Technique for producing slice with pin-holing forming design and production tool

A technology for making crafts and tools, applied in artist hand tools, crafts for producing decorative surface effects, decorative arts, etc., can solve problems such as low efficiency of pinhole piercing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

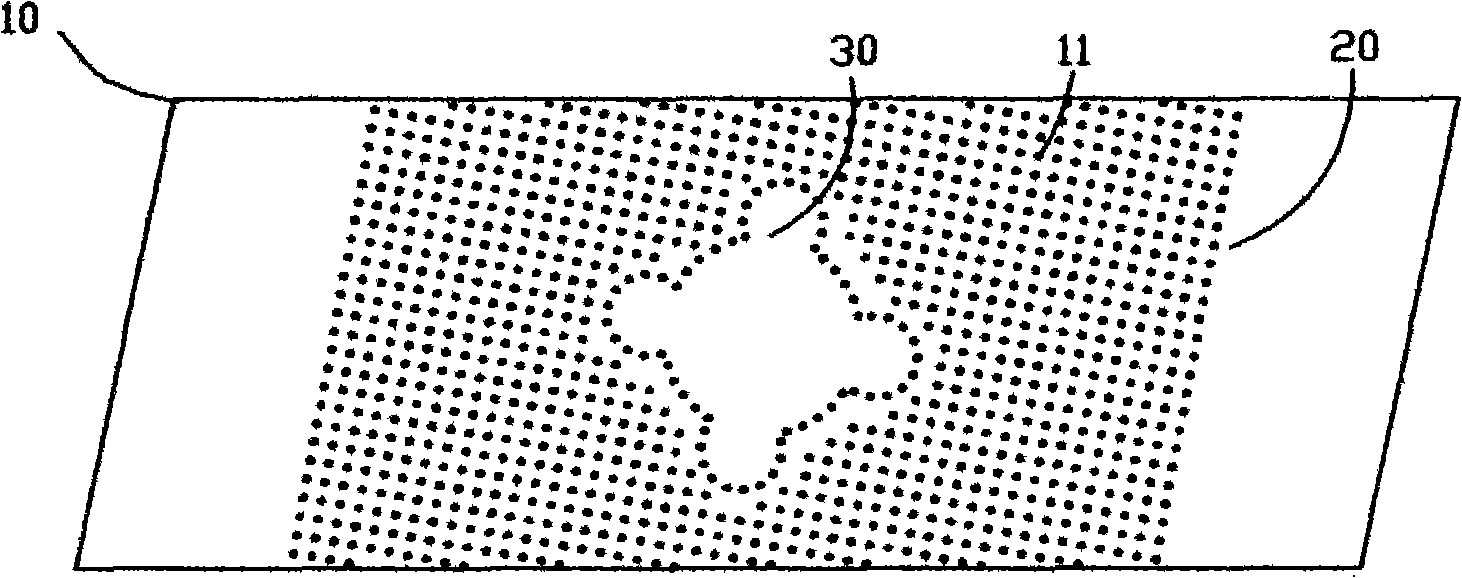

[0028] The existing paper 10 with a pattern composed of pinholes used in the production of folk handicrafts acupuncture boneless lanterns is such as figure 1 As shown, the paper 10 has a rectangular geometric pattern 20 composed of pinholes 11 manually pierced one by one needle by needle, and an arc geometric pattern 30 in the rectangular geometric pattern 20.

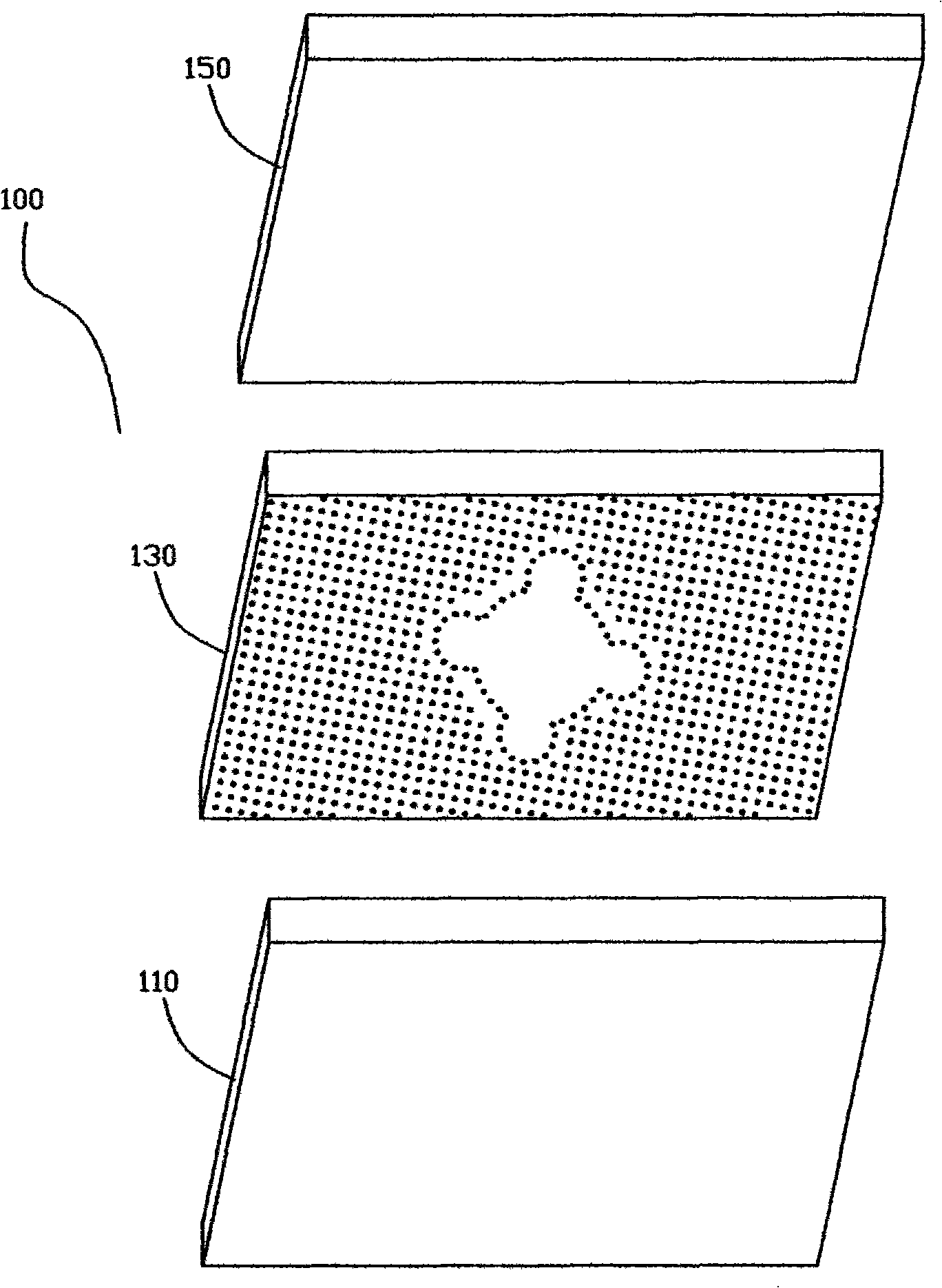

[0029] The production tool 100 of the sheet having a pattern composed of pinholes of the present invention is as figure 2 As shown, the tool 100 includes a backing plate 110, a needle plate 130, and an abutment plate 150.

[0030] The backing plate 110 is a rectangular flat plate made of plastic, wood or rubber.

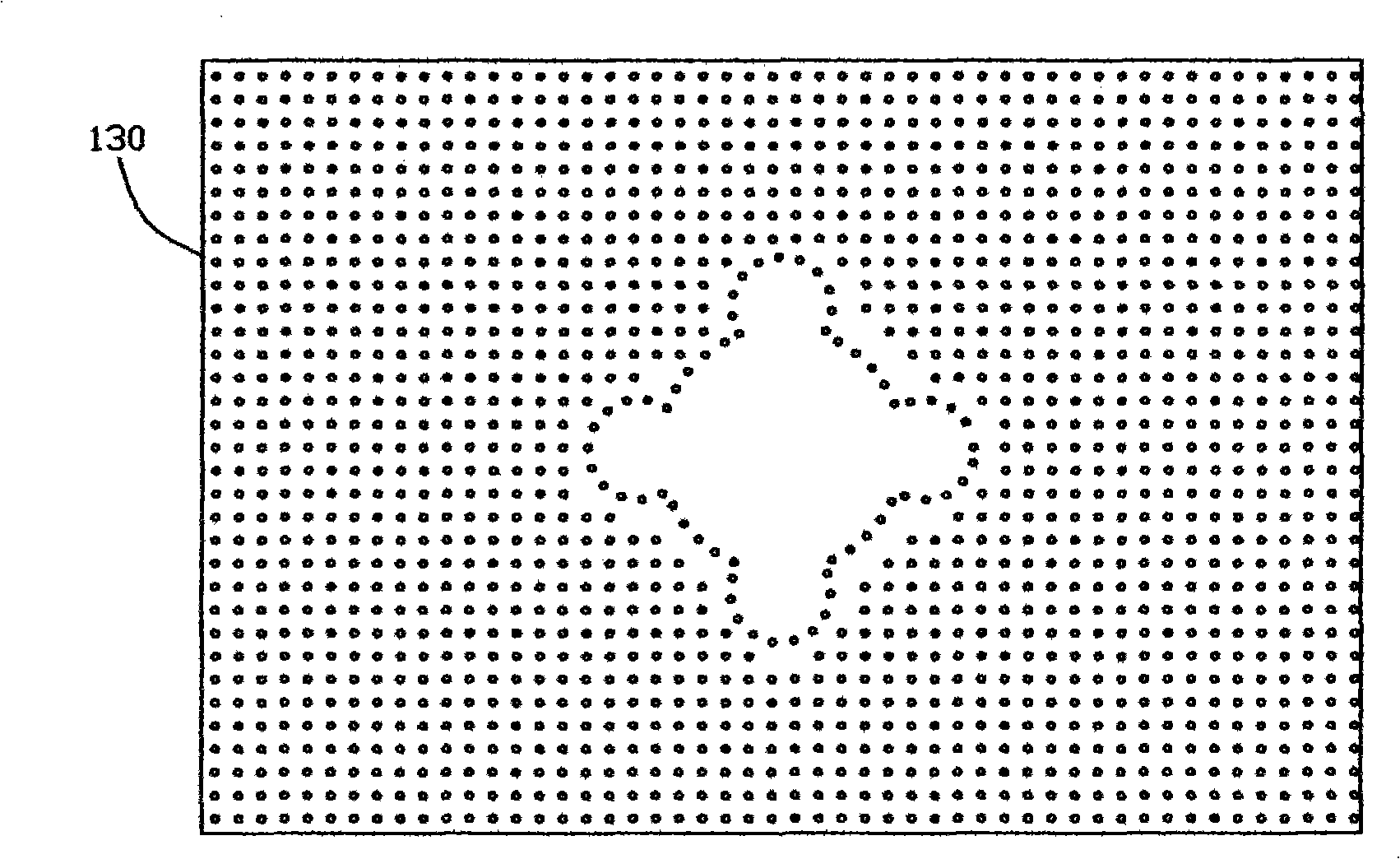

[0031] A structure of the needle plate 130 is as image 3 with Figure 4 As shown, it includes a rectangular metal plate 131 and a pinhole corresponding to the pattern of animals, flowers, or geometric figures on the needling boneless lantern paper. It is perpendicular to the lower surface of the rectangular me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com