Pickled vegetable dehydrating and discharging device

A technology of unloading device and pickles, which is applied in the direction of food science, etc., can solve problems such as troublesome unloading, and achieve the effect of complete unloading and convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

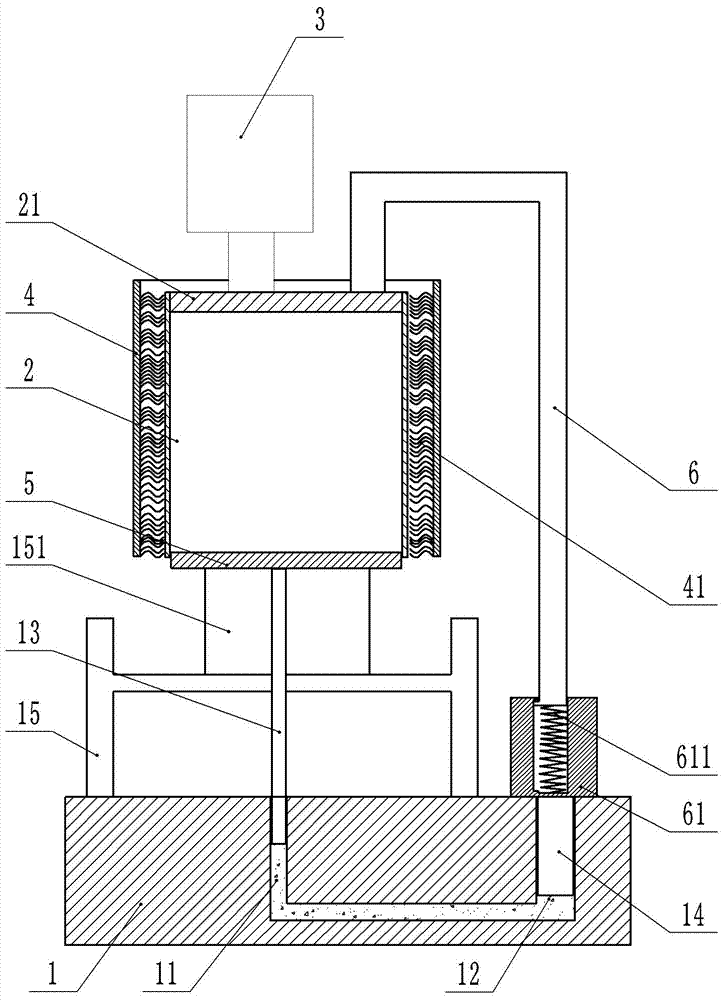

[0023] Such as figure 1 As shown, the pickle dehydration and unloading device includes a workbench 1, a material plate 5, a scrubbing cylinder 4, a dehydration cylinder 2 and a hydraulic cylinder 3 for driving the dehydration cylinder 2 to move up and down, and the dehydration cylinder 2 is positioned above the material plate 5. The plate 5 is slidingly connected with the dehydration cylinder 2 and the material plate 5 can be attached to the inner wall of the dehydration cylinder 2 . The scrubbing tube 4 is arranged around the outer wall of the dehydrating tube 2, and the inner wall of the scrubbing tube 4 is fixed with bristles 41 that are against the outer wall of the dehydrating tube 2. Moving back and forth on the wall, part of the bristles 41 can stretch into the water outlet hole, and the pickles that block the water outlet hole will be squeezed back in the dehydration cylinder 2 to prevent the water outlet hole from being blocked. The lower end of the dehydration cylin...

Embodiment 2

[0027] The difference between Embodiment 2 and Embodiment 1 is that one side of the material plate 5 is hinged on the protruding portion 151 , and the material plate 5 is inclined to the other side under the condition of no external force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com