A kind of biomass water treatment agent based on porous coffee grounds and preparation method thereof

A technology of water treatment agent and coffee grounds, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve difficult conditions and control, cumbersome manufacturing process, and large consumption of chemical materials problems such as good adsorption, simple drying equipment, and the realization of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

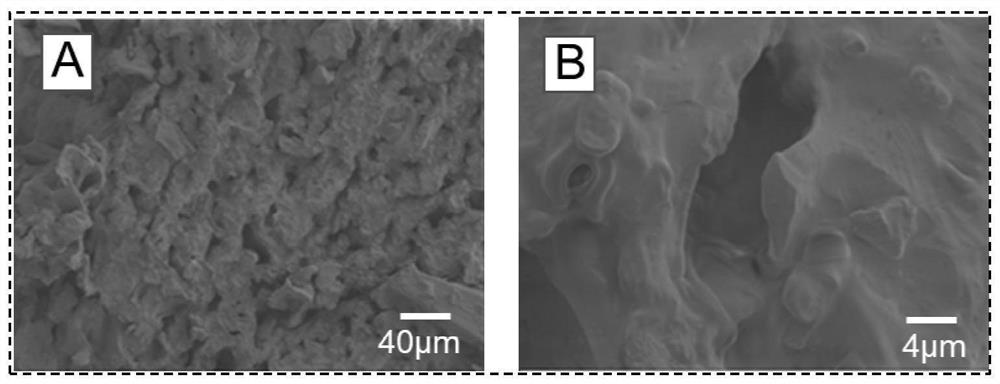

[0045] The natural coffee grounds were selected and photographed with a scanning electron microscope to obtain Figure 1a , Figure 1a Parts A and B of the figure are the effect pictures observed under different magnifications, respectively.

Embodiment 2

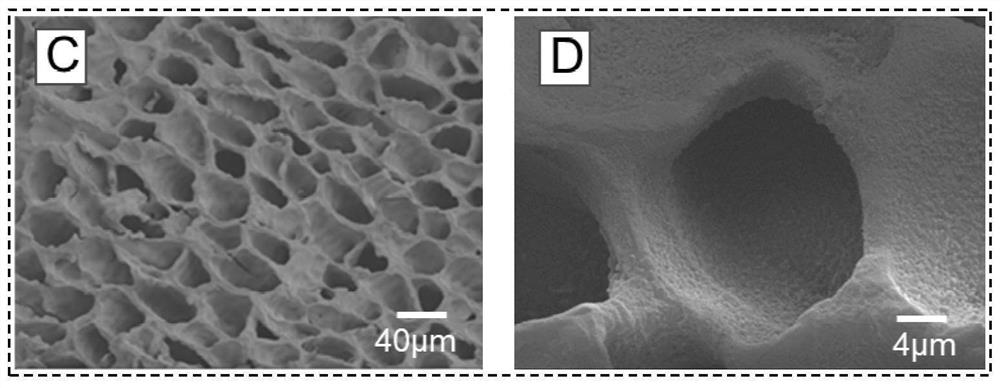

[0047] Weigh 100g of natural coffee grounds and soak in 1000mL of 5wt% sodium hydroxide solution, heat at 90°C for 2 hours, filter and wash with water to remove most of the fatty acids and lignin. 20g sodium chlorite is added in the sodium acetate / acetic acid buffer solution of 100mL again, mix well, obtain sodium chlorite solution, the pH value of described sodium chlorite solution is 4.8; The above-mentioned 100g delignified coffee grounds Add to sodium chlorite solution, mix evenly, heat for decolorization treatment, the temperature of decolorization treatment is 90°C, the time of decolorization treatment is 1.5 hours, filter to collect precipitate, dry in fume hood for 18 hours, put in refrigerator -5°C Freezing, and then freeze-drying to obtain a decolorized product (delignified white coffee grounds). SEM images of delignified white coffee grounds Figure 1b . Figure 1b Parts C and D are the renderings of the delignified white coffee grounds prepared in Example 2 at di...

Embodiment 3

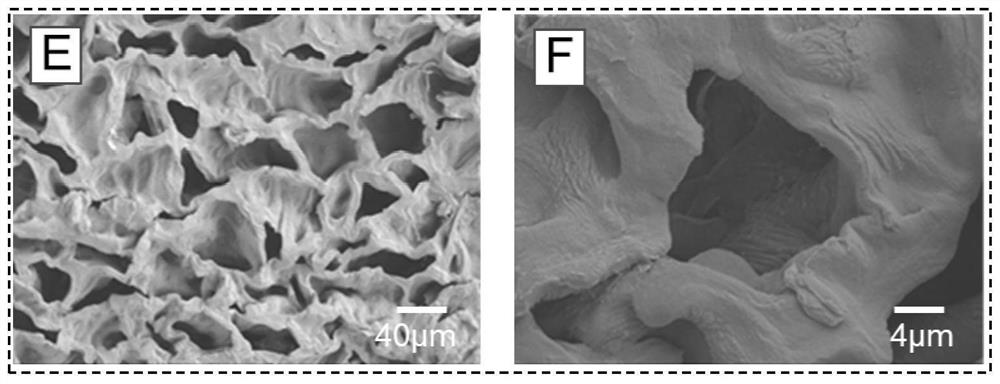

[0049] Add 0.6g of 37% concentrated hydrochloric acid into 100mL of distilled water, then dissolve 0.15g of palladium chloride into the prepared hydrochloric acid solution, and heat at 60°C for 30min. Add 10 g of the delignified white coffee grounds prepared in Example 2 to the palladium chloride hydrochloric acid solution, adjust the heating temperature to 90° C., react for 9 hours, filter to collect the precipitate, and freeze-dry to obtain the porous coffee grounds Biomass water treatment agent (nano palladium modified porous coffee grounds). SEM images of nano-palladium-modified porous coffee grounds Figure 1c . Figure 1c Part E and part F are the effect diagrams of the porous coffee grounds-based biomass water treatment agent prepared in Example 3 at different magnifications.

[0050] Depend on Figure 1a , Figure 1b with Figure 1c It can be found that the surface pores of natural coffee grounds are small and irregular due to the filling of fatty acids and lignin;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com