Energy-saving process for producing melamine

A technology for melamine and production process, which is applied in the field of energy-saving melamine production process, can solve the problems affecting the operation period of the device, the temperature difference between liquid and urine is large, easy to block or form walls, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

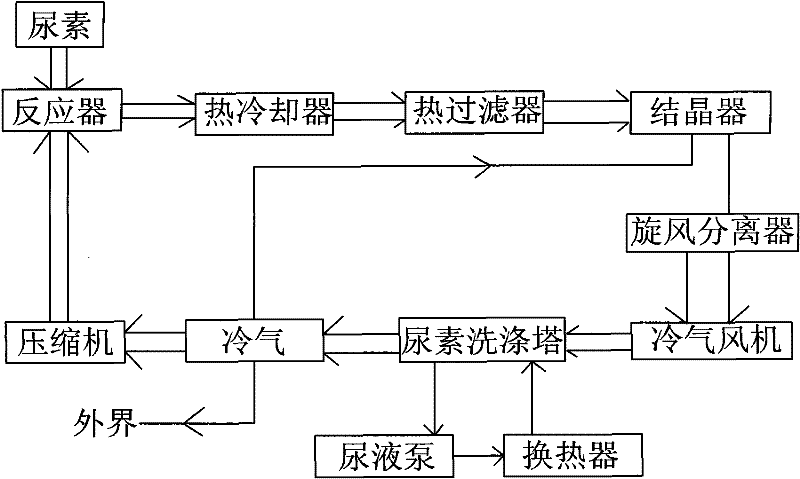

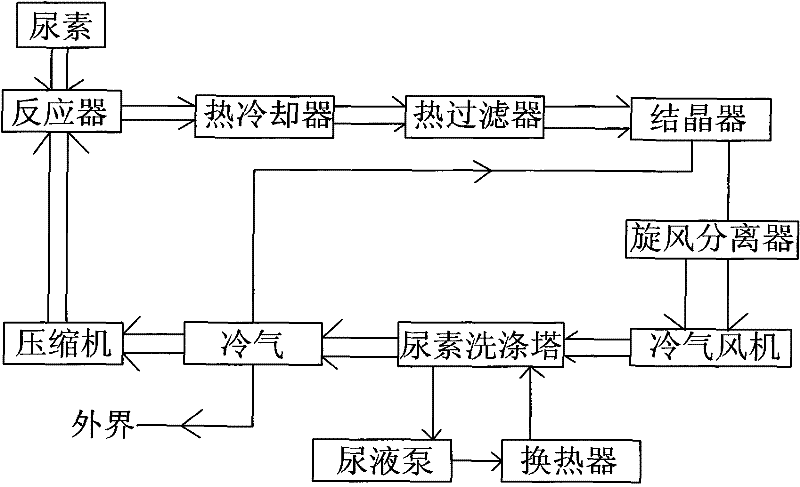

Image

Examples

Embodiment 1

[0010] Example 1: Using urea as a raw material, in a reactor, through the catalytic action of a catalyst, melamine, ammonia and carbon dioxide are reacted at 350°C and a pressure of 0.8MPa, and the material gas coming out of the reactor enters a hot gas cooler, and the cooled The hot process gas enters the filter for filtration, the filtered process gas containing melamine enters the crystallizer, the crystallized melamine enters the cyclone separator, and the separated solid melamine is sent to the bin for packaging, and the gas from the cyclone separator enters the heat exchange The device uses water to cool the gas containing ammonia and carbon dioxide at 200°C to 135°C, then enters the liquid urine scrubber to purify the process gas, and the purified and absorbed gas passes through the separator to separate the liquid urine droplets entrained in the gas. The separated gas is divided into three paths: one path is compressed by a compressor and enters the reactor, one path is...

Embodiment 2

[0011] Example 2: Using urea as a raw material, in the reactor through the catalysis of the catalyst, melamine, ammonia and carbon dioxide are reacted at 380°C and 1MPa pressure, and the material gas coming out of the reactor enters the hot gas cooler, and the cooled heat The process gas enters the filter for filtration, the filtered process gas containing melamine enters the crystallizer, the crystallized melamine enters the cyclone separator, the separated solid melamine is sent to the bin for packaging, and the gas from the cyclone separator enters the heat exchanger , the gas containing ammonia and carbon dioxide at 210°C is cooled to 140°C by water, and then enters the liquid urine washing tower to purify the process gas, and the purified and absorbed gas passes through the separator to separate the liquid urine droplets entrained in the gas, and separates The final gas is divided into three routes: one is compressed by a compressor and enters the reactor, the other is boo...

Embodiment 3

[0012] Example 3: Using urea as a raw material, in the reactor through the catalysis of the catalyst, melamine, ammonia and carbon dioxide are reacted at 400 ° C and 1.2 MPa pressure, and the material gas coming out of the reactor enters the hot gas cooler, and the cooled The hot process gas enters the filter for filtration, the filtered process gas containing melamine enters the crystallizer, the crystallized melamine enters the cyclone separator, and the separated solid melamine is sent to the bin for packaging, and the gas from the cyclone separator enters the heat exchange The gas containing ammonia and carbon dioxide at 210°C is cooled down to 140°C by water, and then enters the liquid urine washing tower to purify the process gas, and the purified and absorbed gas passes through the separator to separate the liquid urine droplets entrained in the gas. The separated gas is divided into three paths: one path is compressed by a compressor and enters the reactor, one path is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com