Ceramic art sculpture process table

A technology of craft table and sculpture, applied in the field of craft table, can solve the problems of short bearing life and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

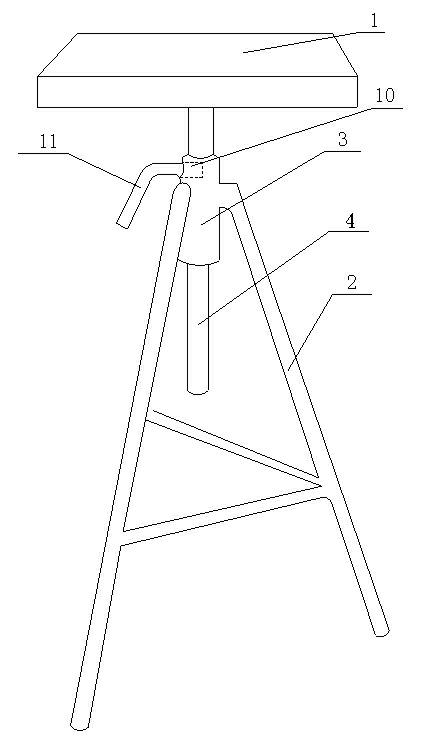

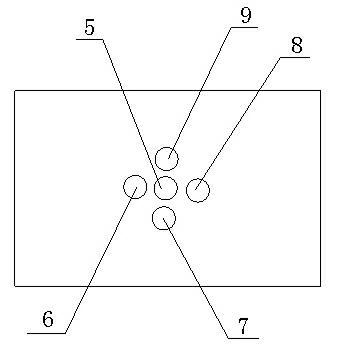

[0013] Such as figure 1 with 2 As shown, a kind of pottery sculpture craft platform of the present invention comprises worktop 1 and triangular support 2, and the top of triangular support 2 is fixed with nut 3, and screw rod 4 is inserted in nut 3, and the bottom surface of worktable 1 is provided with screw mandrel 4. Matching multiple inner holes, the inner holes include vertical inner hole 5, 30° inner hole 6, 45° inner hole 7, 60° inner hole 8 and 75° inner hole 9, the vertical inner hole is the center line of the inner hole and the working The horizontal plane of the table is 90°, the inner hole of 30° is the center line of the inner hole and the horizontal plane of the workbench is 30°, the inner hole of 45° is the center line of the inner hole is 45° to the horizontal plane of the workbench, the inner hole of 60° is the centerline of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com