Pickled vegetable pressing and desalting device

A desalination device and pickle technology, applied in food science and other directions, can solve problems such as clogging of water outlet holes, difficulty in cleaning, and troublesome operation, and achieve the effects of preventing clogging, reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

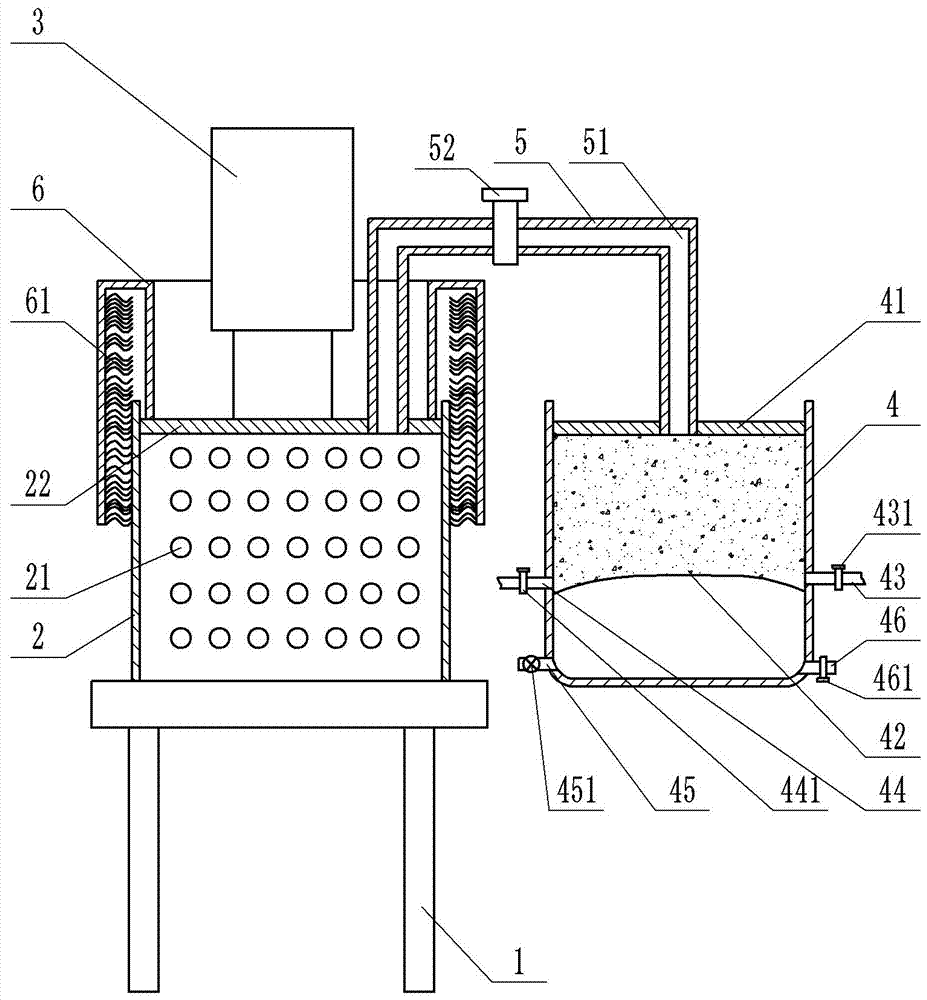

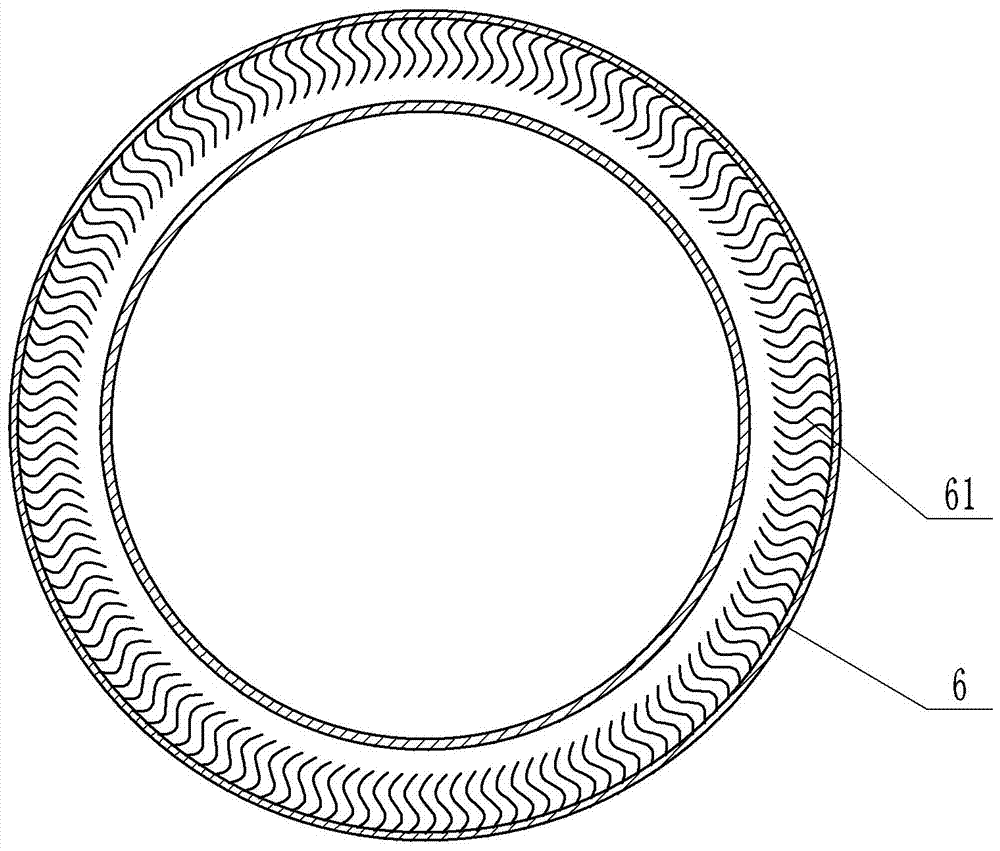

[0023] The reference signs in the drawings of the description include: workbench 1, pressing cylinder 2, water outlet hole 21, briquetting block 22, hydraulic cylinder 3, water storage tank 4, piston 41, air bag 42, water inlet pipe 43, one-way valve 431, Outlet pipe 44, first valve 441, exhaust pipe 45, pressure relief valve 451, air intake pipe 46, valve 461, linkage rod 5, channel 51, second valve 52, scrubbing barrel 6, bristles 61.

[0024] Such as figure 1 As shown, the pickle press desalination device includes a workbench 1, a press cylinder 2 with a plurality of water outlet holes 21 on the side wall, a water storage tank 4, a briquetting block 22 and a hydraulic cylinder 3 for driving the briquetting block 22 to move. The pressing block 22 is slidably connected in the pressing cylinder 2, and the pressing cylinder 2 is fixed on the workbench 1. The upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com