A method and device for simultaneously extracting and deflecting tobacco stems

A technology of tobacco stem and decompression machine, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of difficult screening of qualified cut stems, decrease of qualified rate, entanglement of cut stems, etc., and achieves outstanding sensory style, high pass rate, and manufacturing The effect of improving pulp efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

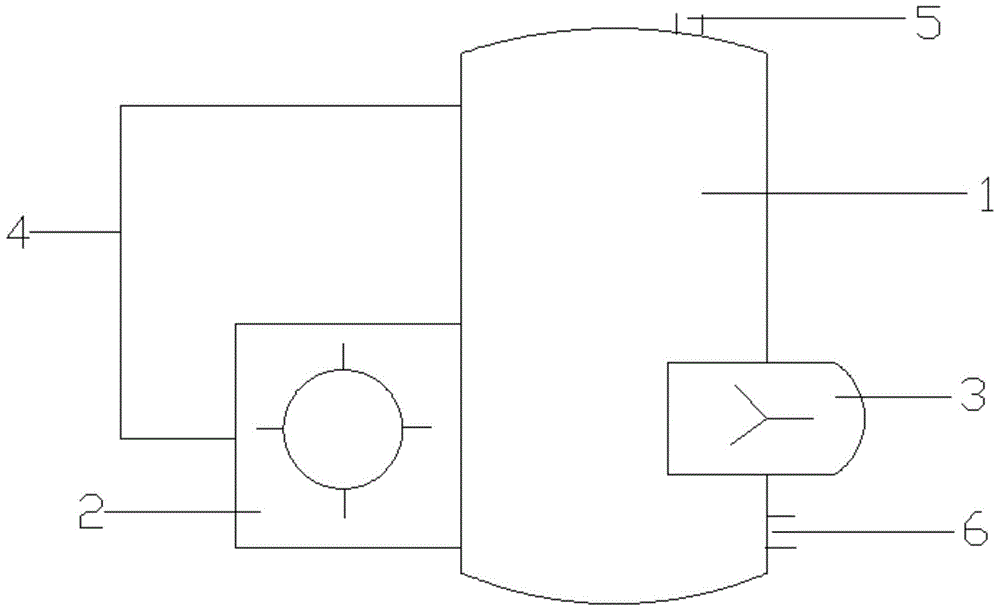

[0048] A device for simultaneously extracting and dispersing tobacco stems, comprising a material storage tank 1 and a disintegrating machine 2, a propeller-type paddle agitator 3 is provided on a side wall in the storage tank 1, and the The feed port is communicated with the storage tank 1 through the side wall of the storage tank 1, and the discharge port of the decomposing machine 2 is connected to the paddle inlet of the storage tank 1 through the circulating paddle tube 4, wherein the propeller blade stirs The running direction of the device 3 is toward the feeding port of the decomposing machine 2; the storage tank 1 is also provided with a feeding port 5 and a discharging port 6.

[0049] The bottom of the storage tank 1 is provided with a resistance temperature transmitter and a differential pressure pressure transmitter, which can detect and control the material temperature and liquid level of the storage tank, and can be detected in real time.

[0050] A concentratio...

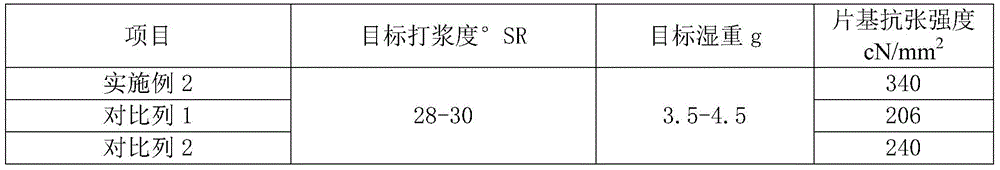

Embodiment 2

[0056] Utilize the device of embodiment 1 to simultaneously carry out the method for tobacco stem extraction and loosening, comprises the following steps:

[0057] (1) Feeding: enter the tobacco stem and water into the storage tank according to the set ratio; the length of the tobacco stem is 3-5cm; the mass ratio of the tobacco stem and the solvent is 1:6.

[0058] (2) stirring: turn on the propelling blade stirrer, stir and mix the material in step (1), the tobacco stem material is tossed from top to bottom, realize the uniform mixing of the material and the solvent, and obtain the tobacco stem mixture; the described The mixing time is 8 min, and the mixing temperature is 65-70°C.

[0059] (3) Removing while extracting: turn on the dispersing machine, under the action of the stirring and driving force of the propelling blade stirrer, the tobacco stem mixture in the storage tank enters the dispersing machine, and then uses the centrifugal force generated by the rotor and the ...

Embodiment 3

[0062] Utilize the device of embodiment 1 to simultaneously carry out the method for tobacco stem extraction and loosening, comprises the following steps:

[0063] (1) Feeding: enter the tobacco stem and water into the storage tank according to the set ratio; the length of the tobacco stem is 3-5cm; the mass ratio of the tobacco stem and the solvent is 1:5.

[0064] (2) stirring: turn on the propelling blade stirrer, stir and mix the material in step (1), the tobacco stem material is tossed from top to bottom, realize the uniform mixing of the material and the solvent, and obtain the tobacco stem mixture; the described The mixing time is 5-10 min, and the mixing temperature is 70°C.

[0065] (3) Removing while extracting: turn on the dispersing machine, under the action of the stirring and driving force of the propelling blade stirrer, the tobacco stem mixture in the storage tank enters the dispersing machine, and then uses the centrifugal force generated by the rotor and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com