Patents

Literature

80results about "Chalks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

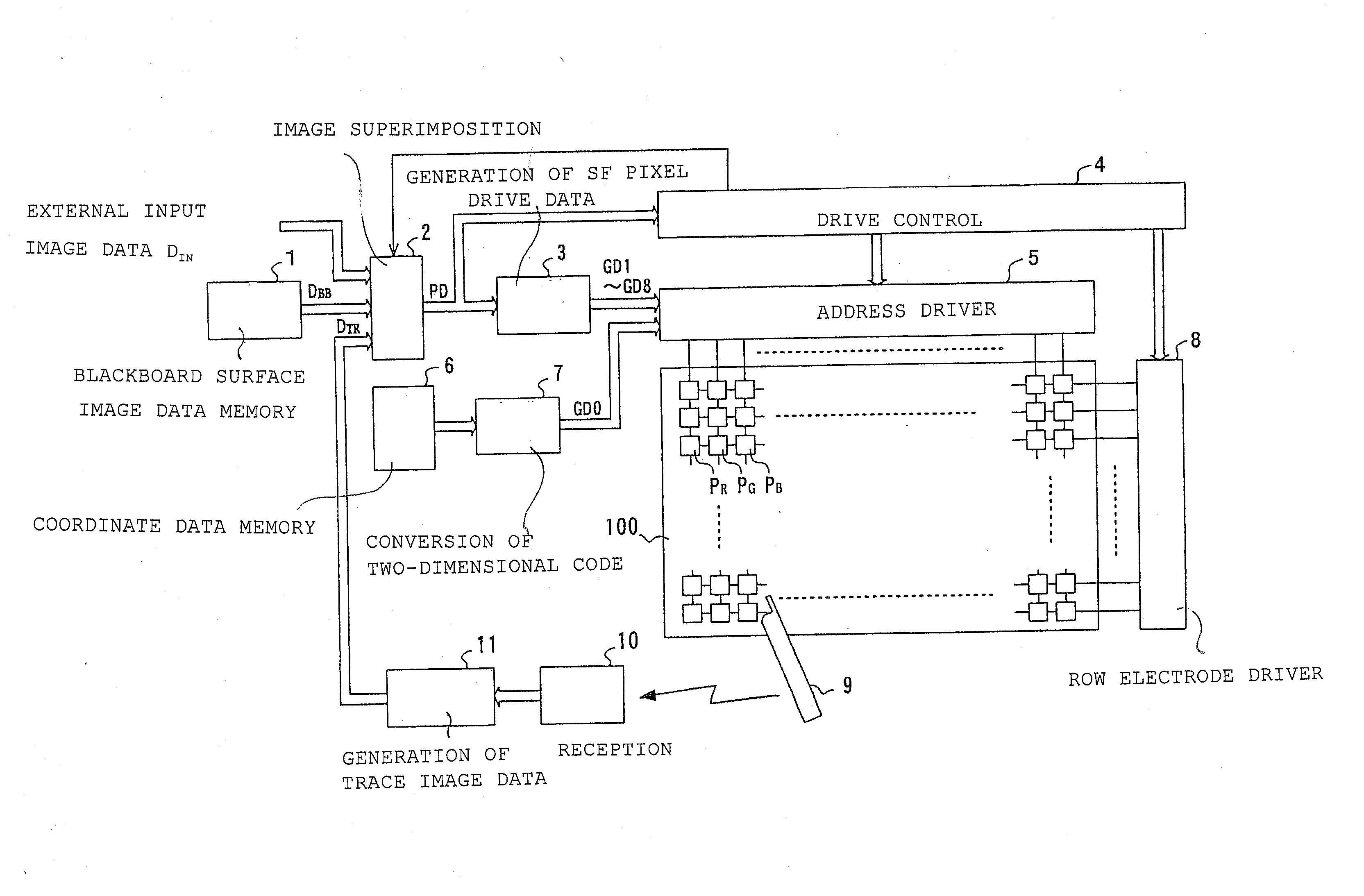

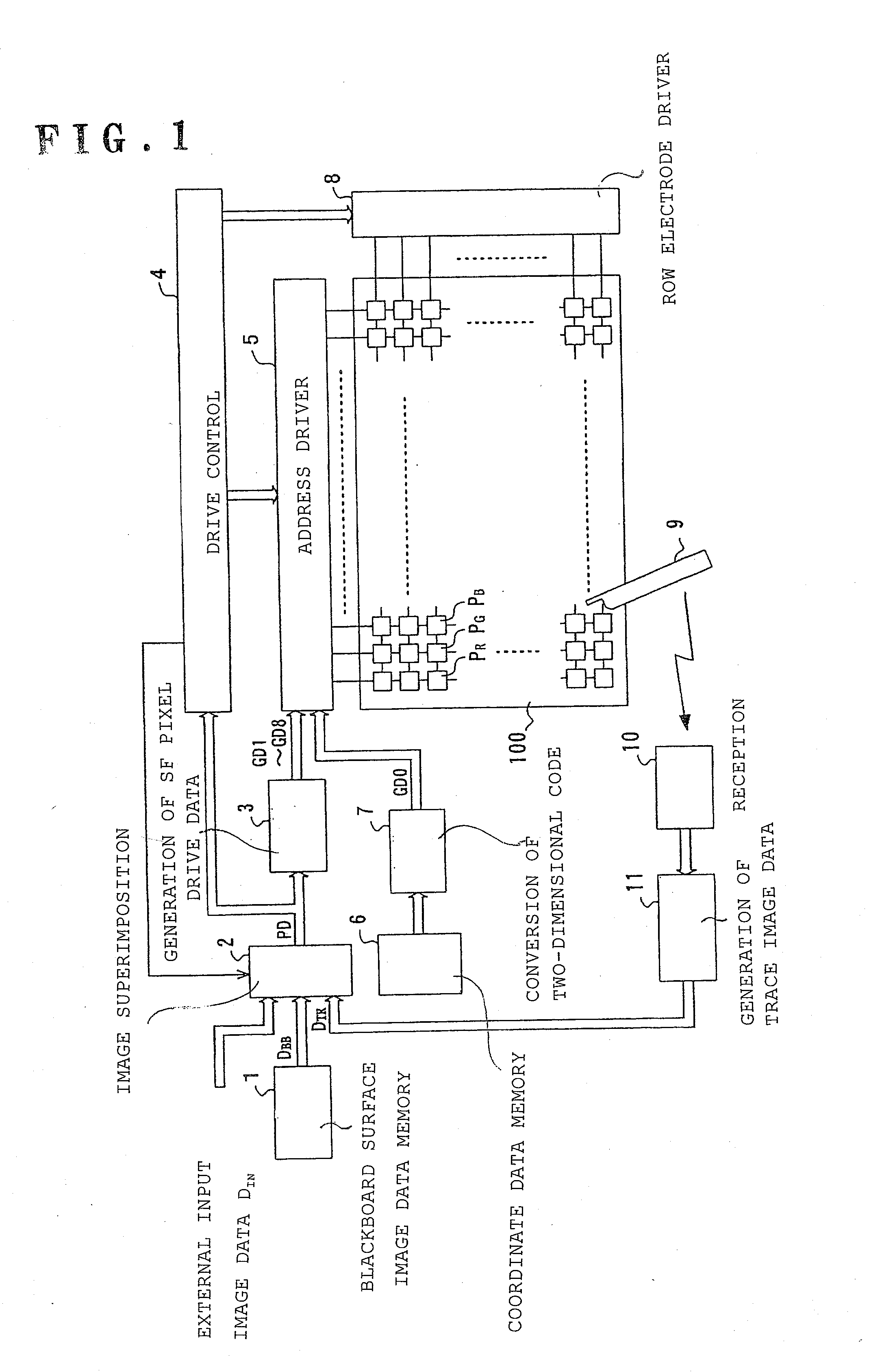

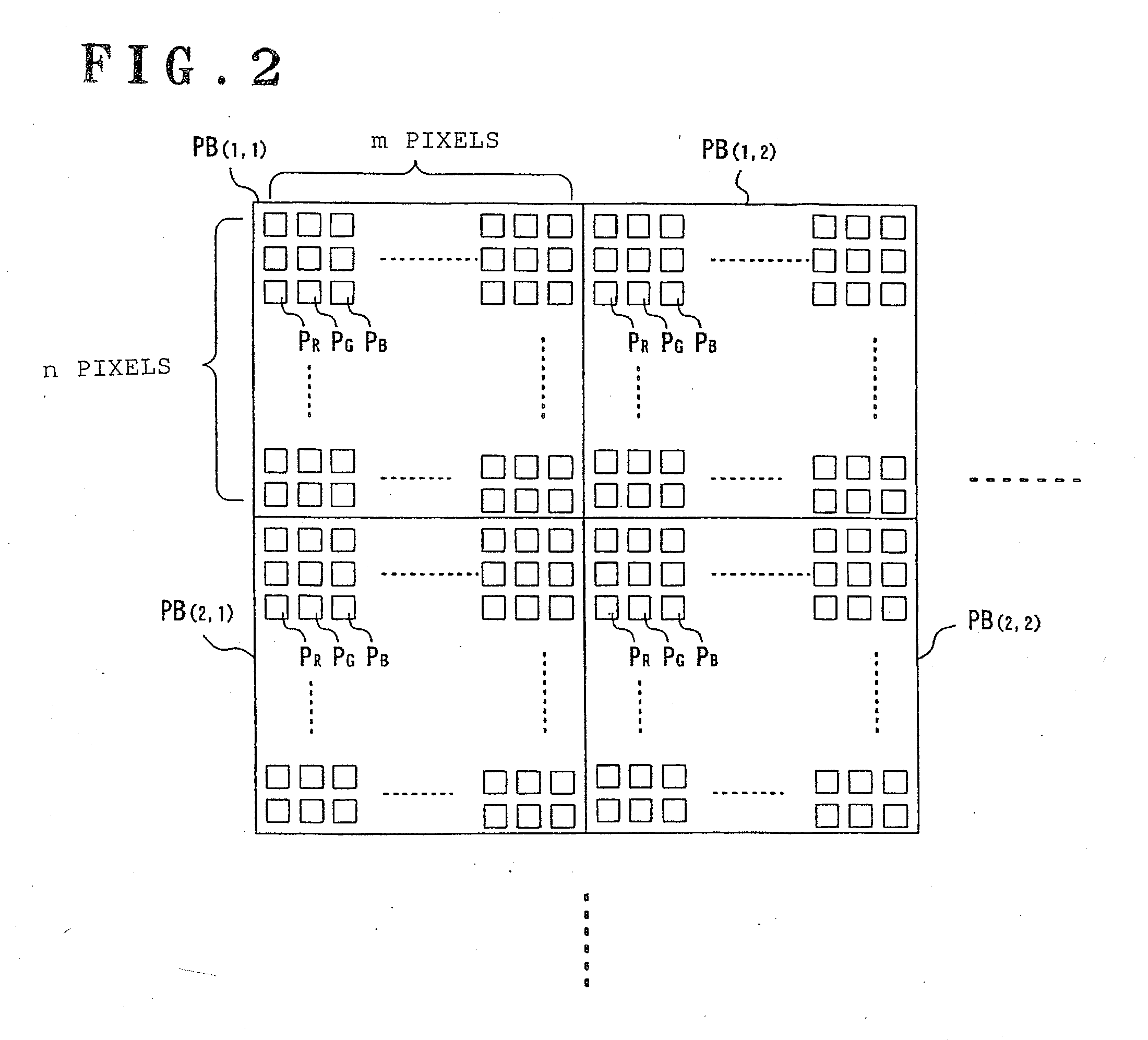

Information code reading apparatus and reading method

An object of the present invention is to provide a method and device for reading an information code in which an information code displayed on a display can be read without increasing the circuit size of the display device. To read the information code displayed on the display in a predetermined area during each frame display interval, a synchronization signal synchronized with each of the frame display intervals is generated based on noise emitted from the display, and the information code is restored from a captured image signal obtained by capturing a screen of the display as an image in accordance with the synchronization signal.

Owner:PIONEER CORP

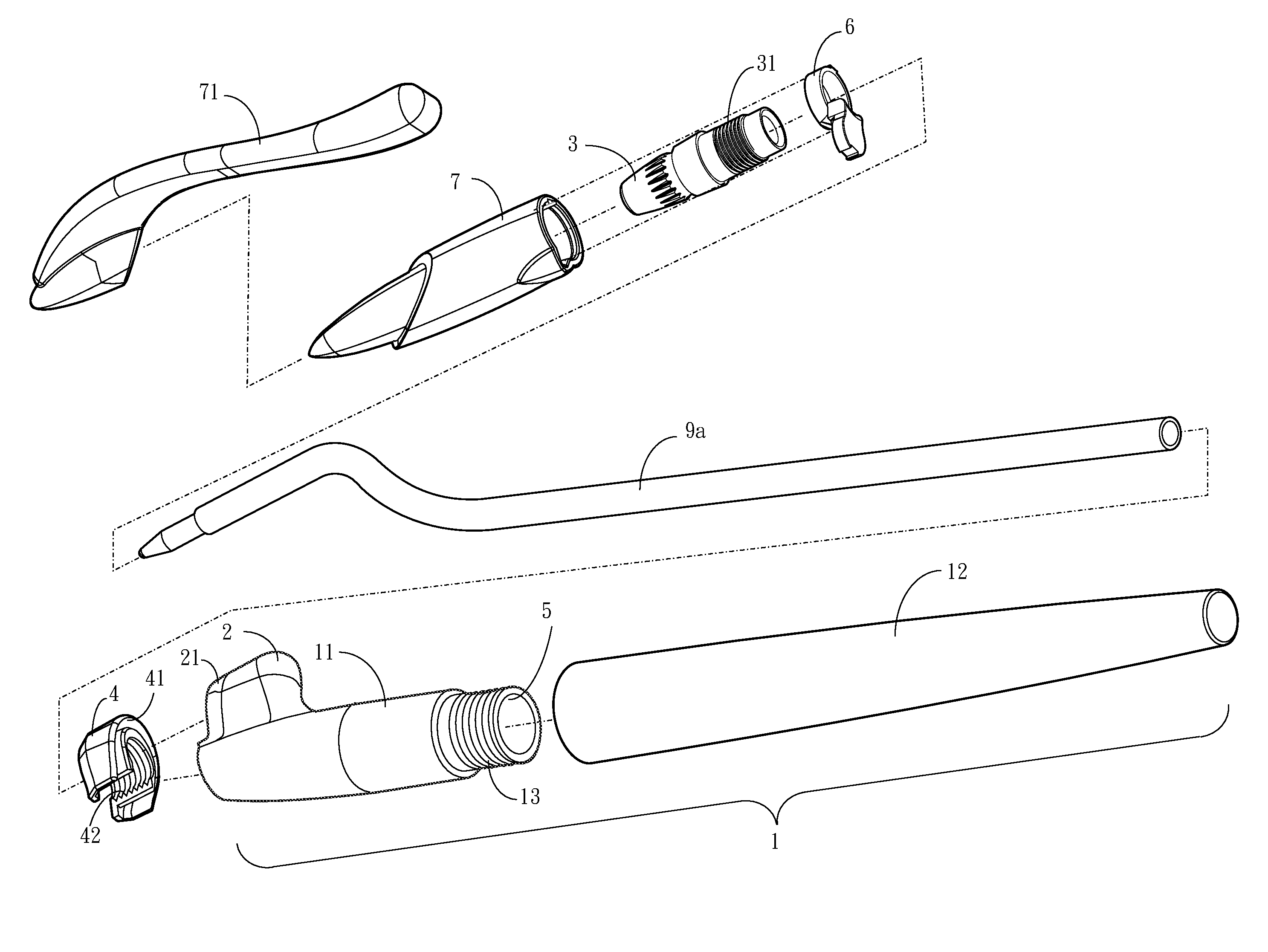

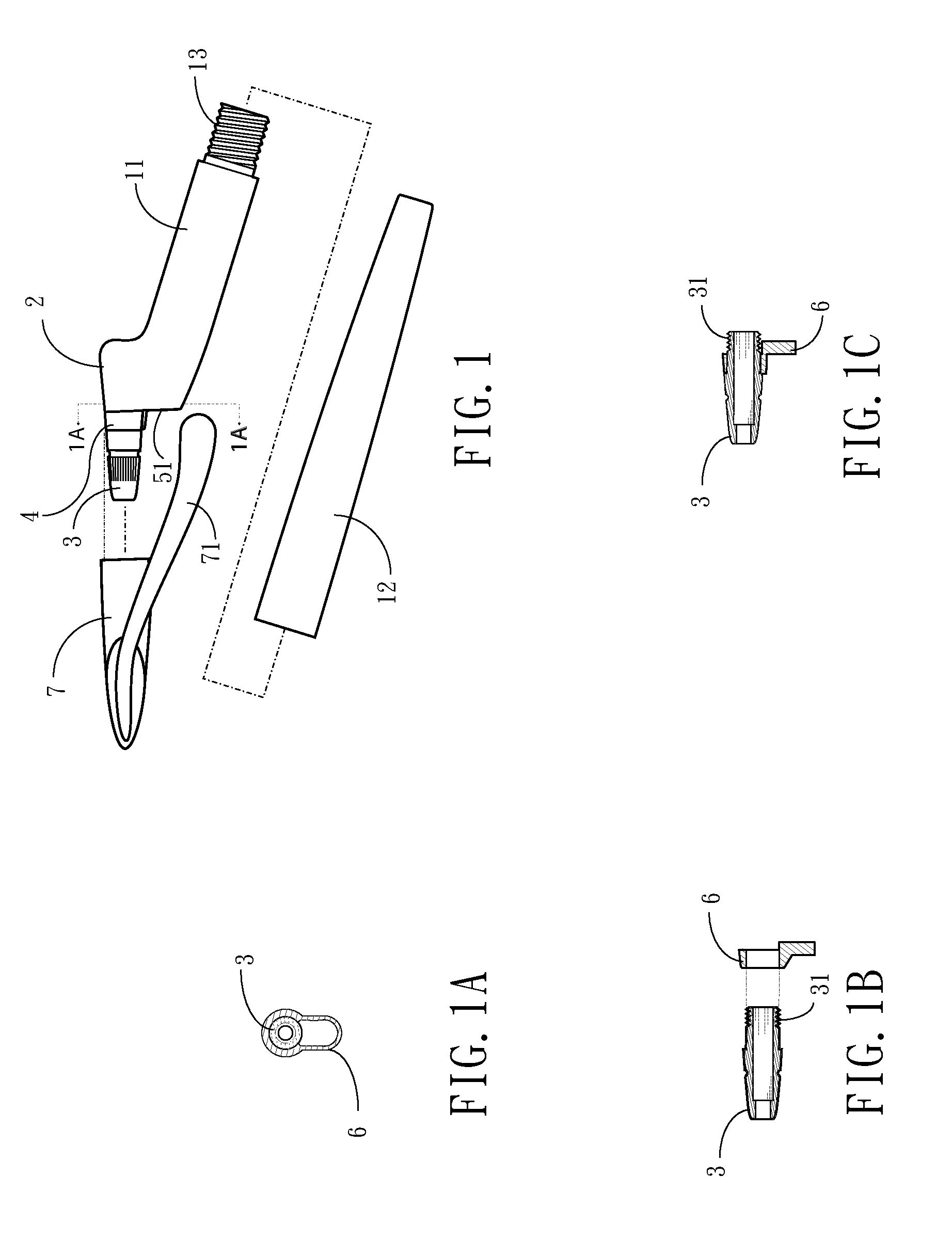

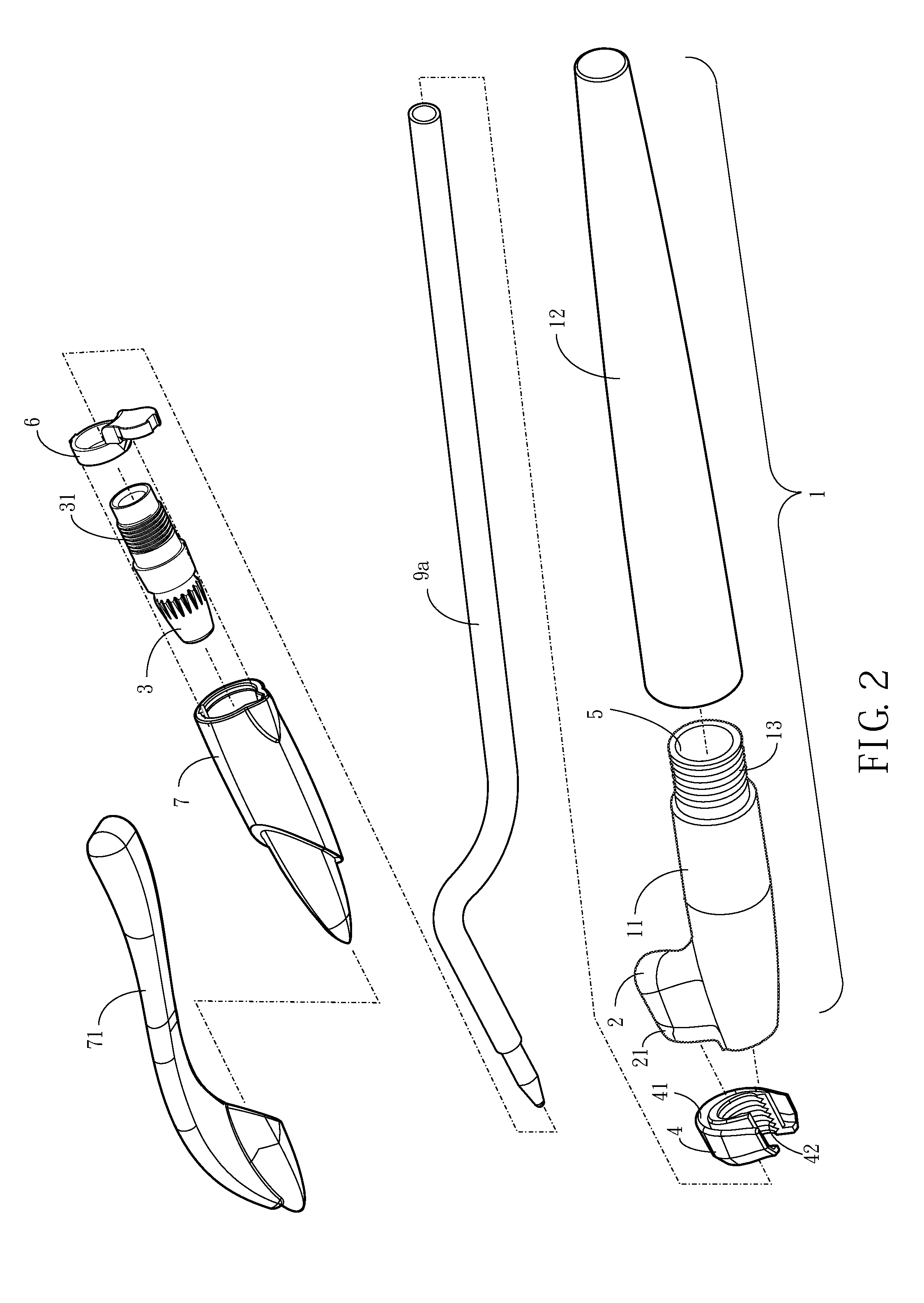

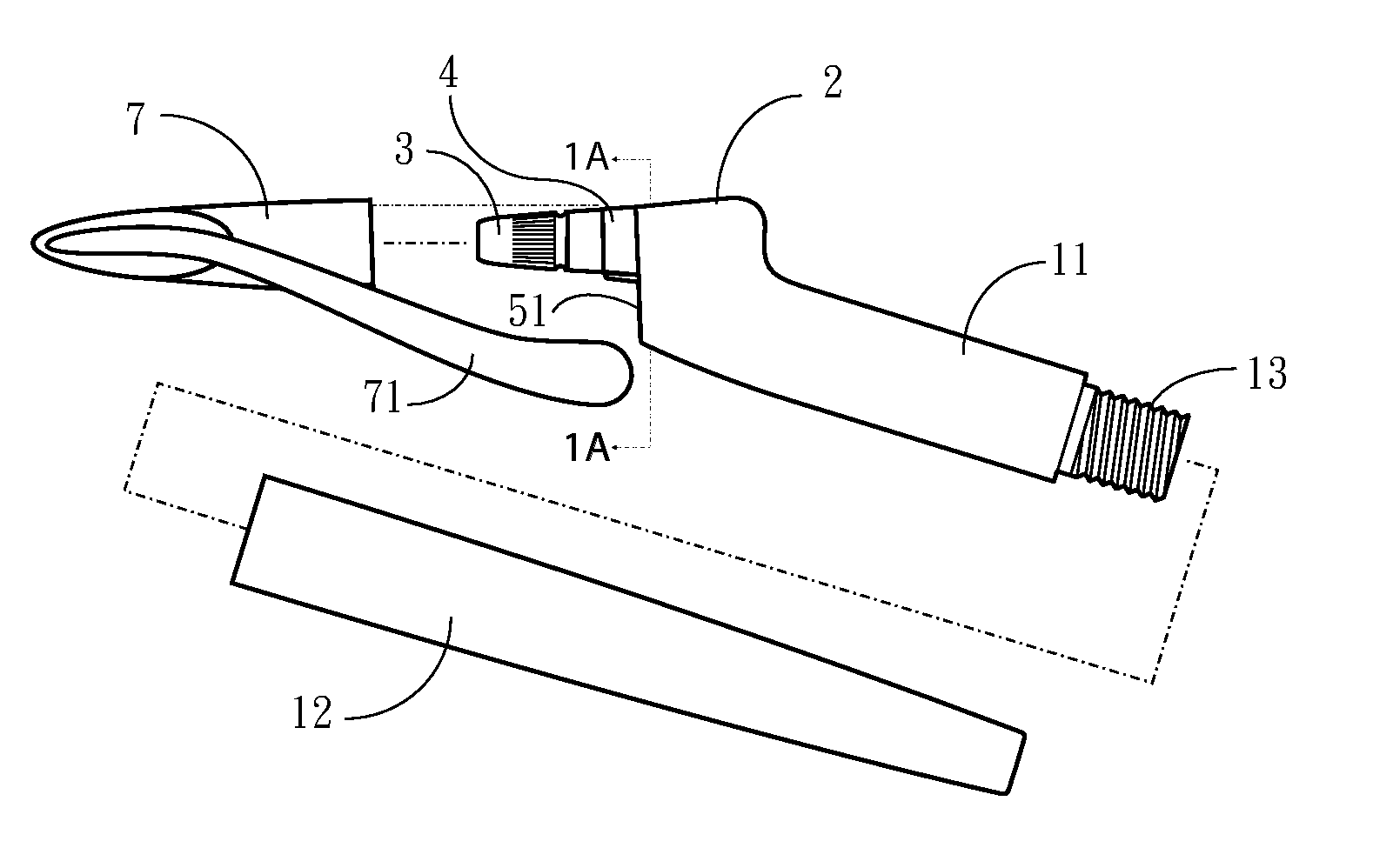

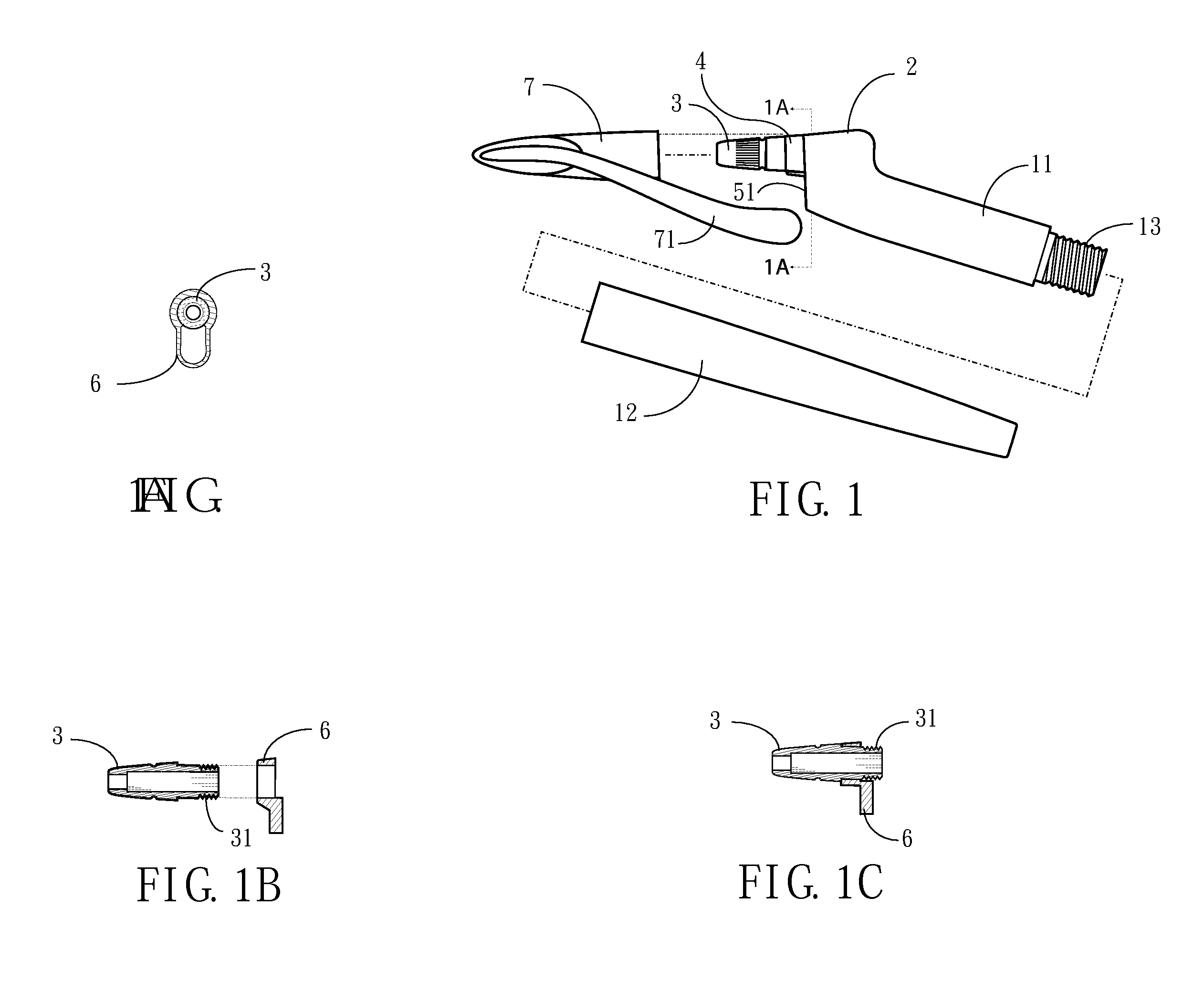

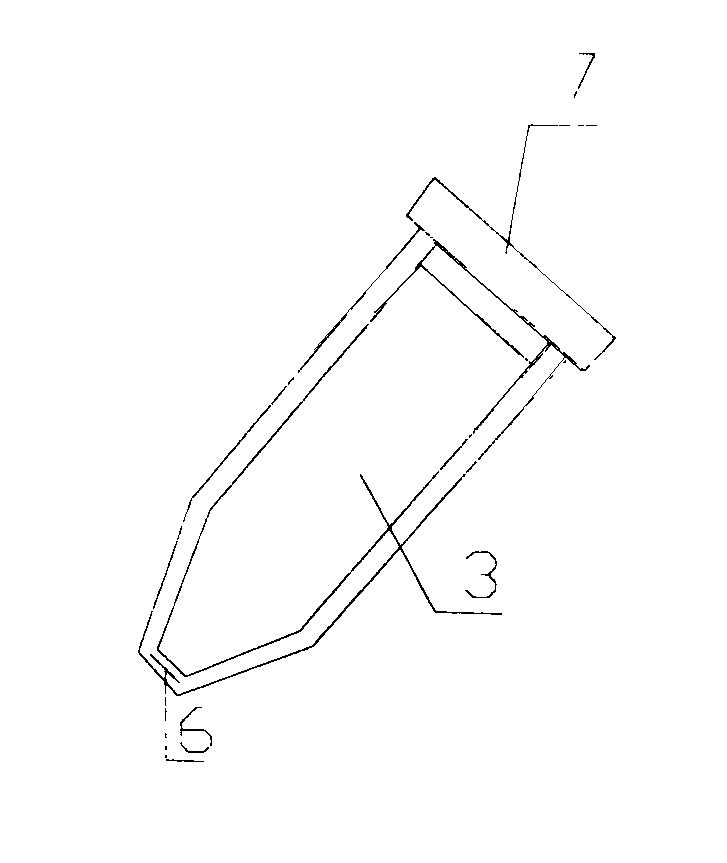

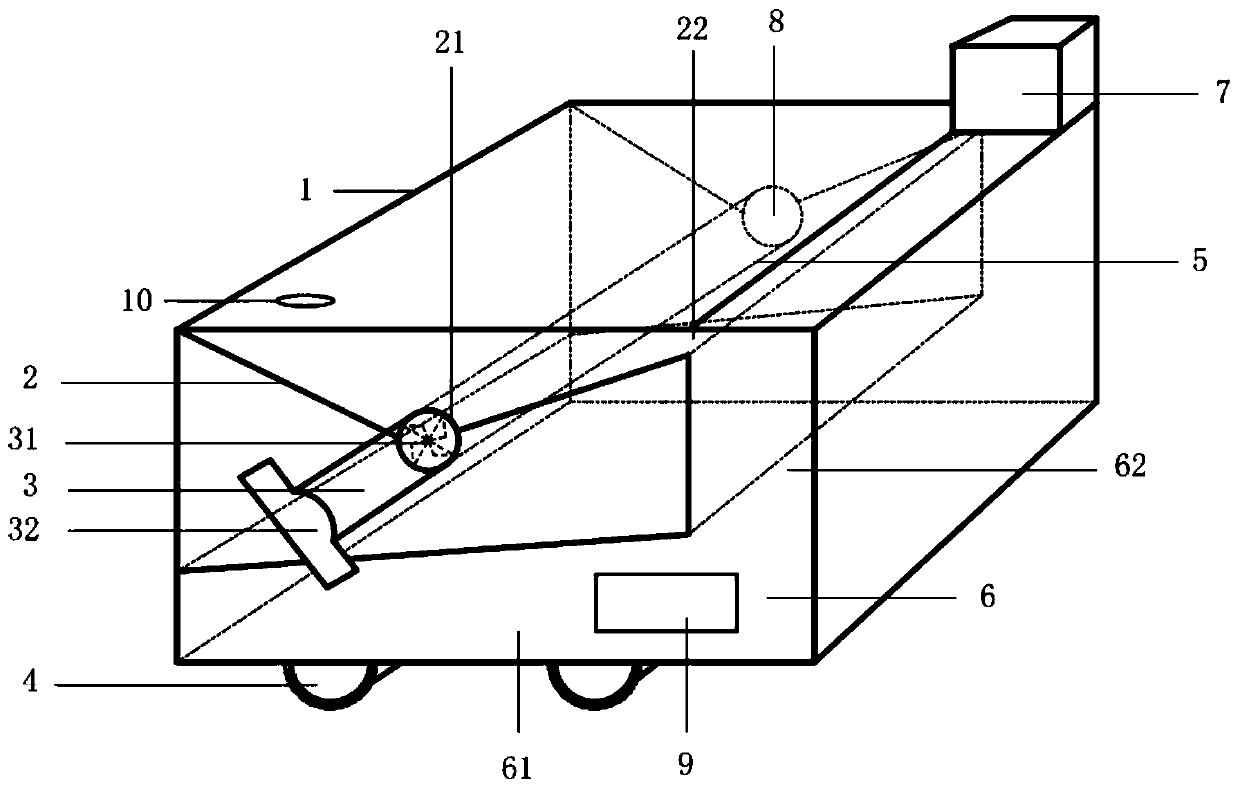

Offset pen structure for rapid assembling

InactiveUS7665921B2Easy to produceQuick assemblyErasing devicesLiquid surface applicatorsEngineeringMechanical engineering

Owner:LIU BAO SHEN

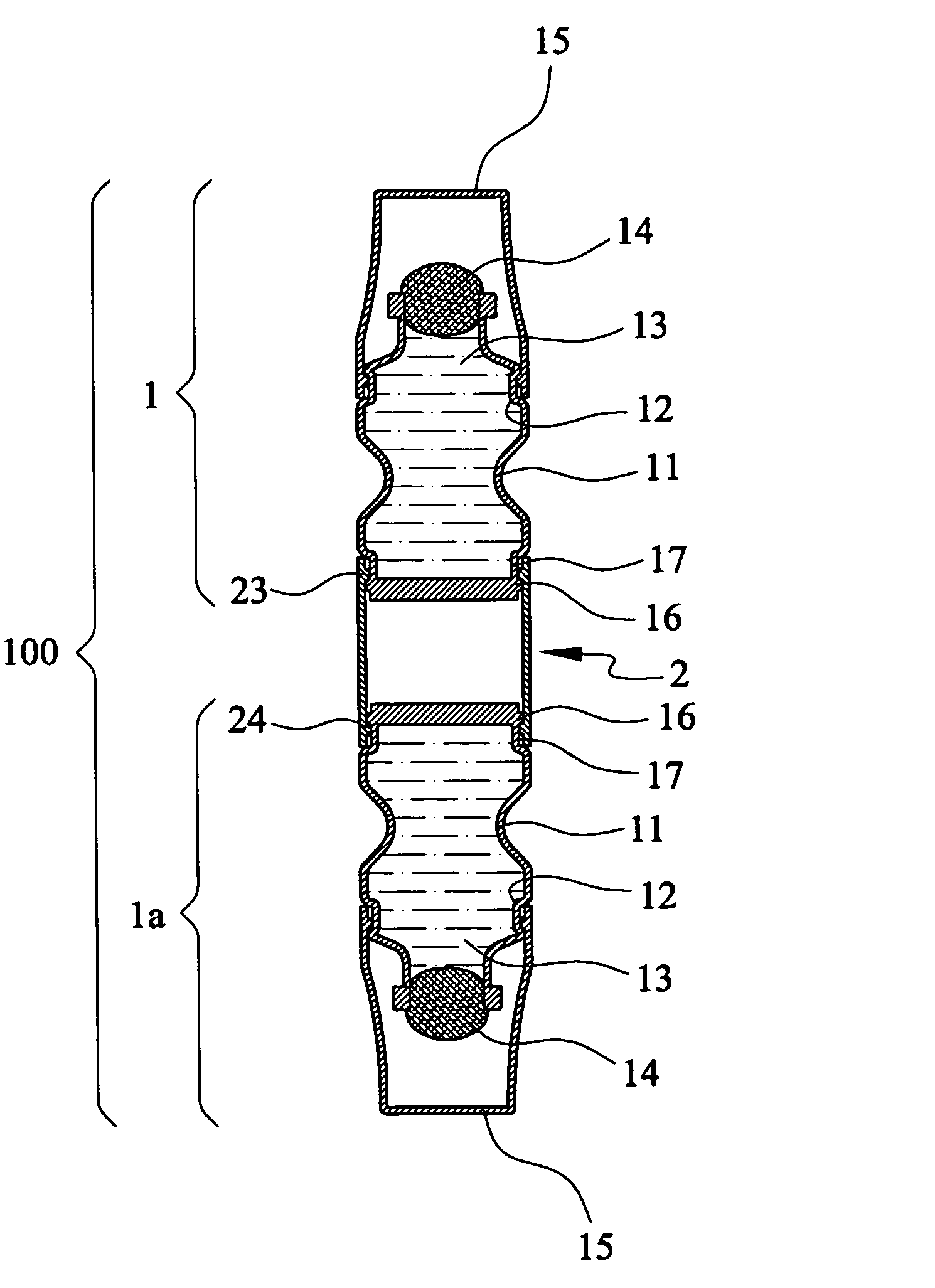

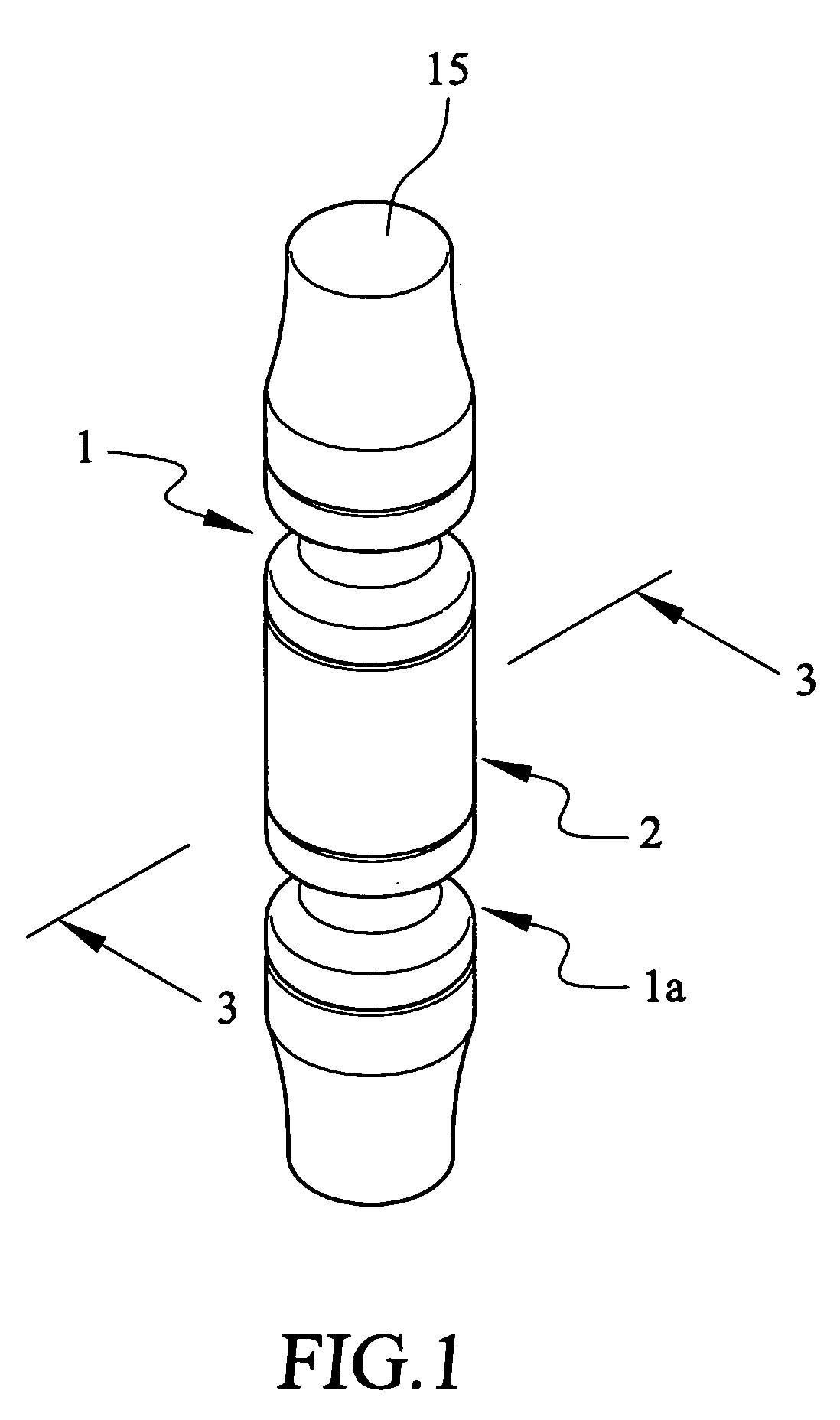

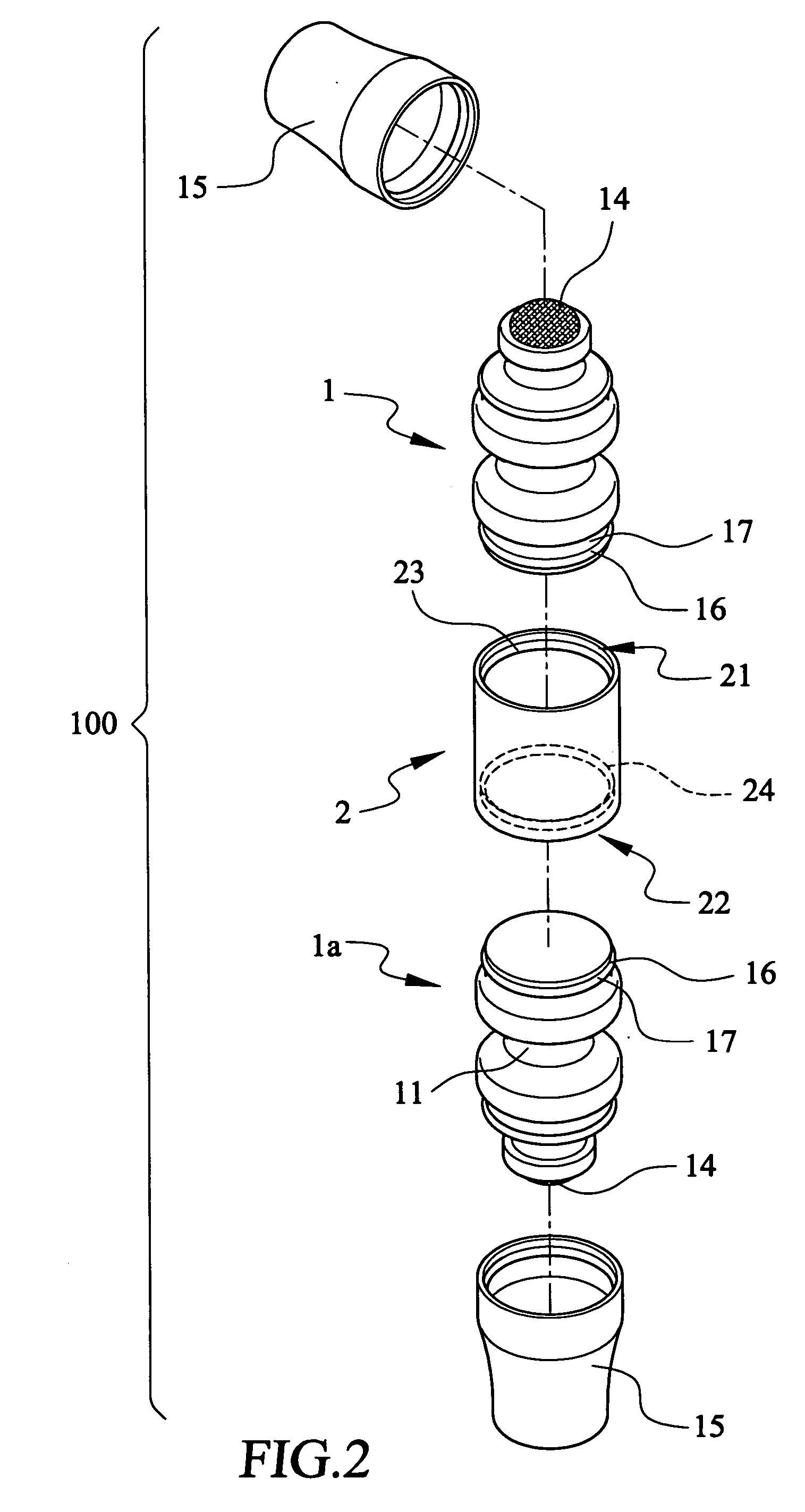

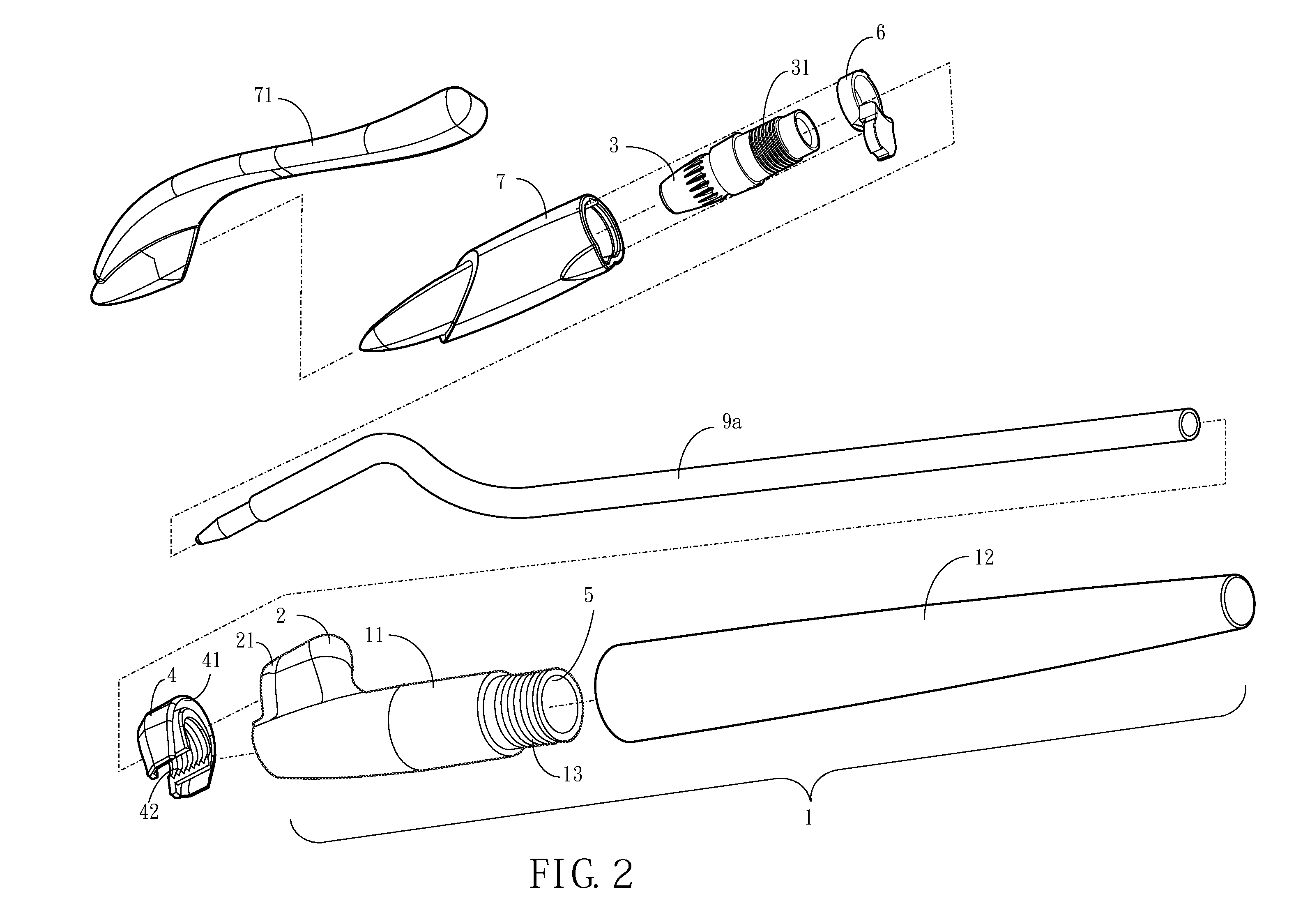

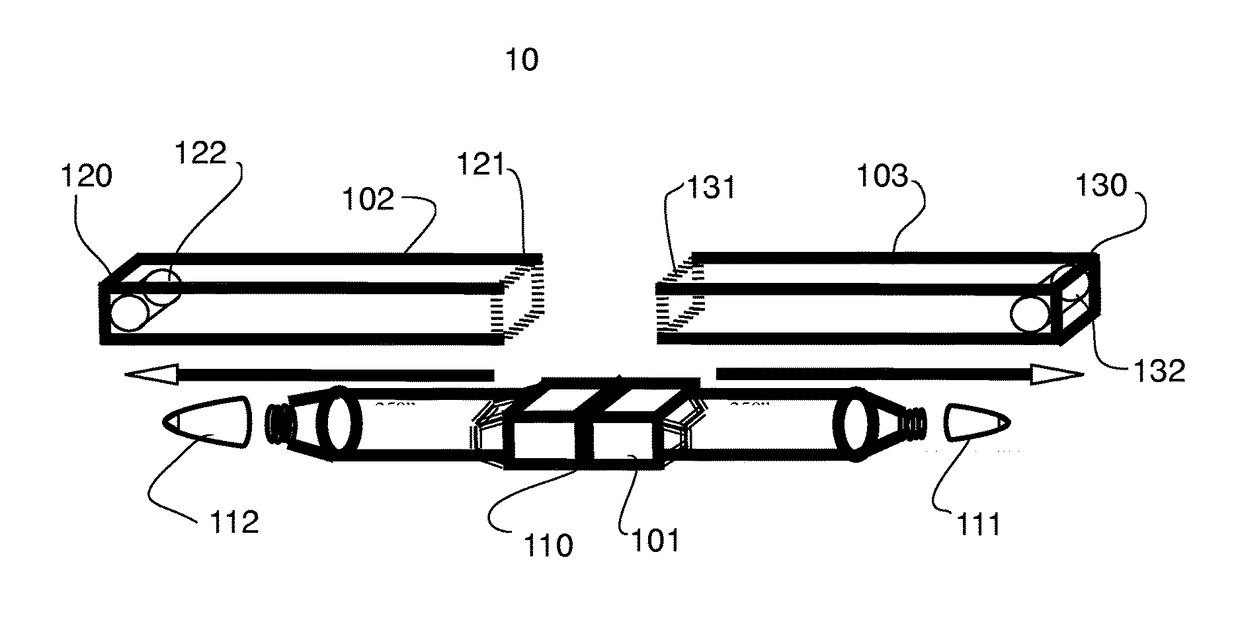

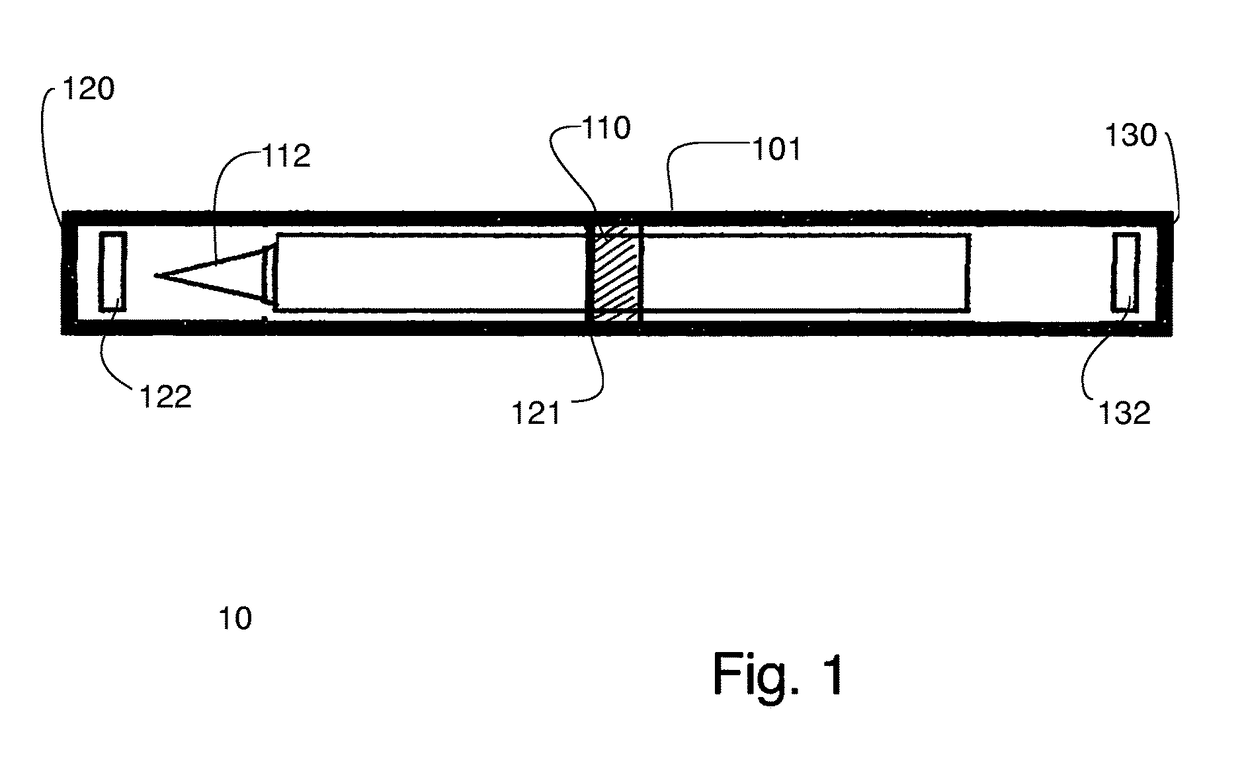

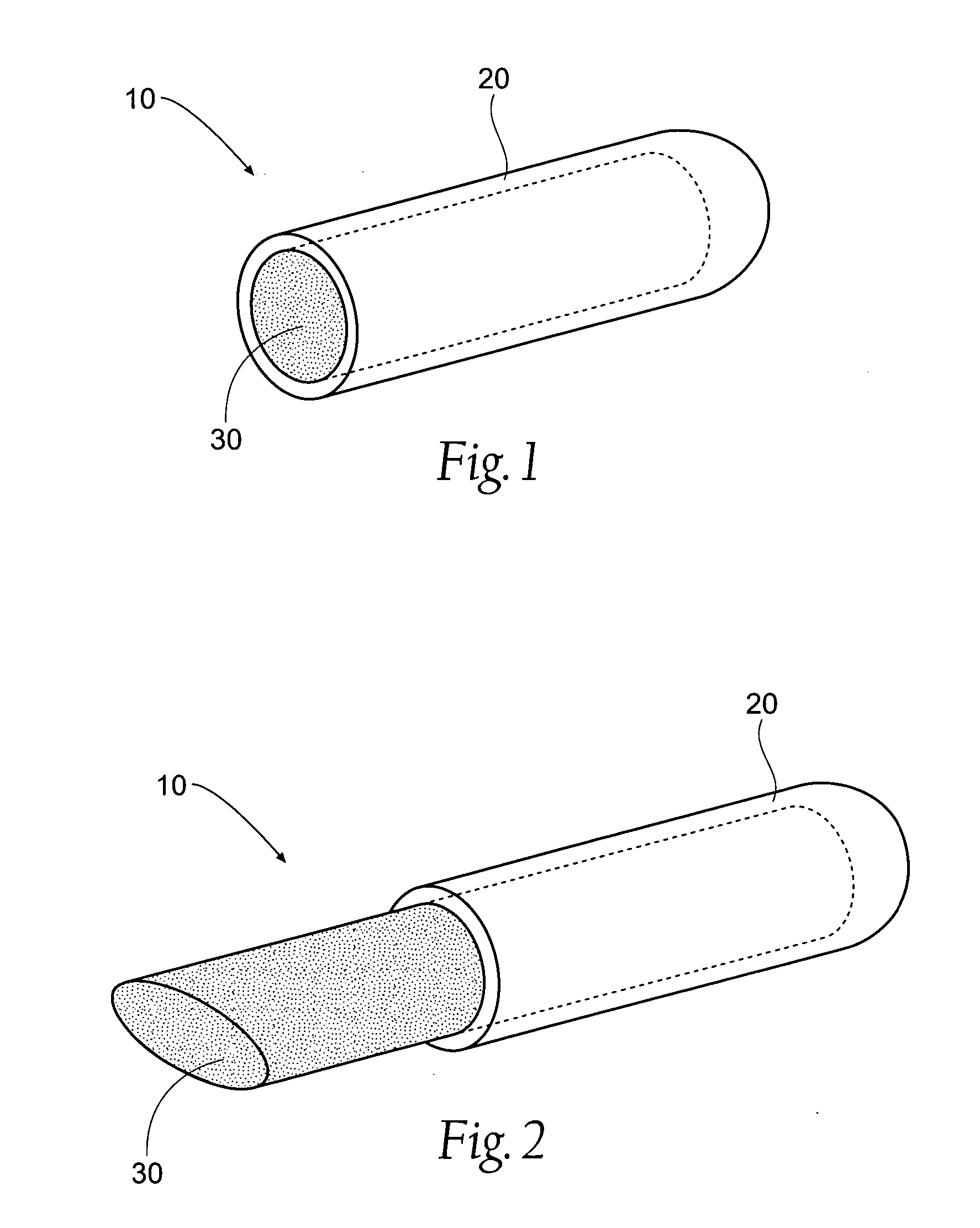

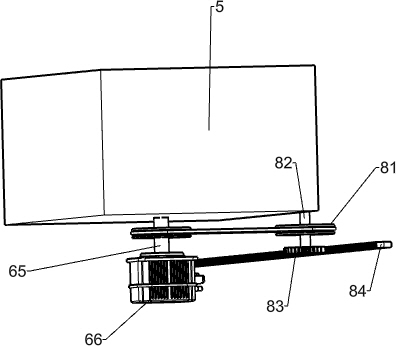

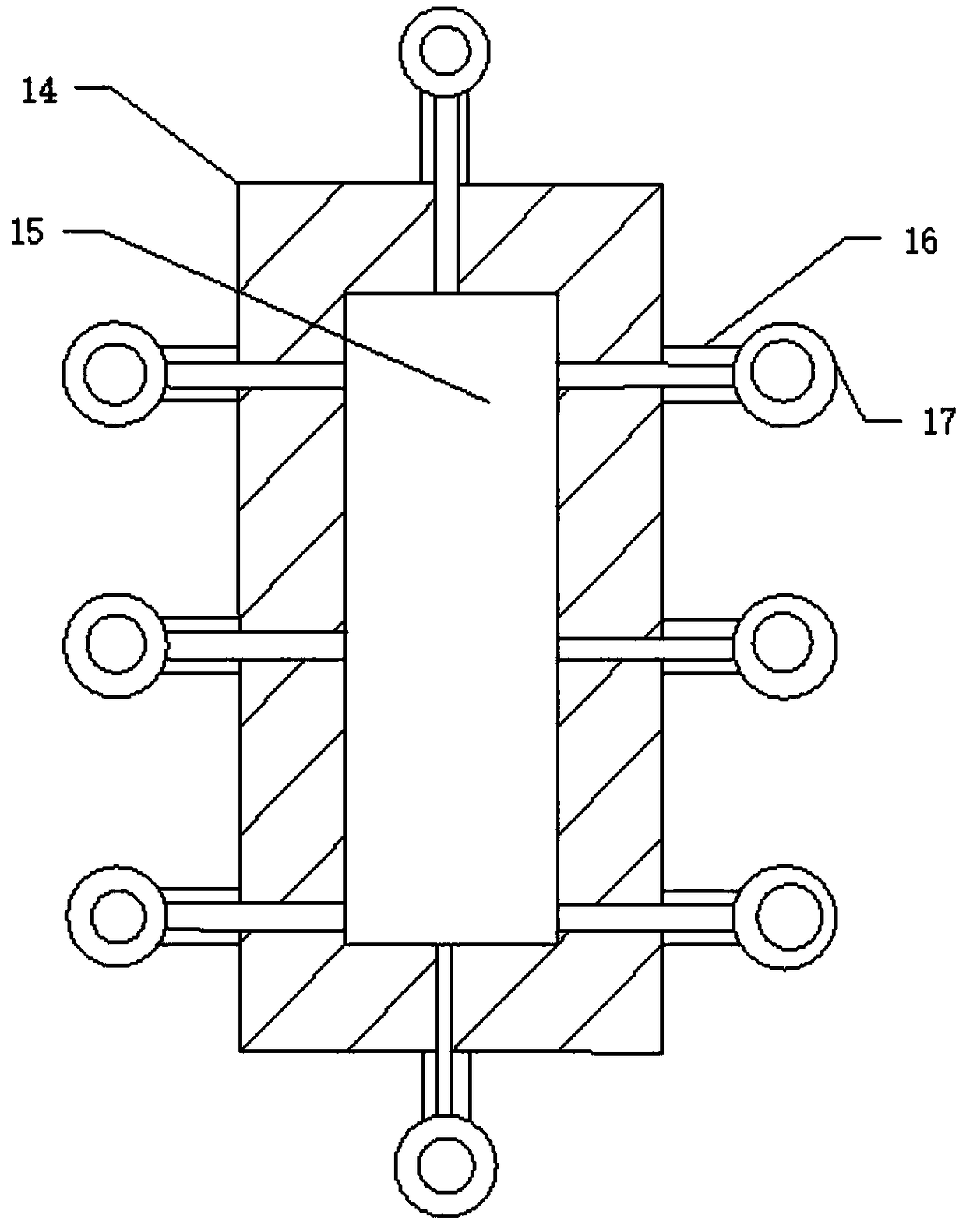

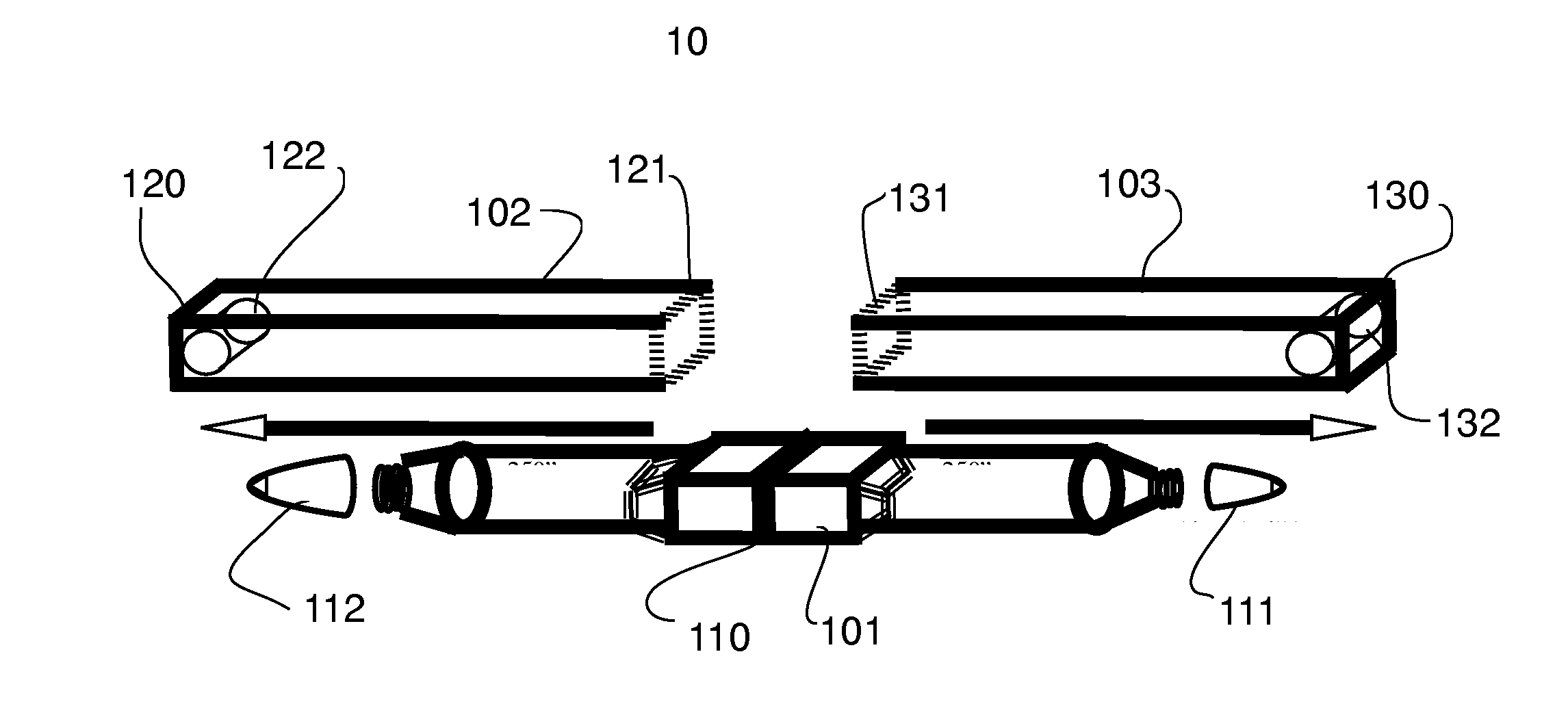

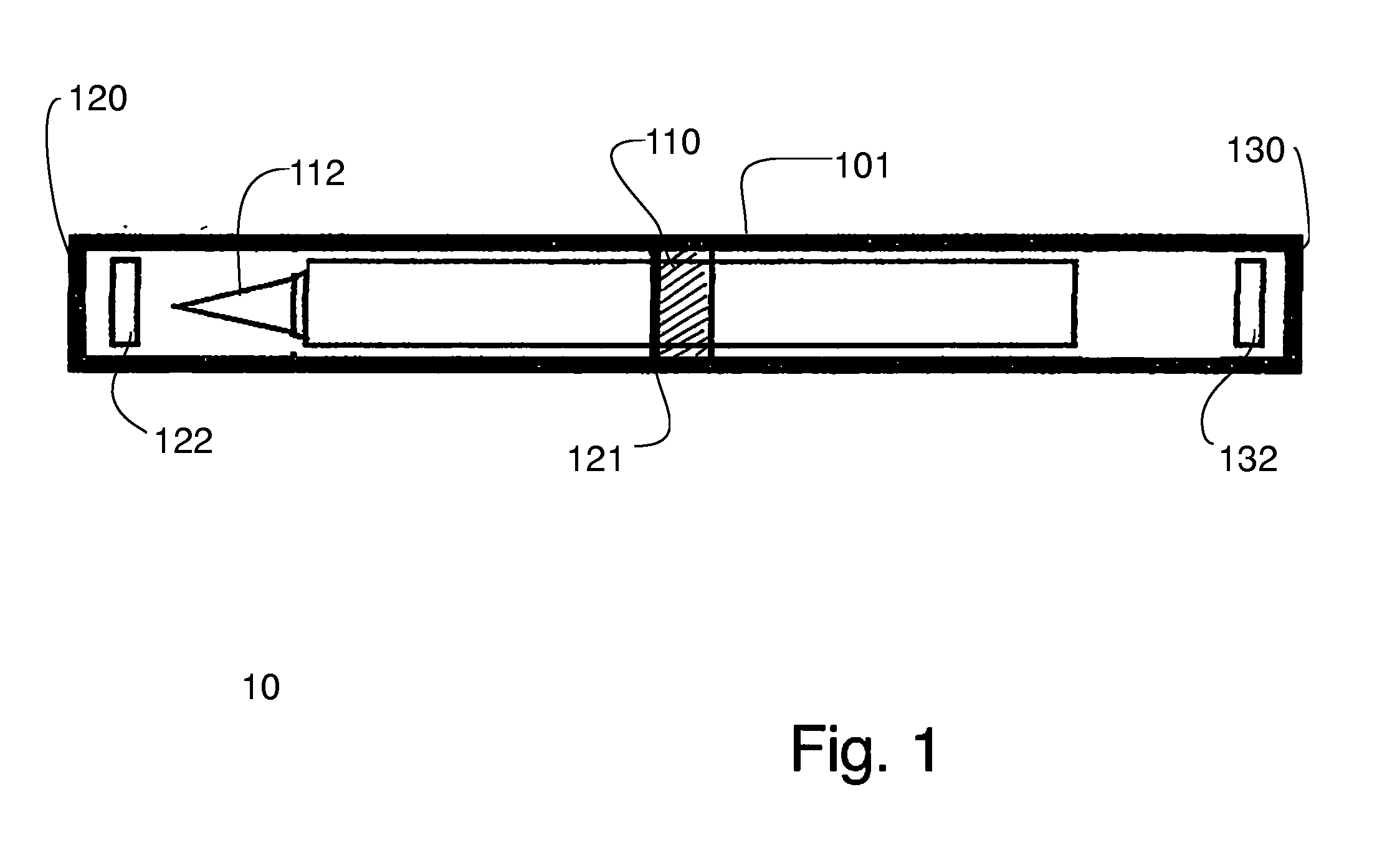

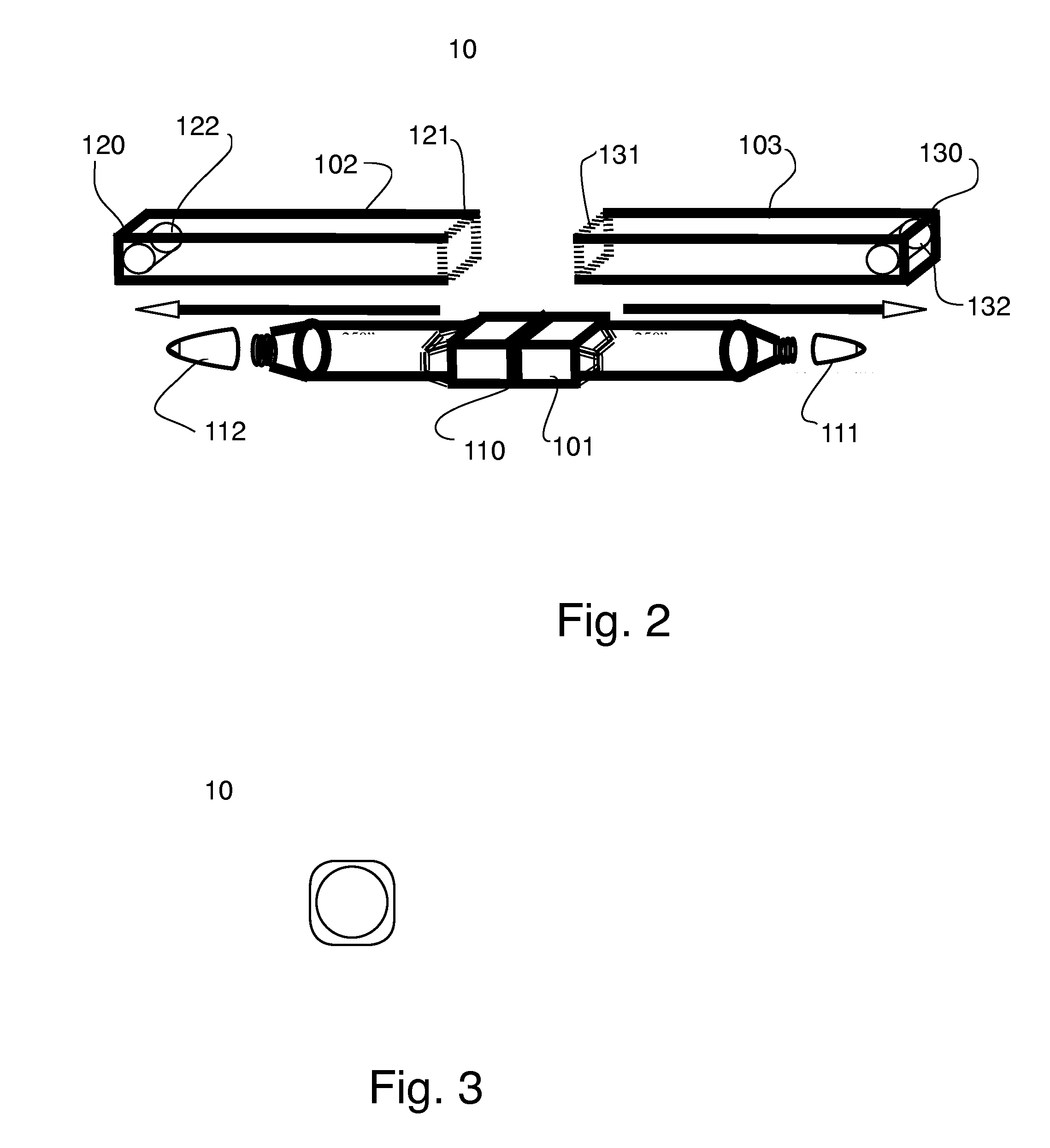

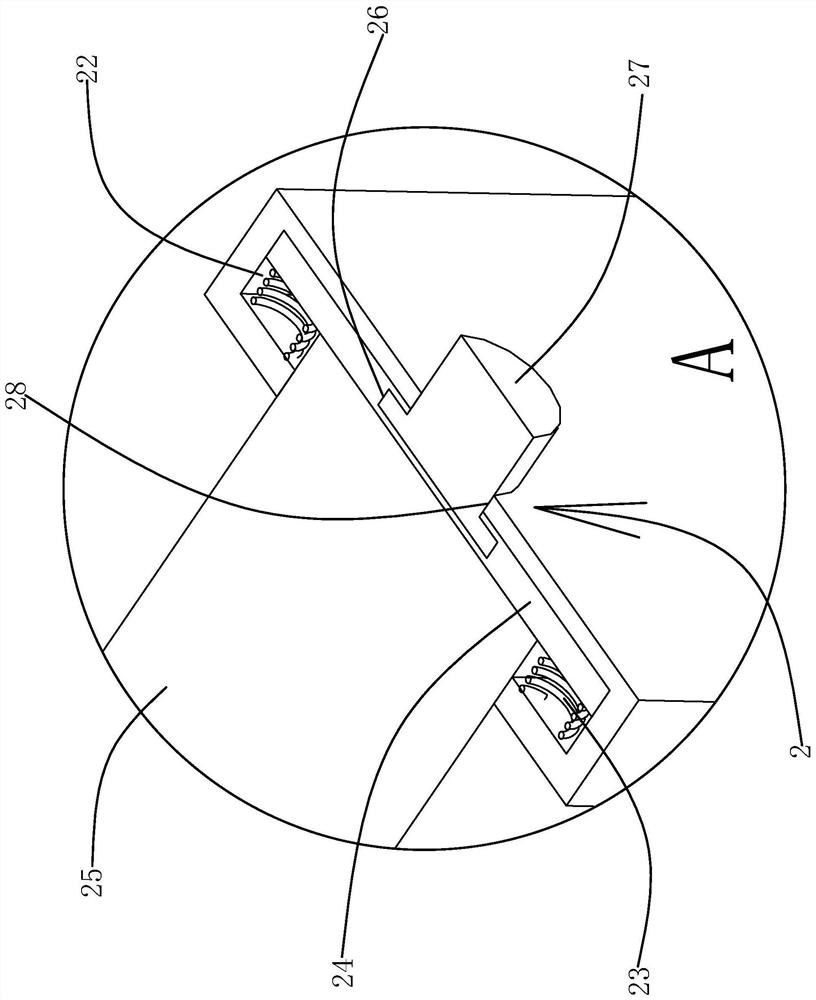

Detachable liquid chalk assembly

InactiveUS20060062630A1Wide choiceSuitable lengthChalksLiquid surface applicatorsCouplingLiquid chalk

A liquid chalk assembly includes a first and a second liquid chalk module that are connected together via a first coupling sleeve to point two writing heads provided at front ends of the two modules to two opposite directions. A second coupling sleeve may be further provided to connect at a first end to the front end of the first liquid chalk module and at a second end to a rear end of a third liquid chalk module. Since differently colored liquid chalk material may be contained in different modules, the liquid chalk assembly provides a user with a wide choice of colors in writing.

Owner:LUCKY STAR ENTERPRISE

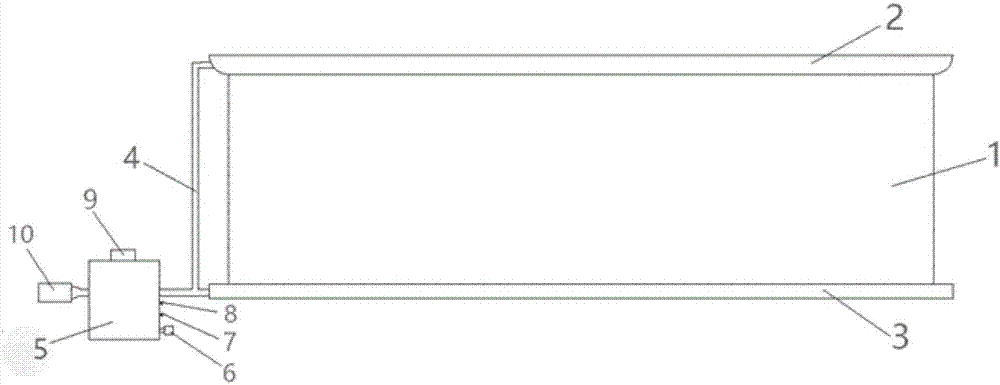

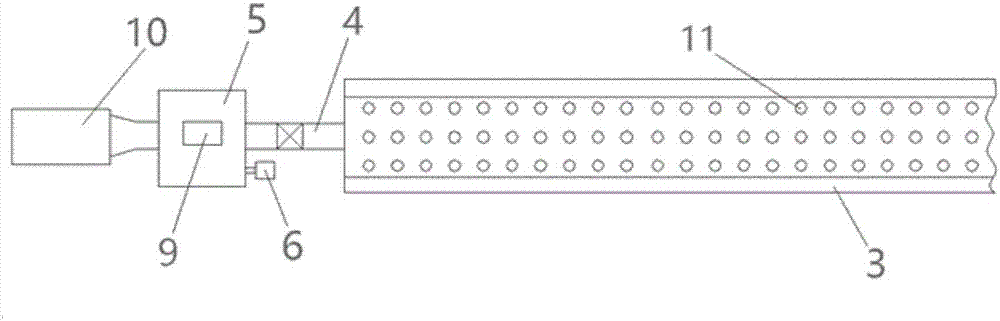

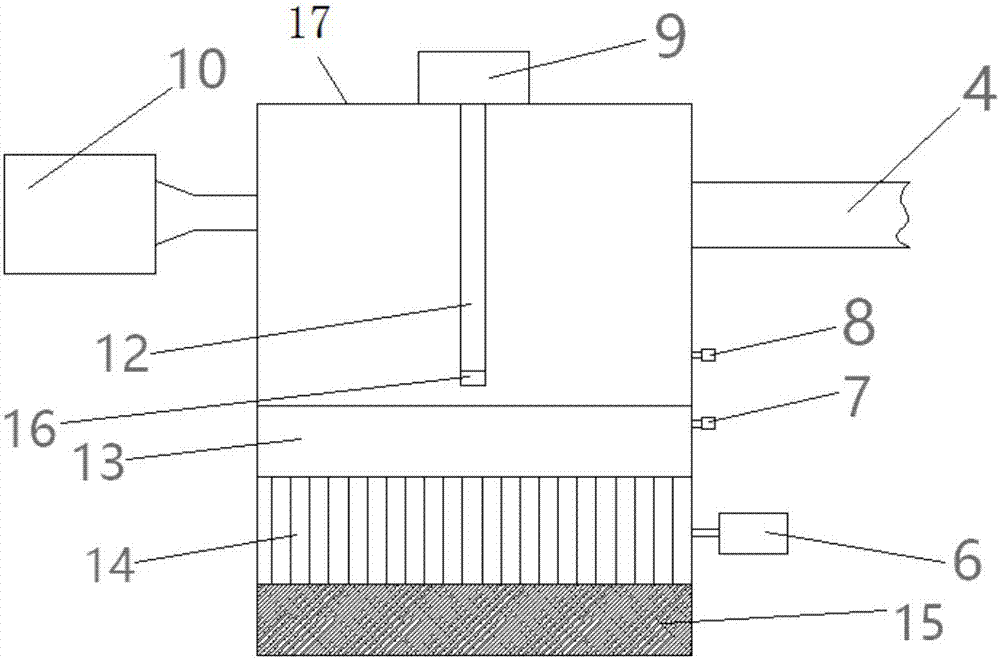

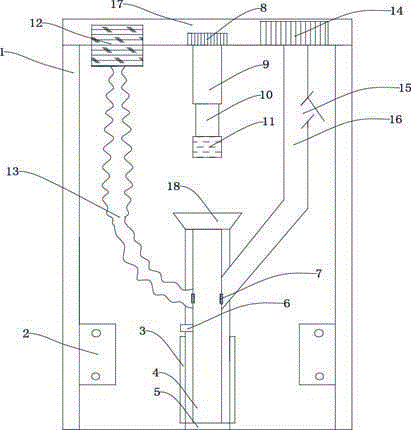

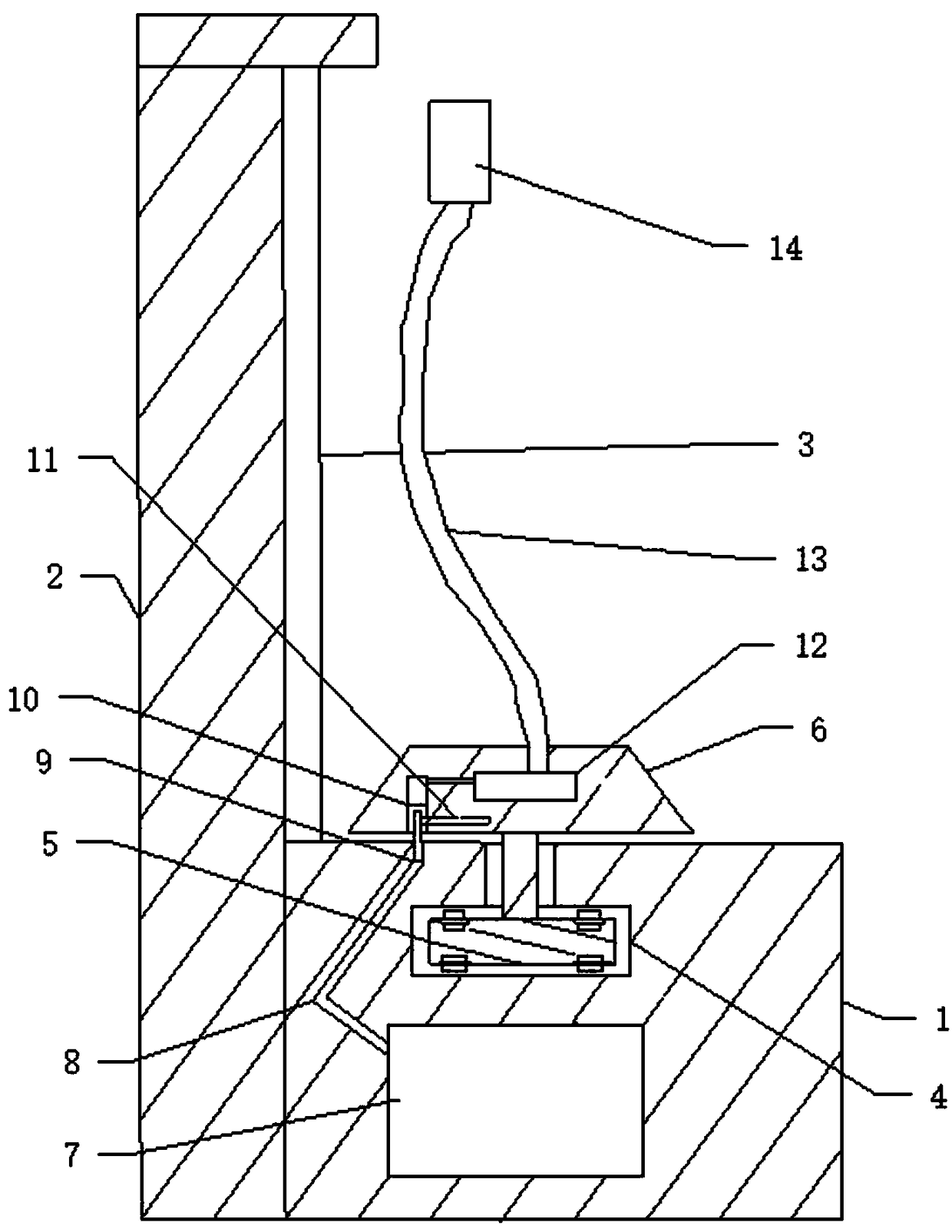

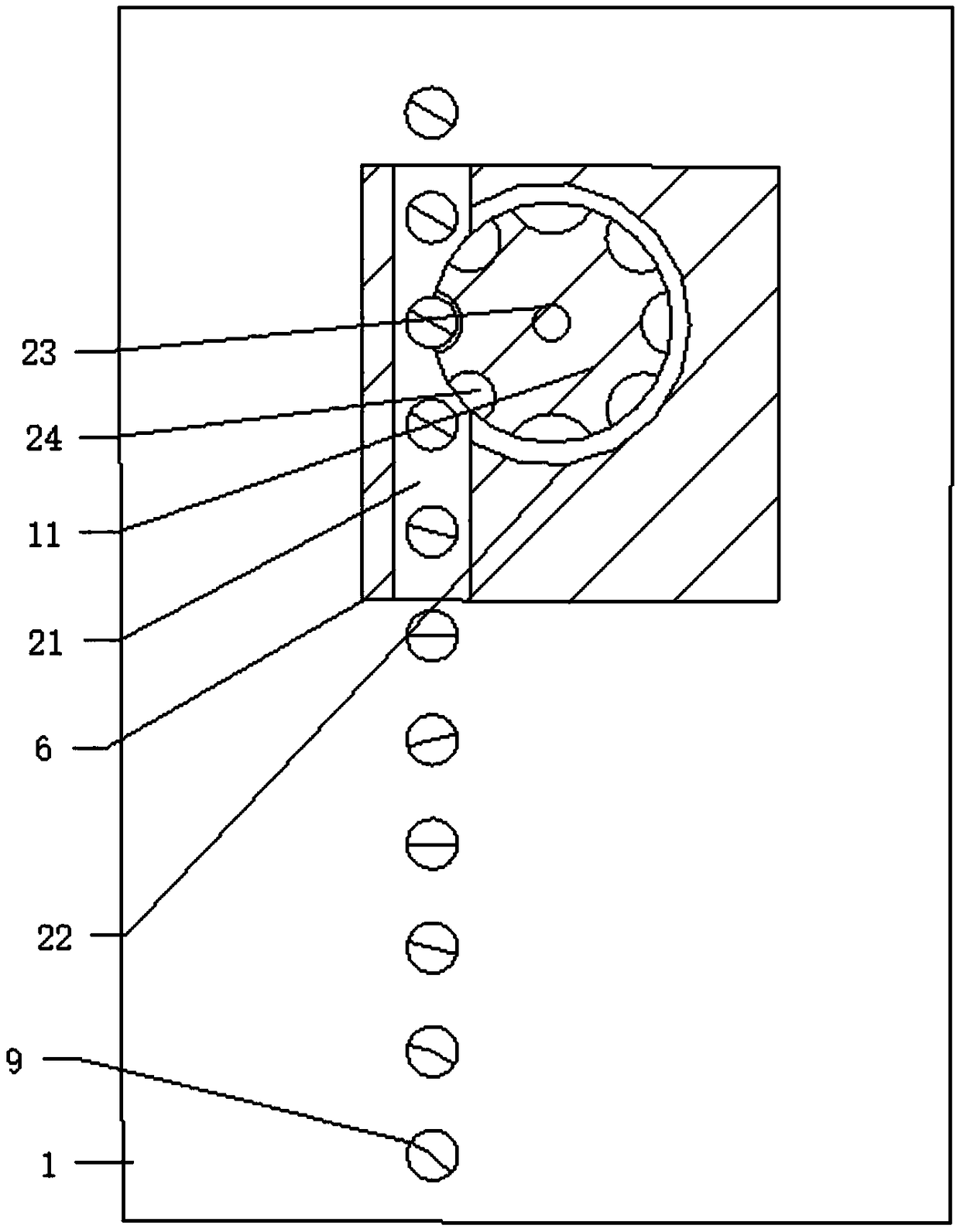

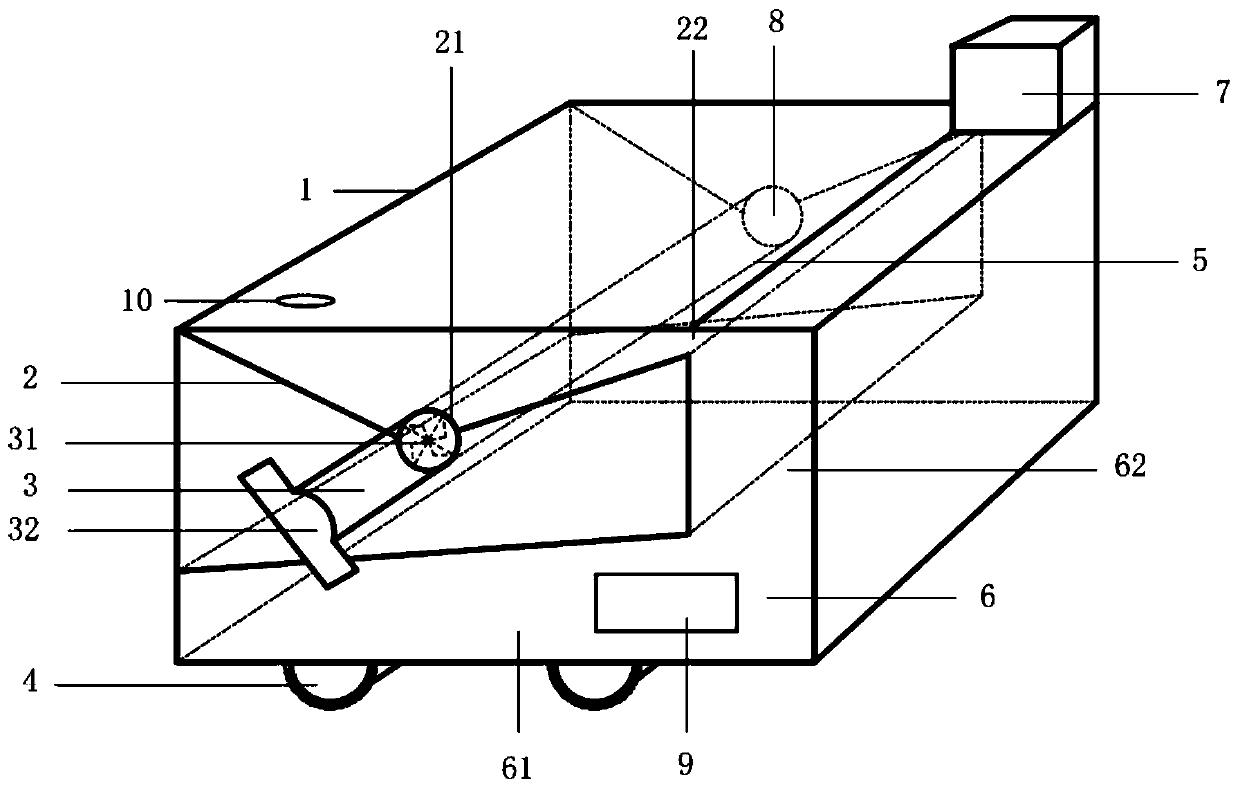

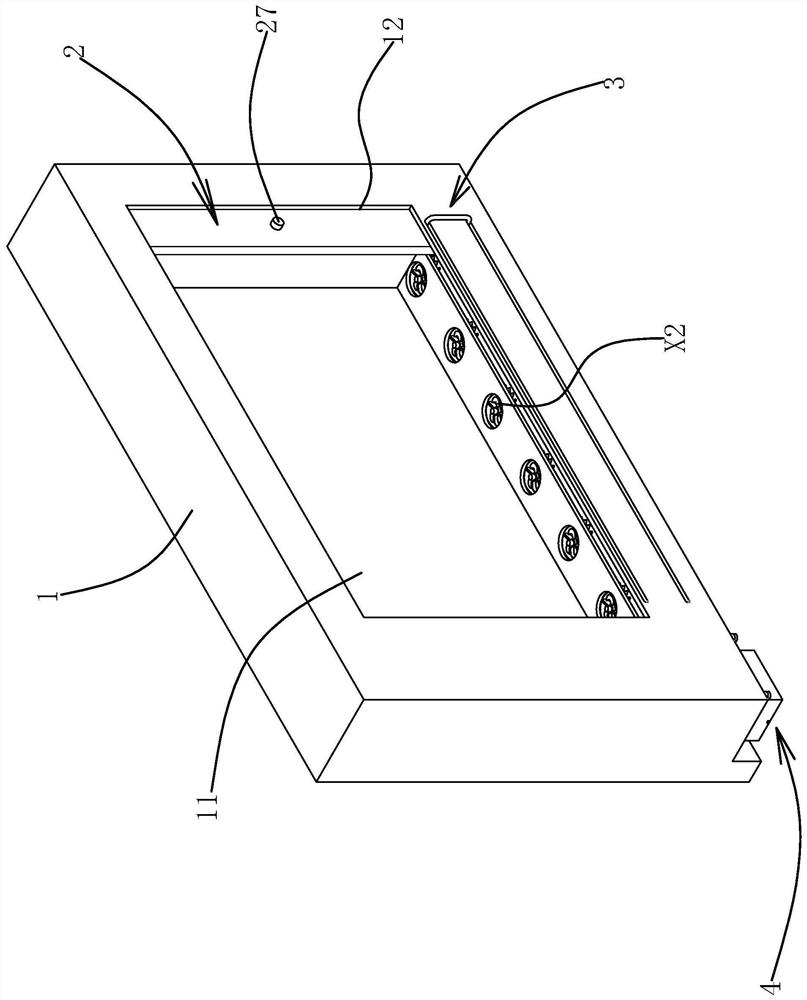

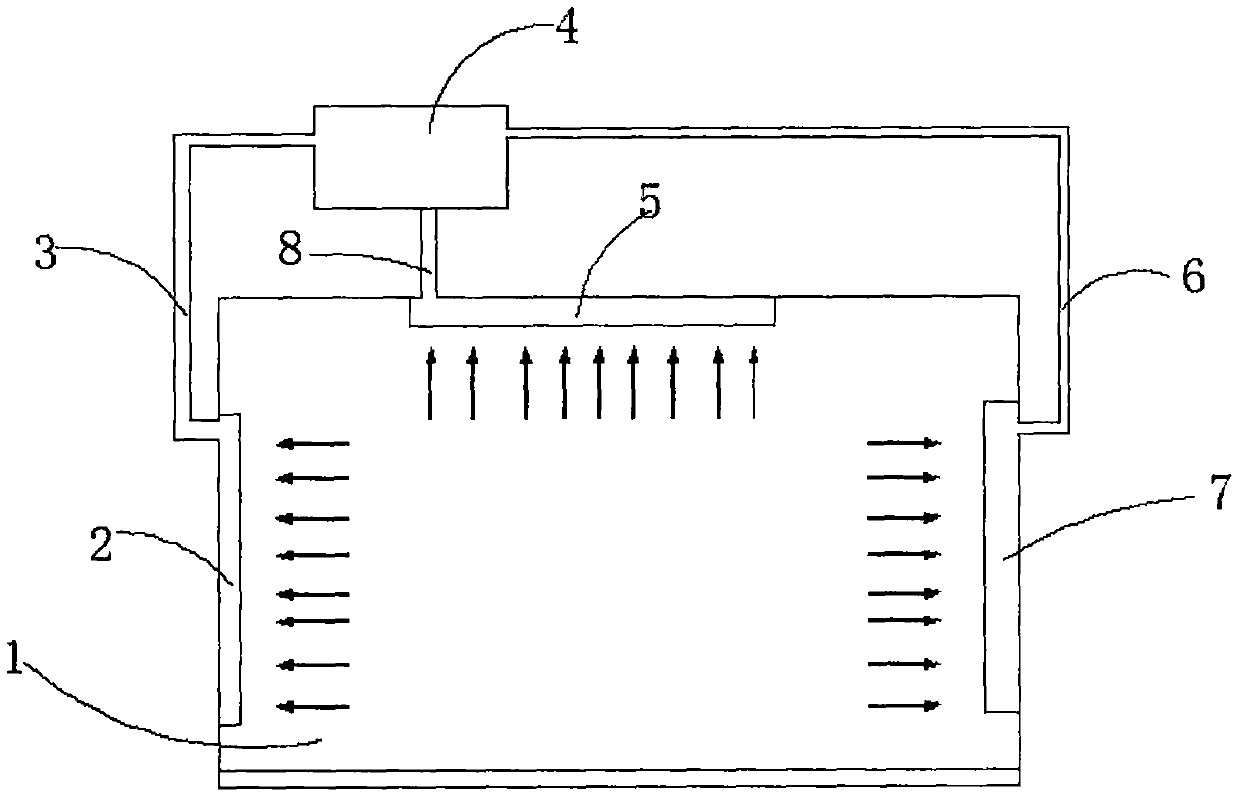

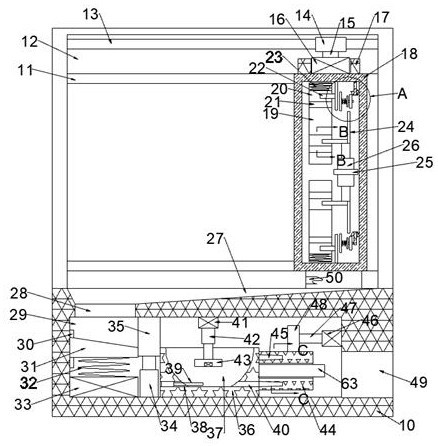

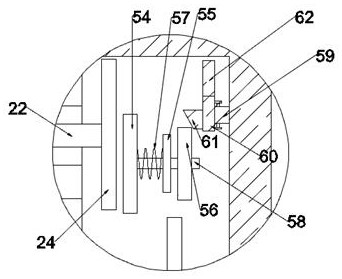

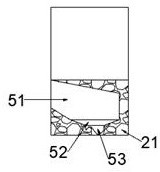

Dust collecting system for recycling chalk

PendingCN107399187ADon't worry about harmKeep healthyBoard cleaning devicesChalksEngineeringAtmospheric pressure

The invention provides a dust collecting system for recycling chalk. The dust collecting system comprises a blackboard body, an upper dust suction device, a lower dust suction device, a chalk regeneration device, an air introducing device, a controller and a display screen; the upper dust suction device and the lower dust suction device are connected to the chalk regeneration device through guide pipes so that the function that when a teacher wipes a blackboard in class, chalk dust is automatically sucked into the system and is used for secondary manufacturing of the chalk can be achieved, and therefore a good teaching and learning environment can be created, and in addition, the effects of energy conservation, low carbon and environmental protection can be achieved by secondary utilization of the chalk dust; and an introduced draught fan in the chalk regeneration device starts to work so that the internal air pressure of the device can be decreased, the chalk dust can pass through holes in the surface of a blackboard groove of the upper dust suction device and holes in the surface of a blackboard groove of the lower dust suction device and enter the chalk regeneration device through the guide pipes, and after the chalk dust is collected to a certain degree, the chalk manufacturing is started. The system has the advantages of being low in production cost, simple in structure, wide in application range, convenient to use, high in practicality and the like.

Owner:JIANGSU UNIV

Offset Pen Structure for Rapid Assembling

InactiveUS20080101844A1Easy to produceQuick assemblyErasing devicesChalksEngineeringMechanical engineering

Owner:LIU BAO SHEN

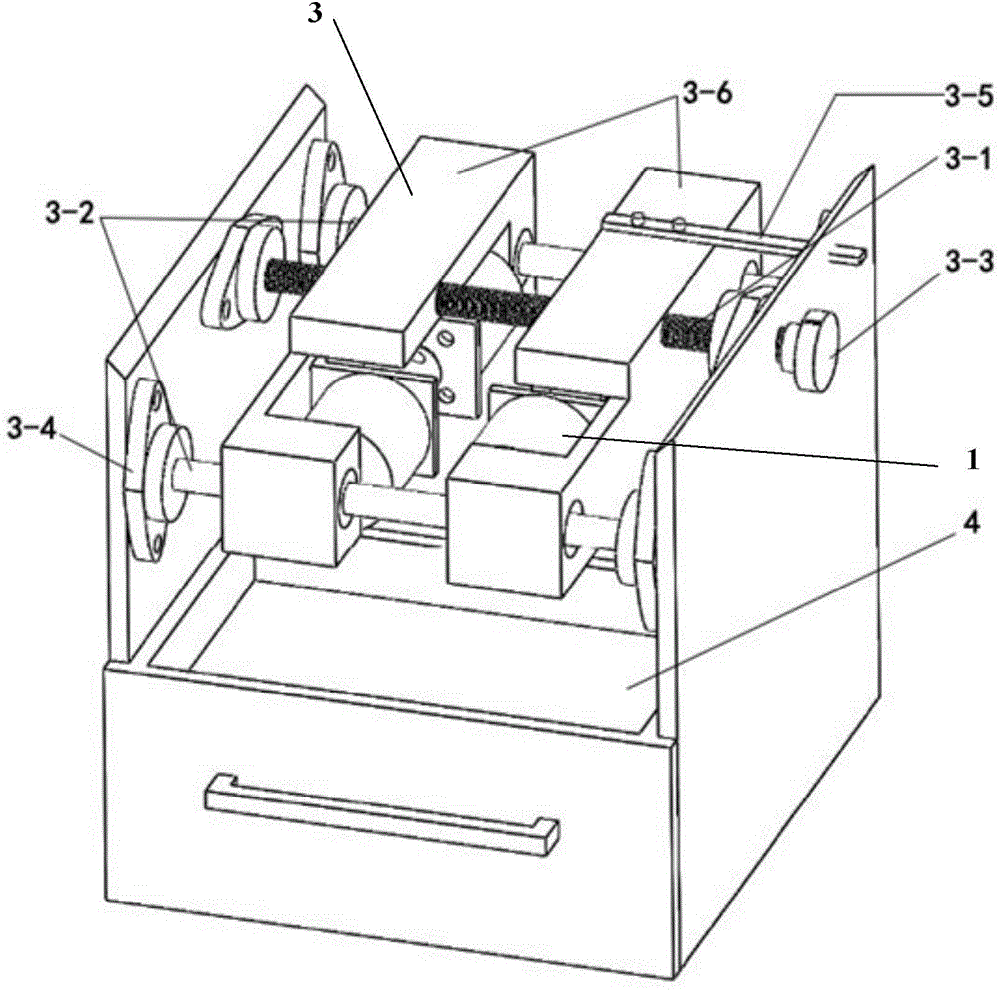

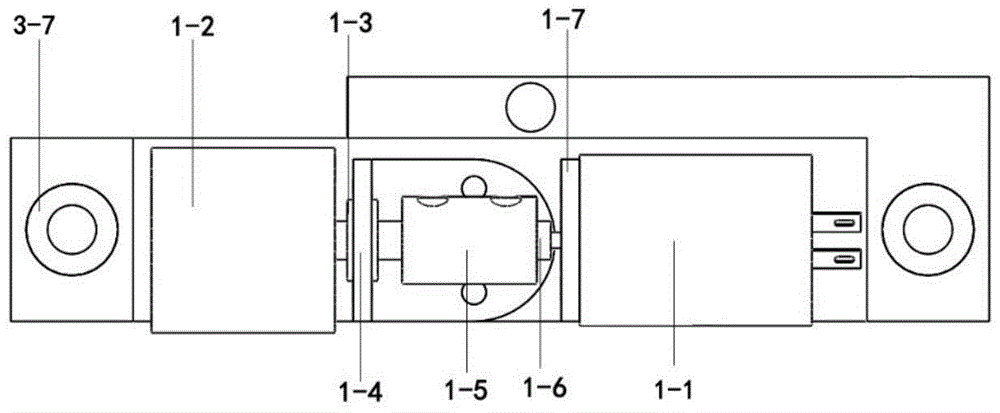

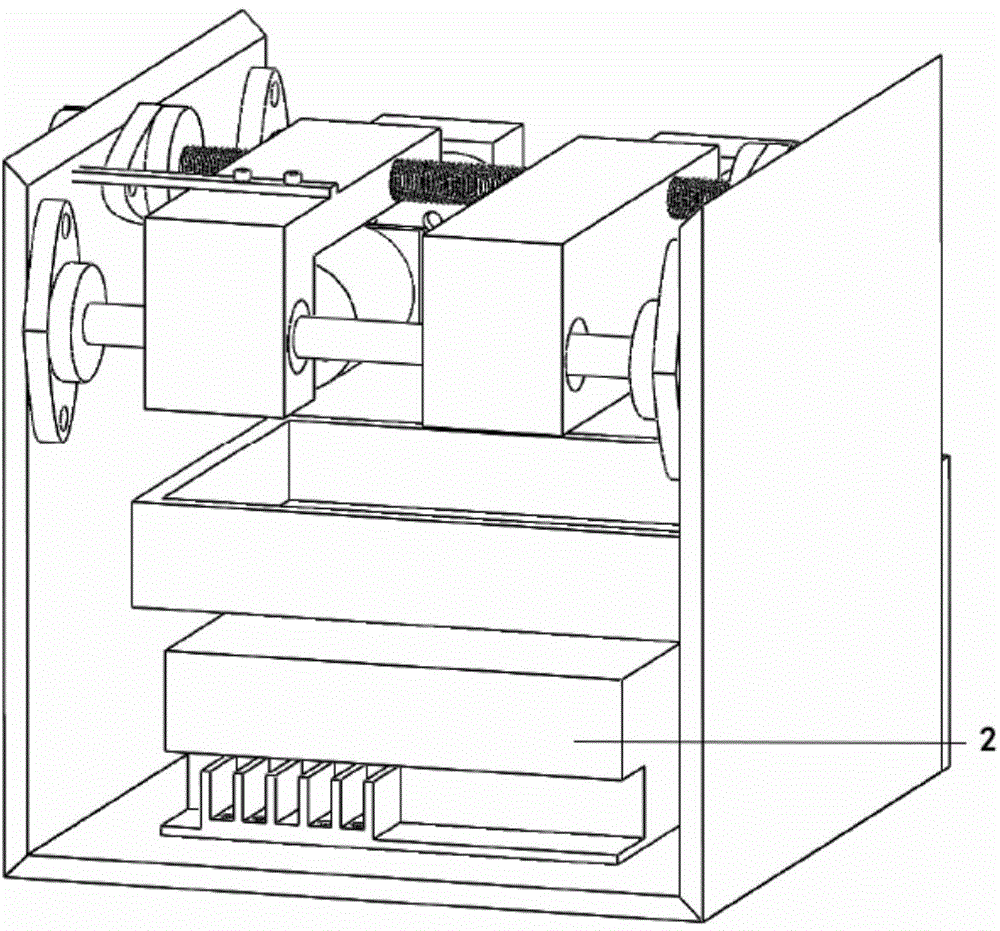

Chalk end recycling and chalk resetting device

A chalk end recycling and chalk resetting device is characterized by comprising a powder sucking assembly, an adhesive assembly and a pressure assembly, wherein the powder sucking assembly comprises a blackboard eraser provided with a powder suction port, and the blackboard eraser is connected with the pressure assembly through a flexible pipeline; the adhesive assembly comprises a fixing pipeline connected with the pressure assembly, and the fixing pipeline is further provided with an air pump and a window used for adding adhesive; the pressure assembly comprises a mixing cylinder and a downward pressing element capable of being pressed into the mixing cylinder, and a heating part is arranged on the lower portion of the mixing cylinder. The chalk end recycling and chalk resetting device has the advantages that chalk powder and chalk ends can be repeatedly used, and energy conservation and environment protection are achieved.

Owner:安徽格太信控科技有限公司

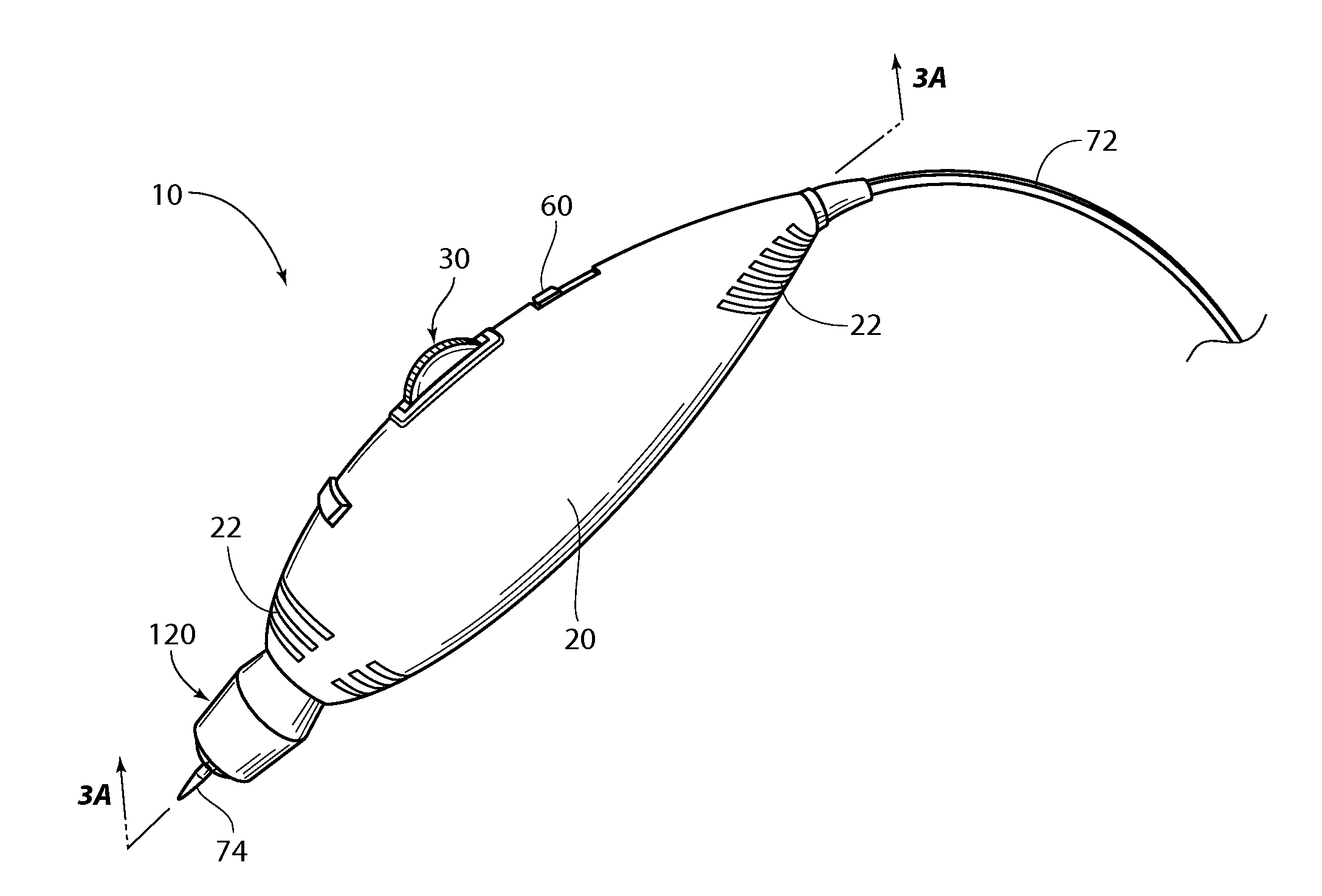

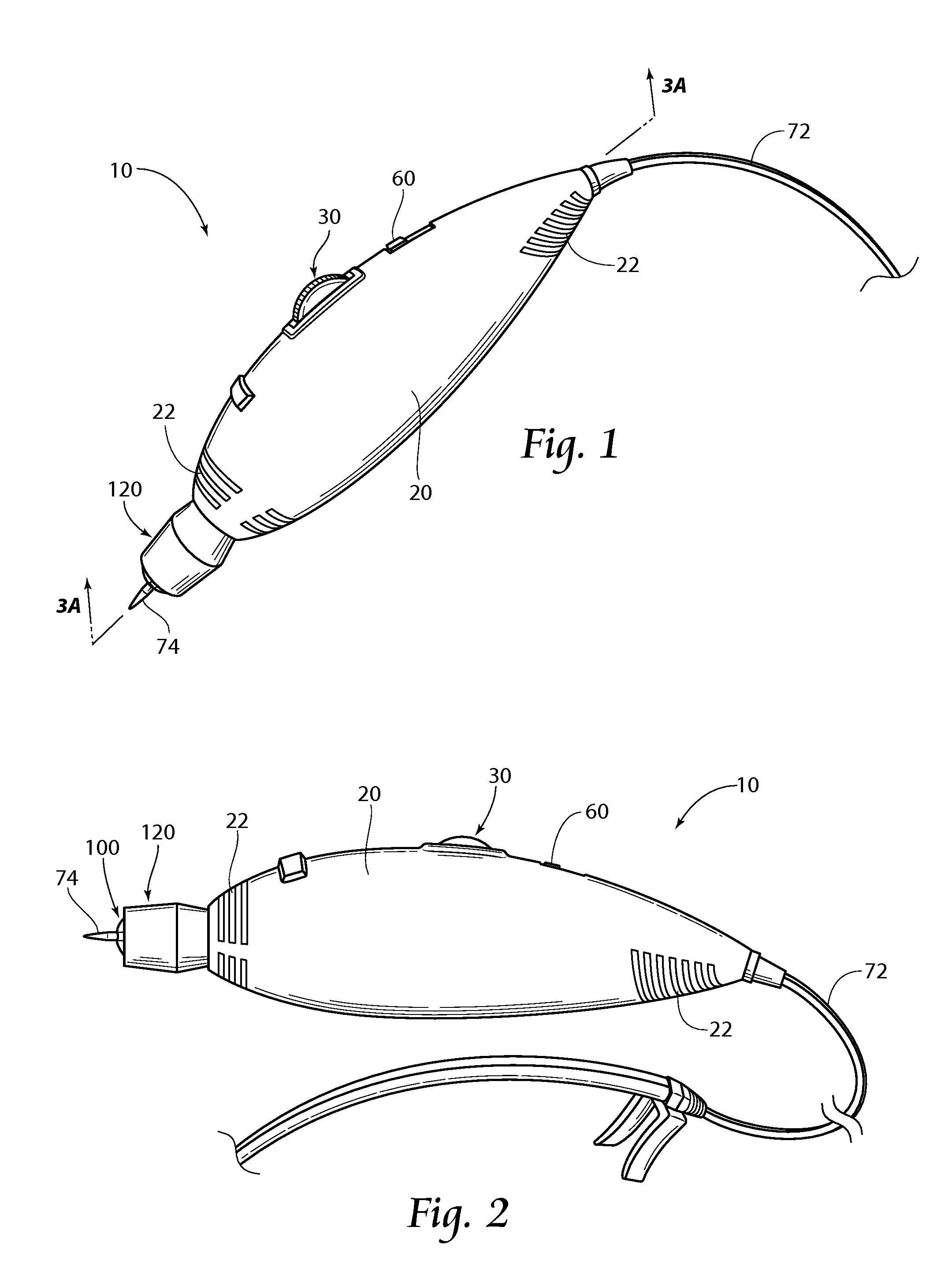

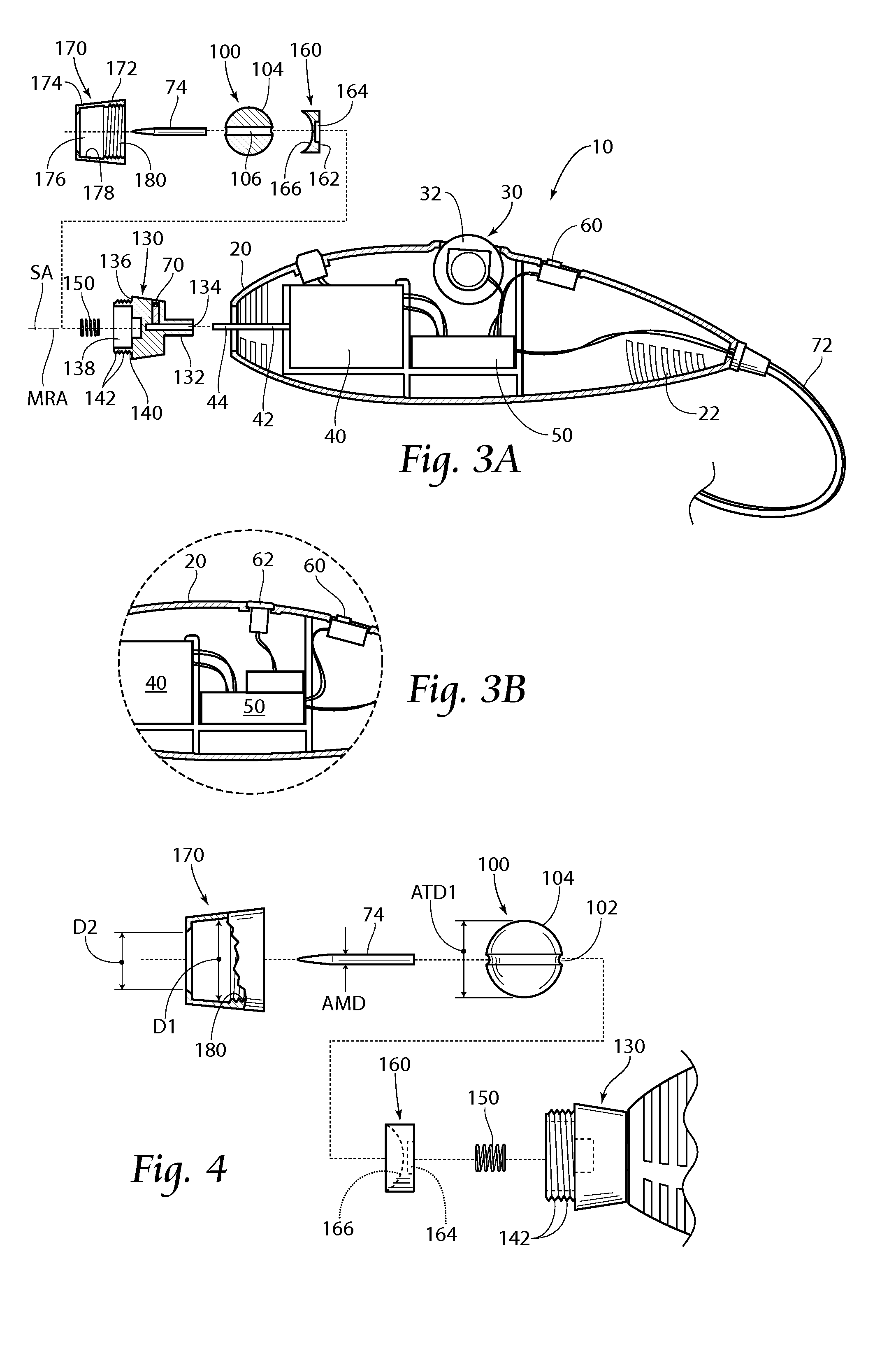

Magnetized writing and amusement device

A magnetized writing and amusement device. The device having a first end and a second end. Each of the ends having a magnet embedded with the interior. The magnetics allowing for the coupling of multiple devices together. The first end functions as a cap for the device and conceals a writing implement located within the internal structure of the device.

Owner:QUIROZ ZIEBART JOSE JOHN

Coated writing apparatus

Chalk or other messy writing material is coated with wax or another easily applied material to the writing material, preventing the writing material from creating an undesirable mess.

Owner:WALBY ALEXIS

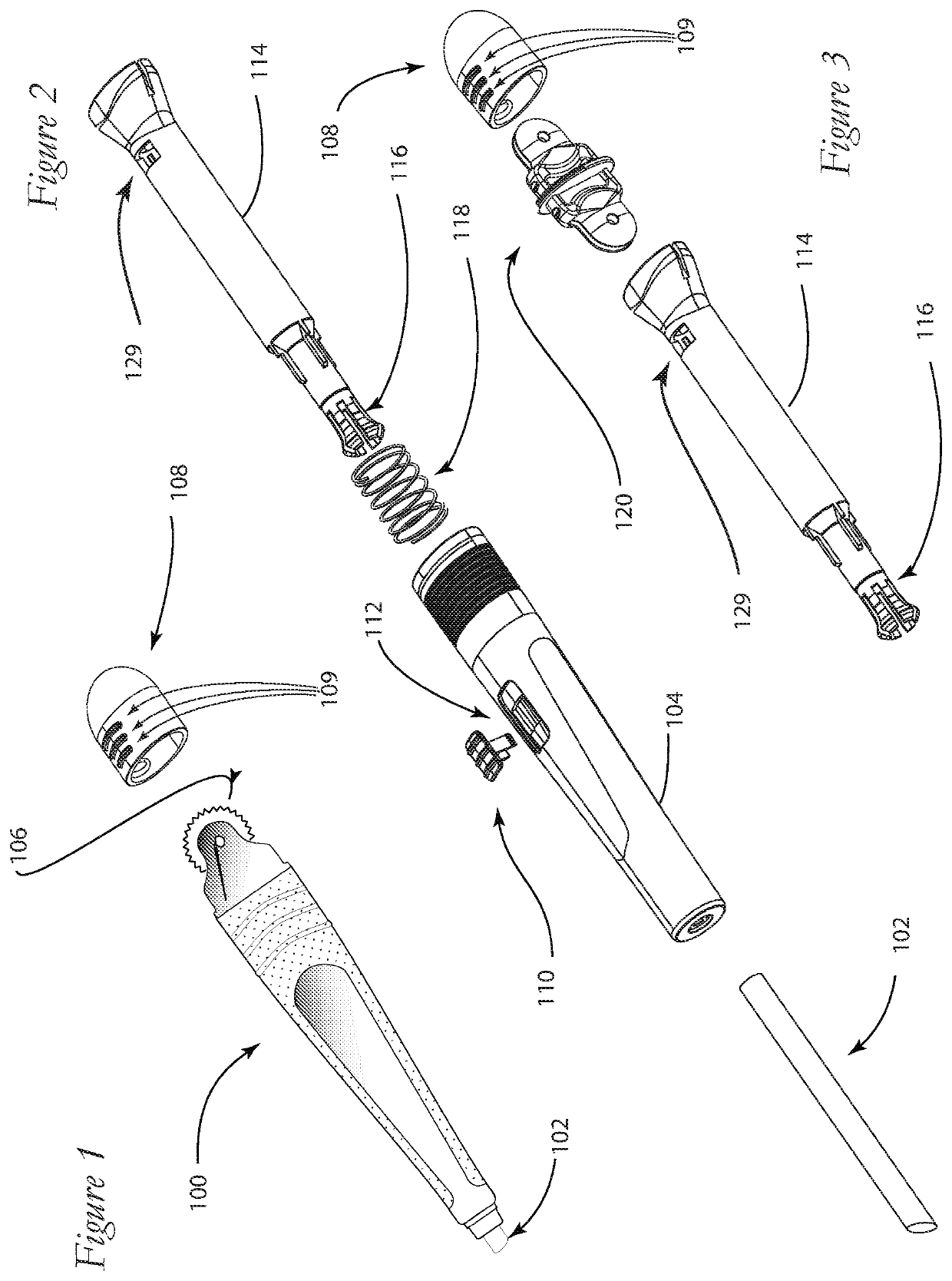

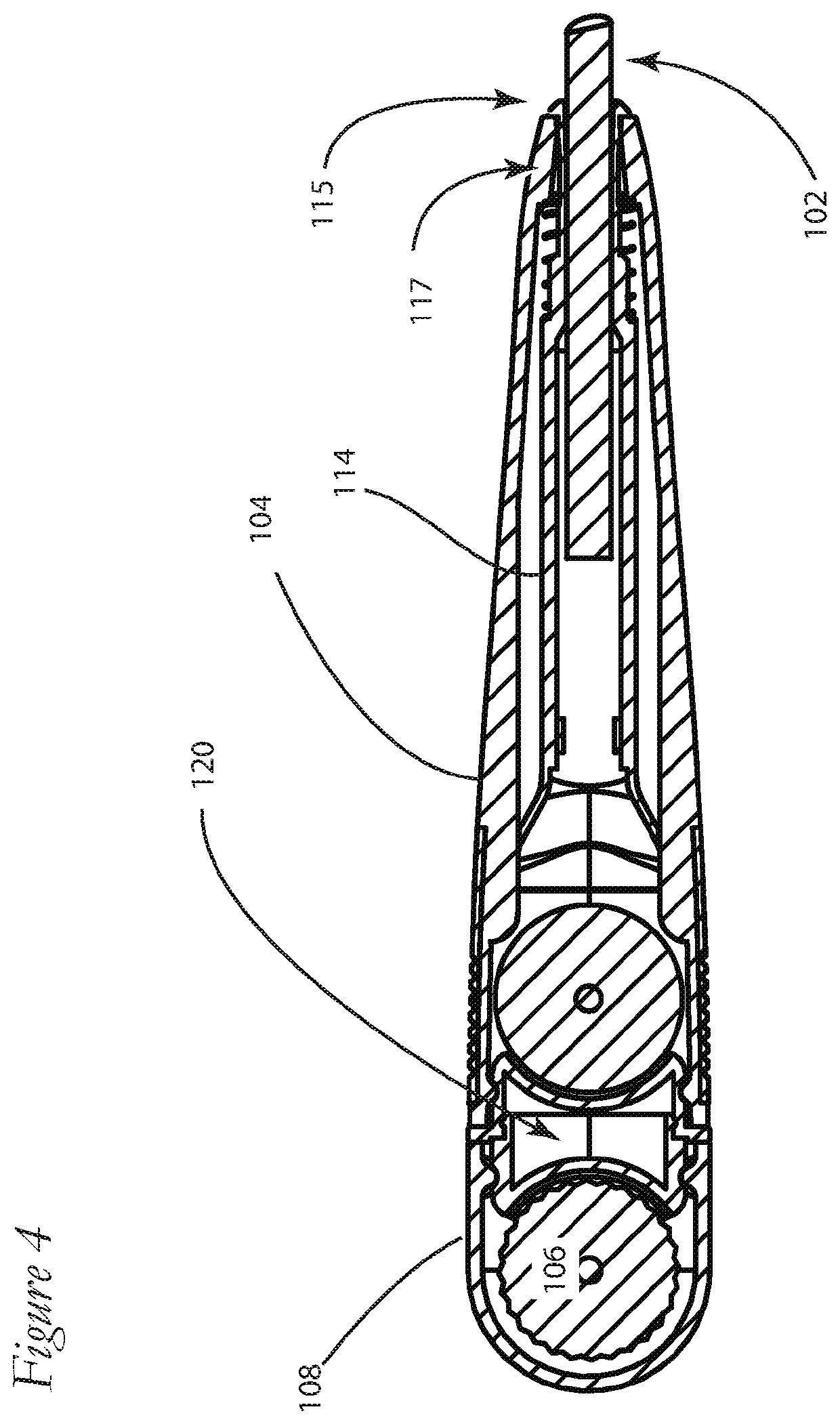

Art Medium Surface Treatment Tool

An art medium applicator includes a rotating shaft and an art medium coupled thereto for causing the medium to travel through an application path for transfer to a substrate. The applicator includes a coupling assembly, and may include an applicator tip including a cavity into which the art medium is inserted and supported. An art medium modifier includes a rotating shaft and an art medium modifier coupled thereto for causing the modifier to travel through an application path for modification of an art medium previously applied to a substrate.

Owner:BUSSIE JACOB G

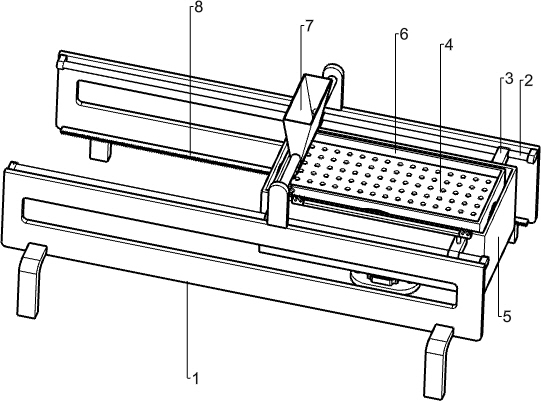

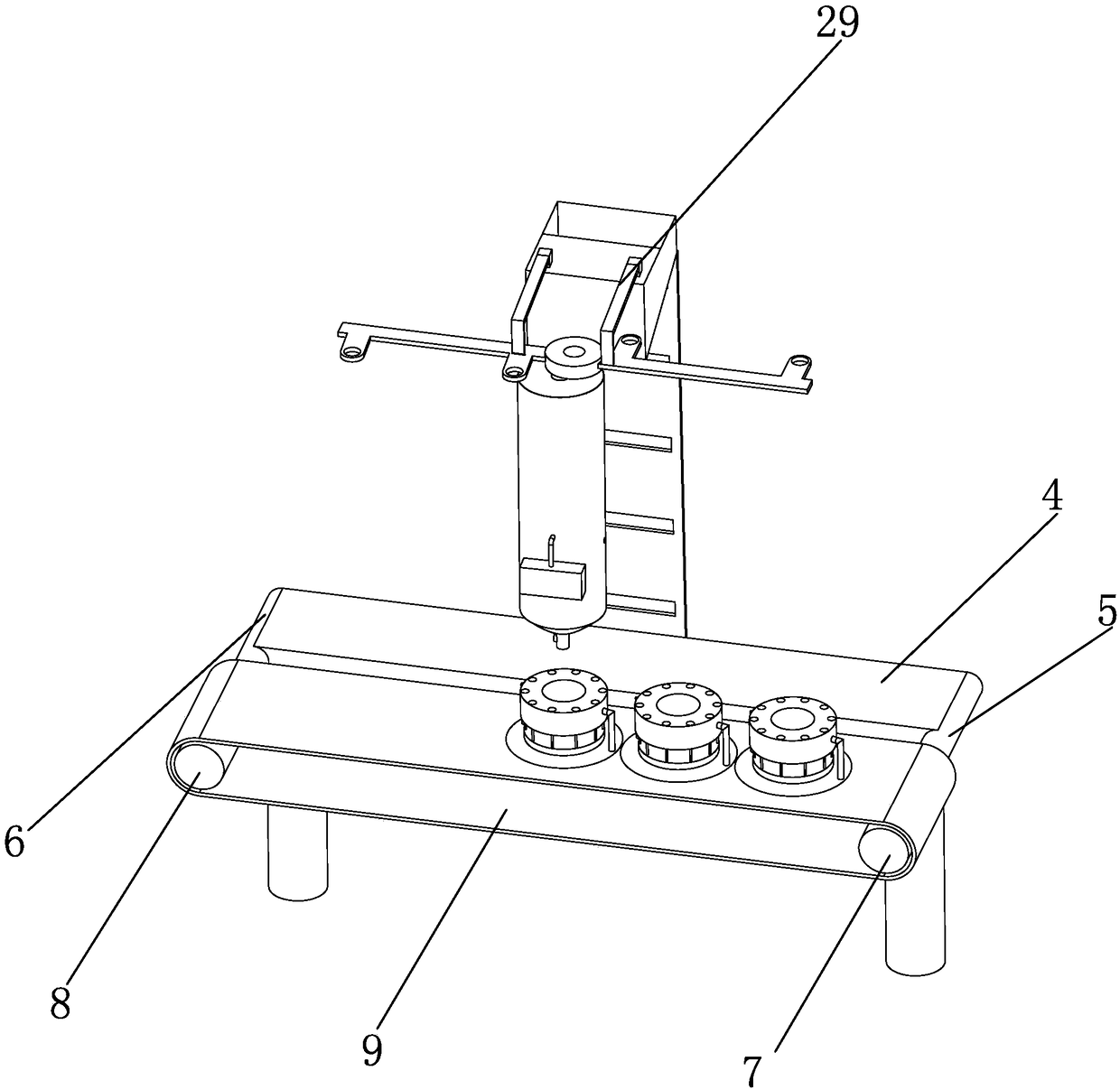

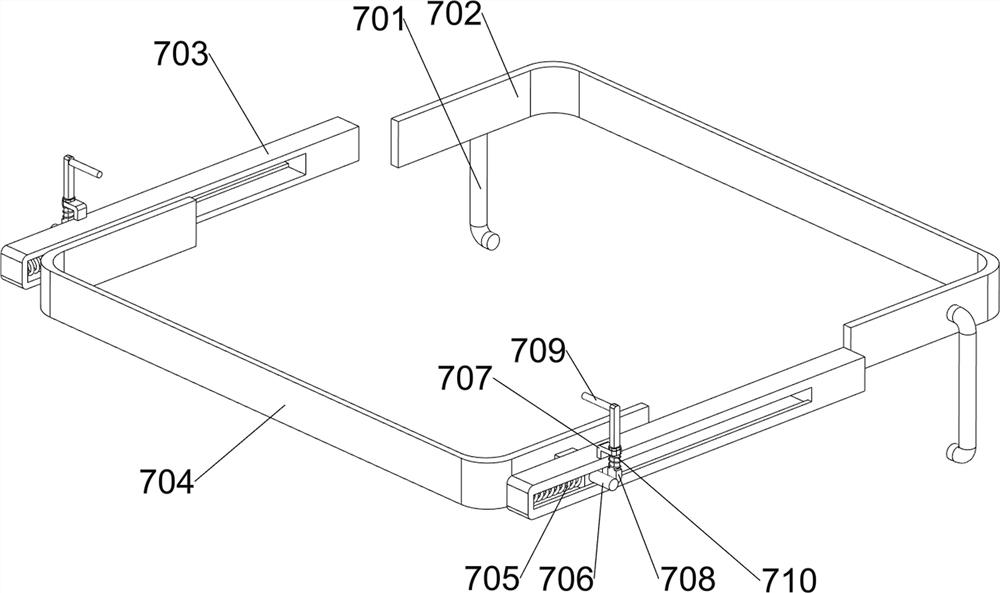

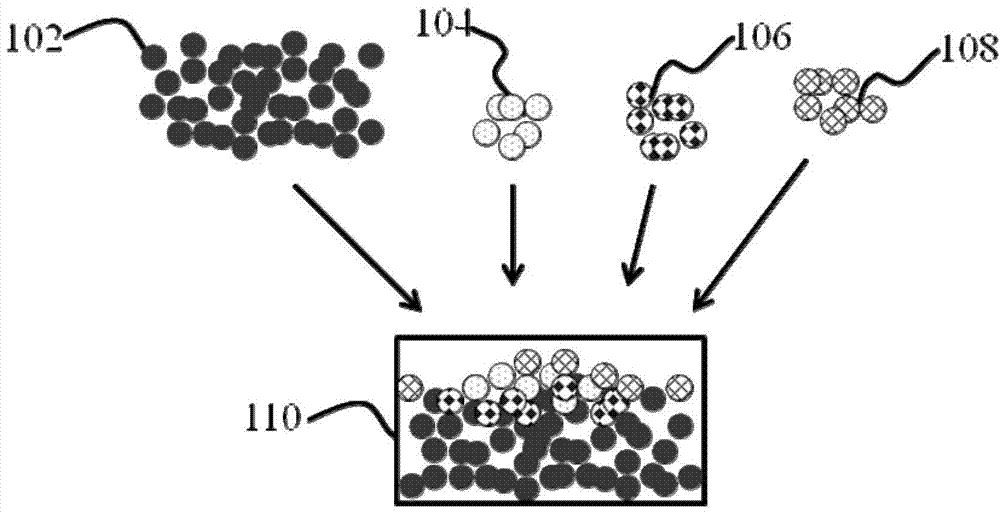

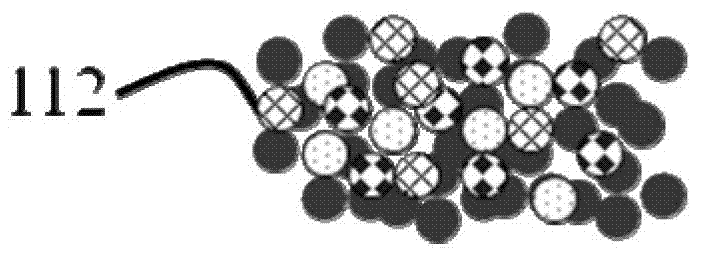

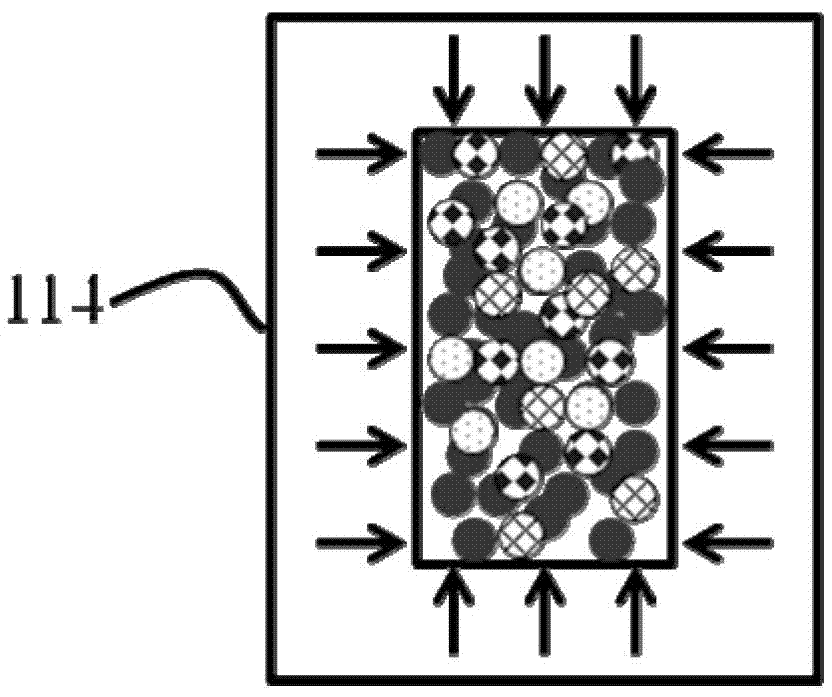

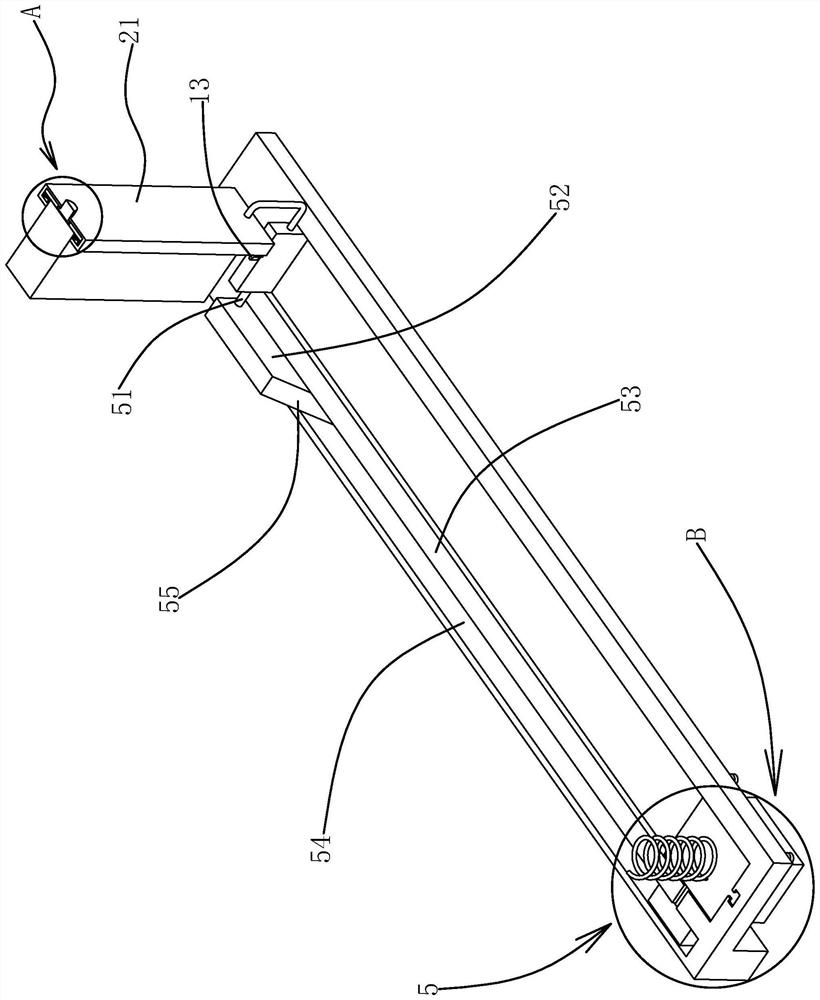

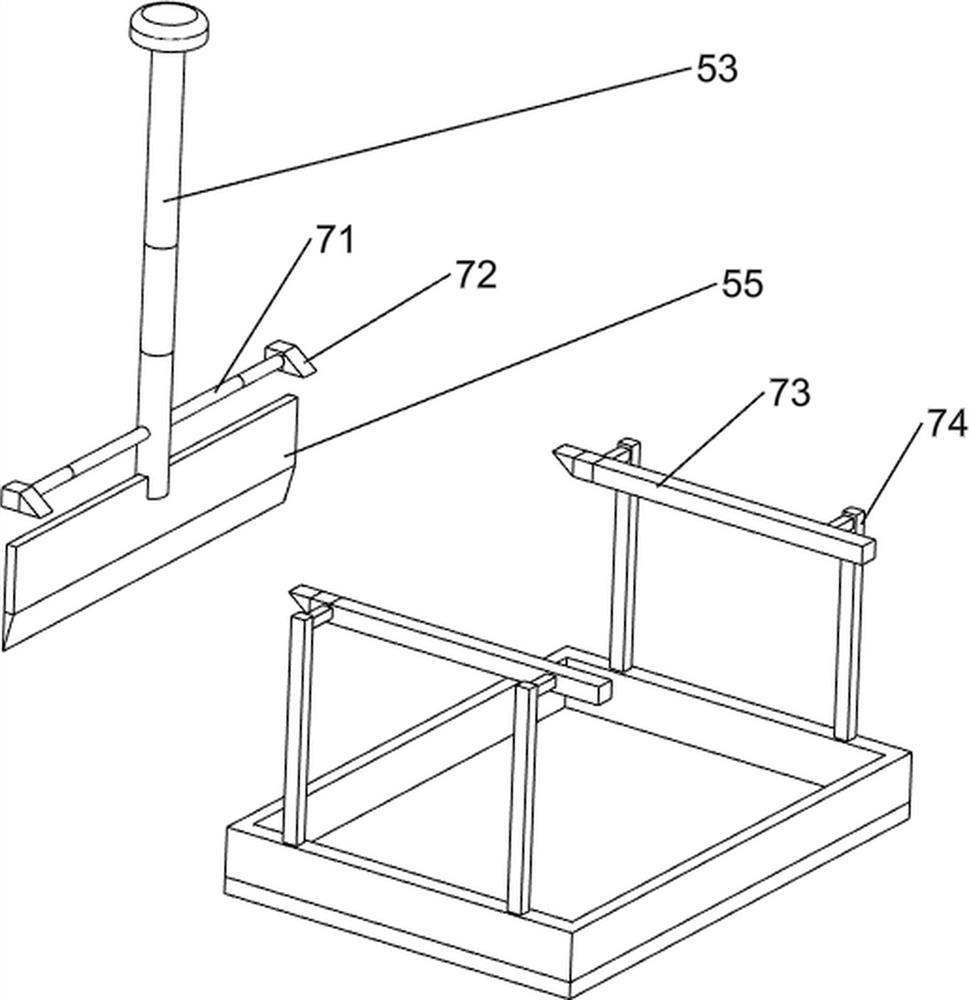

Filling device for chalk manufacturing

InactiveCN111775272AGuaranteed pass rateRealize the purpose of blankingChalksNon-propelling pencilsElectric machineryStructural engineering

The invention relates to a filling device, in particular to a filling device for chalk manufacturing. The filling device for chalk manufacturing aims to simplify and automate the operation process, reduce the fatigue degree of workers, improve the efficiency and reduce the time cost. According to the technical scheme, the filling device for chalk manufacturing comprises sliding rods, sliding sleeves, a sliding rail frame and a shaking mechanism. The sliding rods are connected to one portions of the inner sides of supports on the two sides, the at least two sliding sleeves are slidably connected to the sliding rods, the sliding rail frame is connected between the at least two sliding sleeves, and the bottom side of the sliding rail frame is connected with the shaking mechanism. Through cooperation of a spring, a protruding block frame, a protruding block rod and a motor, the purpose of uniform shaking of raw materials in a die plate is achieved, and the qualified rate of chalks is guaranteed. Through cooperation of a tooth-missing rack, a roller, a discharging frame and a through hole, the raw materials can fall into the whole die plate through the through hole, and the dischargingpurpose is achieved.

Owner:盘秀英

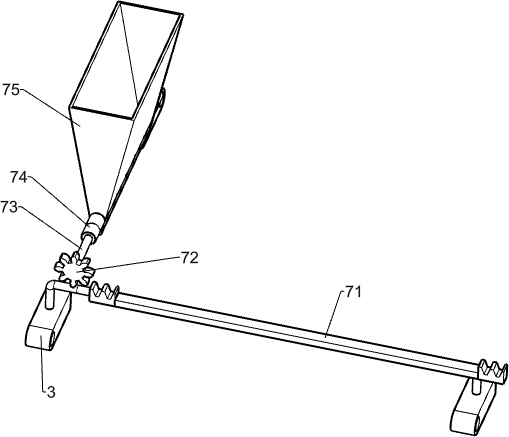

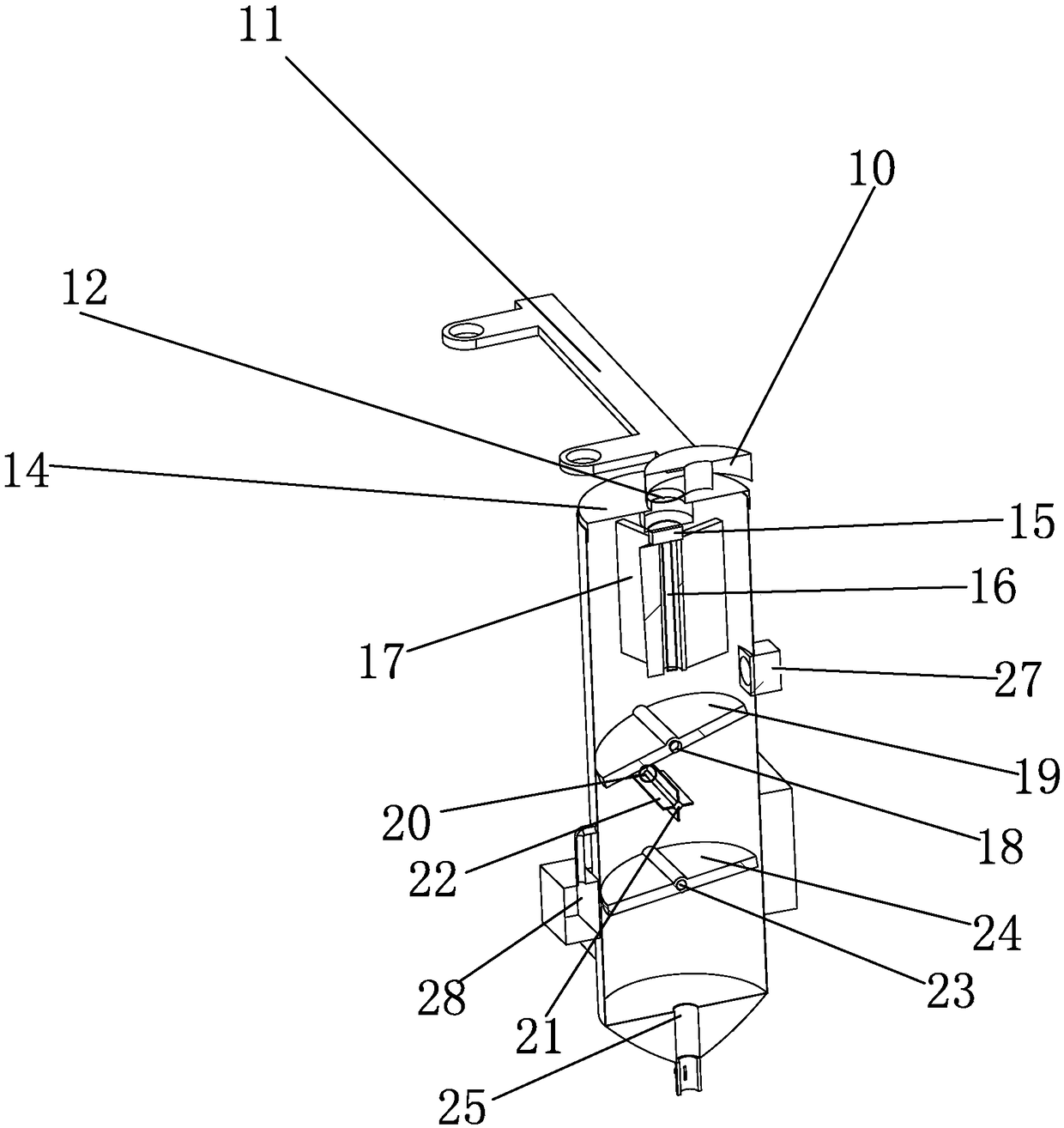

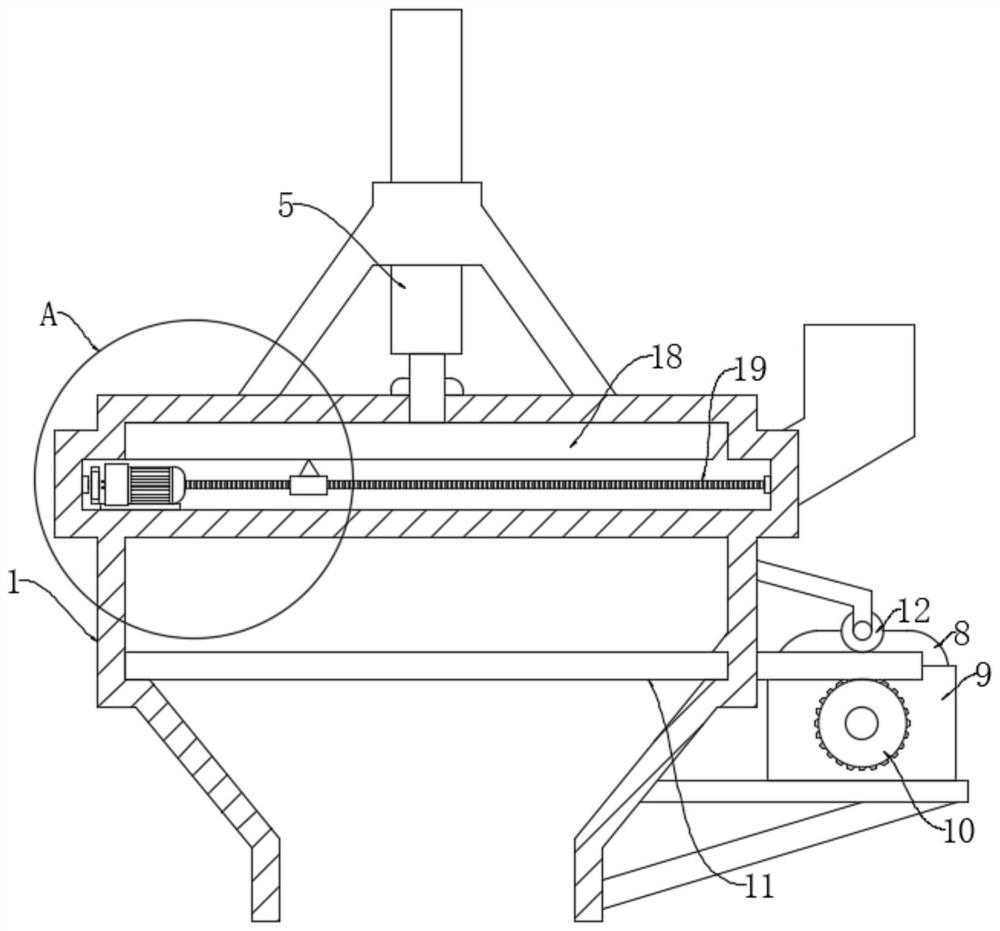

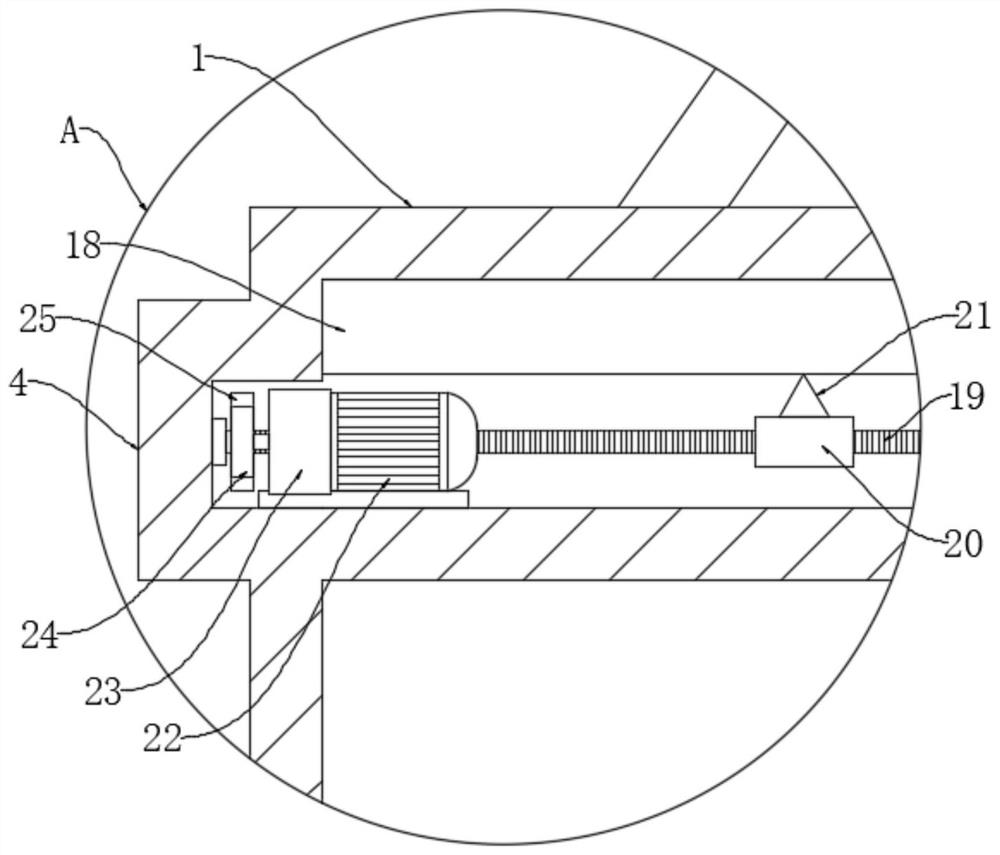

Processing device for manufacturing chalks

InactiveCN108357238AEasy to operateEasy to manufactureChalksNon-propelling pencilsEngineeringWork time

The invention discloses a processing device for manufacturing chalks. The processing device comprises a first support frame, and a second support frame is arranged on one side of the first support frame. The processing device for manufacturing the chalks is characterized in that a first conveying mechanism is disposed at the front end of the first support frame, and a plurality of chalk molds aredisposed above the first conveying mechanism; and a chalk manufacturing box for feeding the chalk molds is disposed above the chalk molds; a rotating mechanism capable of driving the chalk manufacturing box to rotate is arranged above the chalk manufacturing box, and a powdery feeding box capable of adding powder to the chalk manufacturing box is connected to one side of the rotating mechanism; and a second conveying mechanism is disposed on one side of the first conveying mechanism, and the second conveying mechanism is provided with a blowing mechanism capable of air drying the chalk molds.According to the processing device for manufacturing the chalks, by arranging the chalk manufacturing box, the rotating mechanism, the powdery feeding box, the first conveying mechanism, the second conveying mechanism and the blowing mechanism, the operation is simple, quick and integrated, the manufacture is convenient, convenience is brought to the people, working time is greatly reduced, and the problems in the background art are solved.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

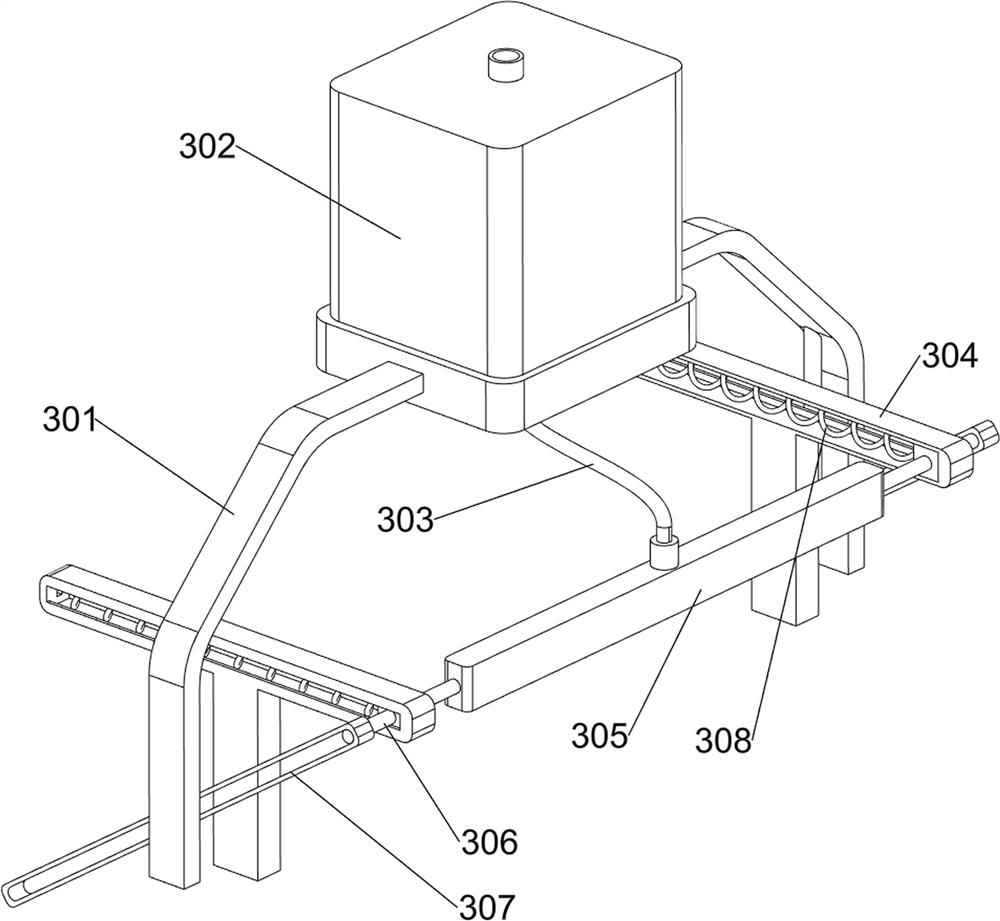

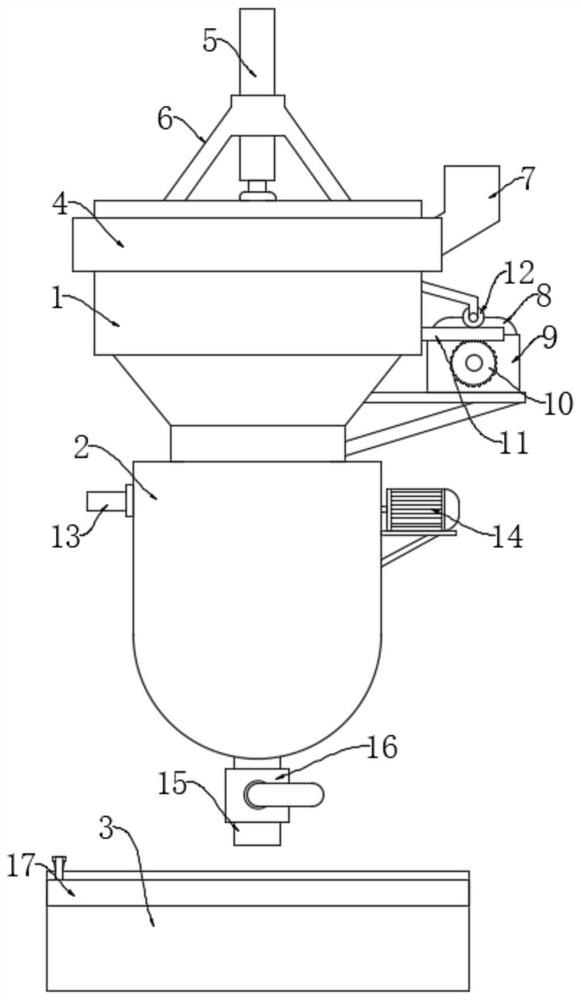

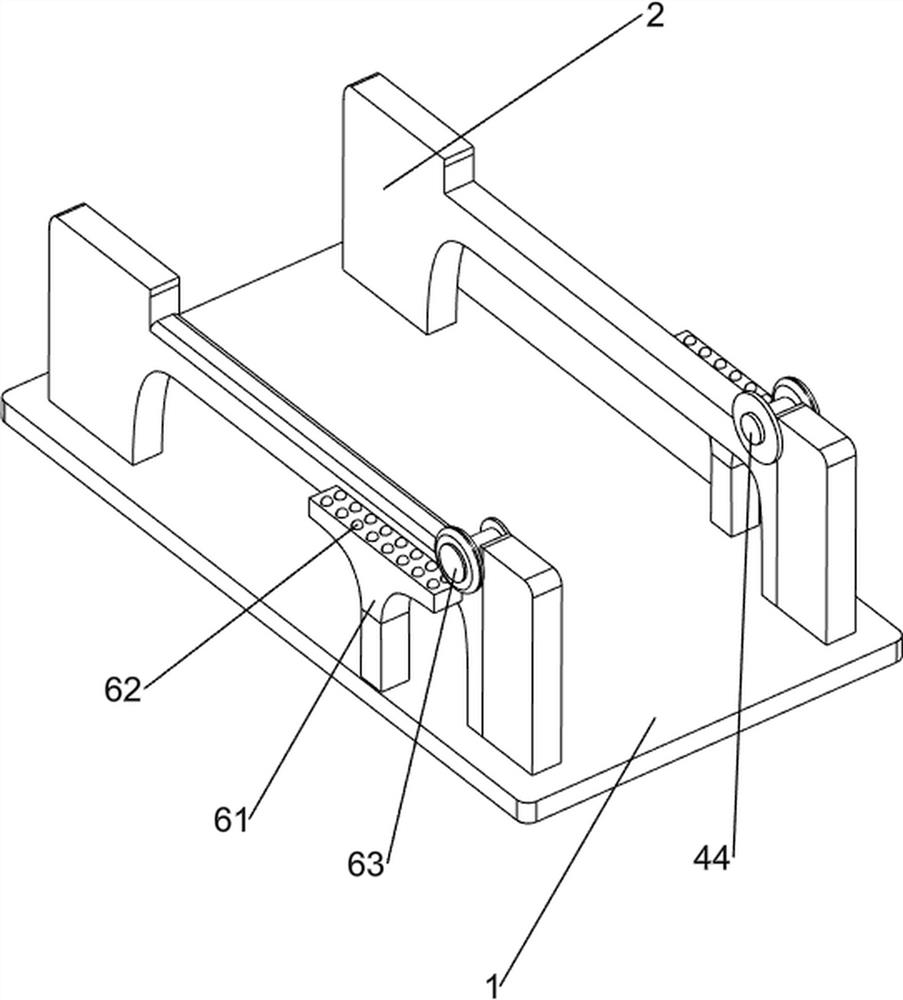

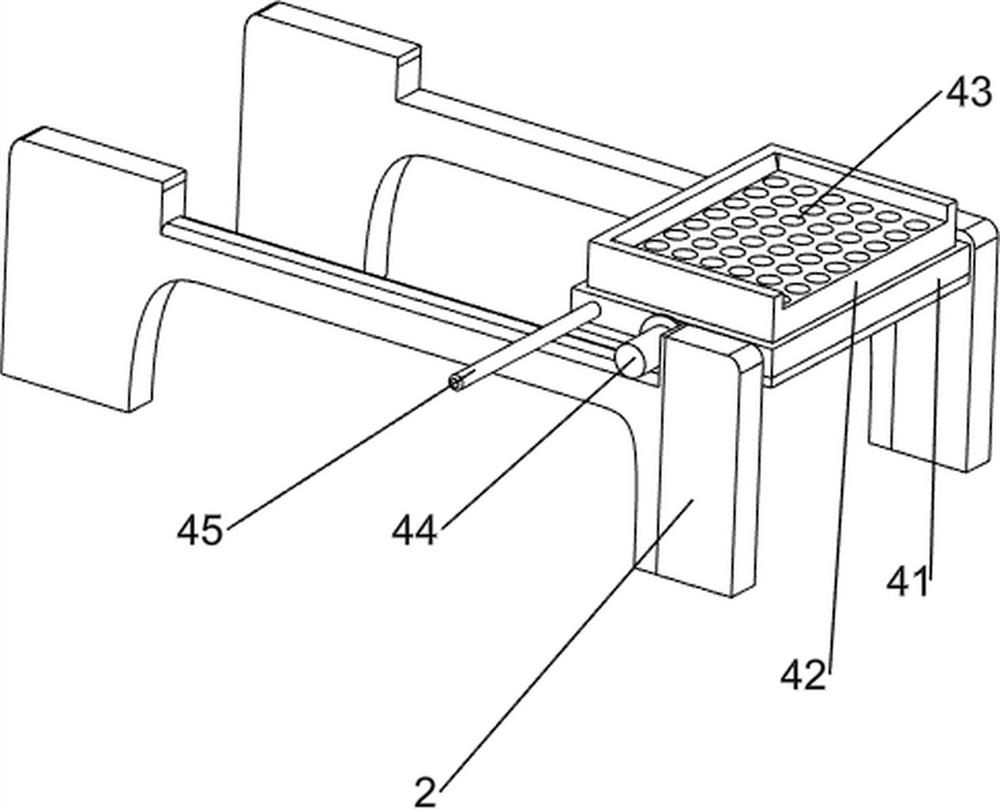

Mold filling equipment for chalk production

The invention relates to filling equipment, in particular to mold filling equipment for chalk production. According to the mold filling equipment for chalk production, automatic filling and automatic discharging are achieved, and splashing is not prone to occurring. The mold filling equipment for chalk production comprises supporting frames, a placing assembly and a discharging assembly. The number of the supporting frames is two. The placing assembly is arranged between the upper parts of the supporting frames. The discharging assembly is arranged at the top of the placing assembly. The mold filling equipment has the beneficial effects that under the action of the discharging assembly, people inject chalk raw materials into a storage cylinder, then a chalk mold is placed in a containing frame, the chalk raw materials in the storage cylinder can flow into the chalk mold through a telescopic hose and a discharging opening, meanwhile, under the action of gravity, the chalk mold can drive the containing frame to move downwards, through transmission, the discharging opening can move towards the front side, and therefore the discharging opening can carry out filling work on the whole face of the chalk mold.

Owner:临沂临港国有资产运营集团有限公司

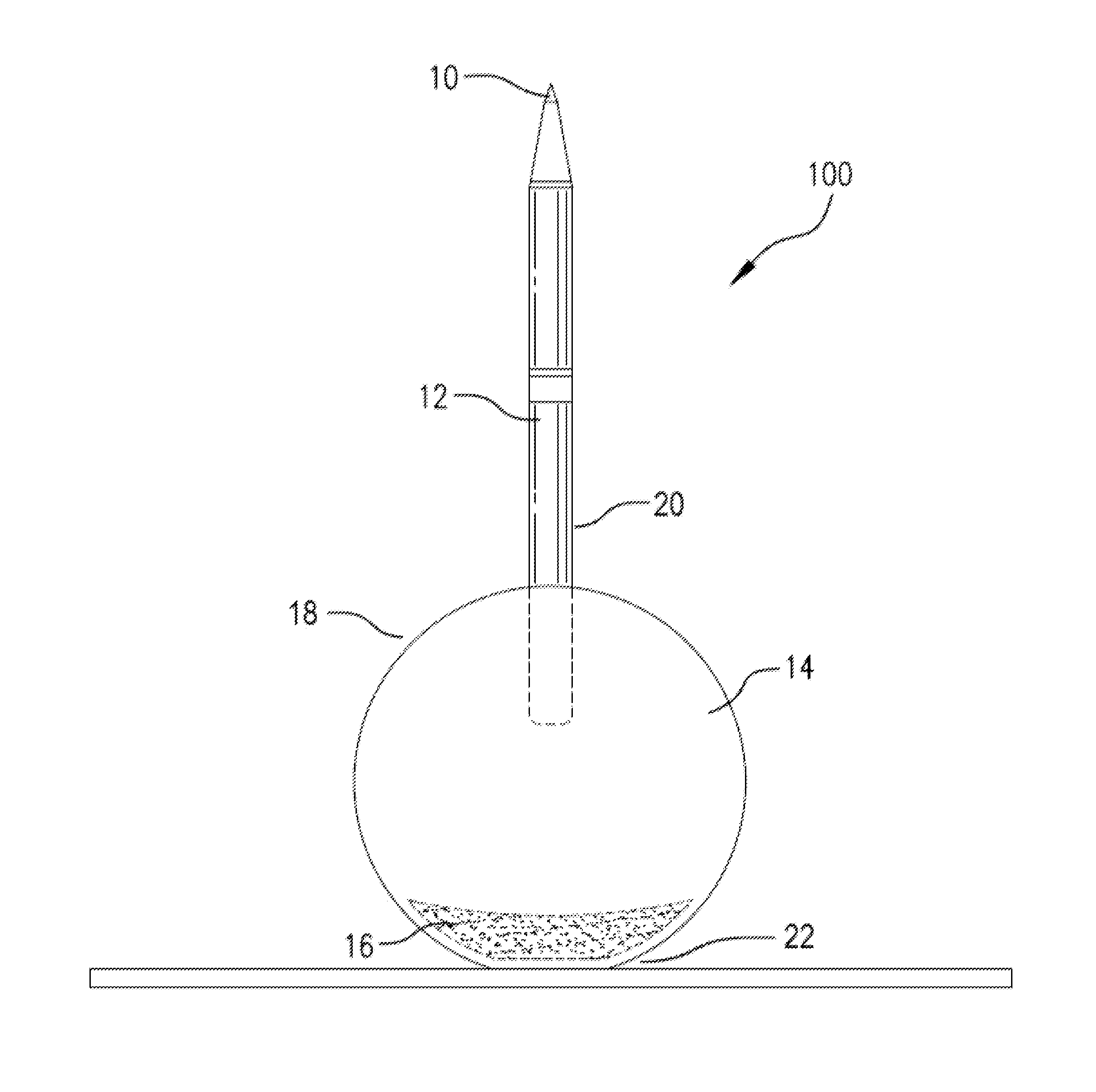

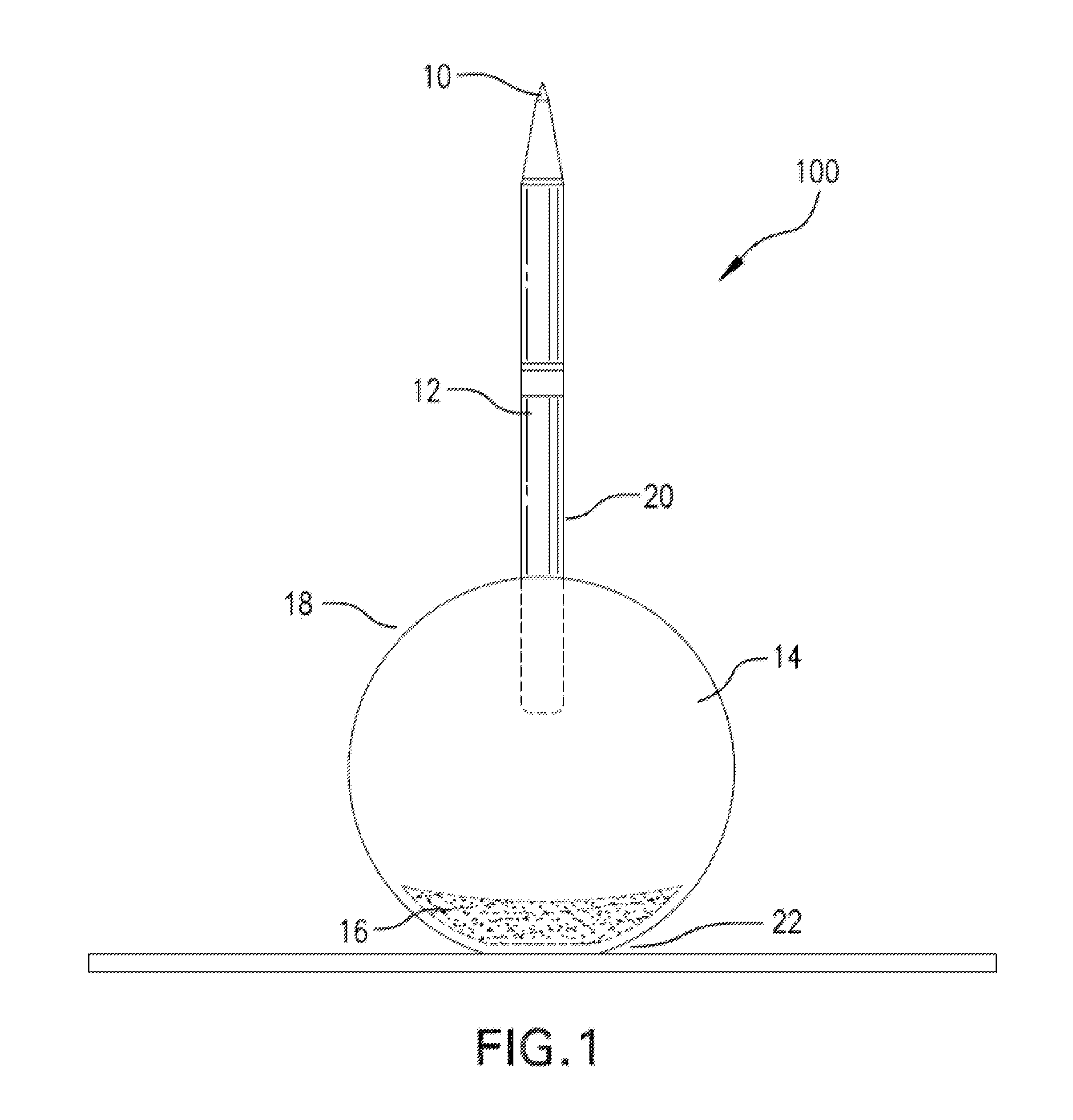

Self-righting handheld utensil

A self-righting handheld utensil comprises a weighted base having a generally rounded bottom end, an elongated region extending outwardly from the base, and a use portion. The base, by virtue of its generally rounded bottom and mass, provide for a self-righting function for the disclosed utensil such that, when placed on a flat or substantially flat surface, it counterbalances the utensil to an upright vertical orientation without the need for user intervention or the application of any external force. The base need not become uncoupled from the elongated region and use portion before the user makes operative use of the disclosed utensil. The bottom end of the base may comprise one of several structural embodiments that retain the self-righting function of the utensil.

Owner:VARTIAN CORP

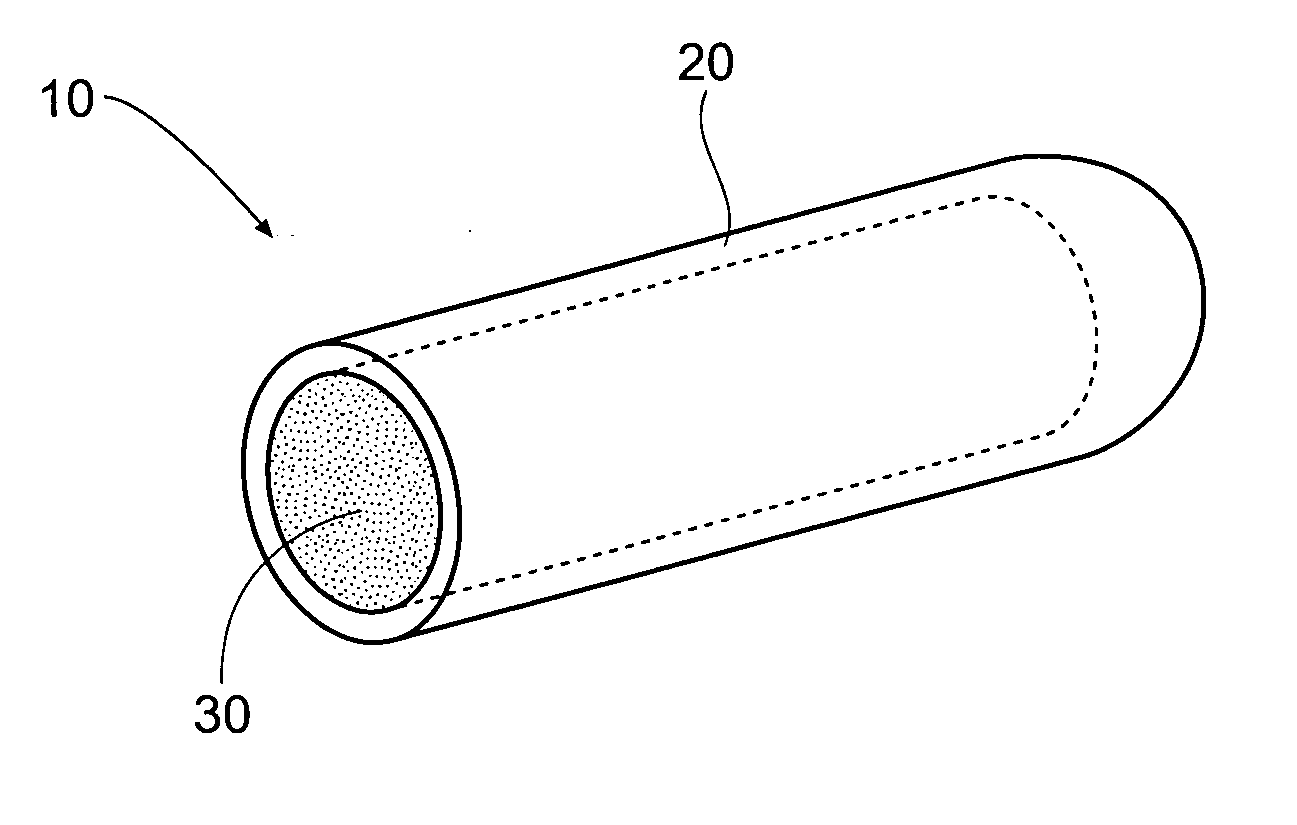

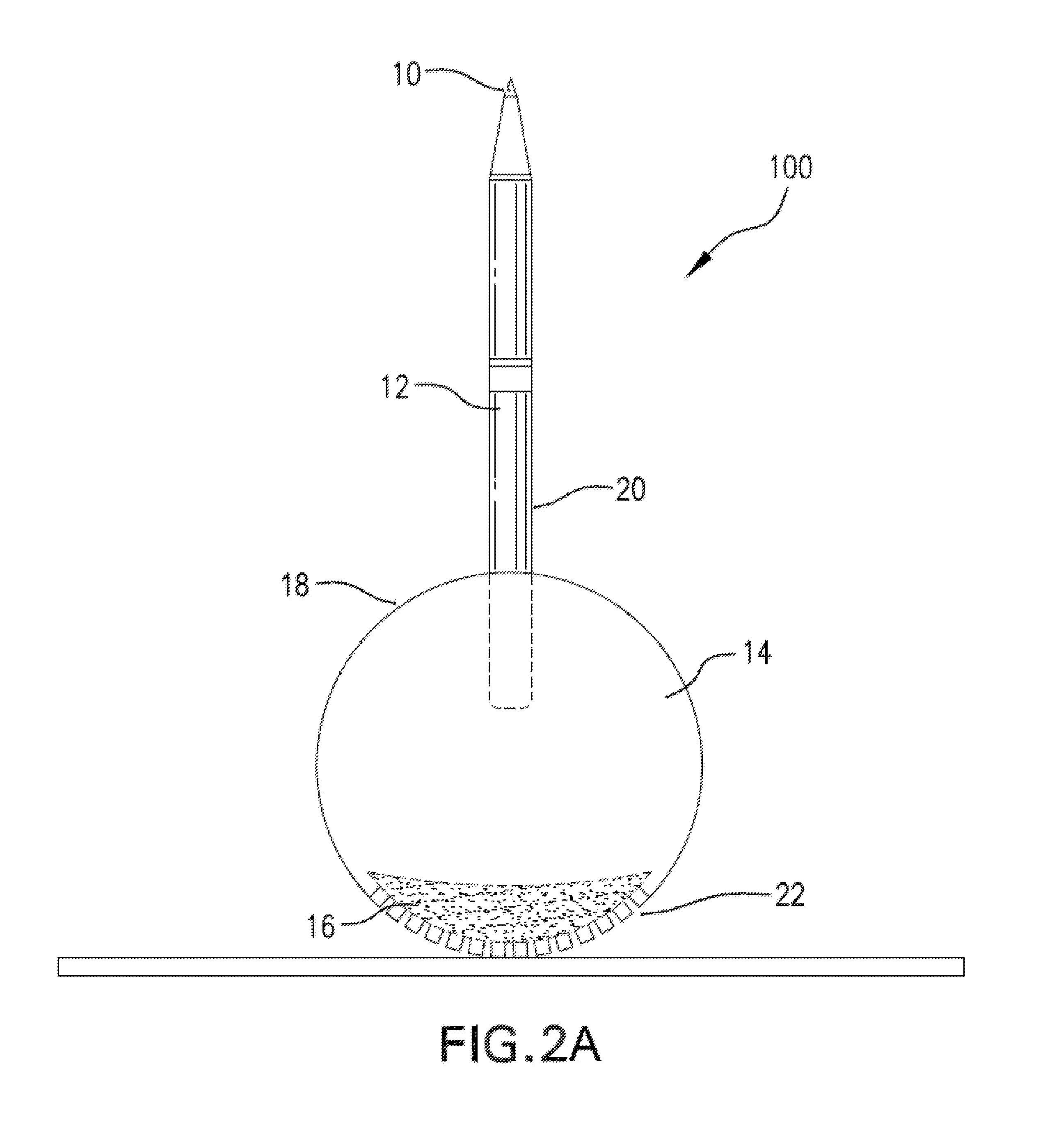

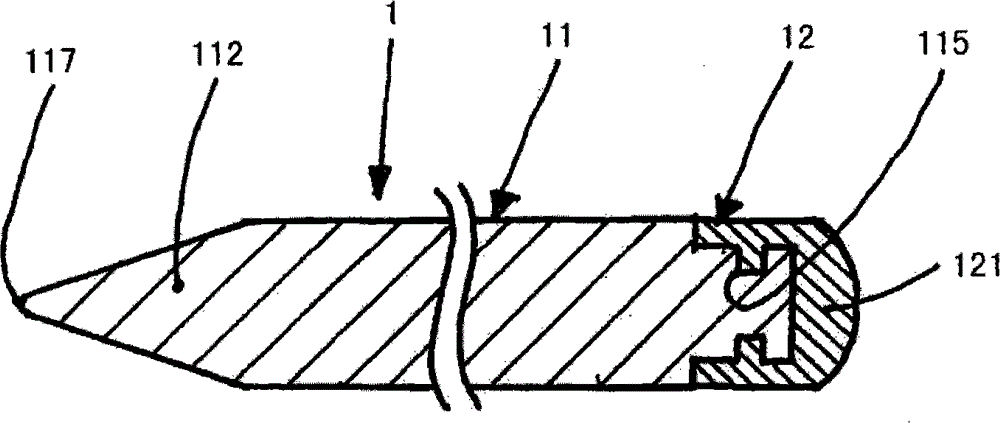

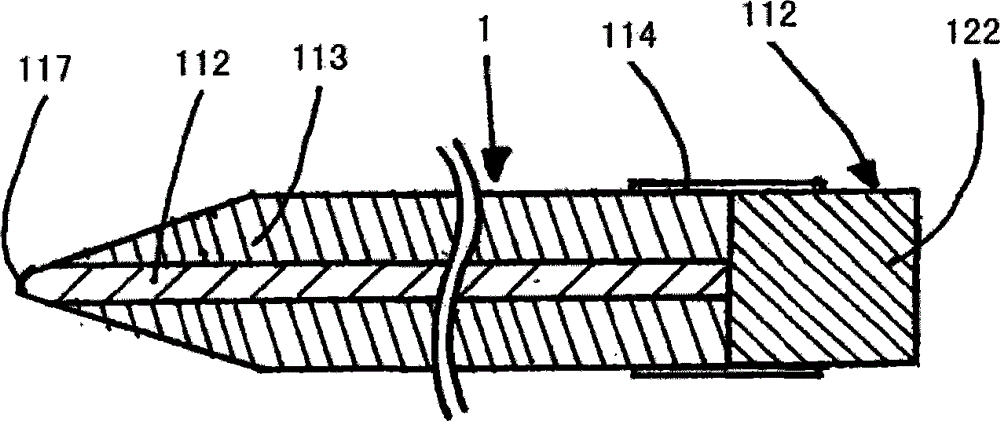

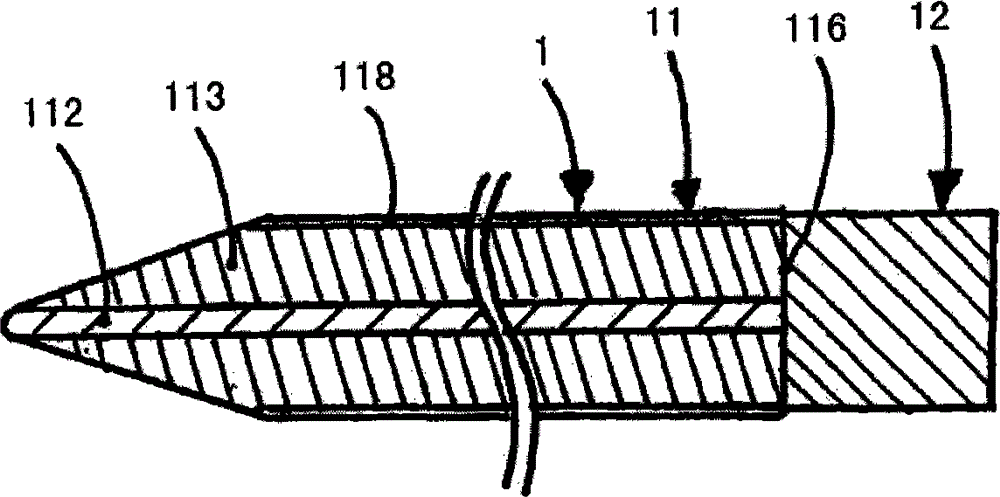

Input device for touch-sensitive, capacitive displays

The invention relates to an input device (1) for capacitive, touch-sensitive displays, said device being a simple stylus (11) that is designed to be sharpened. The device is in the form of a lead / refill, or of a lead / refill with a coating, or of a lead / refill with a casing, or the device has a lead / refill, a casing and a coating, said lead / refill, casing and / or coating being electrically conductive. An element forming a contact element (12) for a tablet / display is located on one end of the device, an electrically conductive material constituting said contact element.

Owner:STAEDTLER MARS GMBH & CO KG

Intelligent teaching blackboard

The invention discloses an intelligent teaching blackboard. A writing wall is arranged on a wall body, and a dust treatment platform is further arranged on the wall body. A first dust suction cavity is formed in the dust treatment platform, and a plurality of dust suction heads which are arranged side by side are arranged on the dust treatment platform. The dust treatment platform is provided witha sliding dust suction sliding block, the end part of a first dust suction pipe is connected with a blackboard eraser, and a plurality of dust suction heads which correspondingly communicate with thefirst dust suction pipe are connected to the blackboard eraser. The two ends of the dust treatment platform are each provided with a chalk making module, and a mixing stirring cavity which communicates with the first dust suction cavity is arranged in each chalk making module. When the blackboard eraser is used for wiping the blackboard, powder can be adsorbed through the dust suction heads. Meanwhile, the powder in the chalk making modules can be used for mixing and stirring so that the purpose of making chalk can be achieved, and the teaching input is further reduced.

Owner:惠安县德虹数控设备有限公司

Magnetic dustproof environment-friendly writing board (chalkboard) tool

A writing board (chalkboard) tool is designed according to the technical principle of attraction between iron materials and magnetic powder. The surface of the writing board (chalkboard) can attract writings of magnetic powder, so that characters in various colors and figures in various colors can be written on the writing board (chalkboard); in addition, a magnetic iron writing board (chalkboard) eraser (9) is covered with a cloth cover (10); when the cloth cover (10) is used with the magnetic iron writing board (chalkboard) eraser (9) to erase the writing board and after the magnetic powder on the writing board is attracted by the magnetic iron writing board (chalkboard) eraser, the cloth cover is placed in a magnetic powder collection box and is then taken off to allow the magnetic powder to leave the cloth cover; the use cycles so, so that saving and environment protection are achieved.

Owner:MAANSHAN JINCHAO RUBBER TECH R&D TECH CO LTD

Energy-saving chalk brush

InactiveCN107757204ASimple structureEasy to useBoard cleaning devicesChalksEngineeringMoulding device

An energy-saving chalk brush includes a box body, a chalk brush body is installed in the box body, and a suction device and a chalk forming device are installed on the box body. The energy-saving chalk brush provided by the invention has simple structure and convenient use, and can solve the problem of chalk dust.

Owner:林弘博

Magnetized Writing and Amusement Device

A magnetized writing and amusement device. The device having a first end and a second end. Each of the ends having a magnet embedded with the interior. The magnetics allowing for the coupling of multiple devices together. The first end functions as a cap for the device and conceals a writing implement located within the internal structure of the device.

Owner:QUIROZ ZIEBART JOSE JOHN

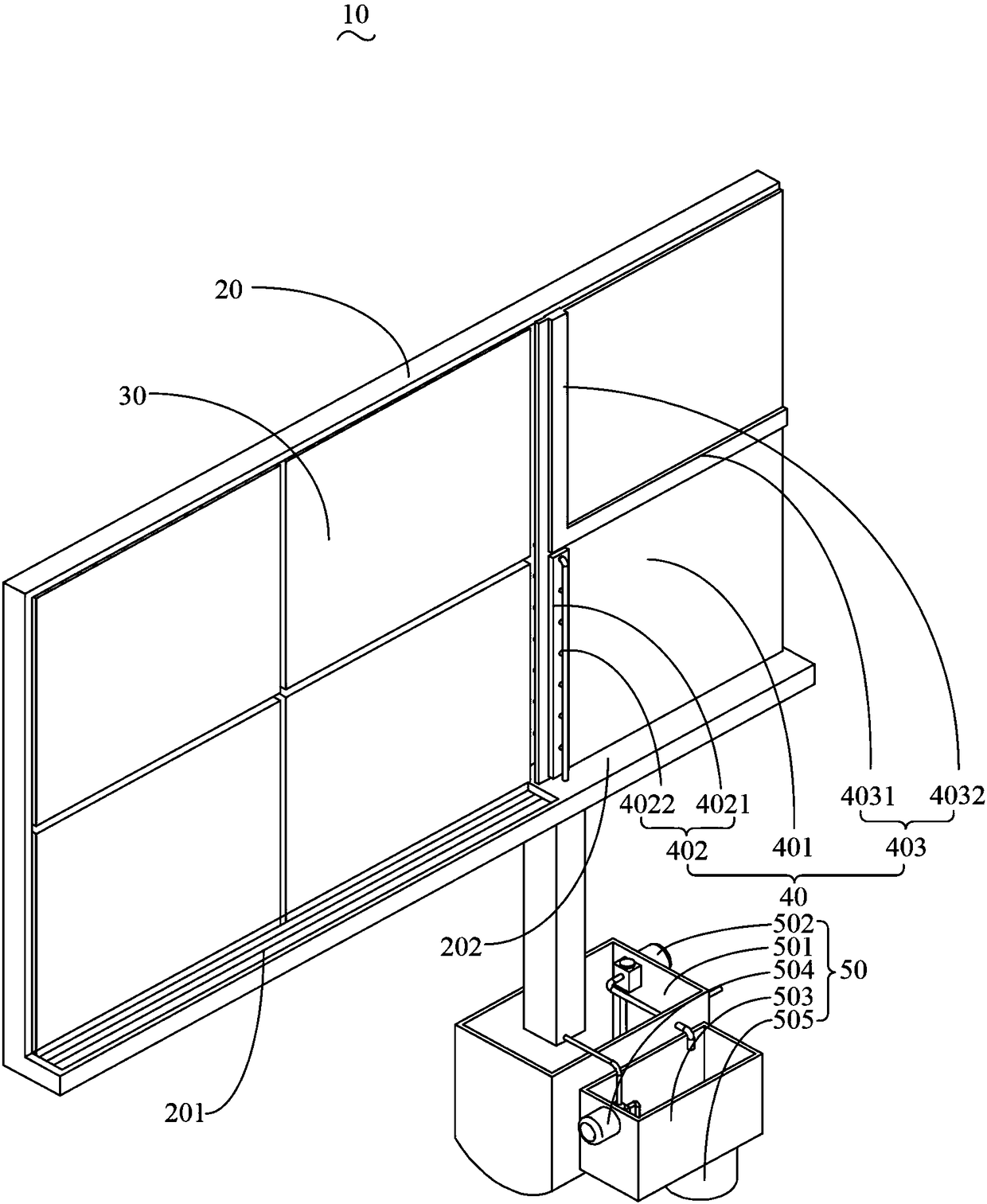

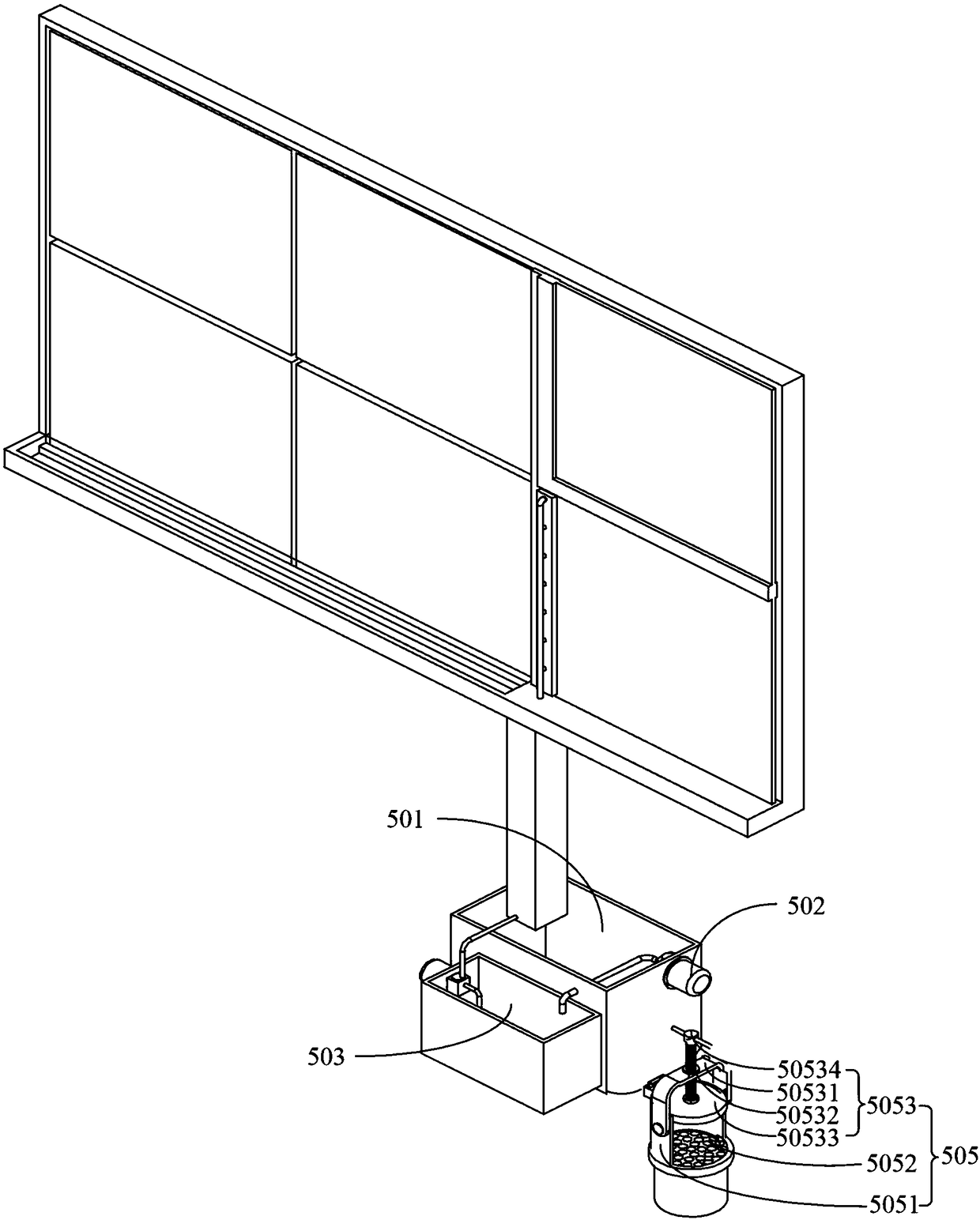

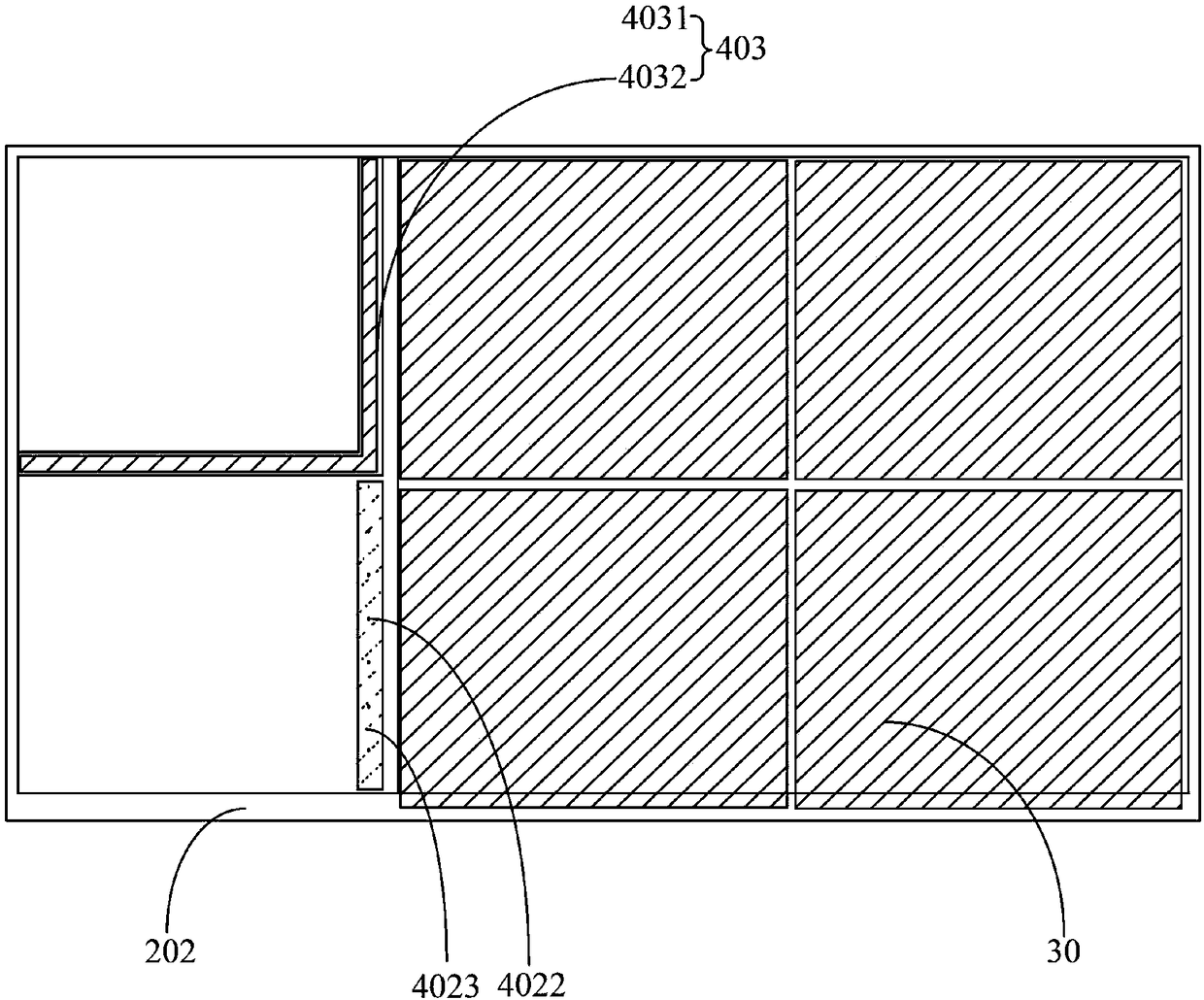

Novel environment-friendly blackboard system

PendingCN108481956AReduce generationPrevent proliferationBoard cleaning devicesChalksWet wipeWater collection

A novel environment-friendly blackboard system comprises a blackboard frame, four blackboards, a blackboard wiping device and a dust and waste water recovery device. The four blackboards and the blackboard wiping device are arranged on the blackboard frame. The blackboards can move in the blackboard frame. The blackboard frame comprises six vacancies, the four blackboards are located in four of the vacancies of the blackboard frame correspondingly, and the rest of two vacancies including no blackboard can facilitate blackboard movement. A chalk dust groove is arranged below the blackboards andis located at the bottom of the blackboard frame, so that chalk dust generated in the writing process falls into the chalk dust groove. The blackboard wiping device is located on the left side or theright side of the blackboard frame and comprises a dust cover, a wet wiping mechanism and a dry wiping mechanism. The wet wiping mechanism and the dry wiping mechanism are located in the dust cover.The wet wiping mechanism is located below the dust cover. The dry wiping mechanism is located above the dust cover. A water collection groove is further arranged under the wet wiping mechanism and located on the blackboard frame. The dust and waste water recovery device is arranged below the blackboard wiping device.

Owner:NINGXIA UNIVERSITY

Wax-based coloring crayon with a watercolor effect

A wax-based coloring crayon for a porous surface and for a non-porous surface includes at least one wax; an ethoxylated fatty alcohol, stearin, a filler, at least one pigment, and optionally an additive.

Owner:SOC DITE SOC BIC

Environment-friendly blackboard eraser

InactiveCN111152591AAvoid flyingEfficient use ofBoard cleaning devicesChalksEngineeringScrub brushes

The invention discloses an environment-friendly blackboard eraser which comprises a blackboard eraser body. At least one opening is formed in the lower surface of the body. A rotating brush is arranged in each opening and controlled by a motor in the body. Communicating chalk dust channels are formed in the body and include the transverse channel formed in the bottom of the body and the vertical channel formed in one side of the body. The tail end of the vertical channel is provided with an air outlet. One side of the top of the vertical channel is provided with an opening in the direction towards the interior of the body, and the opening communicates with a dust collecting area on the top of the body. The dust collecting area is provided with a water inlet and is in an inverted triangularshape, and the top of the triangular dust collecting area is provided with a storage chamber. When chalk dust is prevented from flying, chalk handwriting is erased, meanwhile the chalk dust is storedto produce regenerated chalks, the number of purchased chalks is reduced, the harm of the chalk dust to human health is reduced, and the chalk dust is effectively utilized.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

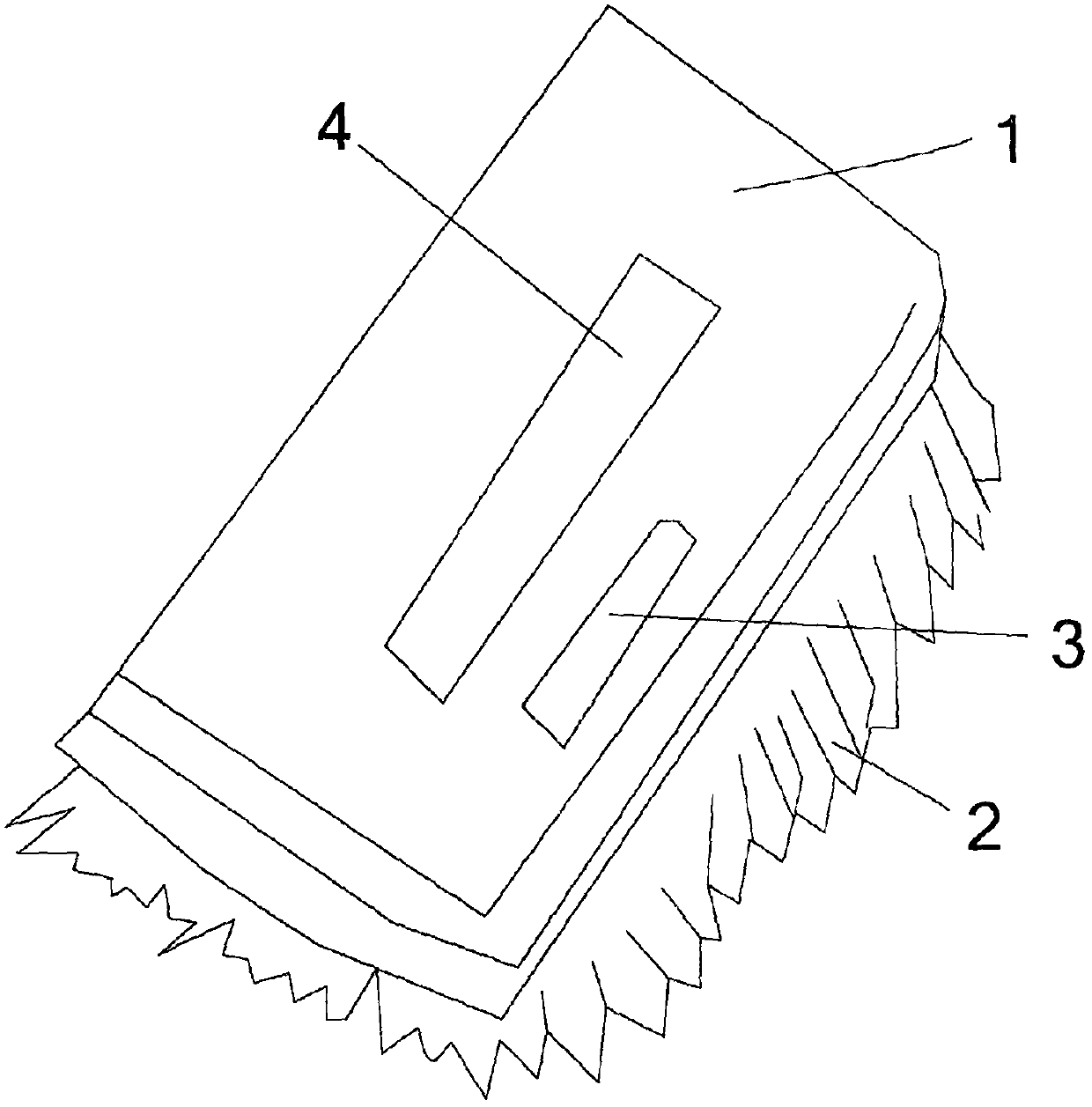

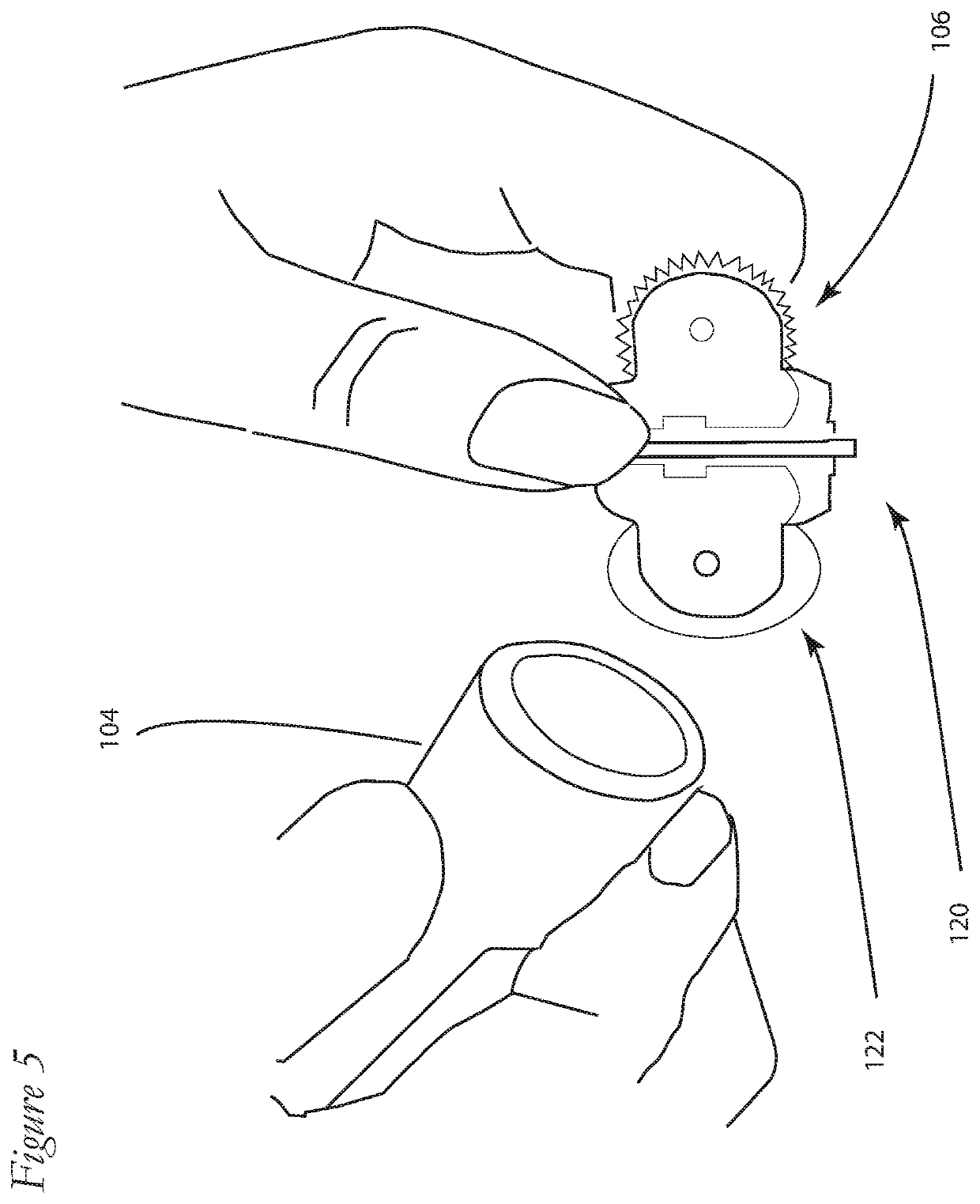

Three-way marker for sewing

A marker ensemble includes a multi-purpose marking tool and a sharpener. The marking tool has a shell, retention sleeve, compression spring, control tab, reversible disk holder, and cap. The shell has an exit opening, an access opening with a mounting socket, and a medially located lateral control slot through which the control tab extends. The retention sleeve has a collet, compressed by the compression spring and uncompressed by the control tab. The disk holder has a body with a retention ridge and a pair of lugs extending from each end to retain a marking disk. One marking disk has a circular periphery and the other marking disk has a toothed periphery. The cap is mounted upon either end. The sharpener includes a blade with a sharpened edge secured to a body with an upper surface, a peripheral surface with a shoulder, waist, and hip, and a lower surface.

Owner:DPG USA

Chalk for low-temperature ceramic painting/marking and preparation method of chalk

The invention relates to a chalk for low-temperature ceramic painting / marking and a preparation method of the chalk. The chalk is a donor material which contains a ceramic-use coloring material with use temperature of 700 to 850 DEG C and / or a ceramic-use glaze and has a certain shape. The chalk can make a painting or mark on a base body.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Multi-functional blackboard wiping device

ActiveCN112078282AExtended service lifeImprove wiping effectBoard cleaning devicesChalksEngineeringMechanical engineering

Owner:BINZHOU POLYTECHNIC

Automatic chalk dust collector

InactiveCN107776299AThe effect of cleanliness and sanitation is achievedSimple structureBoard cleaning devicesChalksOn boardEngineering

The invention discloses an automatic chalk-making instrument, which comprises a blackboard body, a first vacuum cleaner, a second vacuum cleaner, a third vacuum cleaner, a first hose, a second hose, a third hose and a holding box; the first vacuum cleaner , the second vacuum cleaner and the third vacuum cleaner are fixedly installed on the left end, the right end and the upper end of the blackboard body respectively, and the first vacuum cleaner, the second vacuum cleaner and the third vacuum cleaner are respectively connected to the container through the first hose, the second hose and the third hose The box is connected; it arranges a plurality of vacuum cleaners on the blackboard, and discharges the dust inhaled by the vacuum cleaners into the containing box, which changes the situation in the prior art that the dust flies into the human respiratory tract when wiping the blackboard; The effect of cleanliness and sanitation is achieved.

Owner:李舒鑫

Edible chalk and production method thereof

The invention discloses an edible chalk. The chalk comprises beeswax base material: 51-57%, edible calcium carbonate: 4-8%, food-grade coloring material: 32-36%, glycerin: 2-4%. Oxidant: 2-4%, the beeswax base material includes surfactant: 14-18%, edible oil 8-11%, white beeswax: 52-57%, ethanol: 2-3%, palm oil: 16-22% %; The present invention is made from food-grade raw materials, and has the characteristics of non-toxic, edible and high safety.

Owner:华蓥市红军小学

Drawing chalk sharpener

ActiveCN104889856AFree laborSpecifications that are conducive to classroom drawing and displayChalksNon-propelling pencilsMotor driveStandard line

Owner:HANGZHOU DIANZI UNIV

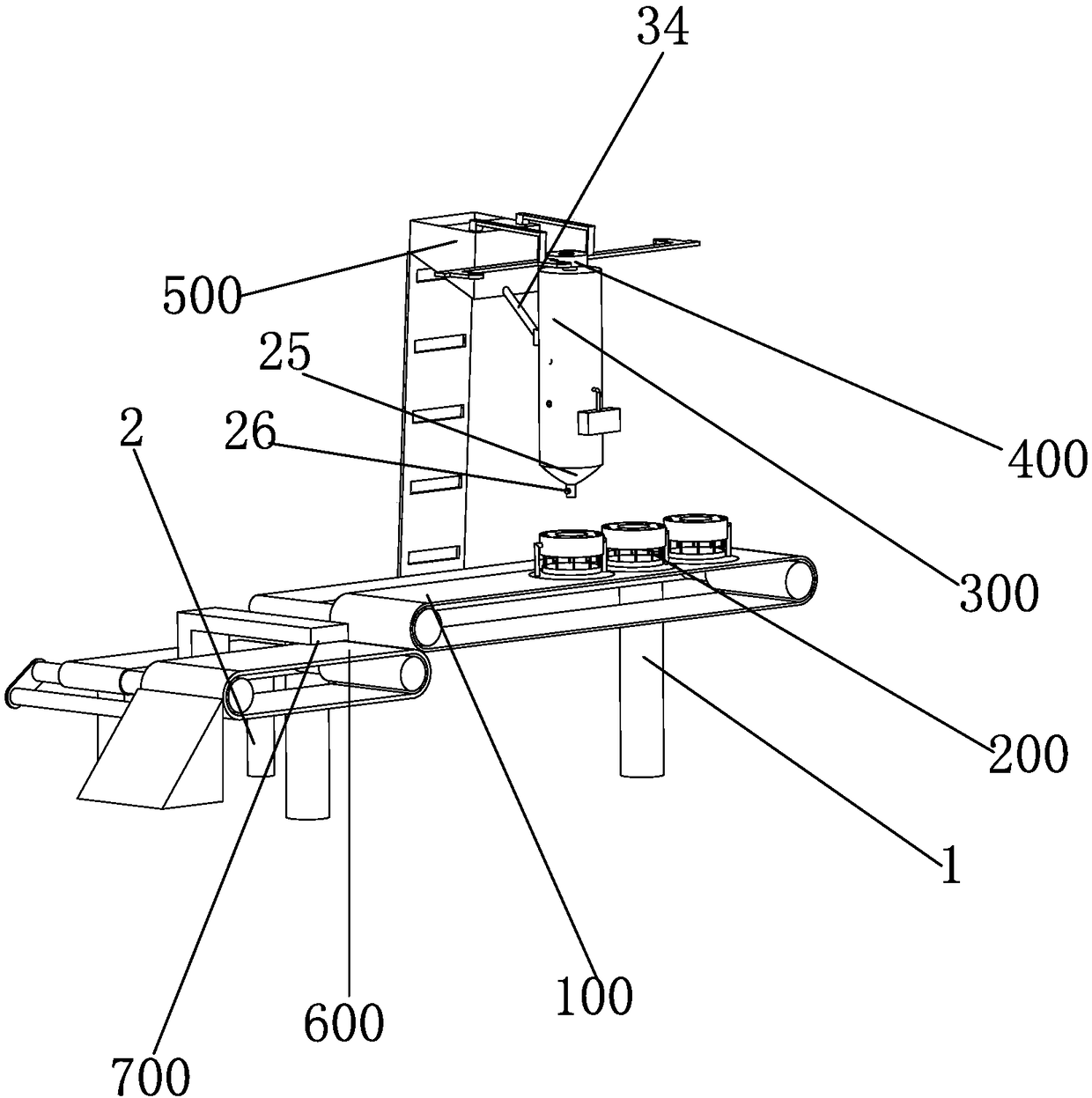

Waste chalk end treatment equipment for teaching and using method thereof

InactiveCN112427443ATake advantage ofImprove processing efficiencyChalksTransportation and packagingElectric machineryProcess engineering

The invention discloses waste chalk end treatment equipment for teaching and a using method thereof, relates to the technical field of chalk, and aims to solve the problem that waste chalk ends for teaching in the prior art are low in treatment efficiency in the treatment process. A stirring box is mounted below a crushing box, the stirring box is fixedly connected with the crushing box, a pressing plate and a toothed bearing plate are arranged in the crushing box, the pressing plate and the toothed bearing plate are both slidably connected with the crushing box, a stirrer is arranged in the stirring box, a water inlet pipe is mounted at one side of the stirring box, the water inlet pipe is fixedly connected with the stirring box through a flange, a second motor is installed at the other side of the stirring box, the second motor is fixedly connected with the stirring box, a transverse moving box is installed on the front end face of a chalk mold base, and the transverse moving box isfixedly connected with the chalk mold base.

Owner:SUZHOU DESIMIER SMART TECH CO LTD

Device capable of collecting and recycling chalk dust

InactiveCN112009146AAvoid passingProtection securityBoard cleaning devicesChalksMining engineeringMechanical engineering

The invention discloses a device capable of collecting and recycling chalk dust. The device comprises a working box, wherein a working groove is formed in the working box, sliding grooves are formed in the upper portion and the lower portion of an inner cavity in the working groove, a collecting box is arranged in the working groove, moving sliding blocks are fixedly installed on the upper and lower end faces of the collecting box, the moving sliding blocks are installed in the sliding grooves in a sliding mode, inner cavities of the collecting box are symmetrically arranged up and down, and achannel opening is formed in the rear wall surface of an inner cavity of the collecting box. After the device is placed at a designated position, the device can automatically clean a blackboard and collect the dropped chalk dust, the collected chalk dust is reshaped into a mold and can be reused, erasing is rapid, simple and convenient, dust is prevented from being transmitted in air, and the safety of a respiratory tract of a teacher is protected.

Owner:杭州晋建环保科技有限公司

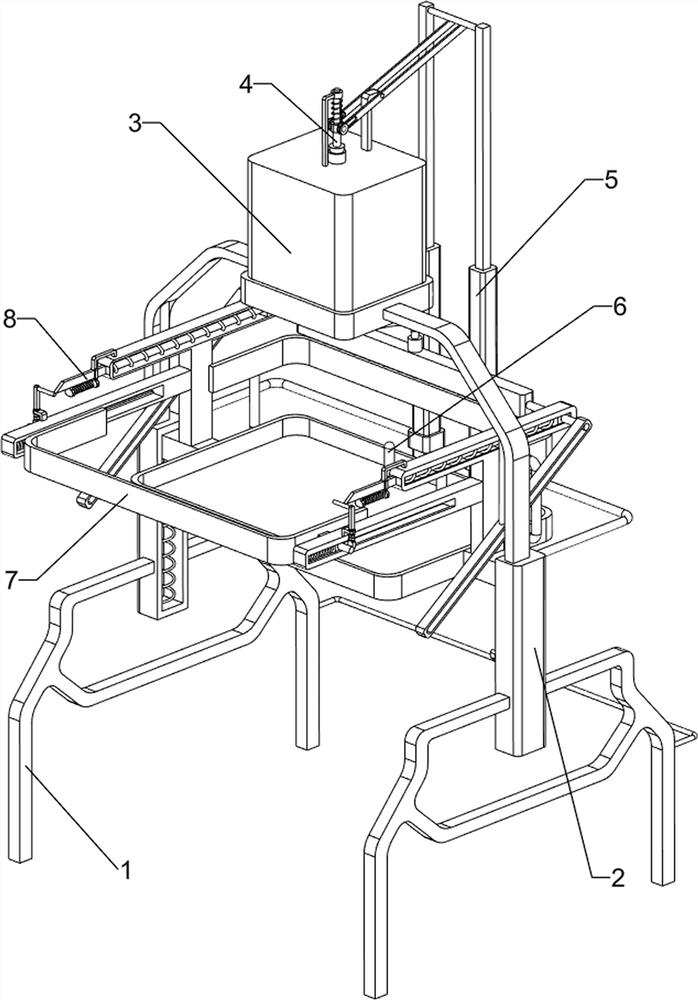

Pouring type chalk forming device

ActiveCN112847737ARealize the effect of watering and feedingRealize the pressure effectChalksNon-propelling pencilsStructural engineeringWorkbench

The invention relates to a chalk forming device, in particular to a pouring type chalk forming device. The pouring type chalk forming device is high in production efficiency and low in labor intensity, and uses recycled chalks for remanufacturing. The pouring type chalk forming device comprises a bottom plate, a mounting frame, a first supporting column, a feeding mechanism, a scraping mechanism and the like, wherein mounting frames are arranged on the left side and the right side of the bottom plate correspondingly, first supporting columns are arranged on the tops of the rear sides of the two mounting frames correspondingly, a feeding mechanism is arranged on the tops of the front sides of the two mounting frames, and the scraping mechanism is arranged between the two first supporting columns. According to the device, a handle is pushed backwards to drive a rolling shaft to rotate backwards, so that a workbench is driven to move backwards, a pouring table is driven to move backwards, and the pouring and feeding effects are achieved; and the top end of a movable rod is pressed, the movable rod is pressed downwards, and a spring is compressed, so that the movable rod is driven to move downwards, a scraping plate is driven to move downwards, and the pressing effect is achieved.

Owner:邳州市景鹏创业投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com