Rapid mixing device for two-component chemical reagent

A technology of chemical reagents and mixing equipment, which is applied in the direction of mixers with rotating containers, mixers, chemical instruments and methods, etc., which can solve the problems of poor mixing effect, reagent splashing, and difficulty in fully mixing reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

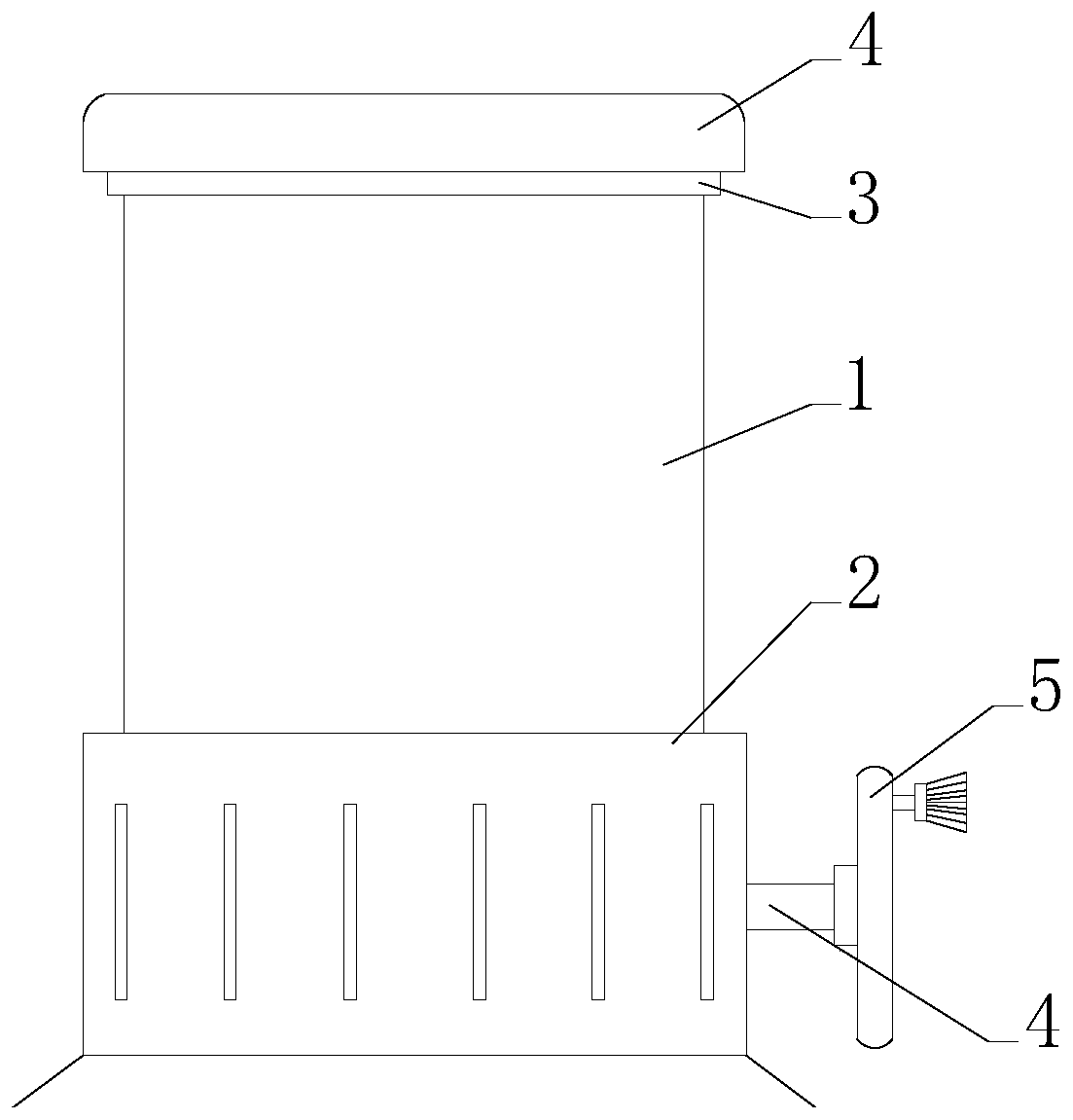

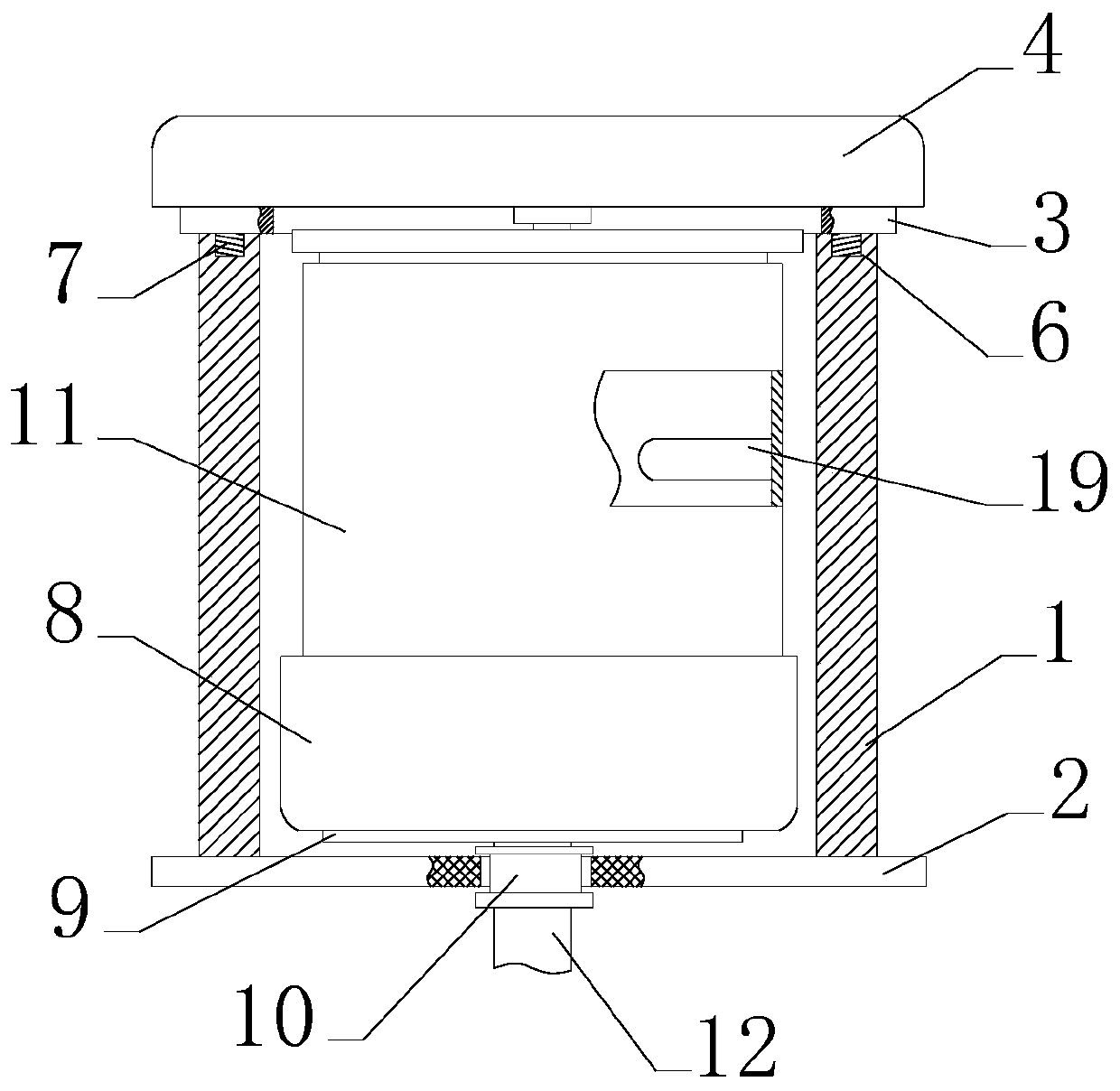

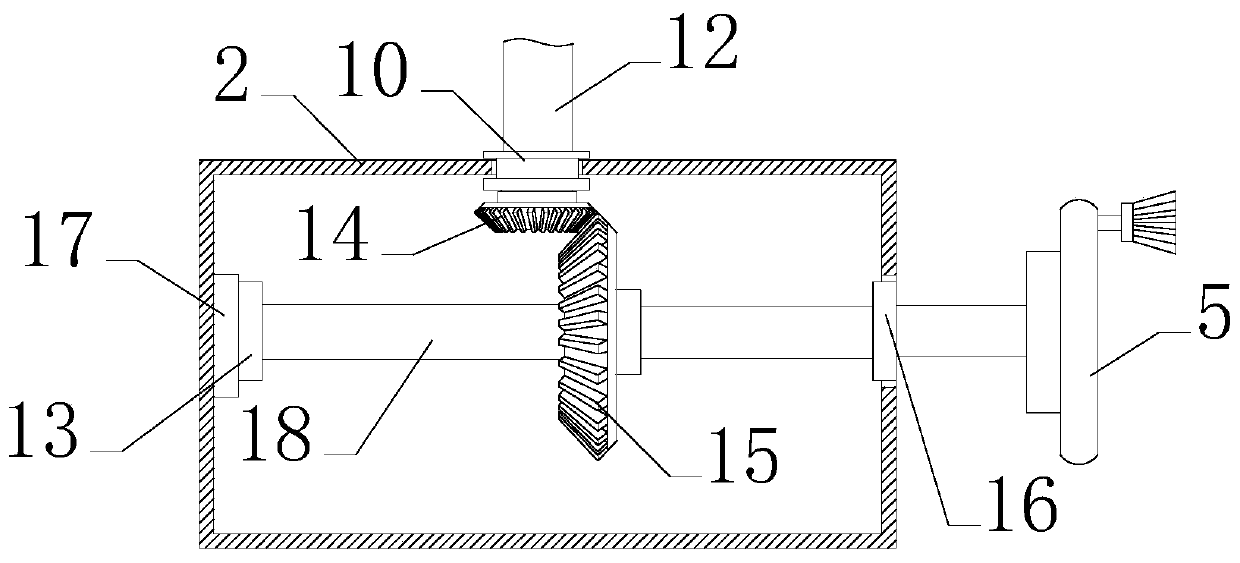

[0031] see Figure 1-4 , a rapid mixing device for two-component chemical reagents, comprising a case 1 and a reaction vessel cover 8, the case 1 is fixedly connected to the upper end of the base 2, the case 1 is fixedly equipped with a lower cover 3, the The upper cover 4 is threadedly installed on the lower cover 3, and the lower end of the reaction vessel cover 8 is fixedly connected with a tray 9, and the tray 9 is fixedly connected with a support 12, and the support 12 is rotatably sleeved with a sleeve 10. The sleeve 10 is fixedly inserted on the base 2, and the second bevel gear 14 is fixedly connected to the pillar 12, and the second bevel gear 14 is meshed with the first bevel gear 15, and the first bevel gear 15 is fixedly sleeved on the rotating column 18, one end of the rotating column 18 is fixedly plugged into the inner ring of the second bearing 13, the second bearing 13 is fixedly installed in the base 2, and the other end of the rotating column 18 is fixed In...

Embodiment 2

[0039]A rapid mixing device for two-component chemical reagents, comprising a case 1 and a reaction vessel cover 8, the case 1 is fixedly connected to the upper end of the base 2, the case 1 is fixedly equipped with a lower cover 3, the lower The upper cover 4 is threadedly installed on the cover 3, and the lower end of the reaction vessel cover 8 is fixedly connected with a tray 9, and the tray 9 is fixedly connected with a support 12, and a sleeve 10 is rotatably sleeved on the support 12. The barrel 10 is fixedly inserted on the base 2, and the second bevel gear 14 is fixedly connected to the pillar 12, and the second bevel gear 14 is meshed with the first bevel gear 15, and the first bevel gear 15 Fixedly socketed on the rotating column 18, one end of the rotating column 18 is fixedly inserted into the inner ring of the second bearing 13, the second bearing 13 is fixedly installed in the base 2, and the other end of the rotating column 18 is fixedly inserted into the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com