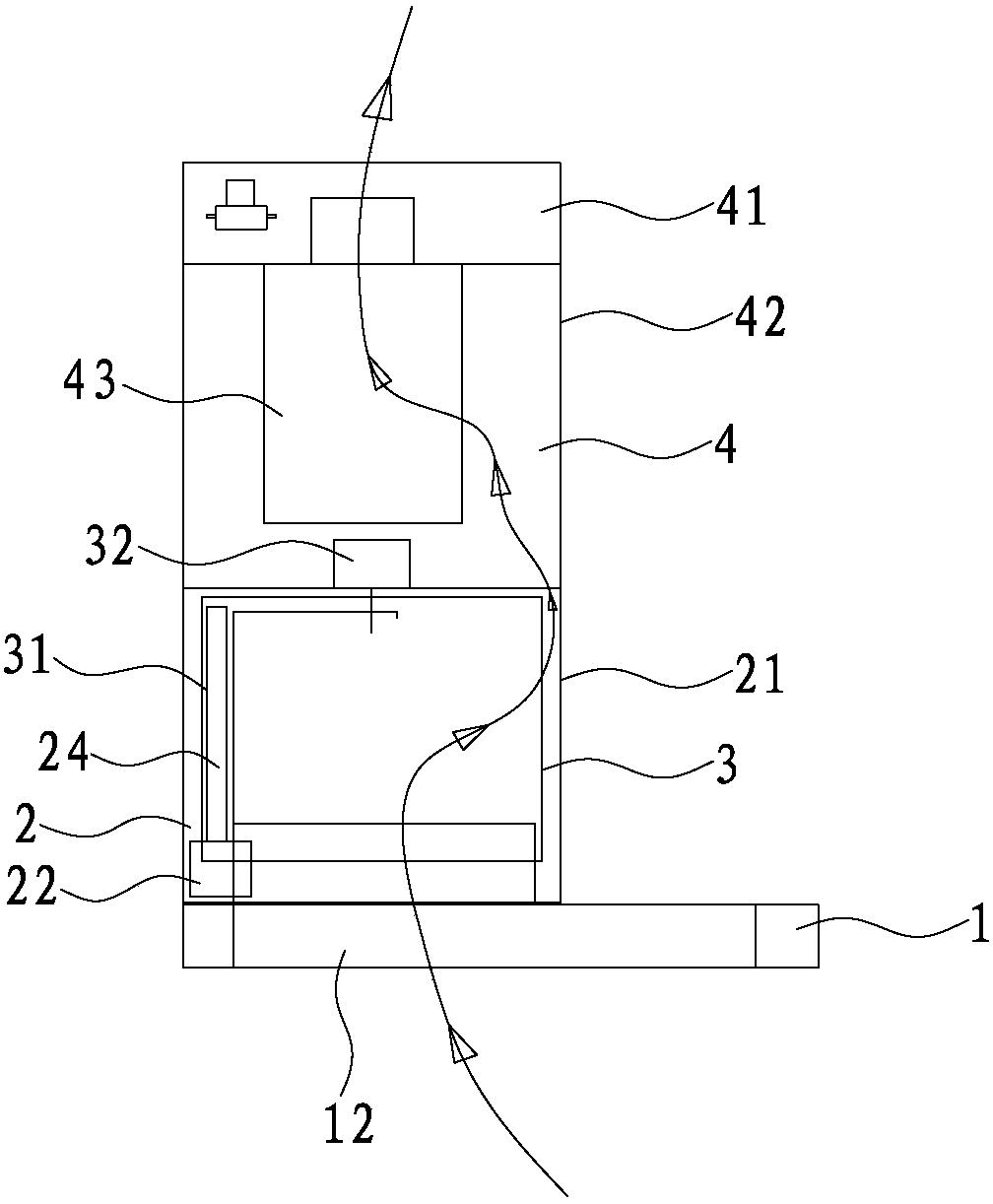

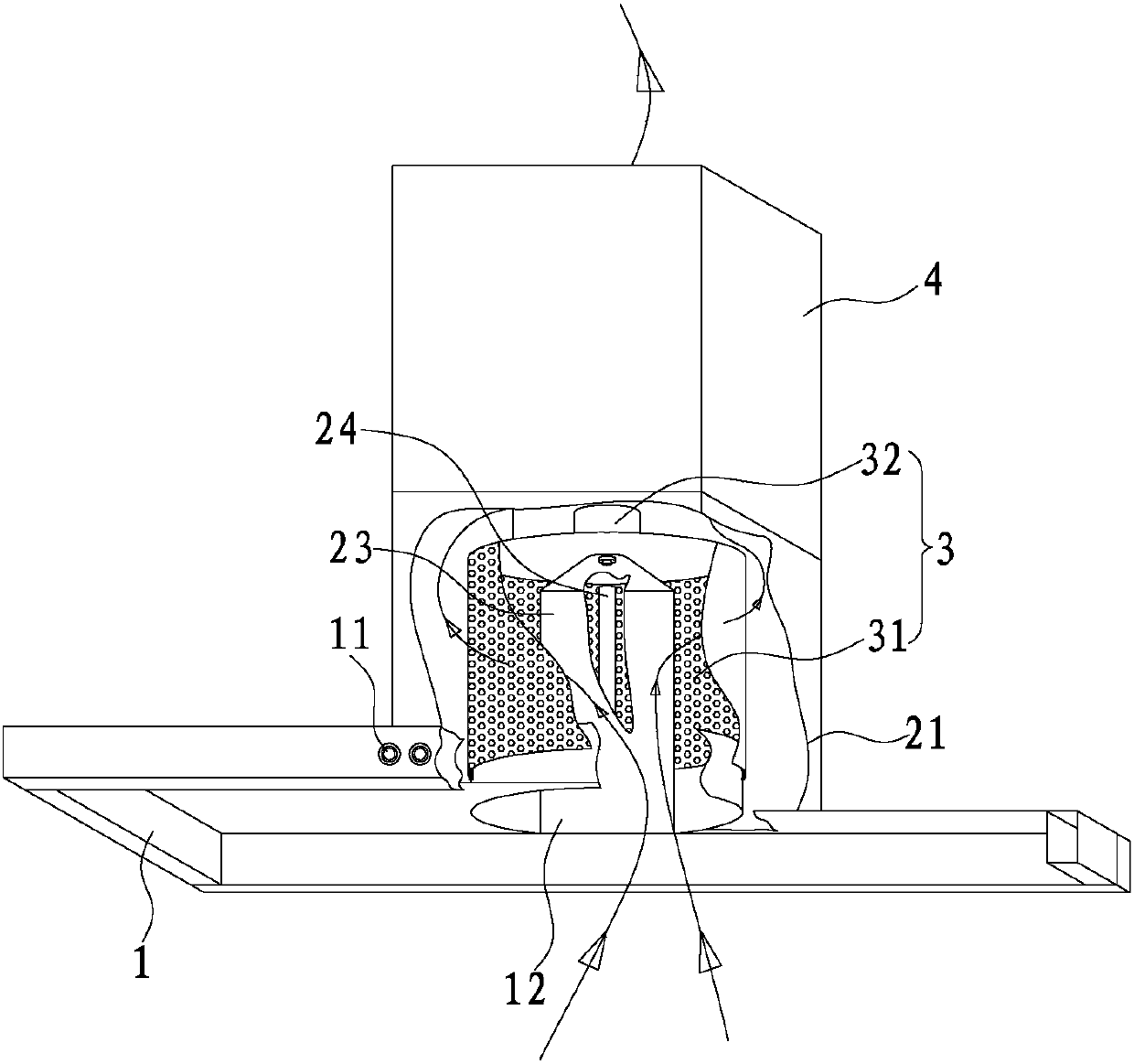

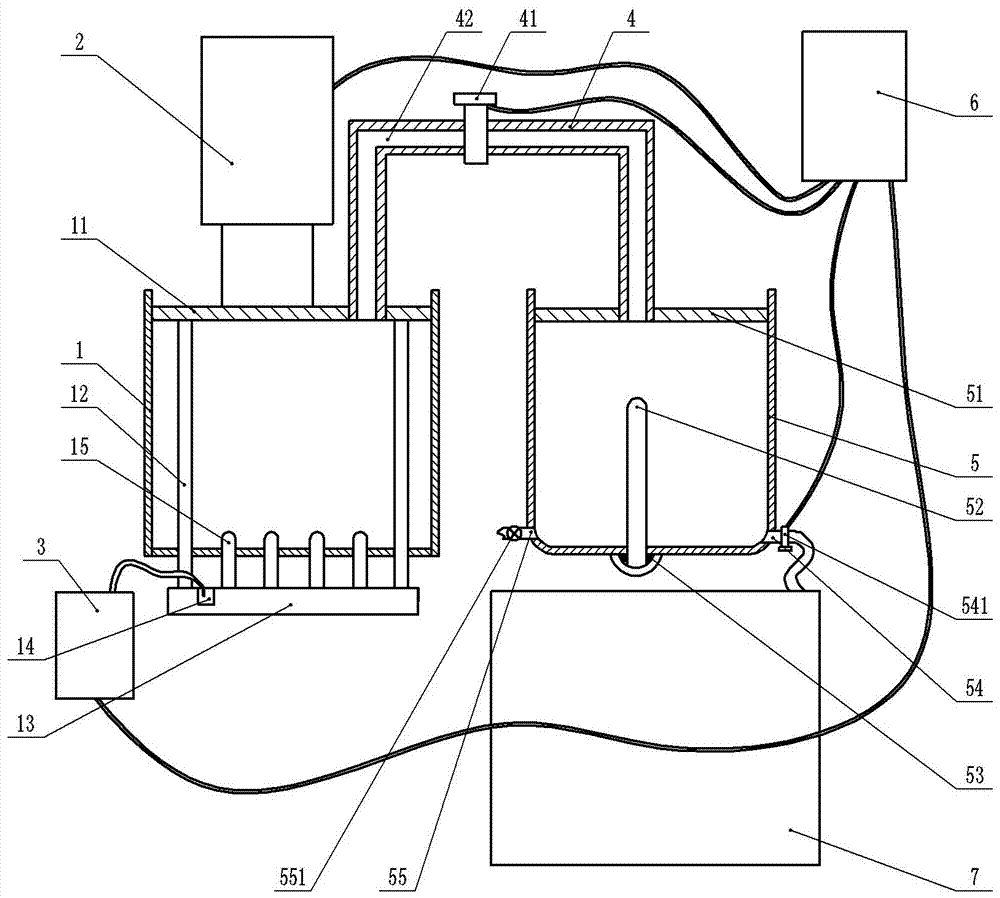

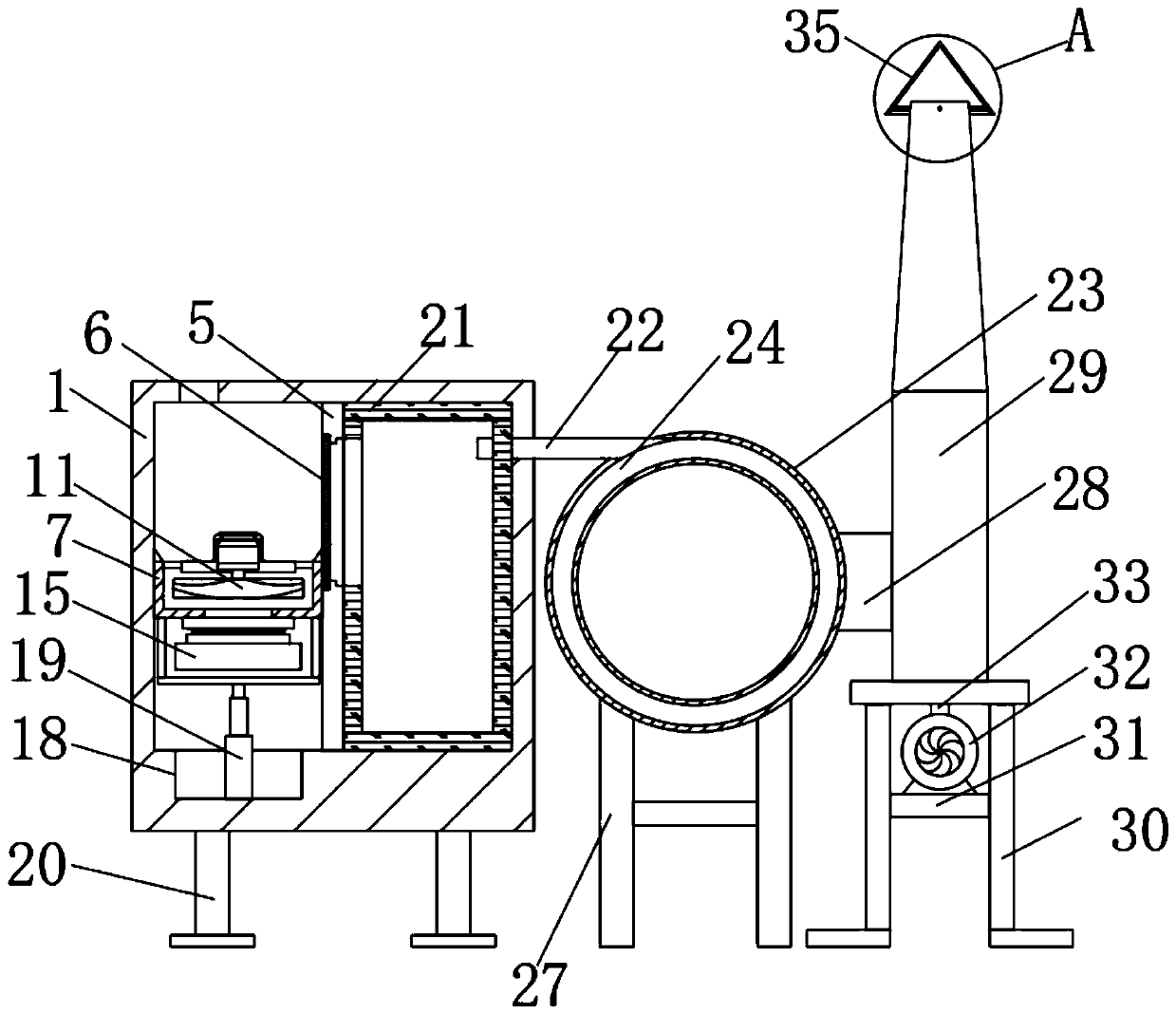

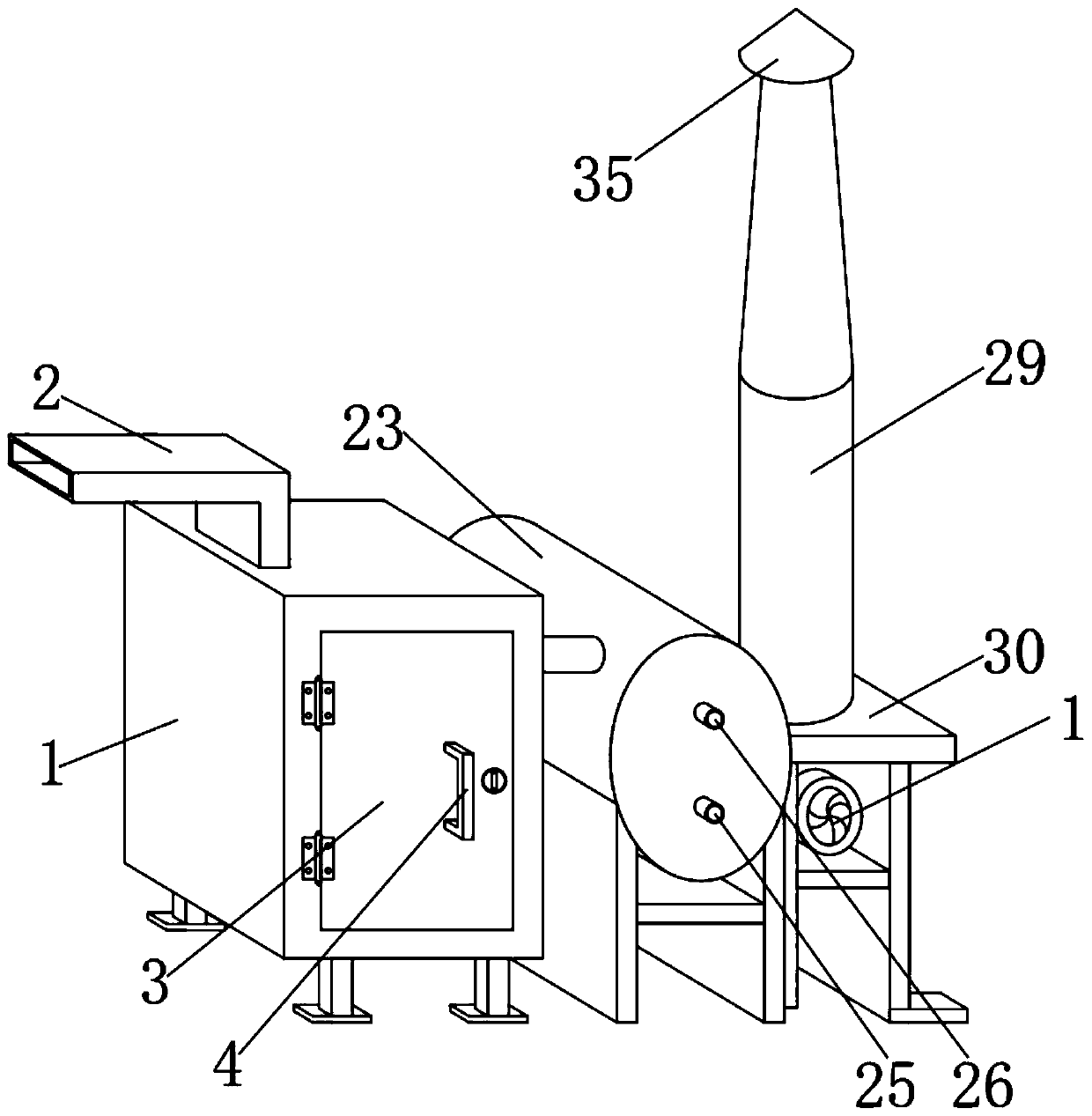

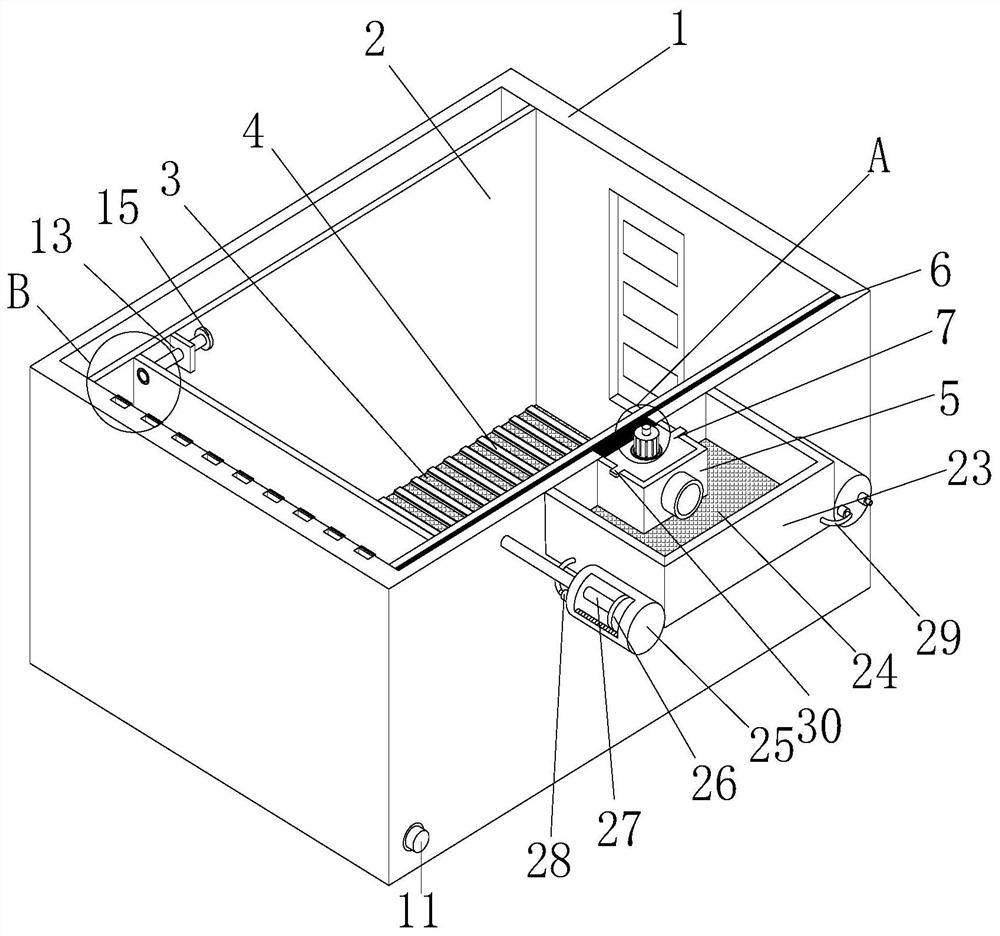

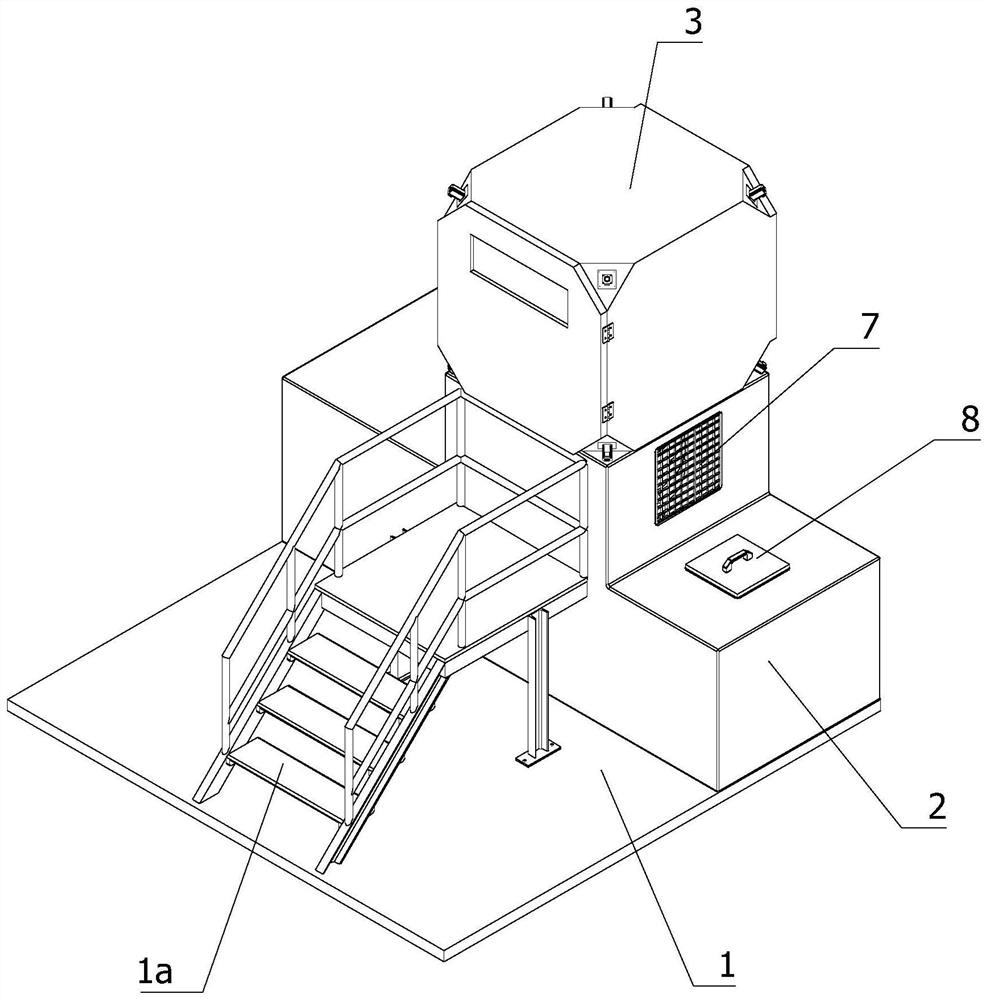

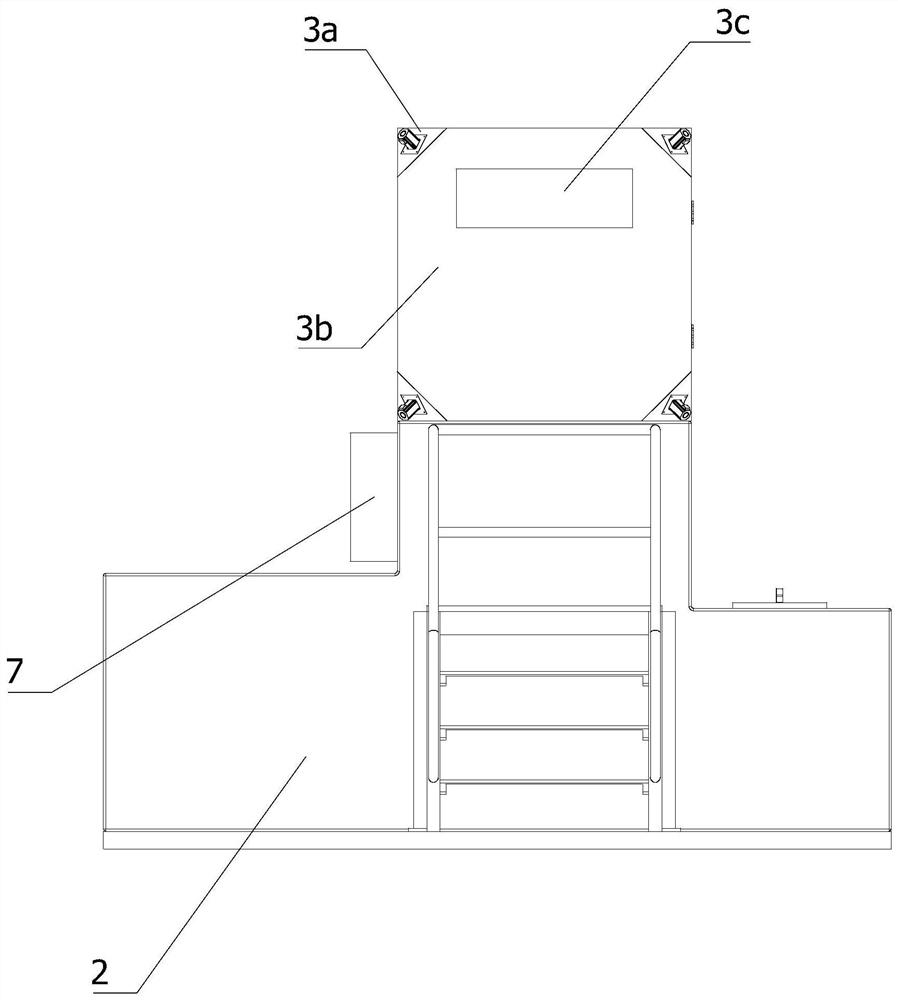

Self-cleaning smoke exhaust ventilator

InactiveCN103697521AAvoid cleaning hassleCompact structureDomestic stoves or rangesLighting and heating apparatusMixed flowPulp and paper industry

The invention relates to a self-cleaning smoke exhaust ventilator. The self-cleaning smoke exhaust ventilator comprises an air draft hood, a cleaning pool unit, a filter net unit and a blower box unit, wherein the cleaning pool unit is arranged at the top of the air draft hood; the filter net unit is arranged in the cleaning pool unit; the blower box unit is arranged above the cleaning pool unit to be communicated with the cleaning pool unit; the cleaning pool unit comprises a box body and a cleaning pool positioned at the lower part of the box body; the filter net unit comprises a rotating barrel-shaped filter net; the barrel-shaped filter net is longitudinally arranged in the box body of the cleaning pool unit; the lower end of the barrel-shaped filter net covers an air outlet of the air draft hood, and a seal opening is formed in the upper end of the air draft hood; cleaning fluid in the cleaning pool is sprayed to the rotating barrel-shaped filter net to form a cleaning fluid curtain through a cleaning fluid spraying pipe. The self-cleaning smoke exhaust ventilator is simple and compact in structure; when the self-cleaning smoke exhaust ventilator is used, a blower works, a negative pressure area is generated in the filter net unit; when passing through the cleaning fluid curtain of the rotating barrel-shaped filter net through an air inlet of the air draft hood, oil smoke gas and the cleaning fluid form a gas-liquid mixed flow process, and the oil smoke is cleaned in time; the troublesome cleaning of a user is prevented.

Owner:刘恩华

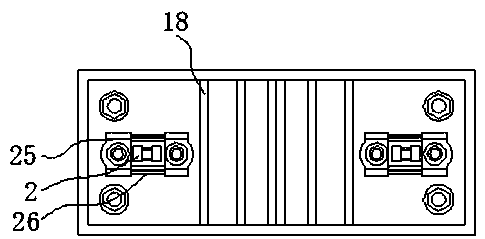

Intelligent monitoring maintaining device for mechanical manufacturing system

InactiveCN109278007AAvoid lifting problemsIntelligent maintenanceWork tools storageLinear motionIntelligent lighting

The invention relates to an intelligent monitoring maintaining device for a mechanical manufacturing system. The device comprises a main body, an air cylinder, a fan and a soft pad; infrared sensors are arranged on the left side and the right side of the upper portion of the main body, the main body and the infrared sensors are fastened through nuts, the air cylinder is arranged on the bottom of the main body, a seal ring is arranged above the air cylinder, an air pipe is connected to the left side of the seal ring, the air pipe and the seal ring are bonded through glue, and a telescopic rod is arranged in the air pipe in a penetrating manner. The device has the beneficial effects that the intelligent monitoring maintaining device for the mechanical manufacturing system is provided with asliding rail, due to sliding rail design, stability of a monitoring display screen during ascending can be ensured, due to the fact that the monitoring display screen is too heavy, in the ascending process, the display screen is prone to deviating, the sliding rail ensures that under the high load condition, the monitoring display screen achieves high-precision linear motion from the two sides, and the phenomenon that the monitoring display screen and the main body are expanded, and damage is caused is avoided.

Owner:DONGGUAN UNIV OF TECH

Salted vegetable salinity reducing device

InactiveCN106858482AEffective control of salinityRealize automated productionClimate change adaptationPressesElectricityHydraulic cylinder

The invention belongs to the technical field of salted foods or salted food stuffs, and particularly discloses a salted vegetable salinity reducing device. The salted vegetable salinity reducing device comprises a pressing plate, a compressing cylinder, a hydraulic cylinder, a controller, a water inlet pipe, a water outlet pipe and a water storage tank, wherein the pressing plate is in sliding connection to the compressing cylinder; the water storage tank communicates with the water inlet pipe and the water outlet pipe; a one-way valve is arranged on the water inlet pipe; a first electromagnetic valve is arranged on the water outlet pipe; a piston is in sliding connection to the water storage tank; an interlocking rod is arranged on the piston; a flow channel is formed in the interlocking rod; a second electromagnetic valve is arranged on the interlocking rod; a pressure valve and a sliding connecting sealing column are arranged at the bottom of the water storage tank; a guiding rod is fixed to the pressing plate; a bottom plate is connected to the lower part of the guiding rod; a plurality of push rods are fixed to the bottom plate; a groove is formed in the bottom plate; a salinity detector is connected to the groove; and the controller is electrically connected with the salinity detector, the hydraulic cylinder, the first electromagnetic valve and the second electromagnetic valve. Through the adoption of the salted vegetable salinity reducing device disclosed by the invention, pickled vegetables are compressed for reducing salinity, and the salinity of the pickled vegetables can be accurately controlled, so that the salinity of the pickled vegetables conforms to requirements.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Micro-bubble generator for air floatation treatment of sewage

ActiveCN103193288BEffective generationUniform sizeWater/sewage treatment by flotationForeign matterMicro bubble

The invention discloses a micro-bubble generator for air floatation treatment of sewage. The micro-bubble generator comprises a water cavity pipe and a micropore pipe; one end of the water cavity pipe is connected with the micropore pipe, and the other end of the water cavity pipe is a closed end; the side wall of the water cavity pipe is provided with an inlet water pipe; an air cavity pipe is sleeved outside the micropore pipe, and a closed air cavity is formed between the air cavity pipe and the micropore pipe; the side wall of the air cavity pipe is provided with an inlet air pipe; and an opening end of the micropore pipe is connected with an outlet pipe. When the micro-bubble generator is in use, the treatment water and the treatment air respectively enter the water cavity pipe and the air cavity pipe of the micro-bubble generator through the inlet water pipe and the inlet air pipe, micro bubbles can be formed by cutting the air through the micropore pipe and continuous scouring and shearing the air through the treatment water flow, and the formed micro bubbles are carried by the water flow to be discharged through the outlet pipe. Due to the adoption of the micro-bubble generator, sufficient micro bubbles with a uniform size can be effectively generated, and the requirement of the air floatation purification process can be completely met; and the trouble for clearing the foreign matters in the treatment water blocking the micropore pipe can be avoided, the micro-bubble generator can be operated stably for a long time, no rotating part exists, and simplicity in use, installation, maintenance and repairing can be realized.

Owner:CHINA NAT OFFSHORE OIL CORP +1

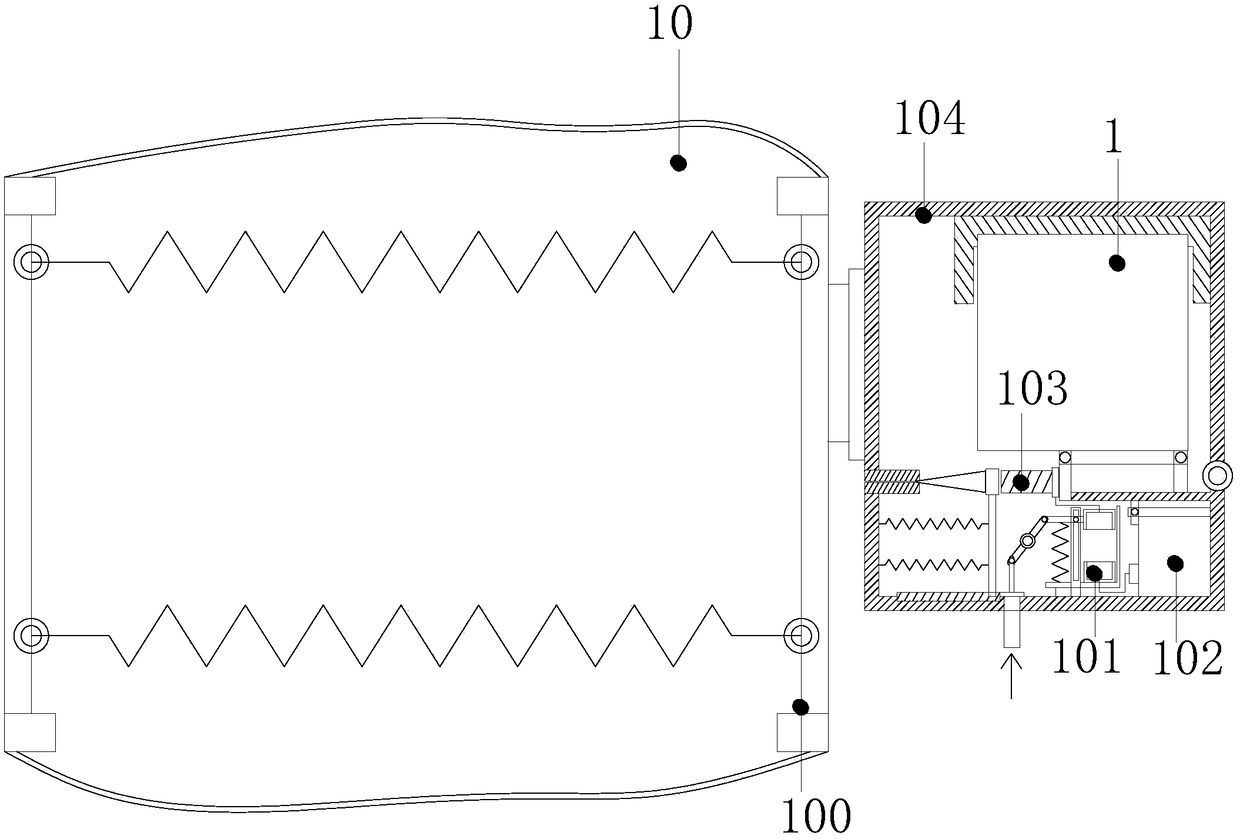

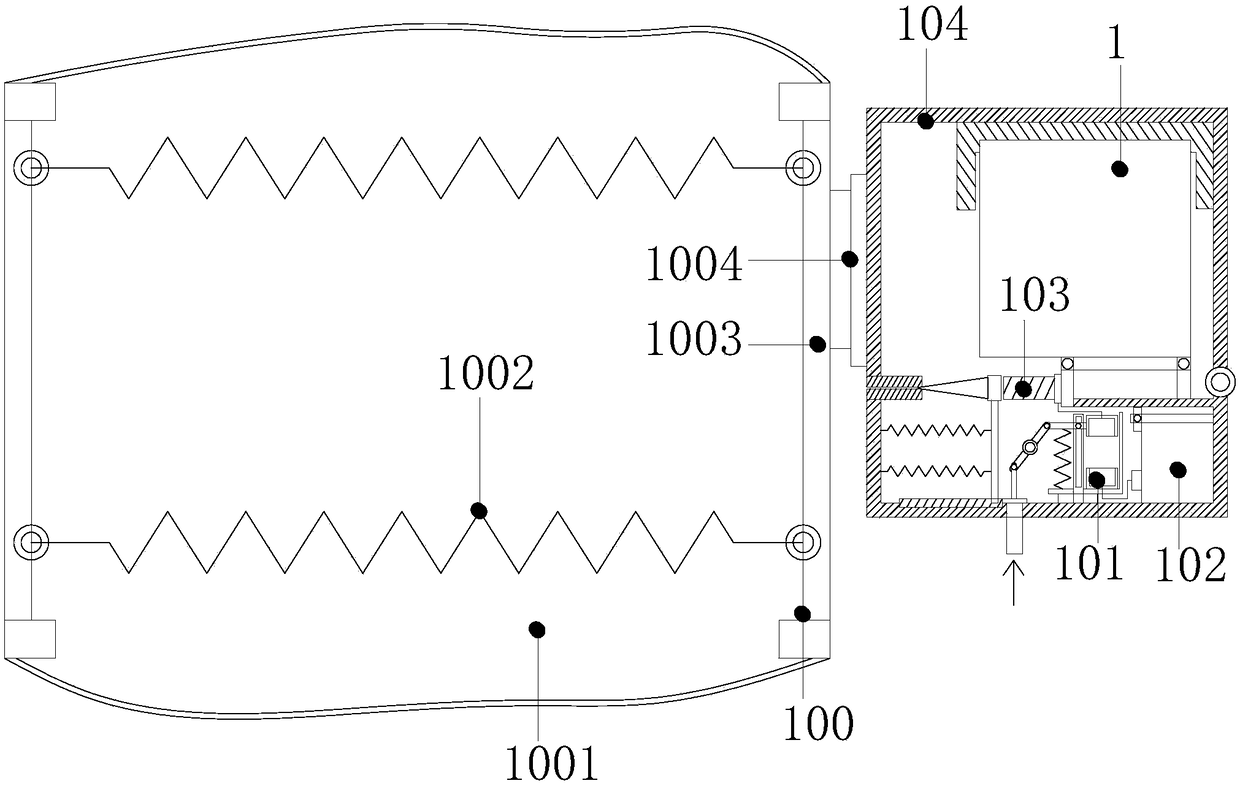

Floor sweeping robot and rolling brush cleaning device thereof

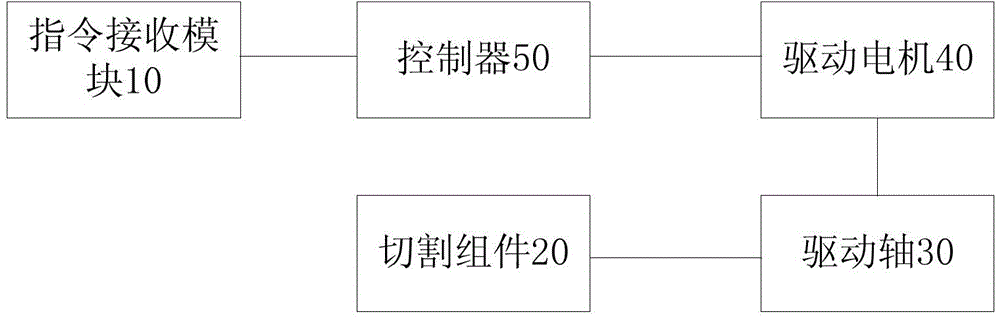

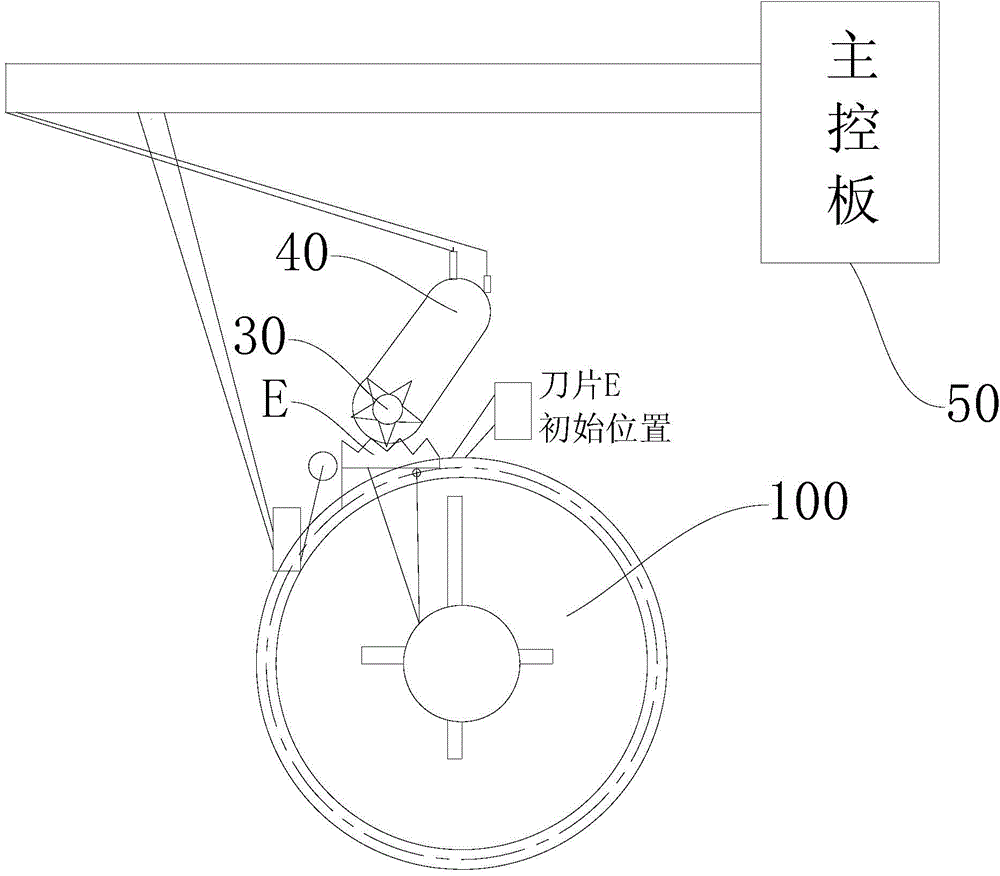

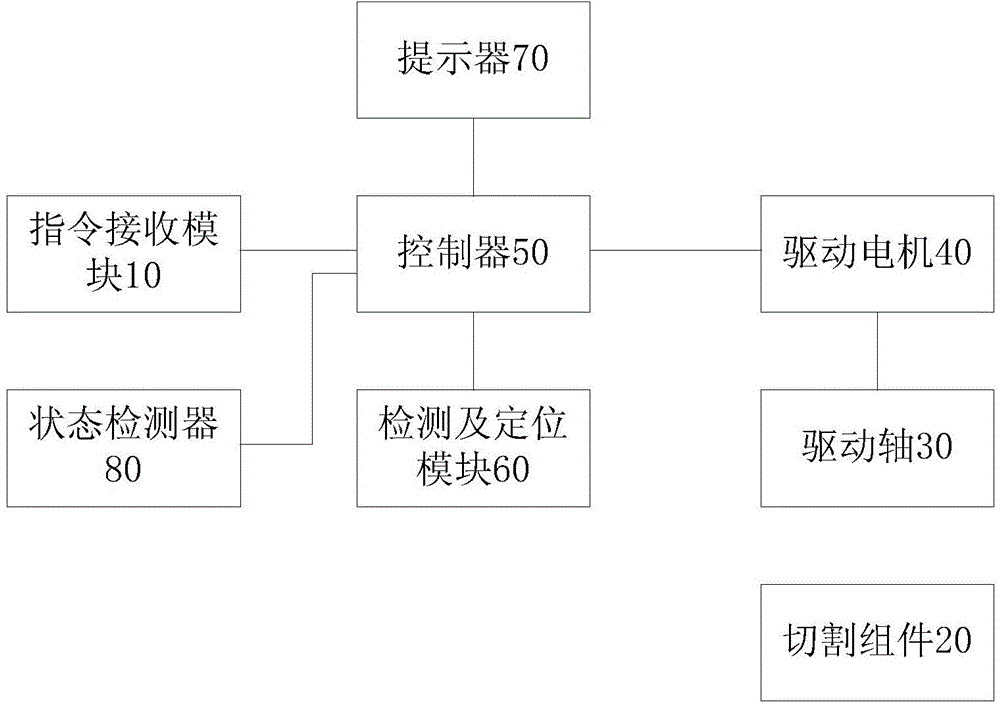

ActiveCN106175604AAvoid cleaning hassleFully meet the needsMachine detailsFloor sweeping machinesForeign matterDrive shaft

The invention discloses a roller brush cleaning device for a sweeping robot, which comprises: an instruction receiving module for receiving cutting instructions; a cutting assembly for cutting foreign matter on the roller brush; a drive for driving the cutting assembly to move shaft; a drive motor for driving the drive shaft; and a controller, the controller controls the drive motor to drive the cutting assembly to cut the foreign matter on the roller brush according to the cutting instruction. The roller brush cleaning device cuts the foreign matter on the roller brush, such as hair, silk, etc., to prevent foreign objects from being entangled on the roller brush and bring cleaning troubles to the user, which brings great convenience to the user and fully meets the needs of the user. . The invention also discloses a sweeping robot provided with the roller brush cleaning device.

Owner:MIDEA ROBOZONE TECH CO LTD

Pickled vegetable pressing and desalting device

InactiveCN106962852AReduce labor intensityIncrease productivityFood scienceHydraulic cylinderBristle

The invention belongs to the technical field of pickled food or food materials, and particularly discloses a pickled vegetable pressing and desalting device. The pickled vegetable pressing and desalting device comprises a worktable, a pressing block, a pressing barrel, a hydraulic cylinder, a water inlet tube, a water outlet tube and a water storage tank, wherein the pressing barrel is fixed on the worktable; the pressing block is slidably connected to the inside of the pressing barrel; the water inlet tube and the water outlet tube respectively communicate with the water storage tank; a one-way valve which only can be opened towards one side of the water storage tank is arranged on the water inlet tube; a first valve is arranged on the water outlet tube; the inside of the water storage tank is slidably connected with a piston; the piston is provided with a linkage rod which is connected with the pressing block; a channel which communicates with the water storage tank and the pressing barrel is formed in the linkage rod; a second valve is arranged on the linkage rod; an annular brushing barrel is arranged on the upper surface of the pressing block; and bristles which are extruded by the outer wall of the pressing barrel are arranged on the inner wall of the brushing barrel. Pickled vegetables are pressed and desalted by the device, a water outlet hole can be prevented from being blocked, the trouble of cleaning is avoided, the pickled vegetables can be cleaned in a pressing process, and therefore, salinity of the pickled vegetables is reduced effectively.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Salted vegetable dewatering device

InactiveCN106858481AEasy and thorough unloadingAvoid cloggingFood scienceElectric machineryPulp and paper industry

The invention belongs to the technical field of salted foods or salted food stuffs, and particularly discloses a salted vegetable dewatering device. The salted vegetable dewatering device comprises a machine frame, an upper pressing block, a lower pressing block, an annular cylinder and a motor for driving the annular cylinder to rotate, wherein the motor is fixed to the machine frame; threads of which the rotating directions are opposite are respectively formed in the upper part and the lower part of the inner wall of the annular cylinder, and a plurality of dewatering holes are formed in the root of each thread; a first thread in thread fit with the upper part of the inner wall of the annular cylinder is formed in the side wall of the upper pressing block; a second thread in thread fit with the lower part of the inner wall of the annular cylinder is formed in the side wall of the lower pressing block; grooves are respectively formed in the top of the first thread and the top of the second thread; a push ball is movably connected to each groove; a spring is connected between each push ball and the corresponding groove; sliding grooves distributed in the height direction are separately formed in the machine frame; and protrusions separately fitted with the corresponding sliding groove are separately arranged on the side wall of the upper pressing block and the side wall of the lower pressing block. Through the adoption of the salted vegetable dewatering device disclosed by the invention, in the process of squeezing salted vegetables, the dewatering holes cannot be blocked up; and after the operation of squeezing the salted vegetables is completed, the salted vegetables can be automatically separated from the annular cylinder, so that the problem that discharging is troublesome is solved.

Owner:CHONGQING ZHOUYI FOOD CO LTD

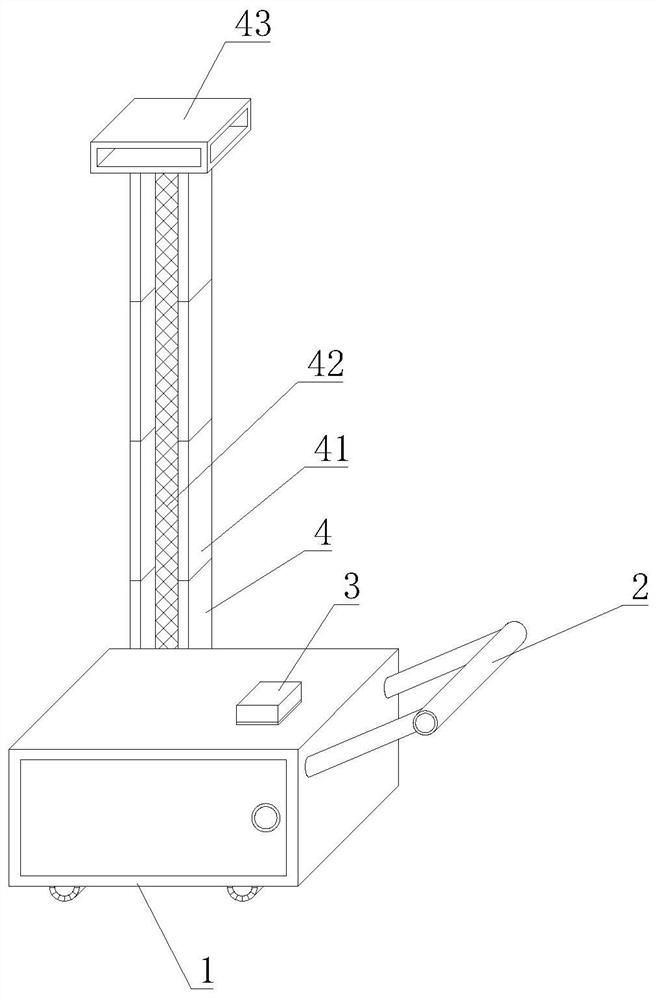

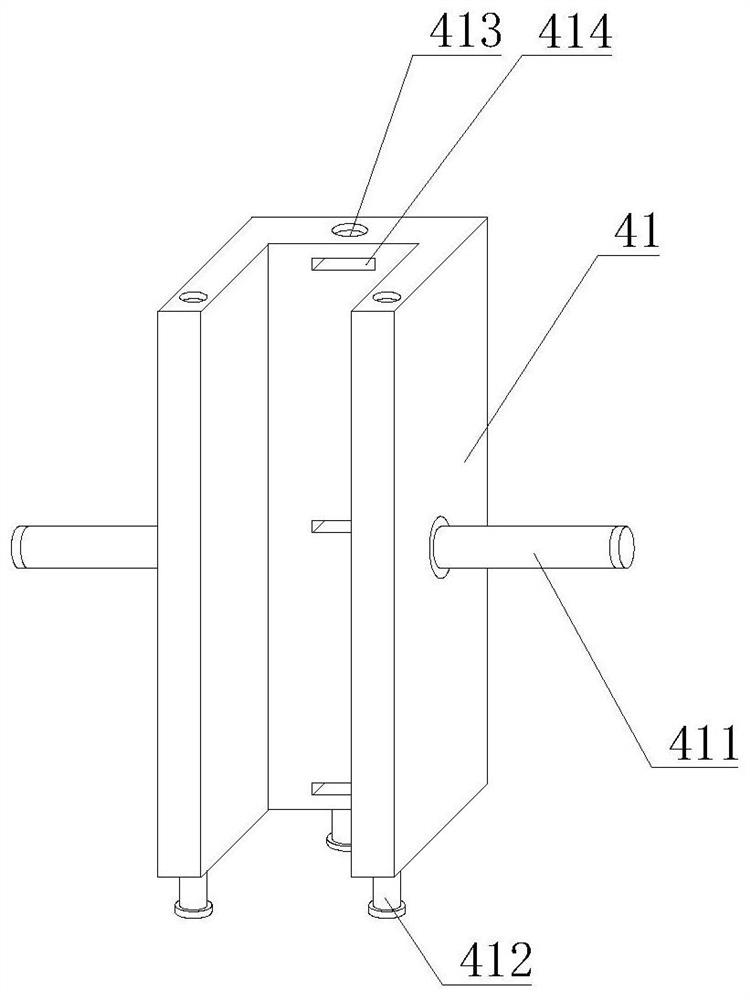

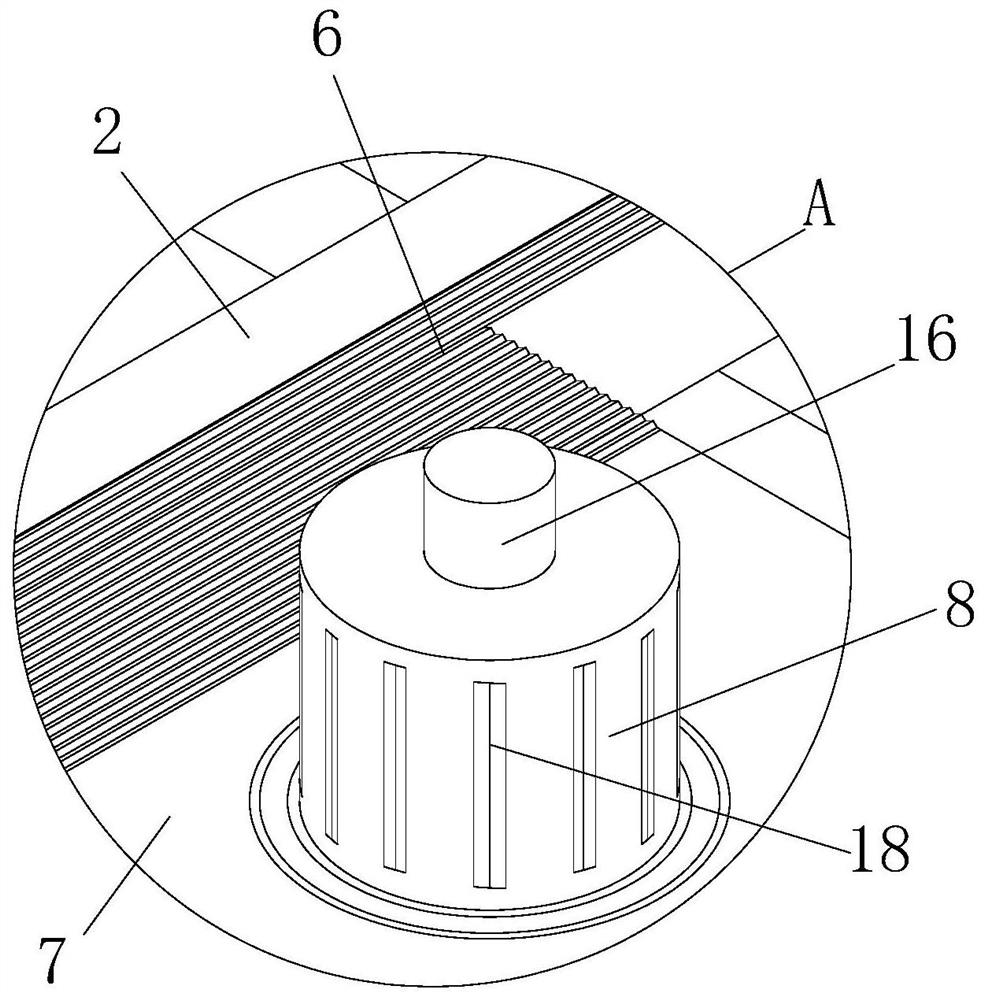

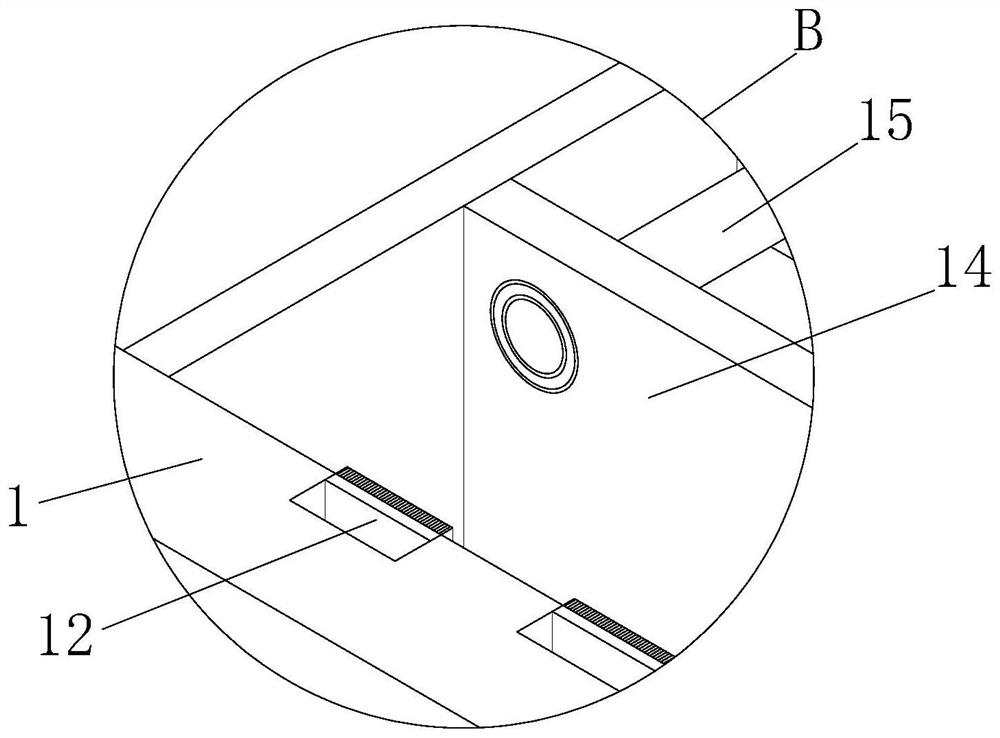

Rapid mixing device for two-component chemical reagent

PendingCN109865455AAvoid cleaning hassleEnhance the effect of turning and stirringRotating receptacle mixersMixer accessoriesBiochemical engineeringBevel gear

The invention discloses a rapid mixing device for a double-component chemical reagent. The rapid mixing device comprises a housing (1) and a reaction vessel cover (8). The housing (1) is fixedly connected to an upper end of a base (2); a lower cap (3) is fixedly arranged on the housing er (1); an upper cap (4) is arranged on the lower cap (3) by means of threads; a lower end of the reaction vesselcover (8) is fixedly connected with a tray (9) which is fixedly connected to a supporting column (12); a sleeve (10) rotationally sleeves the supporting column (12), and the sleeve (10) is fixedly plugged in the base (2); the supporting column (12) is fixedly connected with a second bevel gear (14) which is engaged with a first bevel gear (15); the first bevel gear (15) fixedly sleeves the rotating column (18); one end of the rotating column (18) is fixedly inserted into the inner race of a second bearing (13); and the second bearing (13) is fixedly mounted in the base (2). The rapid mixing device for a double-component chemical reagent is characterized in that with the designs of the bevel gears, the rotating column and the reaction vessel cover, the rotating column is rotated by turninga hand wheel so as to drive the tray and the reaction vessel cover to rotate, thereby rotationally mixing a reagent in a reaction vessel.

Owner:JIAOZUO UNIV

Dust removal device for coal mining machine of coal mine and use method

PendingCN113770120AEasy to disassembleEasy to operateCombination devicesCleaning using gasesMining engineeringDust control

The invention discloses a dust removal device for a coal mining machine and a use method, and relates to the technical field of coal mining machines. The dust removal device comprises a movable dust treatment box, a push-pull frame is fixedly welded to the right side of the movable dust treatment box, a control box is movably connected to the top of the movable dust treatment box, a control button is arranged in an inner cavity of the control box, and a suction fan body is fixedly mounted at the top of an inner cavity of the movable dust treatment box. Through the cooperative design of inserting rods and inserting grooves, adjacent splicing frames can be spliced, so that the splicing frames can be conveniently detached or installed; then the stretching length of a telescopic net pipe is adjusted, the telescopic net pipe is clamped in the inner cavities of the splicing frames through bent pipe fixing grooves, and then holding rods can be mounted on the splicing frames convenient to hold by hand, so that adjustment of the splicing frames are completed, operators with different heights can conveniently and smoothly perform dust removal operation, and the convenience of the device is improved.

Owner:郑伟敏

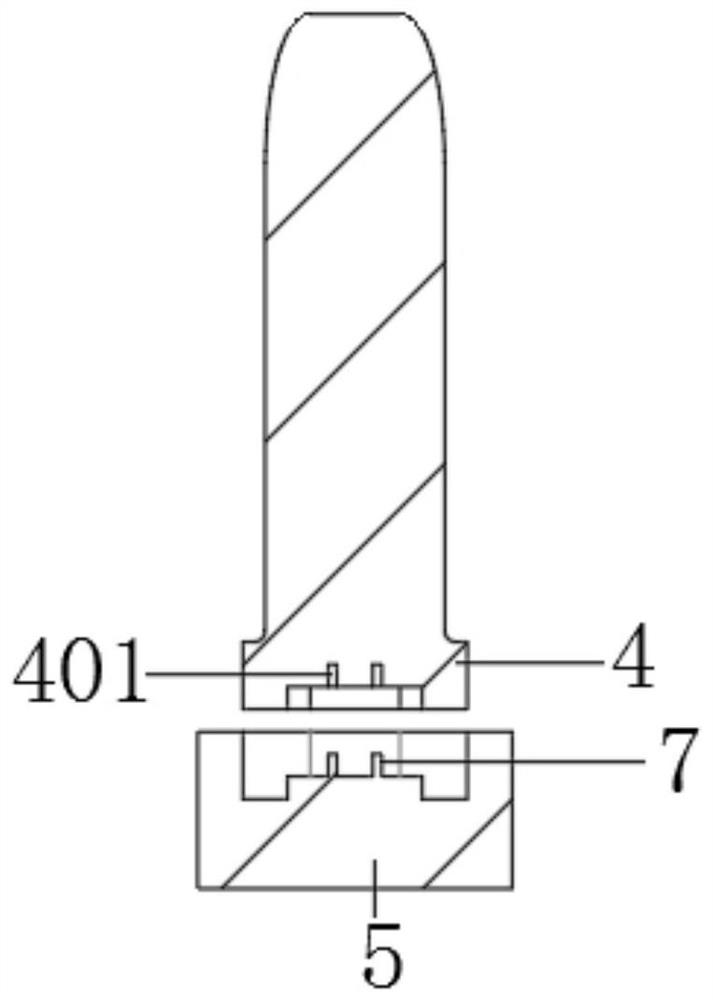

Wall surface punching drilling machine for building decoration and using method

PendingCN112847831AAvoid entanglementAvoid damageWorking accessoriesStone-like material working toolsPunchingDrive shaft

The invention relates to the field of building decoration related equipment, in particular to a wall surface punching drilling machine for building decoration and a using method. The wall surface punching drilling machine comprises a machine body, motor supports and a sealing bearing, a grip is arranged at the bottom end of the right side of the machine body, a starting button is arranged at the upper end of the left side of the grip, and a base is fixedly connected to the bottom end of the grip. A storage battery assembly is inserted into the bottom end of the base, a mounting cavity is formed in the machine body, a mounting cover is fixedly connected to the outer wall of the left end of the machine body, a funnel-shaped rubber dust collection cover is fixedly clamped to the left end of the mounting cover, and a plurality of dust collection grooves are evenly formed in the inner wall of the funnel-shaped rubber dust collection cover. Motors are fixedly mounted on the inner wall of the right side of the mounting cavity through the multiple sets of motor supports which are evenly distributed in a radial shape, and the output ends of the left sides of the motors are fixedly connected with a driving shaft. According to the punching drilling machine, decoration work operation is facilitated, dust can be well collected and cleaned, and meanwhile the punching depth can be well controlled.

Owner:铜陵职业技术学院

An easy-to-clean food purification sink

ActiveCN113273706BEasy to cleanCleanup Coverage GuaranteeVegetable peelingFood treatmentWater flowMechanical engineering

The invention relates to the technical field of food purification, and discloses an easy-to-clean food purification water tank, which includes a water tank, a disinfection lamp is fixedly installed on the inner wall of the back of the water tank, and a vegetable dish composed of two left and right corresponding rectangular plates is inserted into the inner wall of the water tank The bottom of the vegetable storage column is fixedly connected with a filter screen, and the bottom of the inner wall on the left and right sides of the vegetable storage column is fixedly connected with several connecting plates at equal intervals. There is a water injection port on the right side of the water injection cylinder, and the inner wall of the water injection cylinder is inserted with an insert plate. Through the setting of the vegetable storage column, the vegetable storage column is cleaned by injecting water, and the power of the clean water injection is used to drive the vegetable storage column. The reciprocating shaking makes the bottom surface of the vegetable tray and the cleaning rod scrape each other, so as to achieve the function of automatically cleaning the vegetable tray carrying fruits and vegetables. Compared with manual cleaning, the cleaning range is guaranteed, and it has high cleaning efficiency and effect. benefit.

Owner:杭州温理科技有限公司

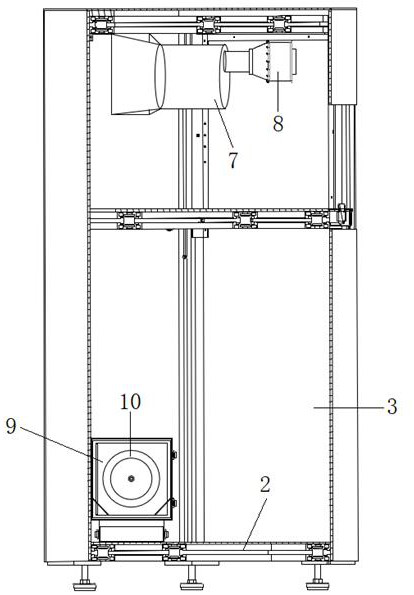

A self-dusting power cabinet with a resistant sound-absorbing structure

ActiveCN110932144BActively adjust cooling statusReduce noiseSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDust controlEngineering

The invention discloses a self-dusting power cabinet with a resistant and noise-absorbing structure, comprising: a power cabinet body, an air inlet is opened at the bottom of one side of the power cabinet body, and an air outlet is opened at the upper rear side of the power cabinet body. A resistance muffler is installed horizontally on the upper part of the power cabinet body. One end of the resistance muffler is sealed and connected to the air outlet through a wind cover, and the other end of the resistance muffler is sealed and connected to the speed-regulating fan through a rubber hose. The inner wall of the air inlet is installed and fixed on the The dust-absorbing bellows at the lower part of the profile skeleton, the dust-absorbing bellows are installed with a dust-absorbing roller through the rotation of the rotating shaft; the unified planning and design of noise reduction, heat dissipation, and dust removal are realized through the cooperation of the resistant muffler and the speed-regulating fan Using it can not only effectively adjust the heat dissipation state in the power cabinet, but also reduce the noise coming out of the power cabinet. The dust removal process is carried out from the source through the dust suction bellows to avoid the trouble of cleaning after dust enters the power cabinet.

Owner:浙江欣裕电子科技有限公司

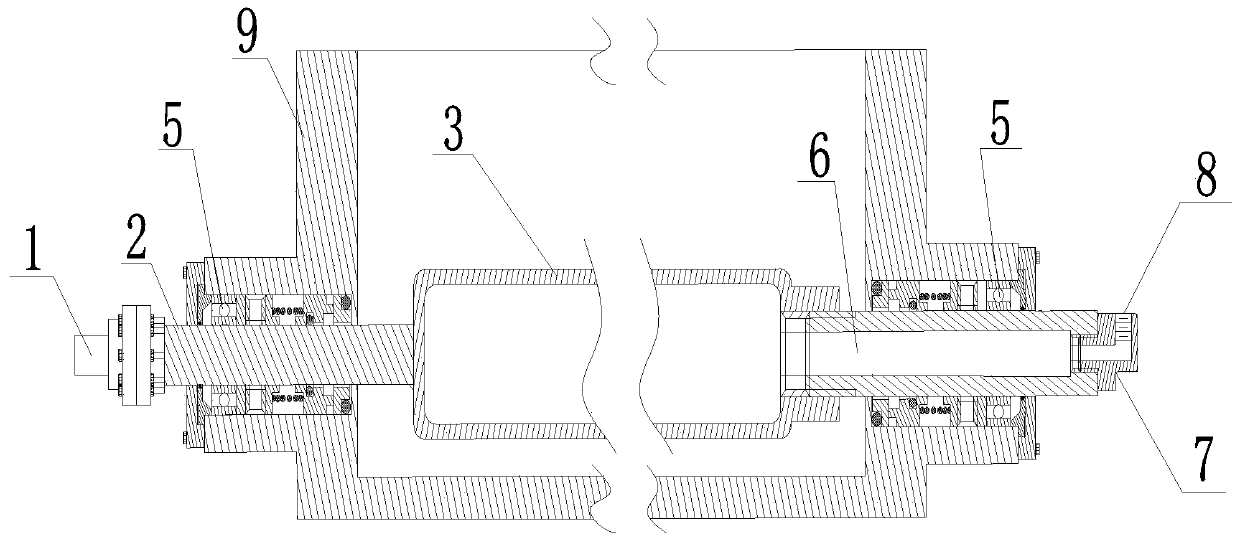

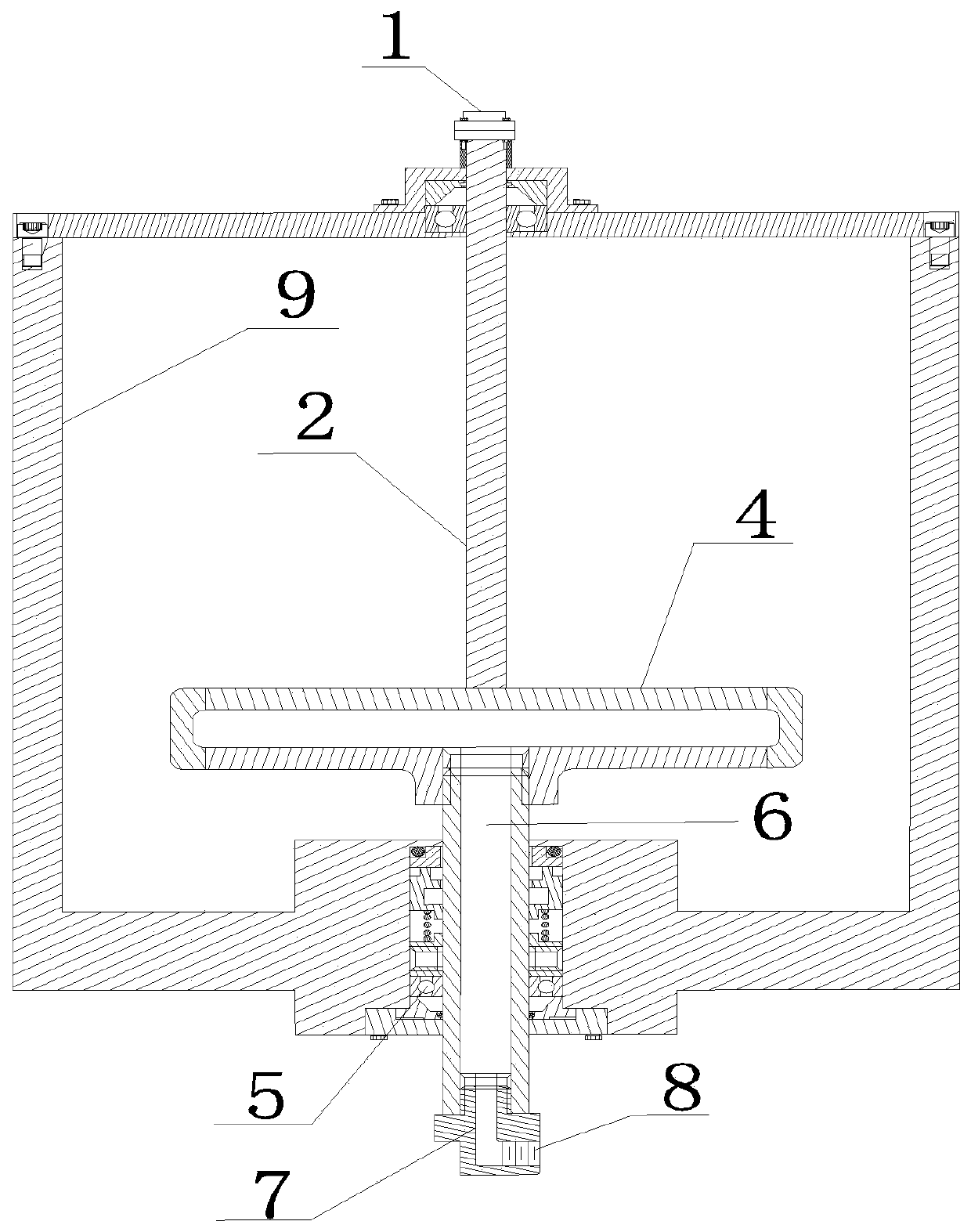

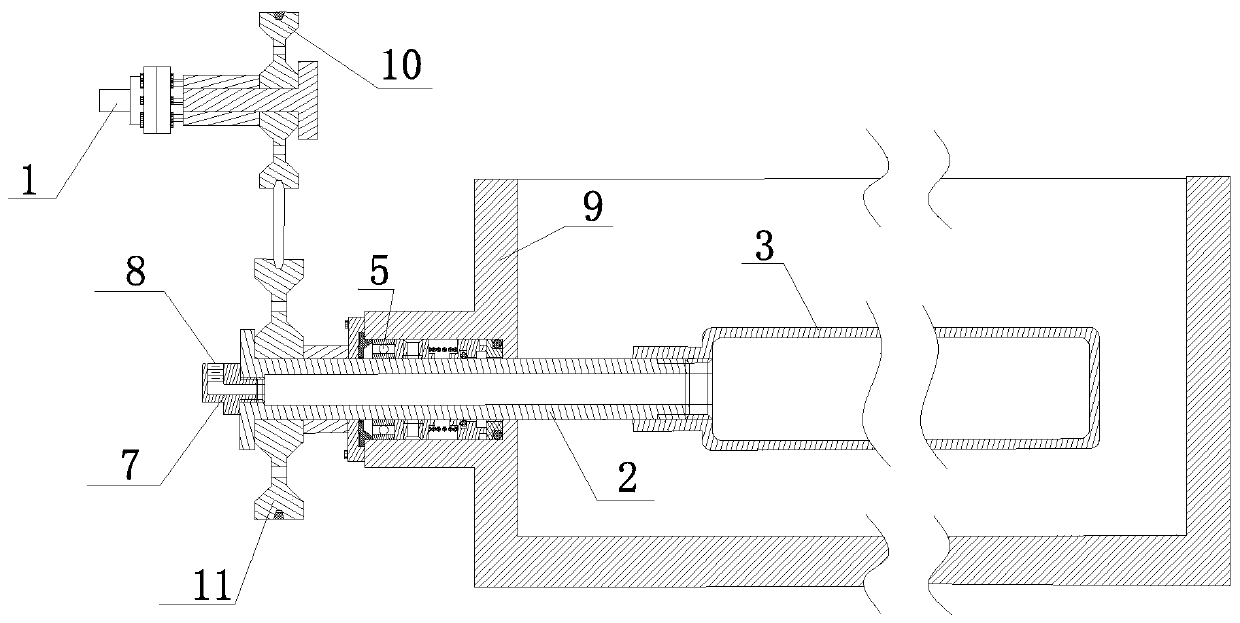

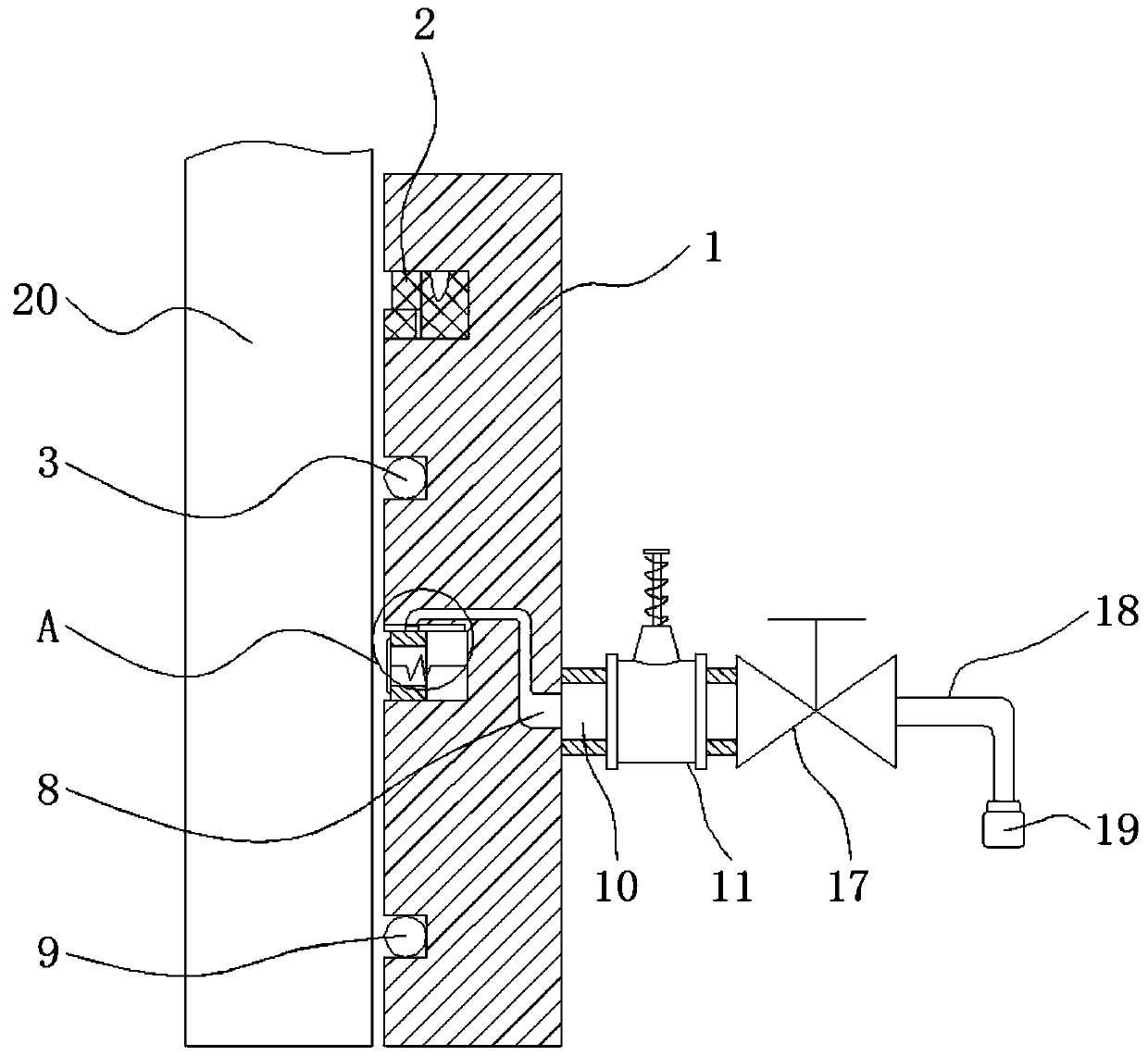

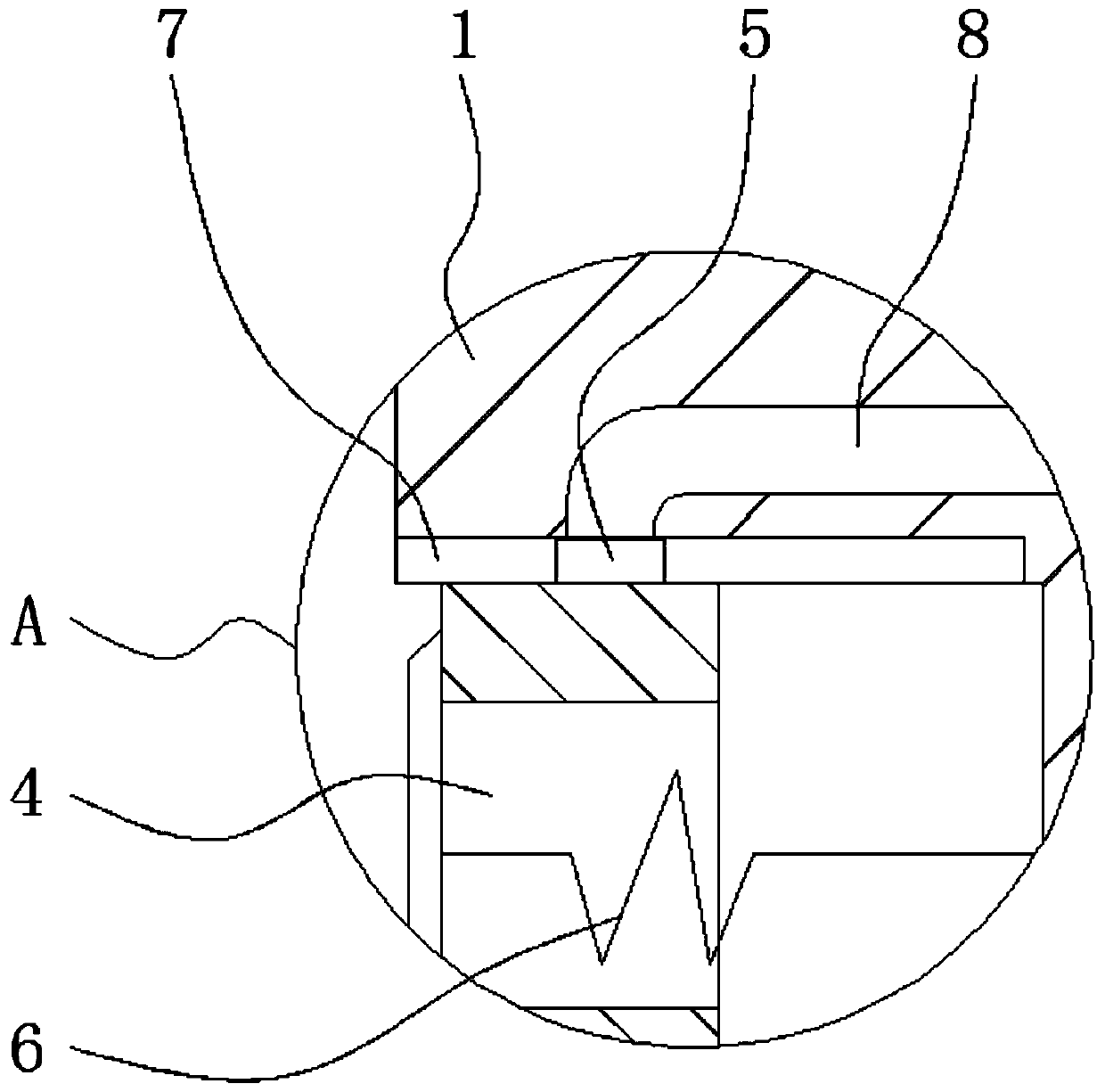

Sealing medium absorption compensation device

InactiveCN109780210APrevent leakageImprove absorption efficiencyEngine sealsAlarmsReciprocating motionSlide plate

The invention discloses a sealing medium absorption compensation device and relates to the technical field of sealing rings. The sealing medium absorption compensation device specifically comprises abase and a filter mechanism; a sealing ring is installed inside the upper portion of the left wall of the base; a movable head is arranged below a first pressure sensor; the outer wall of the movablehead is fixedly connected with a sliding plate; a spring is horizontally arranged inside the movable head; a through hole penetrates through the base; the first pressure sensor and the movable head are both disposed inside the left wall of the base; a second pressure sensor is installed inside the lower portion of the left wall of the base; the right wall of the base is fixedly provided with a connector; and the filter mechanism is installed at the port end of the connector. With the sealing medium absorption compensation device, the problem of leakage of a sealing medium caused by abrasion tothe sealing ring during reciprocating motion of a motive seal can be effectively solved, thus, the purpose of protecting the sealing ring is achieved, production loss is reduced, and the overall production can be carried out smoothly. Meanwhile, the device is relatively simple in structure and has good practicability.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Vertical heat pipe waste heat boiler for chemical flue gas

InactiveCN111396843AGuaranteed normal useEliminates the hassle of cleaningDispersed particle filtrationHollow article cleaningDrive motorFlue gas

The invention relates to the technical field of waste heat boiler equipment, and discloses a vertical heat pipe waste heat boiler for chemical flue gas. The vertical heat pipe waste heat boiler comprises a waste heat boiler body, a heating water tank and a chimney, a waste heat flue gas leading-in pipe is fixedly connected to the top end of the waste heat boiler body, and a partition plate is fixedly connected to the middle of the interior of the waste heat boiler body; a first dust filter screen is installed on the upper side in the partition plate, a sliding frame is slidably connected to one end of the partition plate, dust inlet grooves are formed in the two sides of the top end of the sliding frame, and a driving motor is fixedly installed in the middle of the top end of the sliding frame; and a fan blade is fixedly connected to the output end of the driving motor, the fan blade is rotationally installed in the middle of the sliding frame, and a mounting cylinder is fixedly connected to the middle of the bottom end of the sliding frame. The vertical heat pipe waste heat boiler for the chemical flue gas can be cleaned regularly, the waste heat boiler does not need to be shut down to clean dust, normal use of the waste heat boiler is guaranteed, the situation that the boiler is shut down frequently due to ash deposition and coking blockage is avoided, and economic losses canbe reduced in the cleaning process of the waste heat boiler.

Owner:NANJING CANUO ENERGY EQUIP

Coal grinding device with rotary discharging structure

The invention relates to a coal grinding device with a rotary discharging structure. The coal grinding device comprises a grinding device body, discharging boxes, stirring shafts and discharging pipes; a supporting plate is arranged on the upper part of the grinding device body, the bottom end of the inner side of the supporting plate is fixedly provided with first hydraulic cylinders, the lower parts of the first hydraulic cylinders are connected with connecting rods, motors are arranged below the connecting rods, rotating shafts are arranged at the bottom ends of the motors, and grinding discs are arranged below the rotating shafts; and a groove is inlaid in the grinding device body, wherein grinding boxes are arranged in the groove, handles are fixed on the outer surfaces of the grinding boxes, observation openings are inlaid in the upper sides and the lower sides of the handles, and the discharging boxes are arranged on the left sides and the right sides of the lower parts of the grinding boxes. The coal grinding device with the rotary blanking structure has the beneficial effects that coal can be well isolated through the grinding boxes, and therefore the coal can be separatedand ground.

Owner:陕西长青能源化工有限公司

Food purification water tank convenient to clean

ActiveCN113273706ACleanup Coverage GuaranteeImprove cleaning efficiencyVegetable peelingFood treatmentWater flowEnvironmental engineering

The invention relates to the technical field of food purification, and discloses a food purification water tank convenient to clean. The food purification water tank comprises a water tank body, wherein a disinfection lamp is fixedly arranged on the inner wall of the back surface of the water tank body; a vegetable containing fence consisting of two rectangular plates which correspond to each other left and right is sleeved with the inner wall of the water tank body; the bottom surface of the vegetable containing fence is fixedly connected with a filter sieve; the bottom ends of the inner walls of the left side and the right side of the vegetable containing fence are fixedly connected with a plurality of connecting plates at equal intervals; the top end of the right side surface of the water tank body is in a hollow state and is fixedly connected with a water injection cylinder with a hollow top surface; a water injection opening is formed in the right side surface of the water injection cylinder; and an inserting plate is sleeved with the inner wall of the water injection cylinder. Through the arrangement of the vegetable containing fence, the vegetable containing fence is cleaned by injecting water flow, and meanwhile, the vegetable containing fence is driven to shake in a reciprocating manner by utilizing the power of clean water injection, so that the bottom surface of the vegetable containing fence and a cleaning rod scrape each other, and the function of automatically cleaning the vegetable containing fence for bearing vegetables and fruits is achieved; and compared with manual cleaning, the cleaning range is guaranteed, and the food purification water tank has the advantages of high cleaning efficiency and effect.

Owner:杭州温理科技有限公司

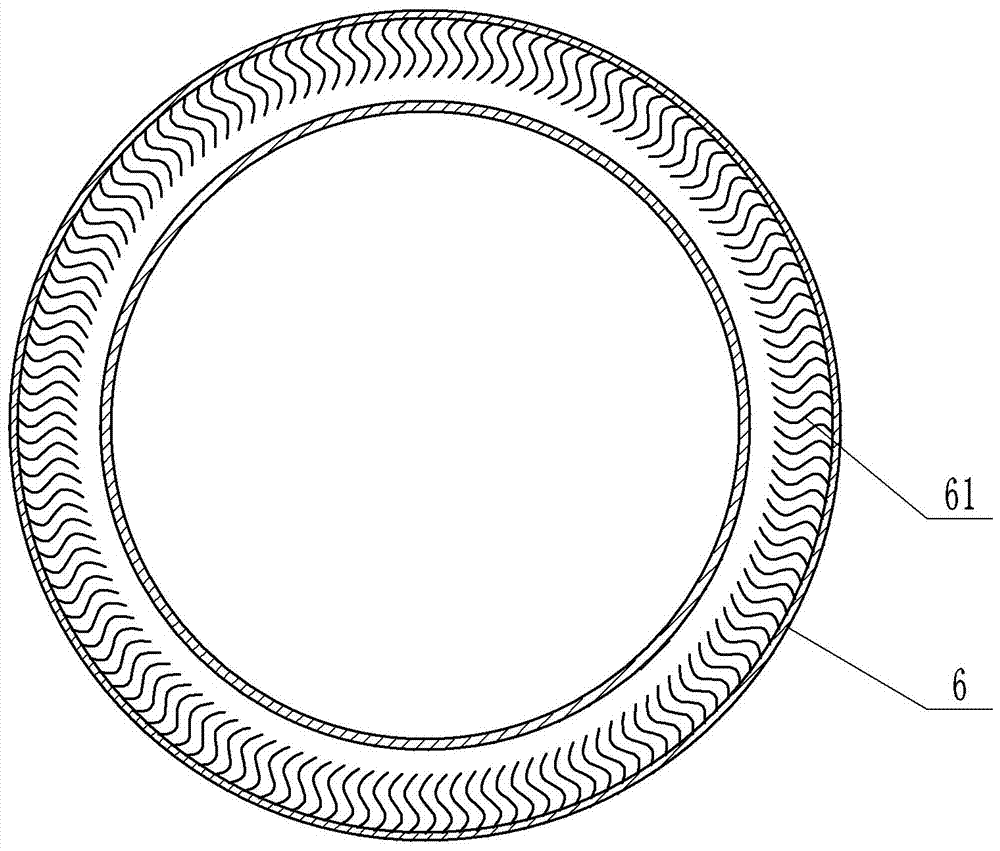

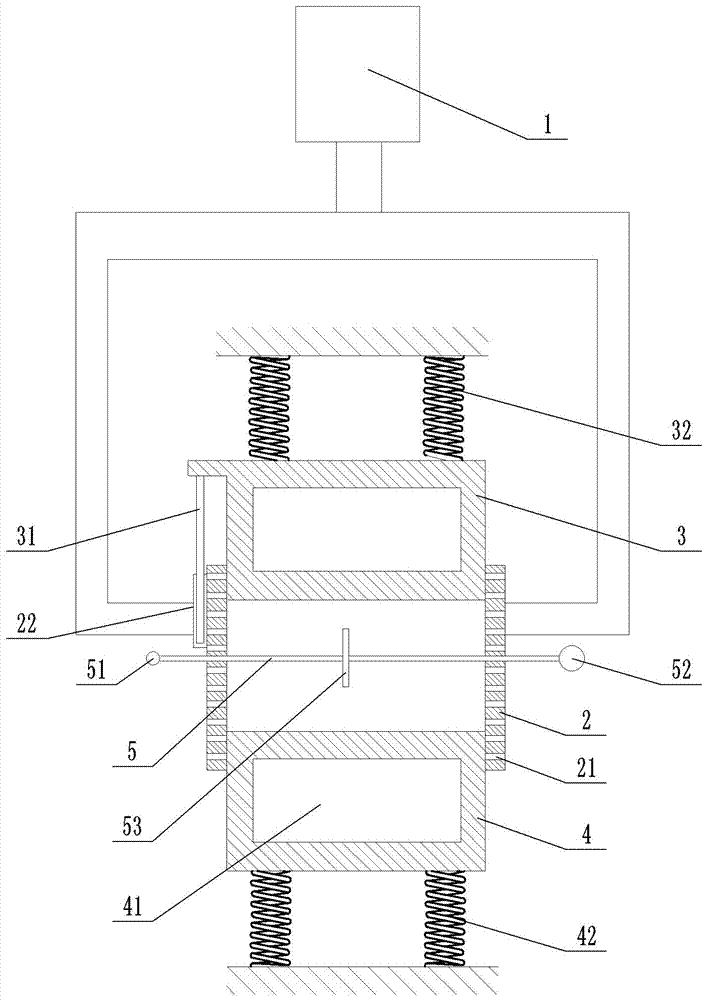

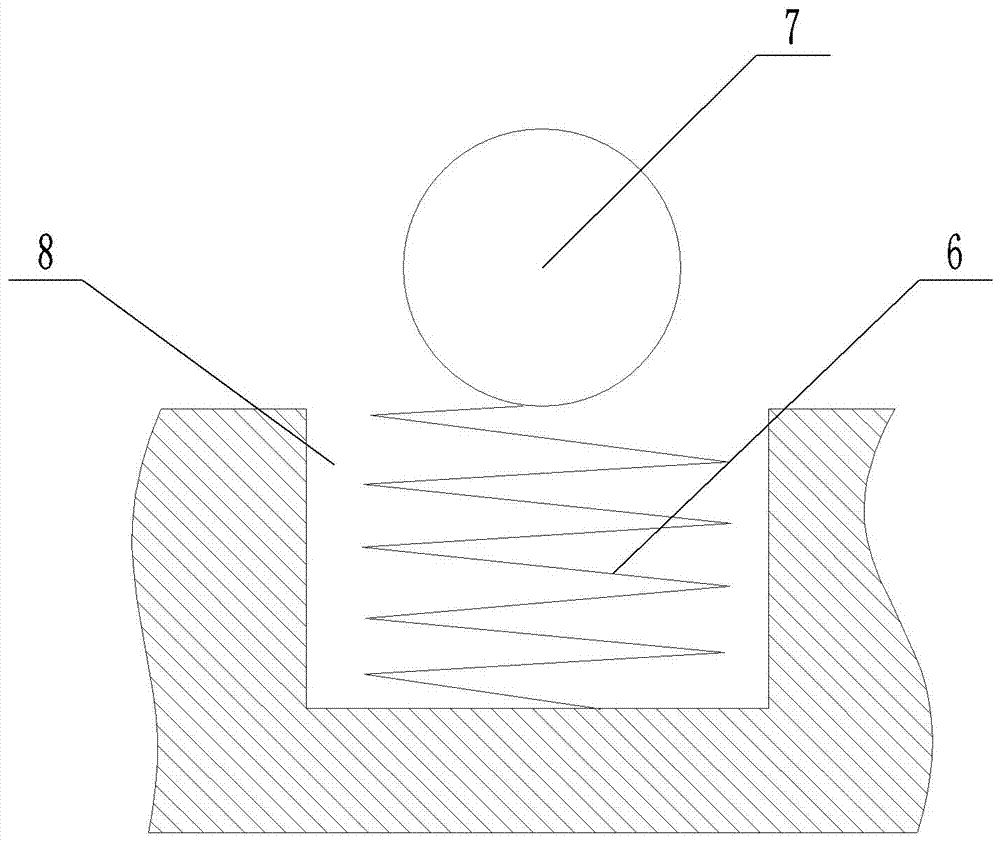

Cleaning-free intelligent heat dissipation ring main unit

ActiveCN113056131AAvoid overall overturningPlay a shock absorbing effectDispersed particle filtrationCasings/cabinets/drawers detailsLiquid cooling systemEngineering

The invention relates to the technical field of gas insulation ring main units, in particular to a cleaning-free intelligent heat dissipation ring main unit which comprises a rack; a heat dissipation control cabinet mounted on the rack; a ring main unit body which is mounted at the upper end of the heat dissipation control cabinet, wherein the bottom part of the ring main unit body is communicated with the heat dissipation control cabinet; a gas tank arranged in the ring main unit body, wherein a gap is reserved between the gas tank and the inner wall of the gas tank; elastic supporting devices, wherein the number of the elastic supporting devices is eight, one end of each elastic supporting device is connected with the first corner cut of the ring main unit body, and the other end of each elastic supporting device is connected with the second corner cut of the gas tank; a liquid cooling system arranged in the heat dissipation control cabinet; an air cooling system installed in the heat dissipation control cabinet, wherein the working end of the air cooling system is arranged towards the elastic supporting device; and a filtering assembly arranged on a passage of the liquid cooling system. The cleaning-free intelligent heat dissipation ring main unit has good self-cleaning capability, is free of cleaning, has a stable protection effect on the gas tank, and has a good heat dissipation effect.

Owner:CHONGQING BOSEN ELECTRONIC GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com