Polyetherimide aqueous emulsion type carbon fiber sizing agent and its preparation method and application

A technology of polyetherimide water and emulsion carbon fiber, which is applied in the direction of carbon fiber, can solve the problems of not being suitable for the production and use of carbon fiber, achieve simple and reliable raw material sources, increase the number of active functional groups and surface free energy, and improve wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

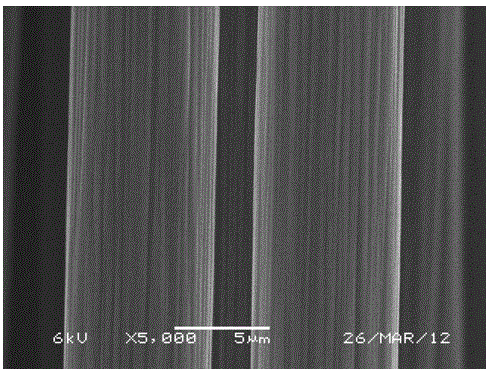

Image

Examples

Embodiment 1

[0030] Weighed 20g of polyetherimide resin with brand Ultem 1000, added it into a beaker containing 180g of dichloromethane, stirred and dissolved, and obtained a dichloromethane solution of polyetherimide. Keep the temperature of the solution in a water bath at 10°C, add 2g of emulsifier Span-40, then adjust the rotation speed of the emulsifier to 8000rpm, and emulsify for 30 minutes. Next, add 35 g of deionized water to the system, keep the temperature and emulsification rotation speed constant, and continue emulsification for 30 minutes. Afterwards, stir with an electric mixer at 10° C. and 500 rpm for 24 hours, and remove methylene chloride in the system by stirring to obtain a polyetherimide aqueous emulsion carbon fiber sizing agent.

[0031] The mass fraction of the main size in the sizing agent is 34.5%, the mass fraction of the emulsifier Span-40 is 6.9%, and the mass fraction of deionized water is 58.6%.

[0032] When in use, raise the temperature of the high-concen...

Embodiment 2

[0034] Weighed 20g of polyetherimide resin with brand Ultem1000F, added it into a beaker containing 140g of dichloromethane, stirred and dissolved, and obtained a dichloromethane solution of polyetherimide. The solution was kept in a water bath at a constant temperature of 30° C., 4 g of emulsifier Span-60 was added, and then the rotational speed of the emulsifier was adjusted to 12000 rpm, and the emulsification treatment was carried out for 110 minutes. Next, add 34 g of deionized water to the system, keep the temperature and emulsification rotation speed constant, and continue emulsification for 50 minutes. Afterwards, use an electric mixer to stir for 36 hours at 30° C. and 1000 rpm, and remove methylene chloride in the system by stirring to obtain a polyetherimide aqueous emulsion carbon fiber sizing agent.

[0035] The mass fraction of the main size in the sizing agent is 34.5%, the mass fraction of the emulsifier Span-60 is 3.4%, and the mass fraction of deionized water...

Embodiment 3

[0038] Weighed 20g of polyetherimide resin with brand Ultem1000P, added it into a beaker containing 150g of dichloromethane, stirred and dissolved, and obtained a dichloromethane solution of polyetherimide. Keep the temperature of the solution in a water bath at 17°C, add 4g of emulsifier Span-40, then adjust the rotation speed of the emulsifier to 8000rpm, and emulsify for 100min. Next, add 76g of deionized water to the system, keep the temperature and emulsification rotation speed constant, and continue emulsification for 100min. Afterwards, stir with an electric mixer, stir for 48 hours at 24°C and 2000rpm, and remove methylene chloride in the system by stirring to obtain a polyetherimide aqueous emulsion carbon fiber sizing agent.

[0039] The mass fraction of the main slurry in the sizing agent is 20.0%, the mass fraction of the emulsifier Span-40 is 4.0%, and the mass fraction of deionized water is 76.0%.

[0040] When in use, raise the temperature of the high-concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com