Waveform conveyor belt with flanges

A technology of corrugated sidewall and conveyor belt, applied in the direction of conveyor, transportation and packaging, can solve the problems of difficult unloading, cleaning and slippage of materials, and achieve the effect of convenient and thorough unloading, prevention of jamming, and smooth transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

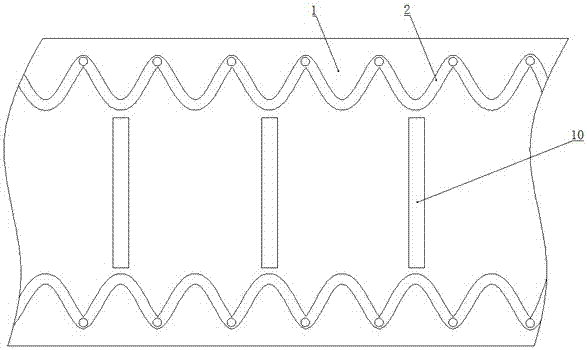

[0017] exist figure 1 , figure 2 Among them, a conveyor belt with corrugated sidewalls includes a base belt 1 , two corrugated sidewalls 2 and several transverse partitions 10 .

[0018] Such as figure 2 As shown, the corrugated ribs 2 are symmetrically arranged on both sides of the outer end surface of the base belt 1 to play the role of retaining material; the transverse partitions 10 are fixed on the base band 1 at intervals, and the transverse diaphragms 10 are perpendicular to the corrugated ribs 2, and the height is the same as that of the corrugated ribs 2. The corrugated ribs 2 are equal, and the transverse partition 10 ensures that the material can be continuously conveyed at any inclination angle of 0-90 degrees.

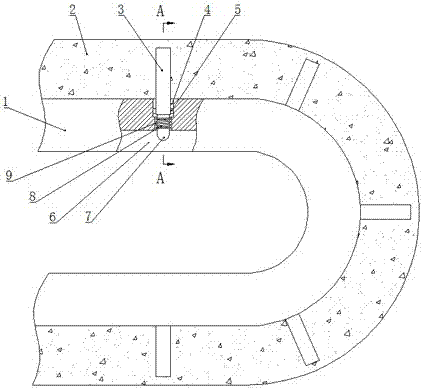

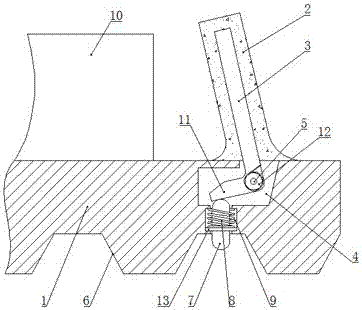

[0019] exist figure 1 , image 3 Among them, several transmission grooves 6 are provided on the inner end surface of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com