Salted vegetable dewatering device

A technology of dehydration device and dehydration hole, which is applied in the direction of food science, etc., can solve the problem of troublesome unloading, and achieve the effect of complete unloading, convenient unloading, and prevention of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

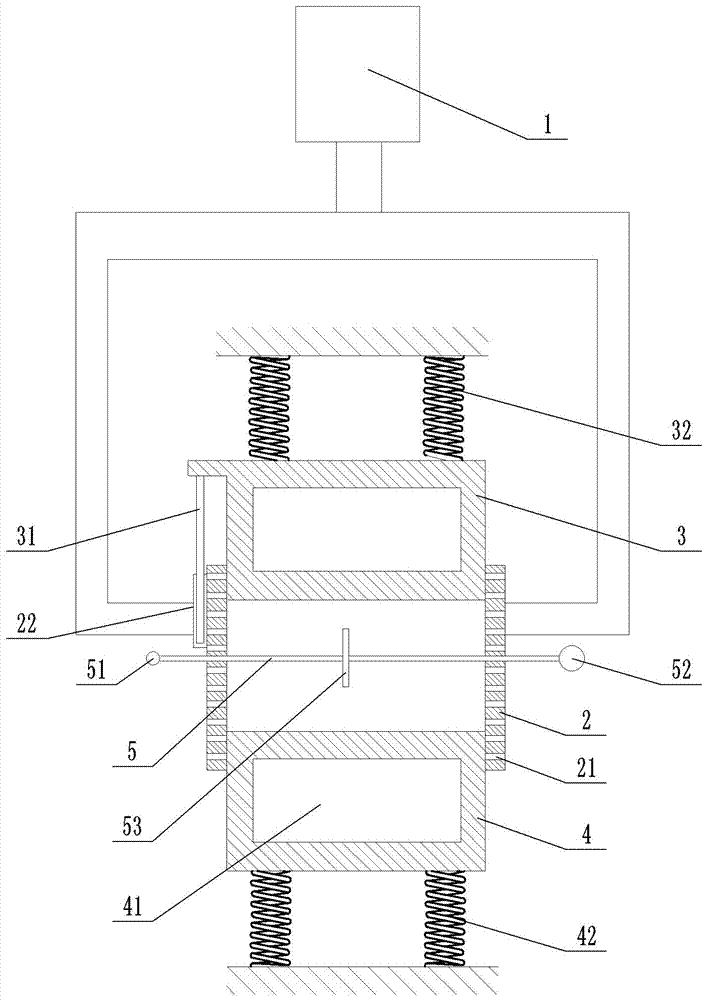

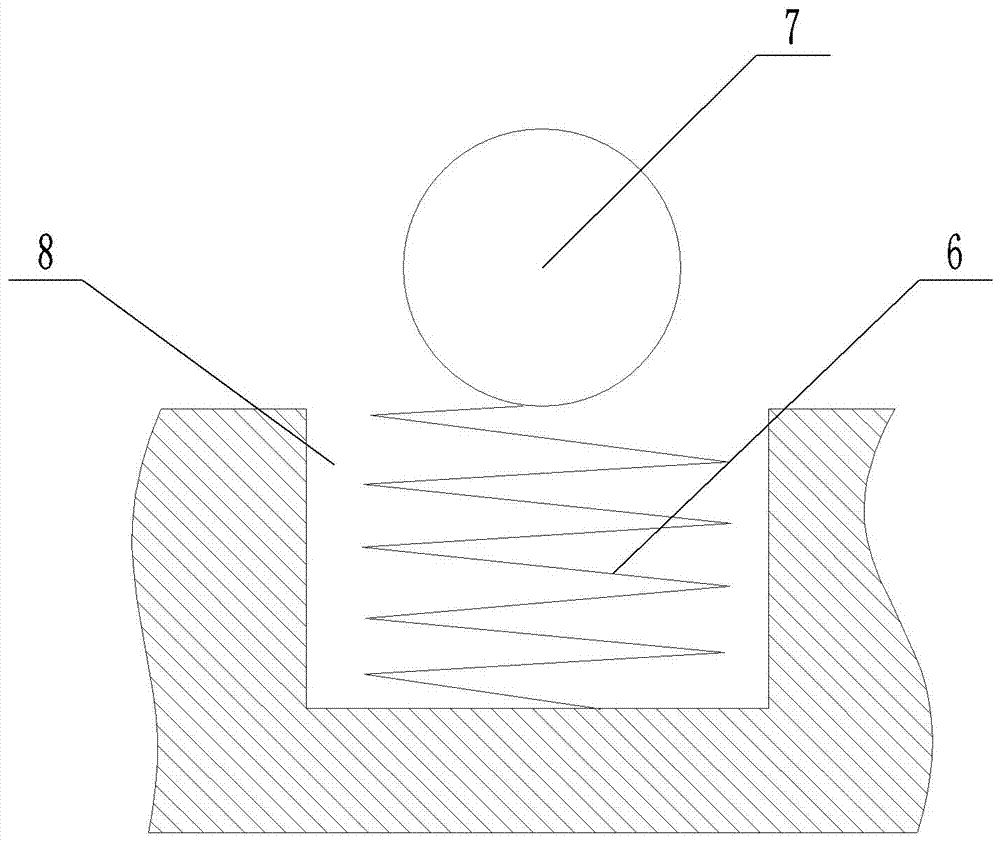

[0019] The reference signs in the accompanying drawings of the description include: motor 1, circular cylinder 2, dehydration hole 21, guide groove 22, upper pressing block 3, guide rod 31, tension spring 32, lower pressing block 4, cavity 41, supporting spring 42, slide bar 5, first ball 51, second ball 52, pressing plate 53, spring 6, push ball 7, groove 8.

[0020] like figure 1 , figure 2 As shown, the pickle dehydration device includes a frame, an upper briquetting block 3, a lower briquetting block 4, an annular cylinder 2 and a motor 1, the motor 1 is fixed on the frame, and the motor 1 is used to drive the annular cylinder 2 to rotate. The frame is provided with chutes distributed along the height direction, and the side walls of the upper pressing block 3 and the lower pressing block 4 are all provided with protrusions matched with the chute. The inside of up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com