Micro bubble generation method and micro bubble generator

A micro-bubble and generator technology, applied in the field of water treatment, can solve the problems of high bubble density, low energy consumption, microbial clogging, etc., and achieve the effects of meeting process needs, low operating costs, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

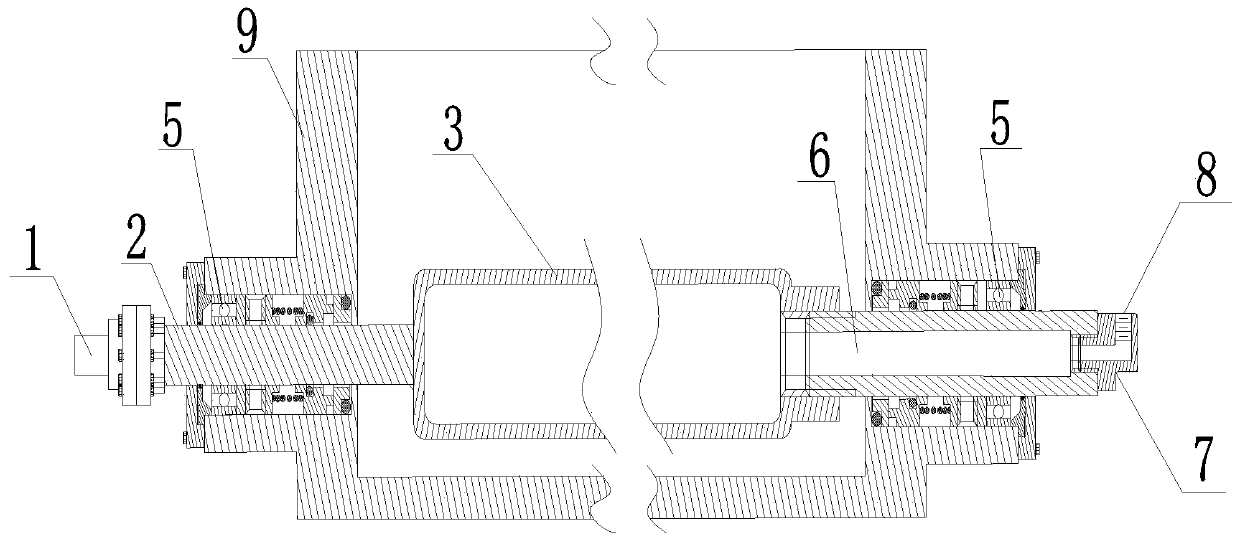

[0035] Such as figure 1 as well as Figure 5 As shown, the microbubble generator provided by the present invention includes a transmission shaft 2, a rotary joint 7, a sealing device, and a cylindrical microporous tube 3 that communicates with the rotary joint 7 and has one end closed. In this embodiment, the transmission shaft 2 is a solid shaft, and the transmission shaft 2 is connected to the sealing end of the microporous tube 3 by means of clamps, threads or welding. One end of the shaft 6 is connected, the other end of the hollow shaft is connected with the rotary end of the rotary joint 7 in the form of a thread opening, and the fixed end of the rotary joint 7 is connected with the air pump. Transmission shaft 2 is installed horizontally. The power comes from the motor 12, and the motor 12 is fixed on the casing 9. The power output shaft 1 of the motor 12 is connected with the solid transmission shaft 2 through a coupling, and the other end of the transmission shaft ...

Embodiment 2

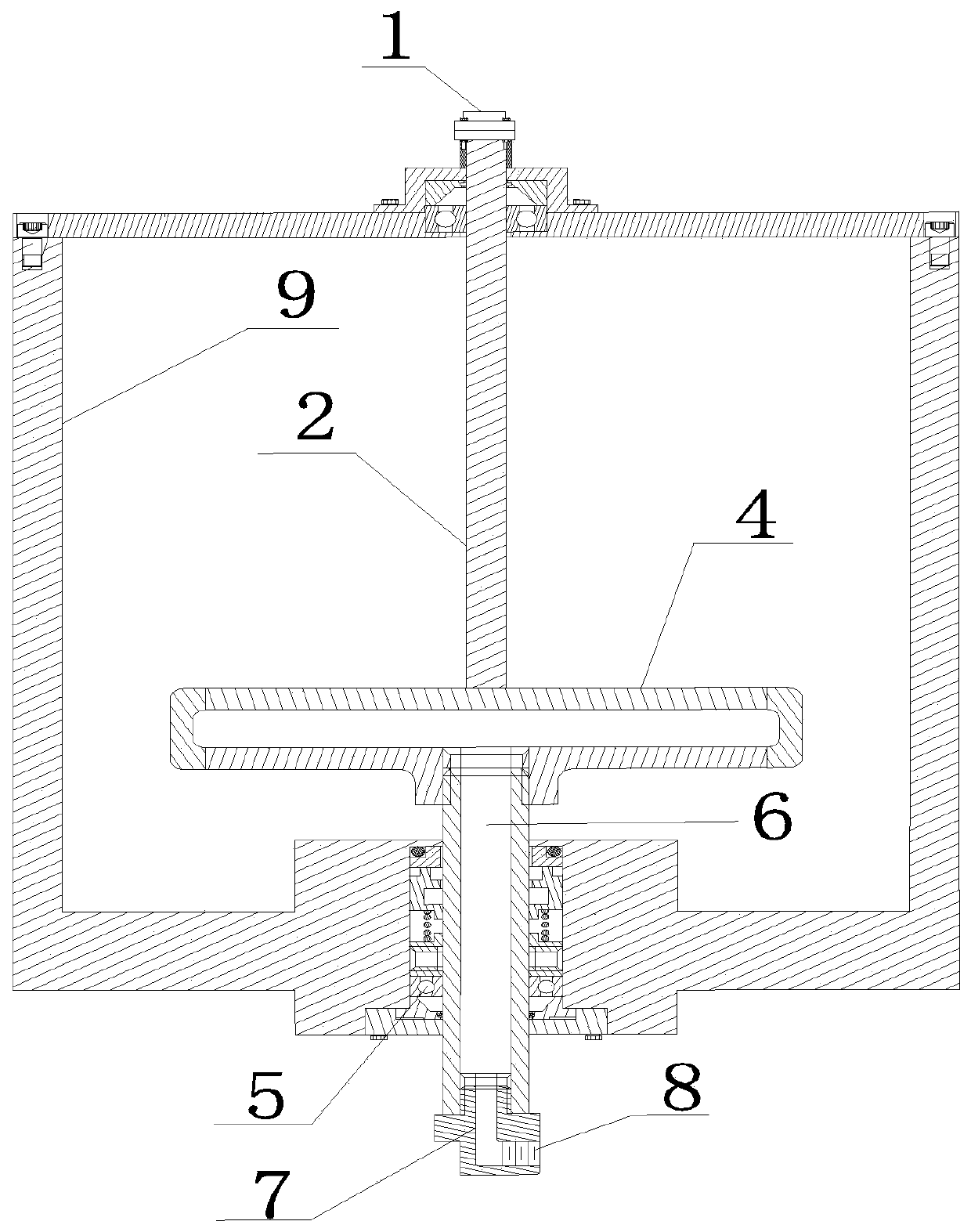

[0037] Such as figure 2 As shown, the microbubble generator provided by the present invention mainly includes a transmission shaft 2, a rotary joint 7, a sealing device, and a disk-shaped microporous disk 4 that is connected to the rotary joint 7 and has one end closed. In this embodiment, the transmission shaft 2 is a solid shaft, and the transmission shaft 2 is connected to the sealing end of the microporous disc 4 by means of clamps, threads or welding. The pipe 6 is connected, and the other end of the hollow pipe 6 is connected with the rotary joint 7 through threads, and the fixed end of the rotary joint 7 is connected with the air pump. Transmission shaft 2 is installed vertically. The power comes from the motor 12, and the motor 12 is fixed on the casing 9. The power output shaft 1 of the motor 12 is connected with the solid transmission shaft 2 through a coupling, and the other end of the transmission shaft 2 is connected with the closed end of the micro-hole disc 4...

Embodiment 3

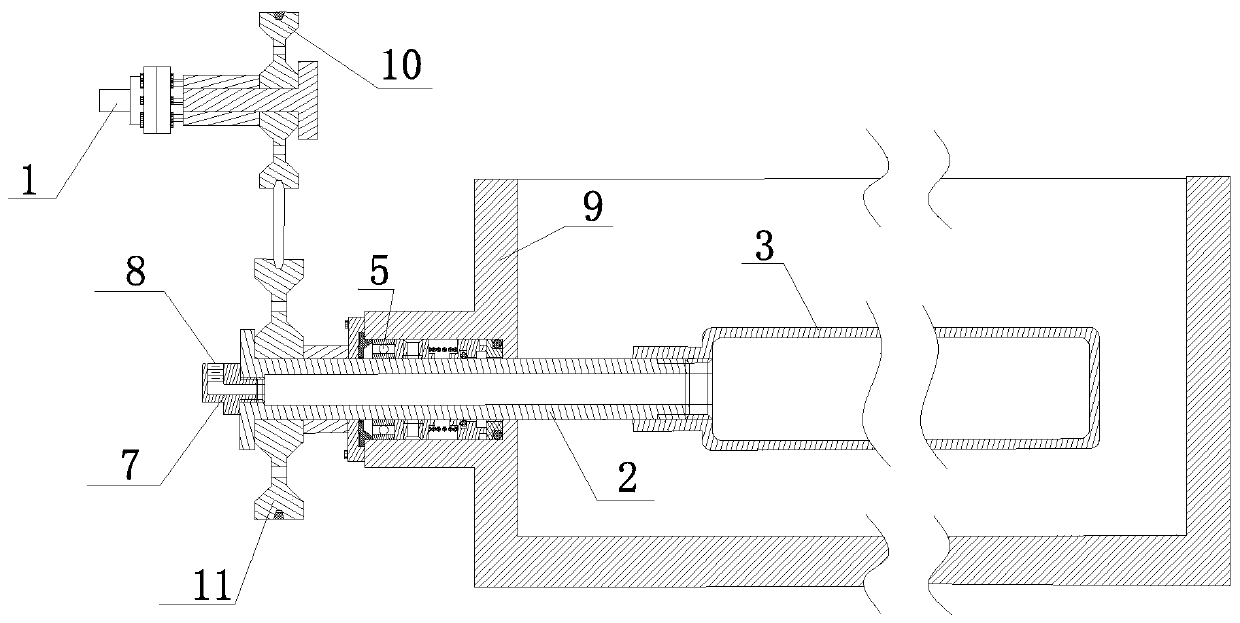

[0039] Such as image 3 As shown, the microbubble generator provided by the present invention mainly includes a transmission shaft 2, a rotary joint 7, a sealing device, and a cylindrical microporous tube 3 that communicates with the hollow tube 6 and has one end closed. In this embodiment, the transmission shaft 2 is a hollow shaft, and the part where the hollow shaft passes through the box body 9 adopts a mechanical seal; the power output shaft 1 drives the transmission shaft 2 through the coupling, the driving wheel 10 and the driven wheel 11 in turn; the transmission shaft 2 is in the One end in the casing is connected with the opening end of the microporous tube 3, and one end of the transmission shaft 2 outside the casing is connected with the rotating end of the rotary joint 7, and the fixed end of the rotary joint 7 is connected with compressed air; in order to make the microporous tube 3 The rotation of the drive shaft is more stable, and the transmission shaft 2 can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com