Mold filling equipment for chalk production

A technology of filling equipment and molds, which is applied in the field of mold filling equipment for chalk production, and can solve problems such as waste, time-consuming and labor-intensive, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

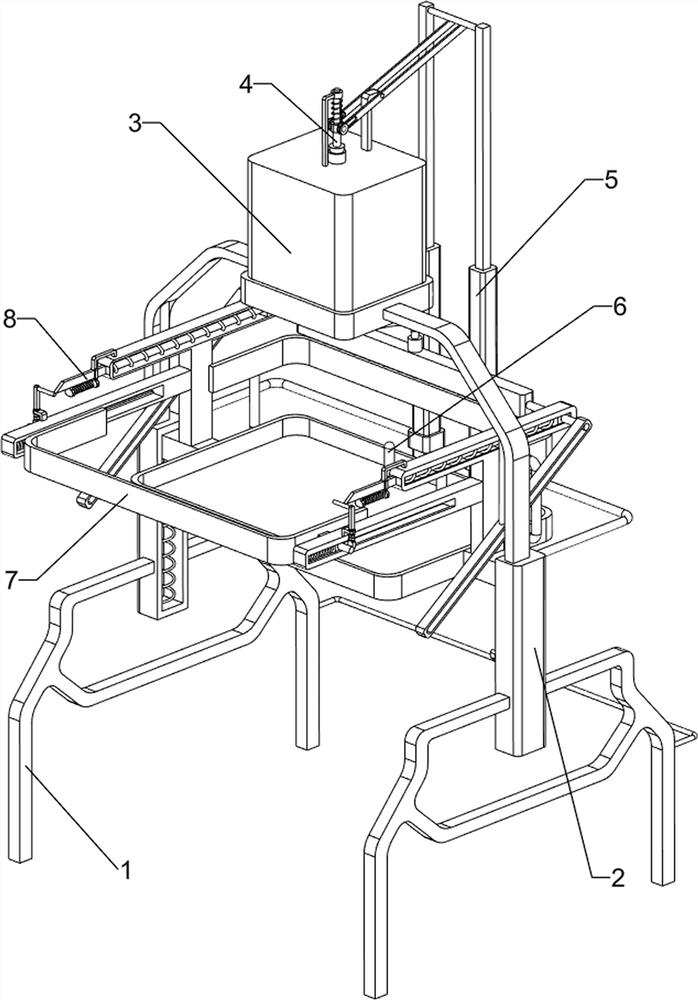

[0031] A kind of mold filling equipment for chalk production, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a support frame 1, a placement assembly 2 and a blanking assembly 3. There are two support frames 1, a placement assembly 2 is provided between the upper parts of the support frame 1, and a blanking assembly 3 is provided on the top of the placement assembly 2.

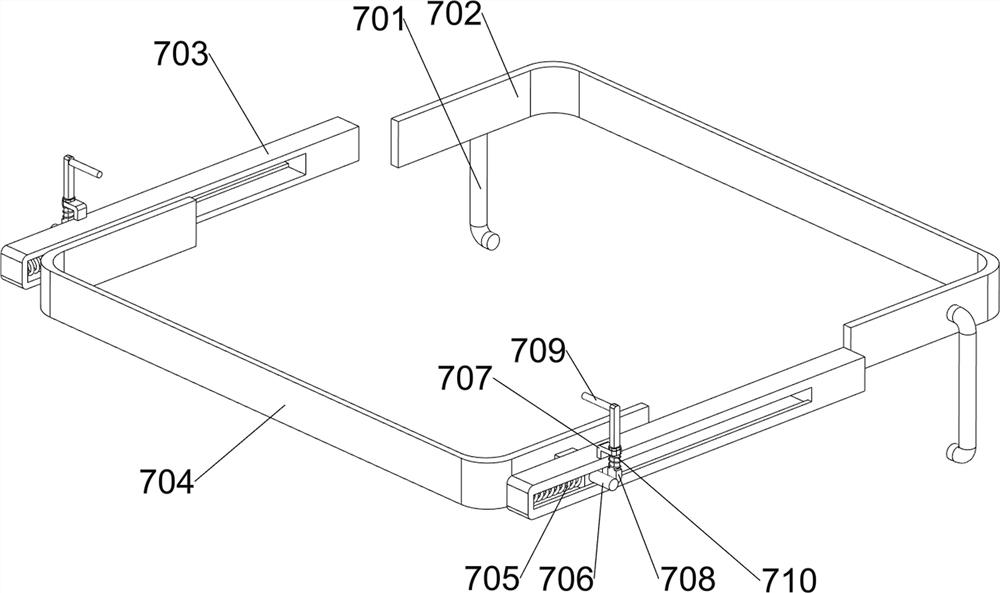

[0032] The placement assembly 2 includes a chute block 201, a slide block 202, a placement frame 203 and a first spring 204. The upper middle side of the support frame 1 is provided with a chute block 201, and the upper part of the chute block 201 is provided with a slide block 202 in a sliding manner. A placement frame 203 is provided between the sliders 202 , and a first spring 204 is connected between the slider 202 and the chute block 201 on the same side.

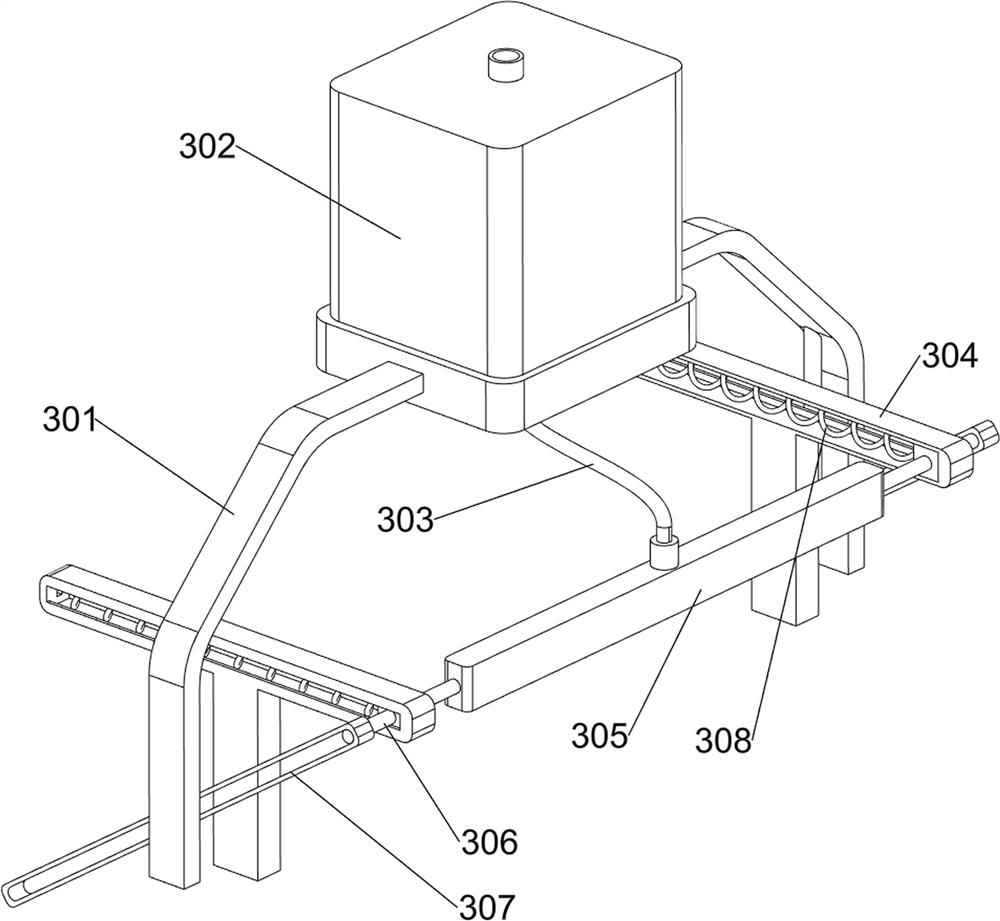

[0033] The blanking assembly 3 includes a support frame 301, a material storage cylinder 302, a flexible hose 303, a fi...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a piston assembly 4 is also included, and the piston assembly 4 includes a first support rod 401, a second slide rod 402, a second spring 403, a first piston 404, a second support rod 405 and a lever 406, and the accumulator cylinder 302 The middle side of the top is provided with a first support rod 401, and the upper side of the first support rod 401 is slidably provided with a second slide rod 402, and a second spring 403 is connected between the second slide rod 402 and the first support rod 401. The spring 403 is set on the second sliding rod 402, the bottom of the second sliding rod 402 is provided with a first piston 404, the first piston 404 cooperates with the storage cylinder 302, and the rear side of the top of the storage cylinder 302 is provided with a second support rod 405 , the upper part of the second support rod 405 is rotatably pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com