Chalk for low-temperature ceramic painting/marking and preparation method of chalk

A technology of low-temperature ceramics and chalk, which is applied in the direction of chalk, application, pencil lead, etc., and can solve the problems such as the report of chalk for ceramic color painting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

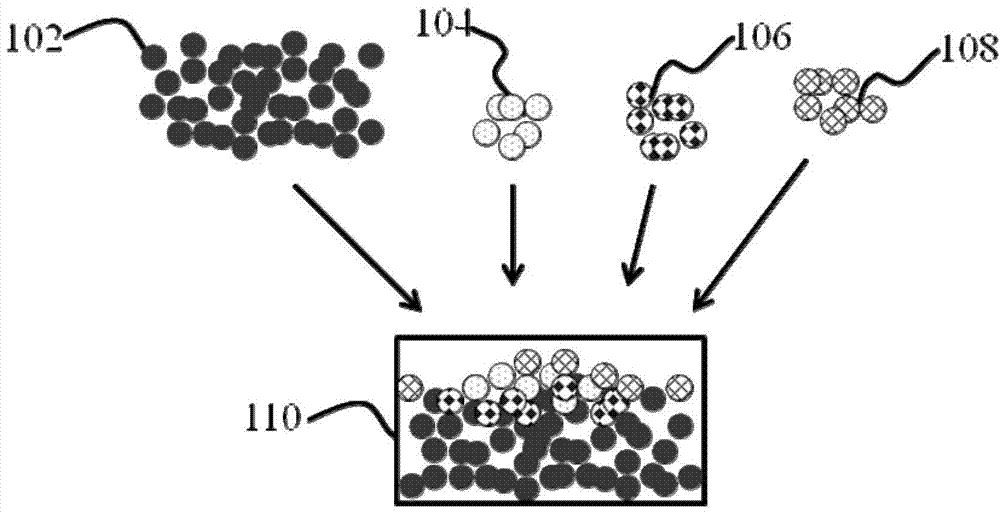

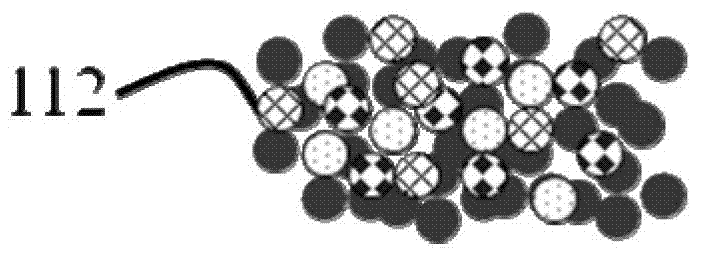

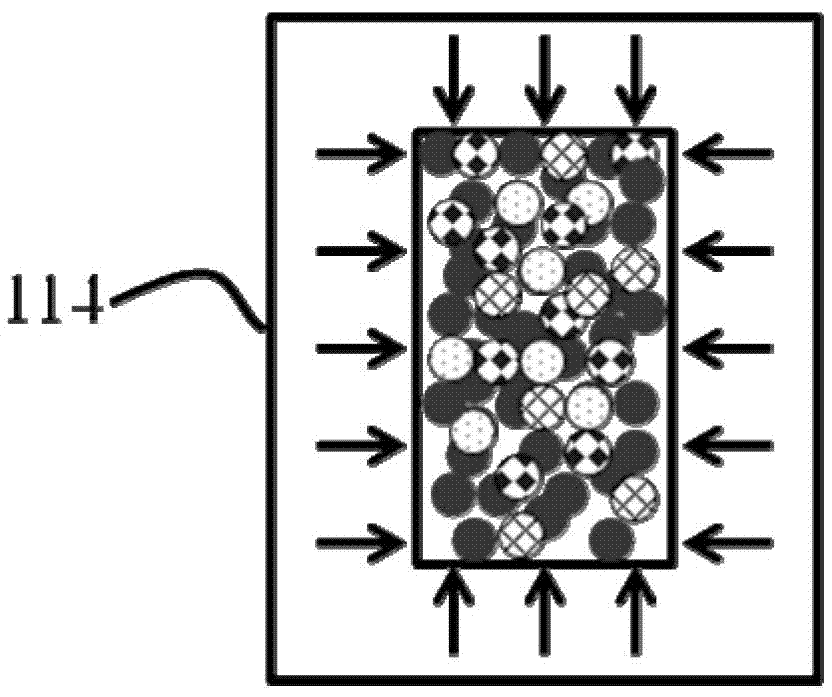

Method used

Image

Examples

Embodiment 1

[0074] First of all, the commercially available zirconium ash (Zr~Si~Ni) low-temperature color glaze with a particle size of 300 mesh and a service temperature of 850° C. with stable performance and mature technology is 99.9% by mass, 0.1% by mass of sodium polyacrylate, Put it into a resin ball mill tank, take it out after mixing for 1.5 hours, pass through a 40-mesh sieve for 3 times, then seal the pretreated raw materials and place them in a cool place away from light for later use; use isostatic pressing molding equipment to press the powder into a cylindrical shape ; Pack the formed product.

Embodiment 2

[0076] Firstly, the commercially available commercially available zirconium-praseodymium yellow low-temperature color glaze with a particle size of 300 mesh and a service temperature of 850°C with a mass percentage of 98.5% and a mass percentage of 1.5% sodium polyacrylate, which are stable in performance and mature in technology, are put into a resin ball mill tank , take it out after mixing for 1.5 hours, pass through a 40-mesh sieve for 3 times, and then seal the pretreated raw materials and place them in a cool place away from light for later use; use isostatic pressing molding equipment to press the powder into a cylindrical shape; pack the formed products .

Embodiment 3

[0078] Firstly, the agate red low-temperature color glaze with a particle size of 320 mesh and a service temperature of 850° C. with stable performance and mature technology is 96.0% by mass, 3.0% by mass of sodium polyacrylate, and 1.0% by mass of ammonium bicarbonate. , put it into a resin ball mill tank, take it out after 2 hours of mixing, pass through a 40-mesh sieve for 3 times, then seal the pretreated raw materials and place them in a cool place away from light for 1 day; use isostatic pressing molding equipment to press the powder into cylinders shape; place the formed product in the laser sintering equipment for processing; then pack the processed formed product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com