Self-cleaning smoke exhaust ventilator

A range hood, self-cleaning technology, applied in the direction of removing oil fume, household heating, lighting and heating equipment, etc., can solve the problems of complex structure, large volume, etc., achieve simple and compact structure, automatic cleaning filter, avoid cleaning the troublesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

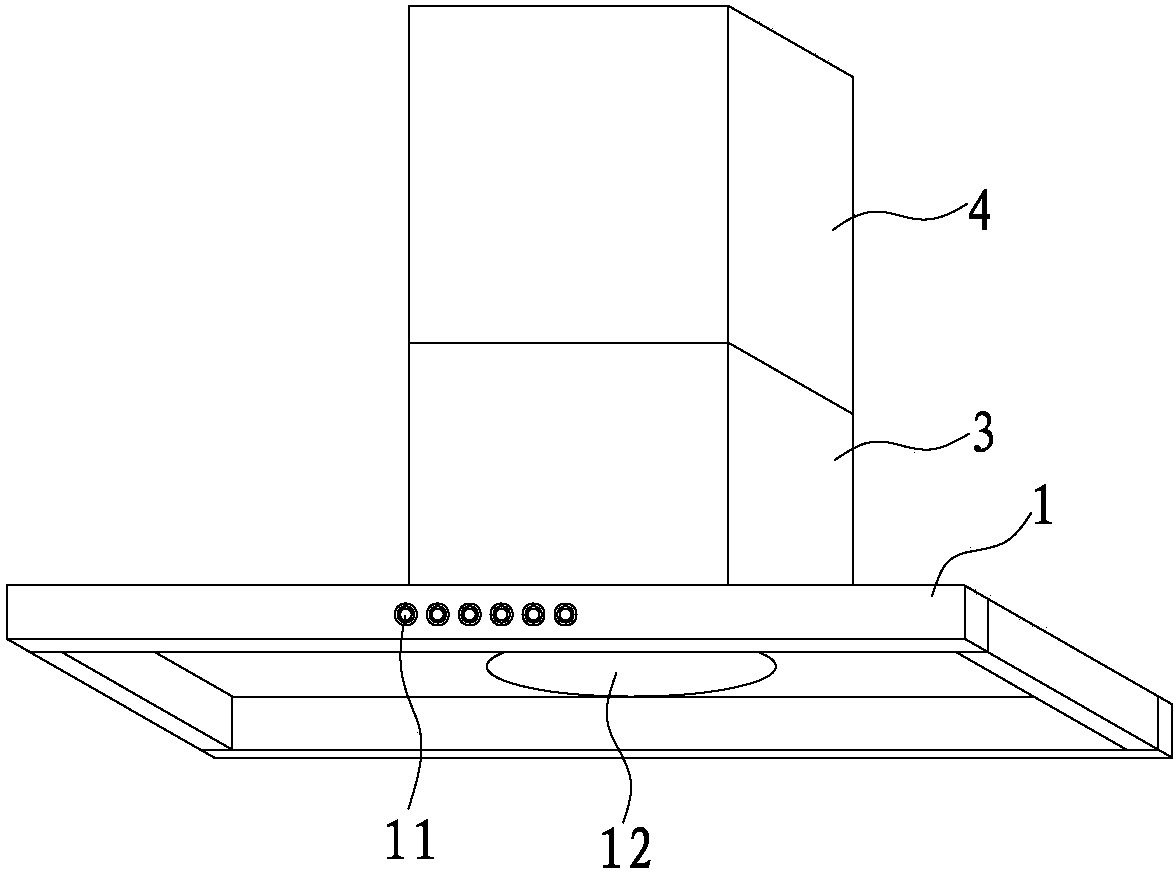

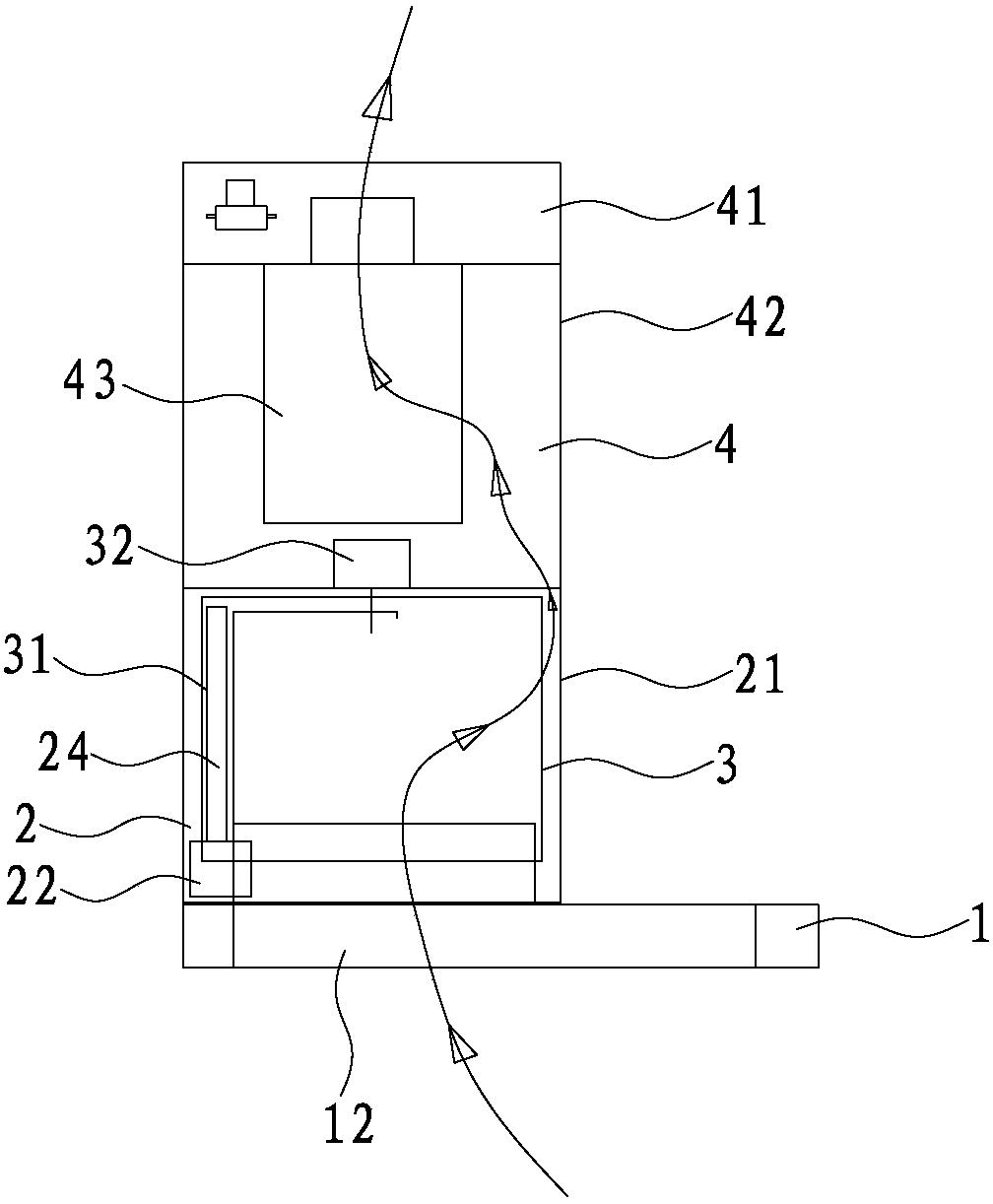

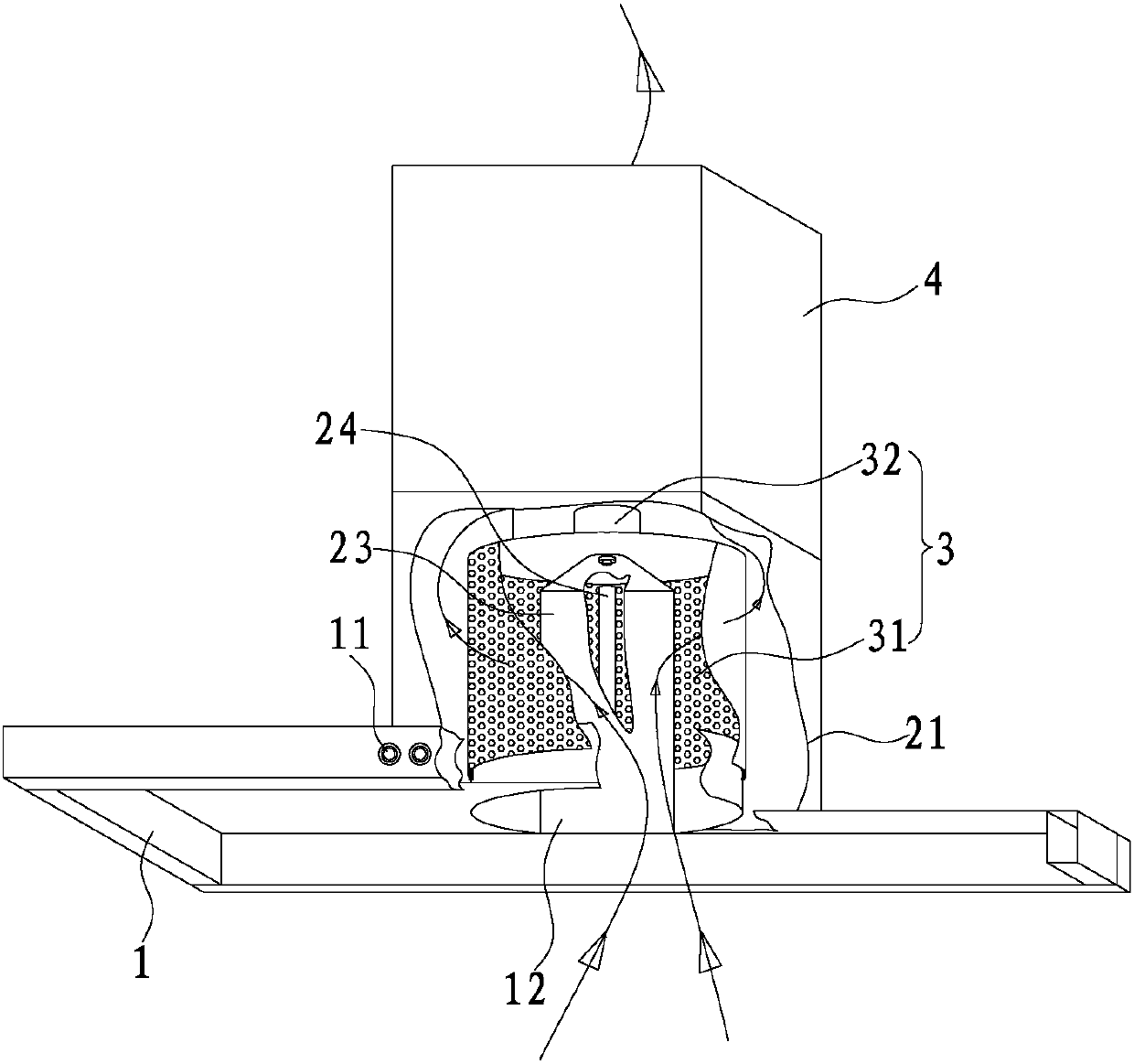

[0020] Such as Figure 1 to Figure 5 As shown, the present invention discloses a self-cleaning range hood, which includes a suction hood 1, a cleaning tank unit 2, a filter screen unit 3 and a fan box unit 4; the cleaning tank unit 2 is arranged on the top of the suction hood 1 , and the filter screen unit 3 is located in the cleaning tank unit 2, and the fan box unit 4 is located on the top of the cleaning tank unit 2 to communicate with it; the key point of the present invention is that the cleaning tank unit 21 includes a box body 21 and is located in the box The cleaning tank 22 on one side of the lower part of the body 21, and the filter screen unit 3 includes at least one cylindrical filter screen 31 that can control the rotation. In the box body 21 of the cleaning pool unit 2, the lower end is covered with the air outlet 12 of the suction hood 1, and the upper end is sealed; the cleaning liquid in the cleaning pool 22 is sprayed to the rotating cylindrical filter throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com