Device and method for modifying surface of micro-nano powder

A powder surface modification, micro-nano technology, applied in vacuum evaporation plating, coating, sputtering and other directions, can solve the problem of less powder and achieve the effect of high coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

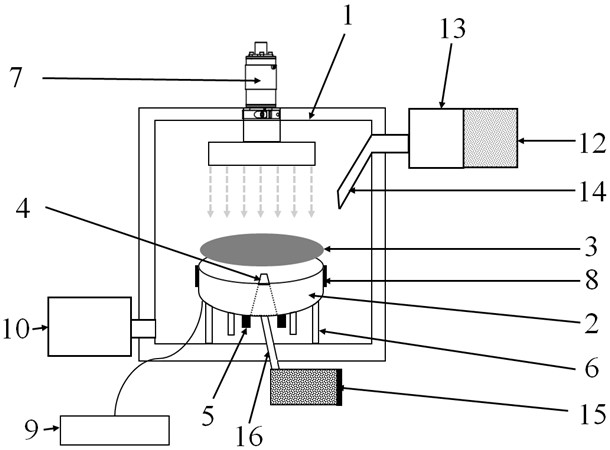

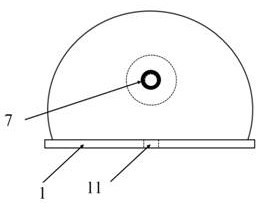

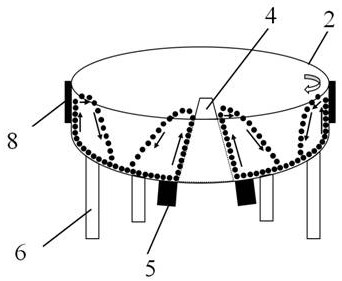

[0039] like figure 1 , figure 2 and image 3 As shown, the device for modifying the surface of micro-nano powder in this embodiment includes a vacuum chamber 1, and a vibrating material turning mechanism is installed in the vacuum chamber 1, and the vibrating material turning mechanism includes a vibrating bowl 2, and the vibrating bowl 2. The upper part is provided with a dust baffle 3 that opens or closes the vibrating bowl 2, the middle part of the vibrating bowl 2 is provided with a guide column 4, the lower side of the vibrating bowl 2 is provided with a vibrator 5, and the lower side of the vibrating bowl 2 There is also a support column 6 for supporting the vibrating bowl 2, an evaporation source 7 for processing the powder inside the vibrating material turning mechanism is installed on the vacuum chamber 1, and the lower part of the vibrating bowl 2 is provided with an opening through the material guide column 4. Or a closed feed port.

[0040] It should be noted t...

Embodiment 2

[0050] This embodiment includes the following steps:

[0051] Step 1: Divide the powder into three equal parts and load them into the vibrating bowl 2, the vacuum chamber 12 and the powder chamber 13 respectively, close the dust baffle 3, and obtain the modification device equipped with the powder; the powder is the total amount. 150g, Ti powder with a particle size of 50nm~100nm;

[0052] Step 2: Evacuate the vacuum chamber 1 of the powder modification device obtained in the step 1 and fill it with argon, then heat the powder in the vibrating bowl 2, and open the dust baffle 3 to obtain A modification device equipped with heated powder; the pressure in the vacuum chamber 1 is 1.0×10 -4 Pa, the heating is to heat the powder to 120°C;

[0053] Step 3, open the vibrator 5 and the vibrating block 8 of the modification device that is equipped with the heating powder obtained in the step 2, so that the powder is turned in the vibrating bowl 2, and the bias power supply 9 is loade...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] Step 1: Load the powder into the vibrating bowl 2, close the dust baffle 3, and obtain a modification device equipped with the powder; the powder is 500 g of Al with a particle size of 200 μm to 300 μm 2 O 3 pink;

[0061] Step 2: Evacuate the vacuum chamber 1 of the powder modification device obtained in the step 1 and fill it with argon, then heat the powder in the vibrating bowl 2, and open the dust baffle 3 to obtain A modification device equipped with heated powder; the pressure in the vacuum chamber 1 is 2.0×10 -3 Pa, the heating is to heat the powder to 100°C;

[0062] Step 3, open the vibrator 5 and the vibrating block 8 of the modification device that is equipped with the heating powder obtained in the step 2, so that the powder is turned in the vibrating bowl 2, and the bias power supply 9 is loaded to the vibrating bowl 2 simultaneously to obtain The modification device of the powder to be modified is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com