Film-coated precise ink-jet structure

A coating and inkjet technology, applied in the direction of spraying devices, etc., can solve the problems of reduced production and processing efficiency, uneven spraying, waste of ink, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

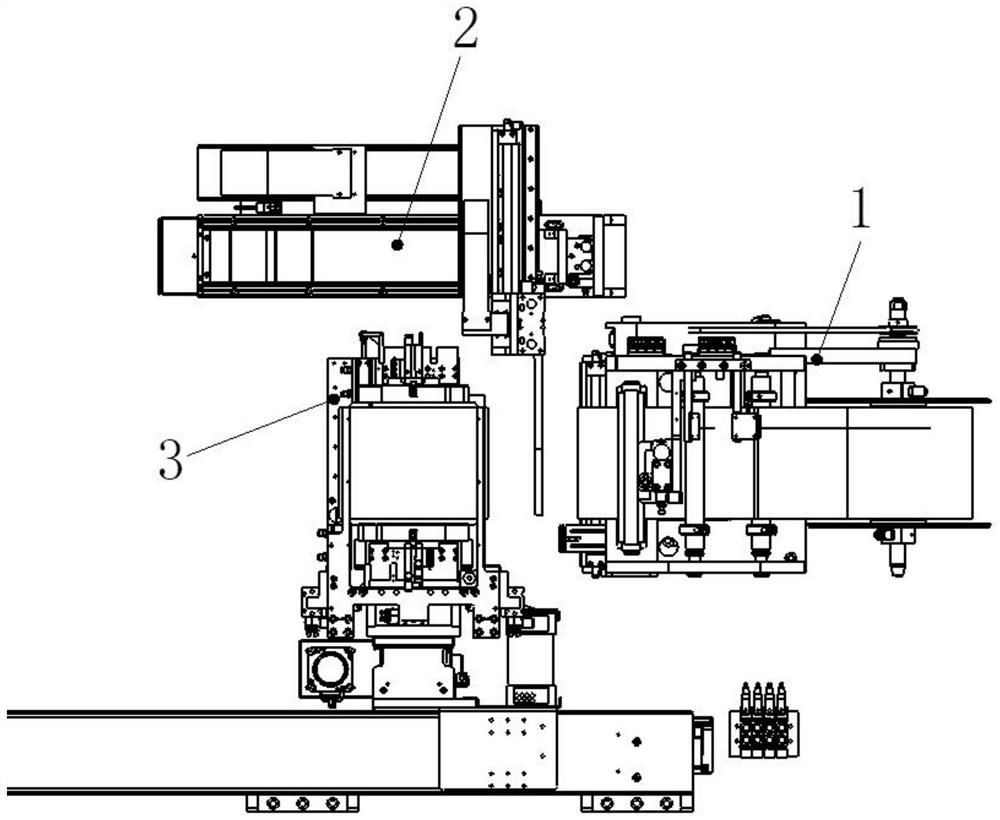

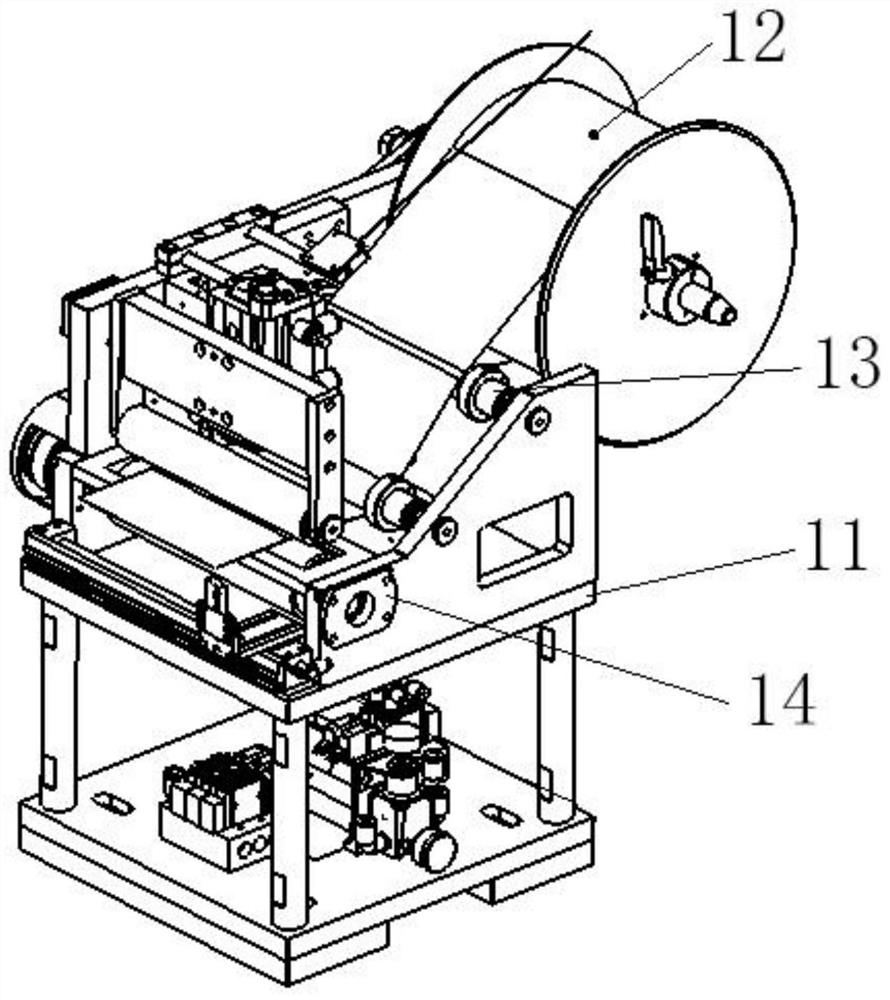

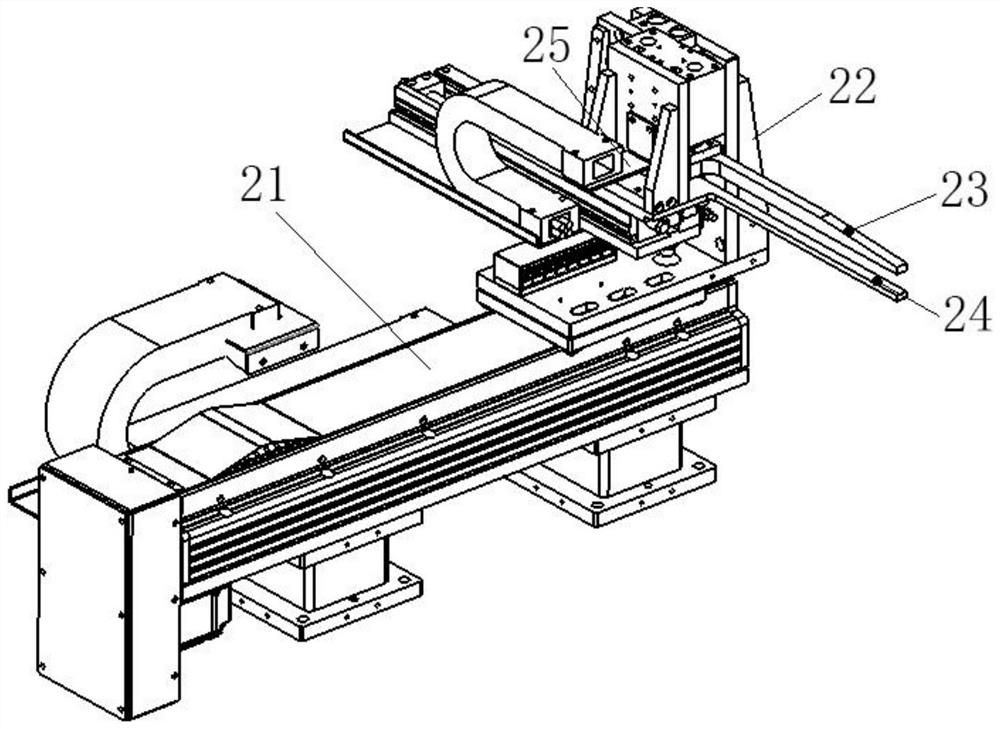

[0029] like figure 1 As shown, the embodiment provides a film-coated precision inkjet structure, including a film supply mechanism 1, a film pulling mechanism 2, a stretch film mechanism 3, a film locking mechanism and an inkjet mechanism arranged in sequence. The film feeding mechanism 1 is used for storing and outputting the film. The film pulling mechanism 2 is used to pull the film from the film supply mechanism 1 to the stretch film mechanism 3 . The stretch film mechanism 3 is used to straighten the film pulled out by the film pulling mechanism 2 . The film locking mechanism is used to press the film onto the product. The inkjet mechanism sprays the ink onto the finished product.

[0030] The lens 6 that needs to be sprayed is placed on the film locking mechanism, and the film supply mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com