Dust removal device for coal mining machine of coal mine and use method

A technology for a dust removal device and a shearer, which is applied in the direction of a cleaning method, a combination device, a separation method using gas flow, etc., can solve the problems of secondary dust pollution, troublesome operation by users, etc., achieve efficient water dust reduction, and improve environmental protection. , the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

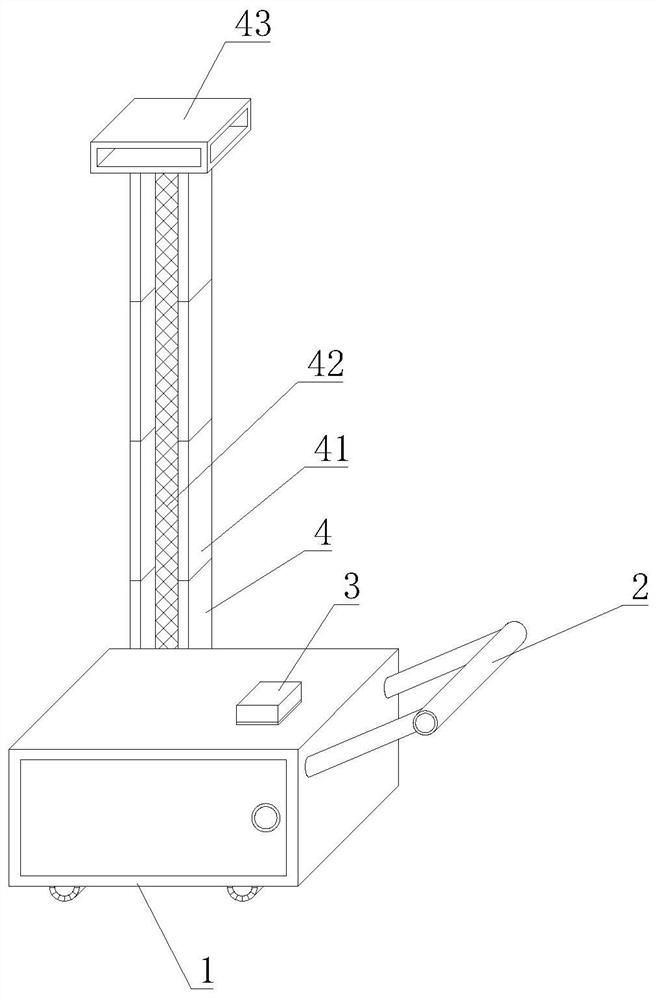

[0040] First aspect, such as Figure 1-9 As shown, the present invention provides a dust removal device for coal mining machines, including a mobile dust processing box 1, the right side of the mobile dust processing box 1 is fixedly welded with a push-pull frame 2, and the top of the mobile dust processing box 1 is movably connected There is a control box 3, the inner cavity of the control box 3 is provided with a control button, the top of the mobile dust treatment box 1 inner cavity is fixedly installed with a suction fan body 11, and the air outlet end of the suction fan body 11 is fixedly connected with a connecting pipe 12, and the mobile The bottom of the dust treatment box 1 is fixedly equipped with universal wheels. Through this design, it is convenient for the user to move the device. The back side of the mobile dust treatment box 1 is provided with an adjustable dust suction mechanism 4, and the inner cavity of the mobile dust treatment box 1 is set There is a dust ...

Embodiment 2

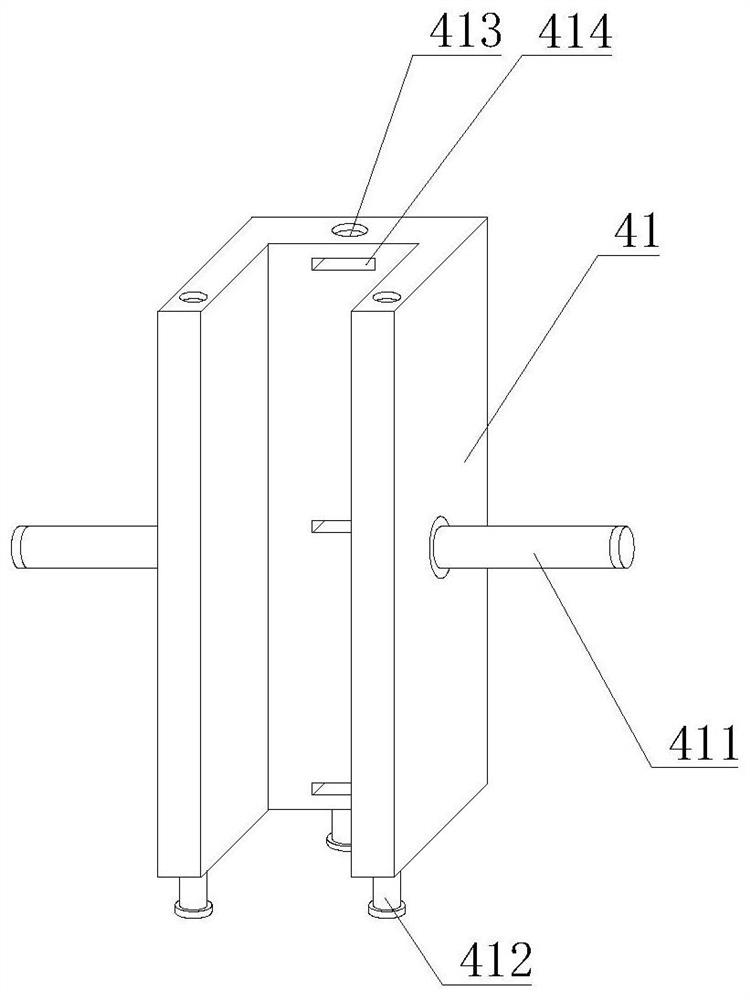

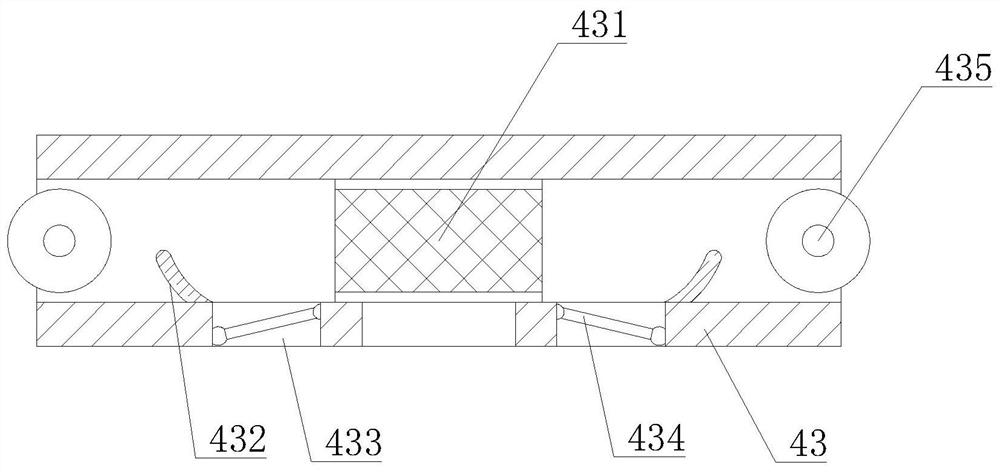

[0042] like Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the top of the telescopic network pipe 42 is fixedly connected to the bottom of the dust collection box 43, and the bottom of the telescopic network pipe 42 is connected to the air intake of the suction fan body 11 Both sides of the splicing frame 41 are movably connected with gripping rods 411, the bottom of the splicing frame 41 is fixedly equipped with an inserting rod 412, and the top of the splicing frame 41 is provided with a splicing slot 413, and the inner cavity of the splicing frame 41 There is an elbow fixing groove 414 on the back, through the cooperation design of the insertion rod 412 and the insertion groove 413, the adjacent splicing frames 41 can be spliced, which is convenient for disassembling the splicing frame 41 or installing the splicing frame 41 operation, and then adjust the extension length of the telescopic network pipe 42,...

Embodiment 3

[0044] like Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the right side of the communication pipe 12 extends to the inner cavity of the dust suppression cylinder 51 and is fixedly connected with a hose 511, and the right side of the hose 511 It is fixedly connected with the left side of the shunt pipe 512, the bottom of the shunt pipe 512 is fixedly connected with a dust filter bag 514, and the inner wall of the dust filter bag 514 is fixedly installed with a vibration bending rod 516, and the end of the vibration bending rod 516 away from the dust filter bag 514 is fixedly connected with a vibration The ball 517 and the bottom of the dust filter bag 514 are fixedly connected with the dust collection bottom tube 515, and the dust processing box 1 is moved back and forth by pushing and pulling the push-pull frame 2, and the inertia of the shunt pipe 512 can be used to make the shunt pipe 512 swing. The desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com