Sulfonated polyaryletherketone water-based sizing agent as well as preparation method and application thereof

A water-based and sulfonated polyaryletherketone technology for sulfonated polyaryletherketone, which is applied in textiles and papermaking, fiber processing, fiber types, etc. Excellent workability, improved wettability and roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A sulfonated polyaryletherketone water-based sizing agent described in this embodiment is prepared from the following raw materials in parts by mass: 0.1 part of sulfonated polyether ether ketone, 0 part of emulsifier, and 100 parts of deionized water.

[0030] The specific preparation process of the sulfonated polyaryletherketone water-based sizing agent is as follows: Weigh 0.1 part of sulfonated polyether ether ketone main slurry with a sulfonation degree of 70%, add it to 100 parts of deionized water, and control the reaction temperature to 60 °C, stirred until no obvious solid remains, and formed a water-based sulfonated polyether ether ketone sizing agent with a concentration of 0.1 wt% after cooling.

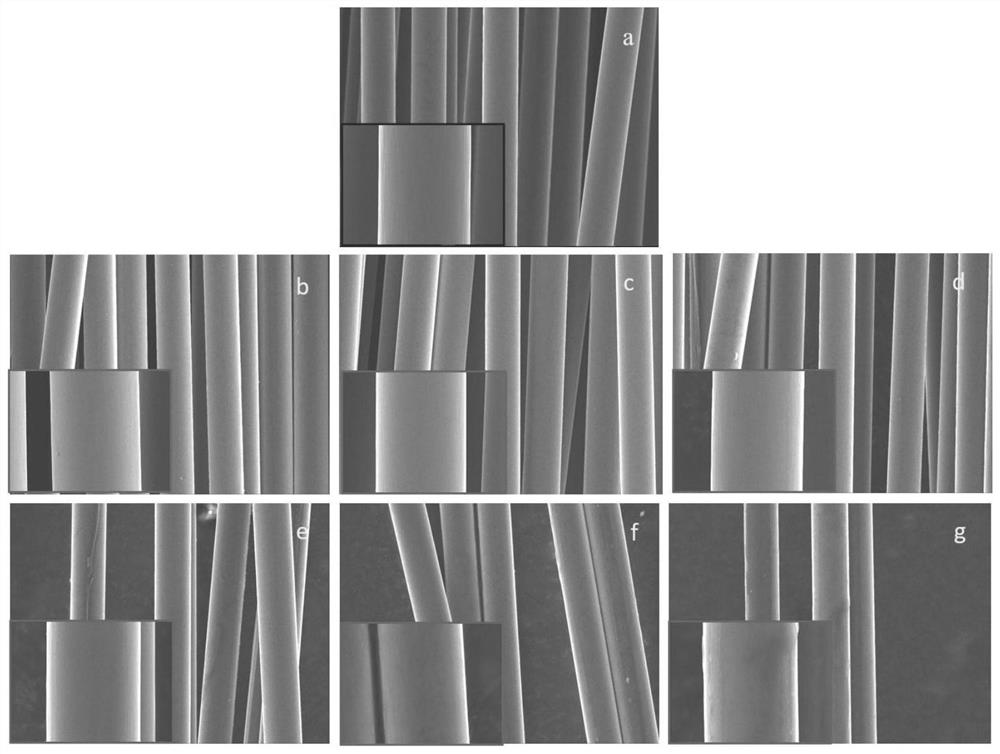

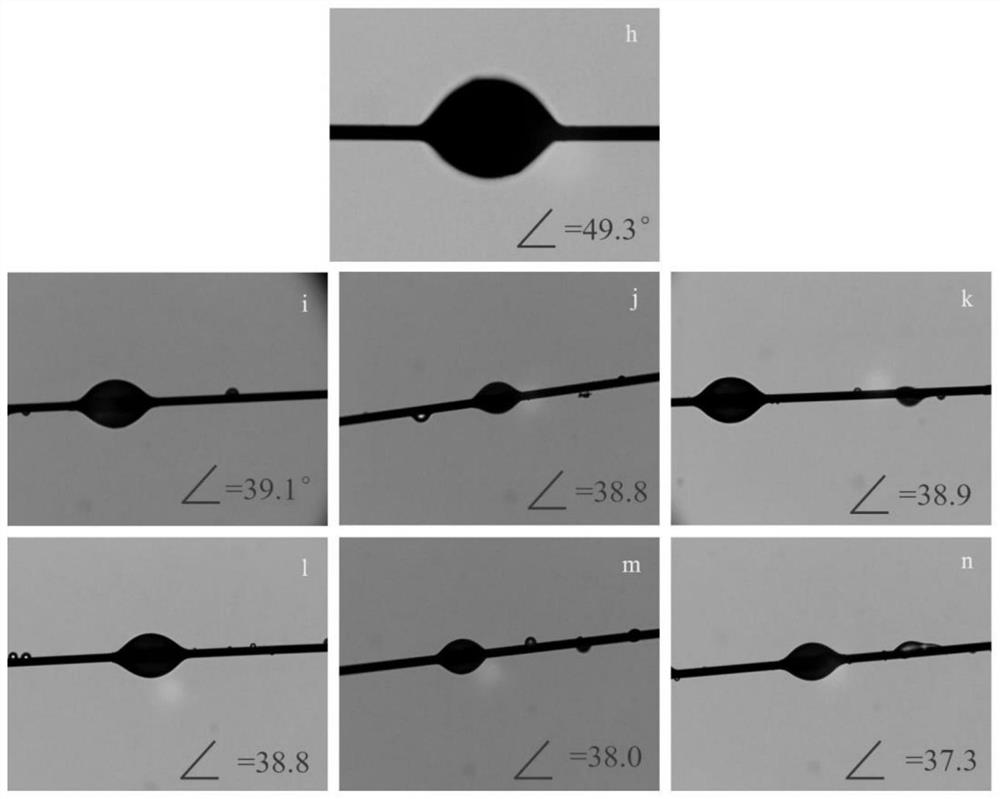

[0031] The application of the sulfonated polyaryletherketone water-based sizing agent described in this example mainly includes the following steps: the 0.1wt% aqueous sulfonated polyetheretherketone sizing agent obtained above is sized by a general dipping sizing p...

Embodiment 2

[0033] A sulfonated polyaryletherketone water-based sizing agent described in this embodiment is prepared from the following raw materials in parts by mass: 40 parts of sulfonated polyetheretherketone, 15 parts of emulsifier, and 100 parts of deionized water.

[0034] The emulsifier used is nonionic surfactant polyoxypropylene lanolin ether, and the HLB value is 10.0.

[0035] The specific preparation process is: weighing 15 parts of polyoxypropylene lanolin ether with an HLB value of 10.0 and adding it to 100 parts of deionized water, controlling the temperature of the system at 5° C., and stirring evenly. After that, 40 parts of sulfonated polyetheretherketone main slurry with a sulfonation degree of 120% was weighed, added to the above emulsifier solution, the reaction temperature was controlled at 50°C, and stirred until no obvious solid remained. After cooling, water-based sulfonated polyetheretherketone was obtained. Ether ether ketone sizing agent.

[0036] The applica...

Embodiment 3

[0038] A sulfonated polyaryletherketone water-based sizing agent described in this embodiment is prepared from the following raw materials in parts by mass: 20 parts of sulfonated polyetherketone, 5 parts of emulsifier, and 100 parts of deionized water.

[0039] The emulsifier used is a nonionic surfactant polyoxyethylene nonionic surfactant with an HLB value of 14.0.

[0040] The specific preparation process is as follows: 5 parts of polyoxyethylene sorbitan with an HLB value of 14.0 are weighed and added to 100 parts of deionized water, the temperature of the system is controlled at 70° C., and the mixture is stirred evenly. Then weigh 20 parts of sulfonated polyether ketone main slurry with a sulfonation degree of 90%, add it to the above emulsifier solution, control the reaction temperature at 70°C, stir until no obvious solid remains, and the water-based sulfonated polyether ketone obtained after cooling Etherketone sizing agent.

[0041]The application of a sulfonated p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com