Pouring type chalk forming device

A molding device and chalk technology, applied in chalk, supply devices, ceramic molding machines, etc., can solve the problems of high labor intensity, remanufacturing, and low production efficiency of the staff, and achieve the effect of scraping materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

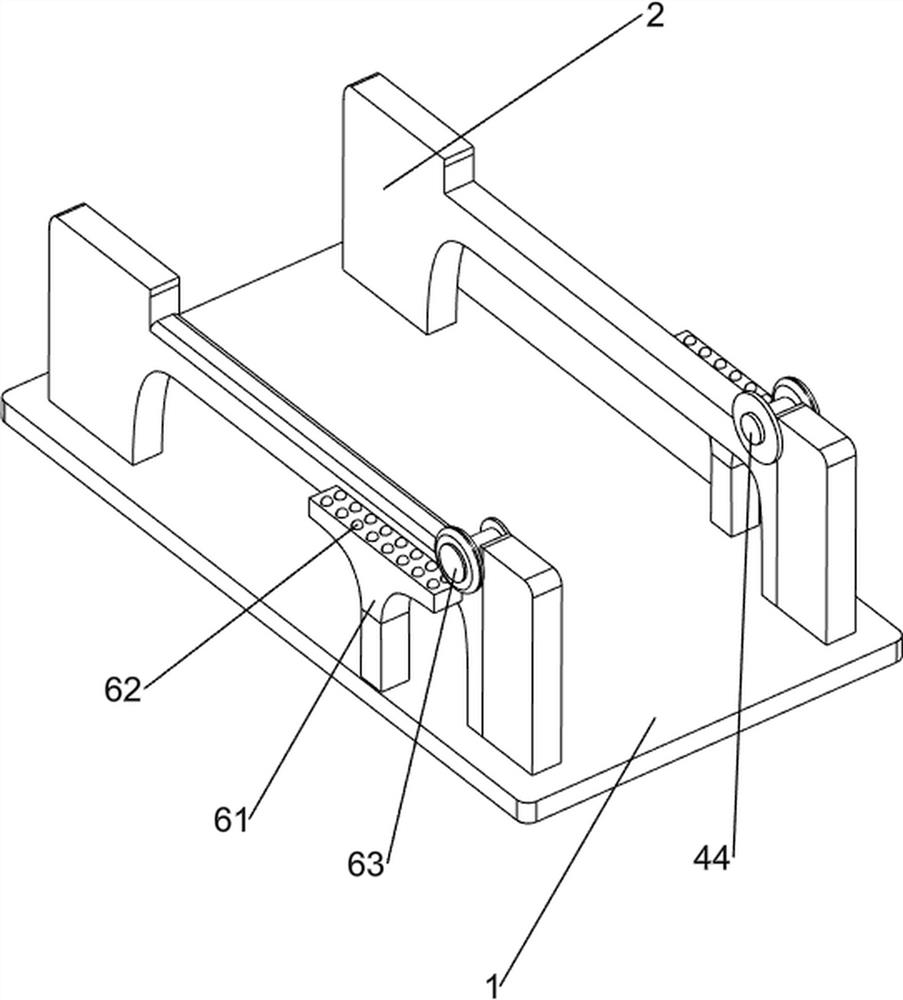

[0024] A pouring type chalk forming device, such as Figure 1-Figure 3 As shown, it includes a bottom plate 1, a mounting frame 2, a first support column 3, a feeding mechanism 4 and a scraping mechanism 5. The bottom plate 1 is provided with mounting frames 2 on the left and right sides, and the tops of the rear sides of the two mounting frames 2 are all provided with There is a first support column 3, a feeding mechanism 4 is provided on the top of the front side of the two installation frames 2, and a scraping mechanism 5 is provided between the two first support columns 3.

[0025] When people want to make chalk, they can use this pouring type teaching chalk forming device. First, the user prepares the chalk liquid separately, then injects the chalk liquid into the feeding mechanism 4, and then passes the chalk liquid through the scraping mechanism 5. Spread evenly and wait for the chalk liquid to set.

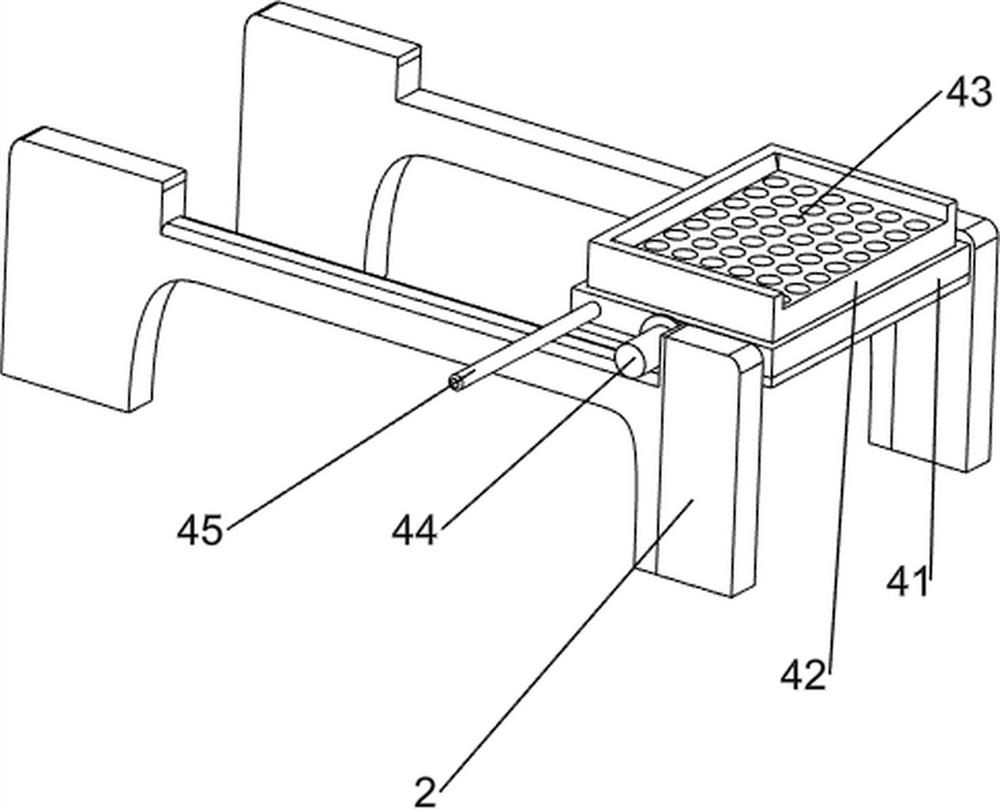

[0026] The feeding mechanism 4 includes a workbench 41, a pouring pl...

Embodiment 2

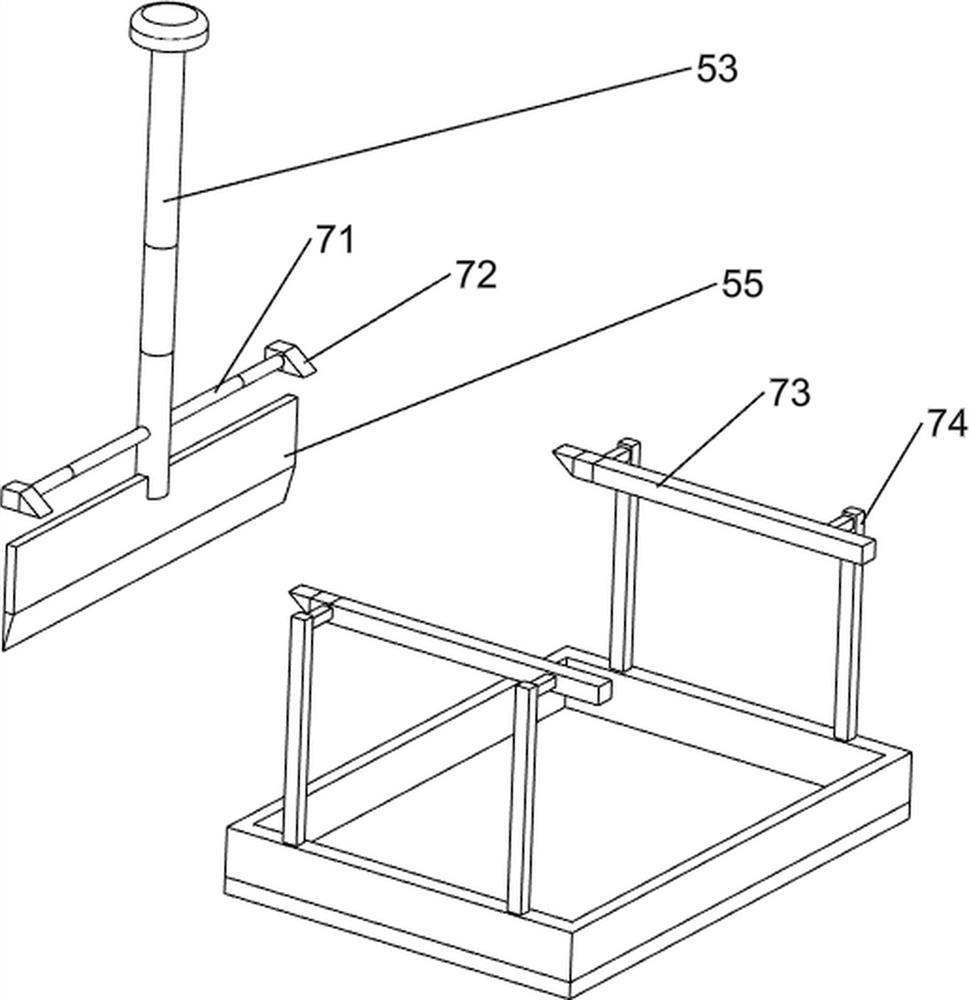

[0031] On the basis of Example 1, such as Figure 4-Figure 6 As shown, a shaking mechanism 6 is also included, and the front side of the bottom plate 1 is provided with a shaking mechanism 6. The shaking mechanism 6 includes a T-shaped connecting block 61, convex grains 62 and rollers 63, and the left and right sides of the front of the bottom plate 1 are provided with T-shaped The connecting block 61 and the tops of the two T-shaped connecting blocks 61 are provided with bumps 62 , and the two rolling shafts 44 are provided with rollers 63 , and the rollers 63 are in sliding contact with the bumps 62 .

[0032] When the rolling shaft 44 rotates backward, the rolling shaft 44 drives the roller 63 to rotate backward, and the roller 63 is in contact with the bump 62 to generate a force of shaking up and down, so that the redundant chalk liquid on the pouring table 42 is shaken out to realize shaking As a result, after the shaking is completed, the rolling shaft 44 rotates forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com