Preparation method of aluminum powder surface-coated flake cobalt hydroxide composite material

A technology of surface coating and cobalt hydroxide, applied in cobalt oxide/cobalt hydroxide, transportation and packaging, metal processing equipment, etc., can solve the problems such as the preparation method of sheet cobalt hydroxide coated on the surface of aluminum powder which has not yet been seen, Achieve the effect of improving high temperature oxidation efficiency, simple production equipment and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

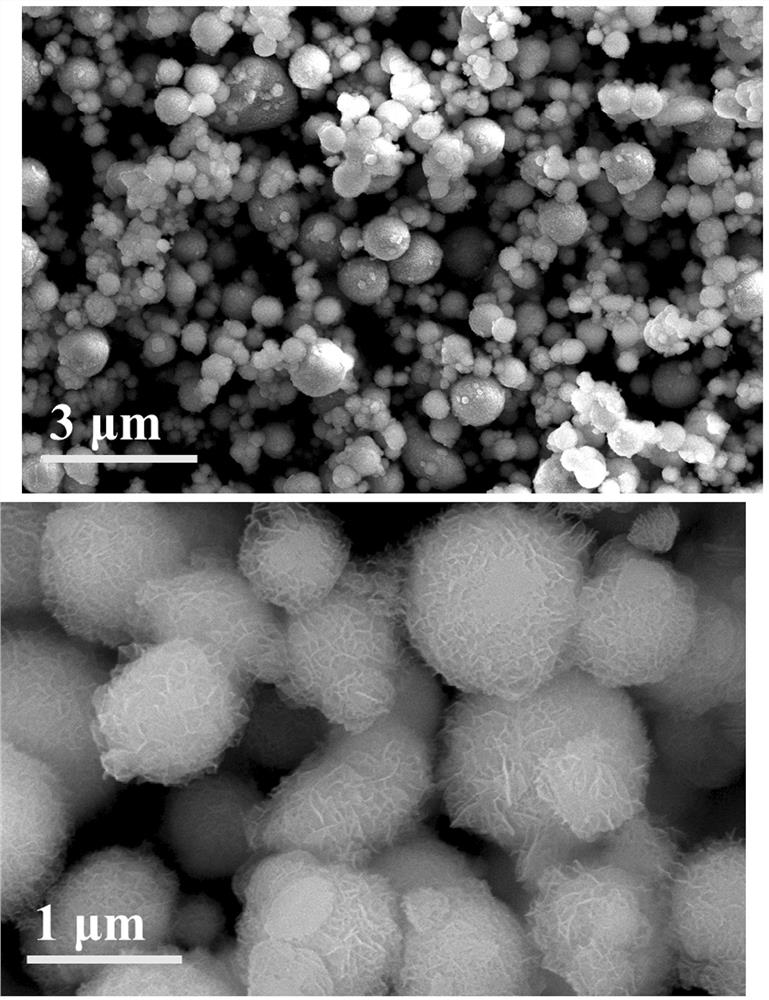

[0033] Embodiment 1: Prepare aluminum powder surface-coated flake cobalt hydroxide composite material according to the following steps

[0034] (1) Add aluminum powder with a particle size range of 50 nm into water for ultrasonic dispersion with a power of 360 W to obtain an aqueous suspension with a concentration of 3 g / L aluminum powder;

[0035] (2) Under normal temperature and pressure, prepare an aqueous cobalt nitrate solution with a concentration of 2 g / L;

[0036] (3) Mix the aqueous phase suspension of aluminum powder and cobalt nitrate aqueous solution at a volume ratio of 1:1, and raise the temperature of the mixture to a reaction temperature of 30°C under the stirring condition of 500 rpm;

[0037] (4) Add sodium fluoride 0.16 times the mass of aluminum powder to the above mixed solution;

[0038] (5) After reacting for 10 minutes, the product was centrifuged and washed, and dried at 30°C to obtain a flaky cobalt hydroxide composite material coated with aluminum p...

Embodiment 2

[0039] Embodiment 2: Prepare aluminum powder surface-coated flake cobalt hydroxide composite material according to the following steps

[0040] (1) Add aluminum powder with a particle size range of 1 μm into water for ultrasonic dispersion with a power of 360 W to obtain an aqueous suspension with a concentration of 6.5 g / L aluminum powder;

[0041] (2) Under normal temperature and pressure, prepare an aqueous cobalt nitrate solution with a concentration of 11 g / L;

[0042] (3) Mix the aqueous phase suspension of aluminum powder and cobalt nitrate aqueous solution at a volume ratio of 1:1, and raise the temperature of the mixture to a reaction temperature of 35°C under the stirring condition of 500 rpm;

[0043] (4) Add sodium fluoride 0.4 times the mass of aluminum powder to the above mixed solution;

[0044] (5) After reacting for 35 minutes, the product was centrifuged and washed, and dried at 30°C to obtain a flaky cobalt hydroxide composite material coated with aluminum ...

Embodiment 3

[0045] Embodiment 3: Prepare aluminum powder surface-coated flake cobalt hydroxide composite material according to the following steps

[0046] (1) Add aluminum powder with a particle size range of 5 μm into water for ultrasonic dispersion with a power of 360 W to obtain an aqueous suspension with a concentration of 10 g / L aluminum powder;

[0047] (2) Under normal temperature and pressure, prepare an aqueous cobalt nitrate solution with a concentration of 20 g / L;

[0048] (3) Mix the aqueous phase suspension of aluminum powder and cobalt nitrate aqueous solution at a volume ratio of 1:1, and raise the temperature of the mixture to a reaction temperature of 40°C under the stirring condition of 500 rpm;

[0049](4) Add sodium fluoride 0.64 times the mass of aluminum powder to the above mixed solution;

[0050] (5) After reacting for 60 minutes, the product was centrifuged and washed, and dried at 30°C to obtain a flaky cobalt hydroxide composite material coated with aluminum p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com